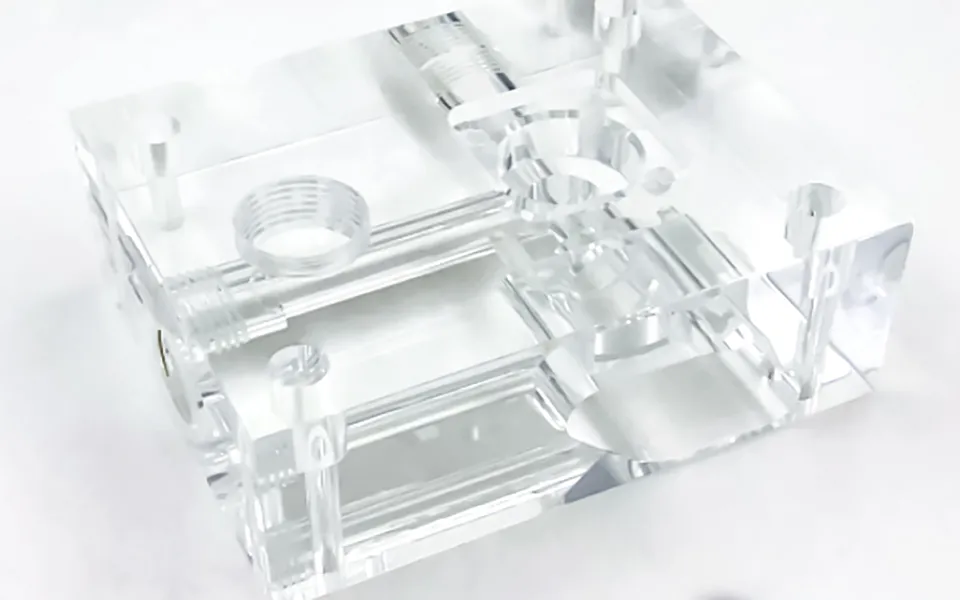

CNC materials

Polycarbonate(PC)

Polycarbonate (PC) is an amorphous thermoplastic resin with excellent comprehensive properties. It has excellent electrical insulation, elongation, dimensional stability and chemical resistance, as well as high strength, heat resistance and cold resistance. It used in engineering are stronger, tough materials, and some grades are optically transparent.