Car Customization - A Unique Turbo Charger for a Customer's Car

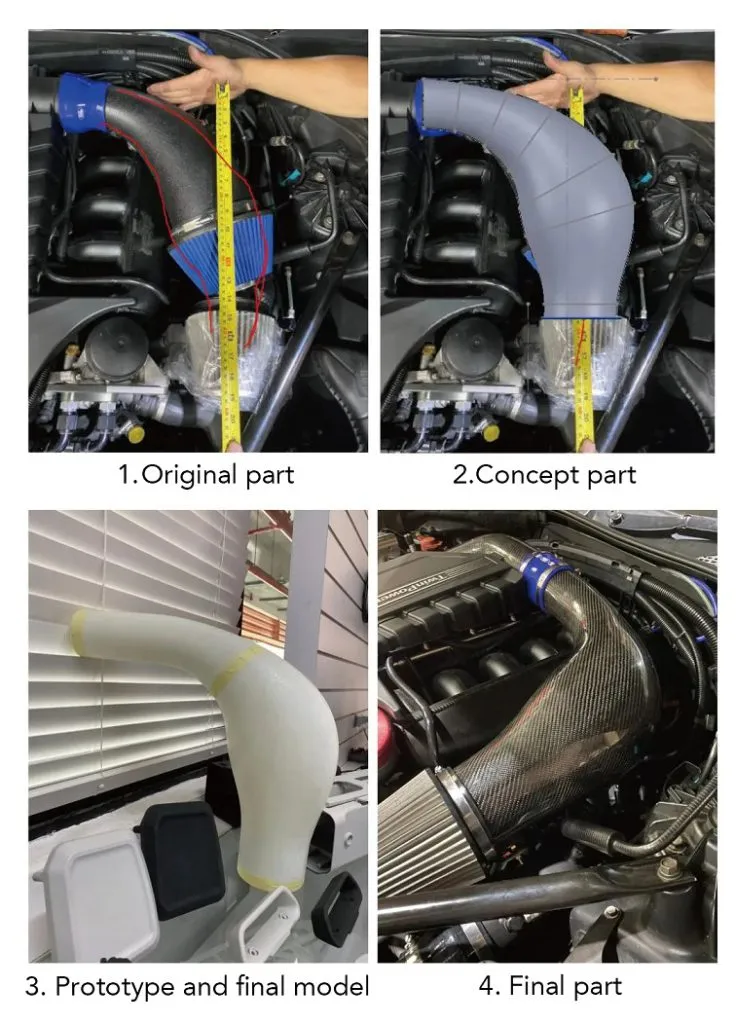

Andy(Not a real name) is a car enthusiast. He wishes to increase his car's performance by modifying the vehicle's turbocharger. He needs to install a custom-made turbocharger that requires a large air storage pipe. Andy has travelled all over local markets but couldn't find the right parts.

Finally, he found Unionfab, Unionfab, Asia's Largest 3D Printing Manufacturing Company for Rapid Prototyping and On-Demand Production Parts online. After communication, We determined the solution, technical route and materials. Andy's retrofitting idea is unique car customization. He hopes to expand the intake space of the turbine as much as possible to increase the supercharging chamber in the middle part of the turbocharger intake pipe.

"This will be the first time Andy will print as a service provider, providing this solution using SLA Resin 3D Printing. Unionfab has exquisite technology, products and solutions in the field of 3D printing SLA.So we are very confident in meeting andy's needs." —David, Sales Engineer (Unionfab)

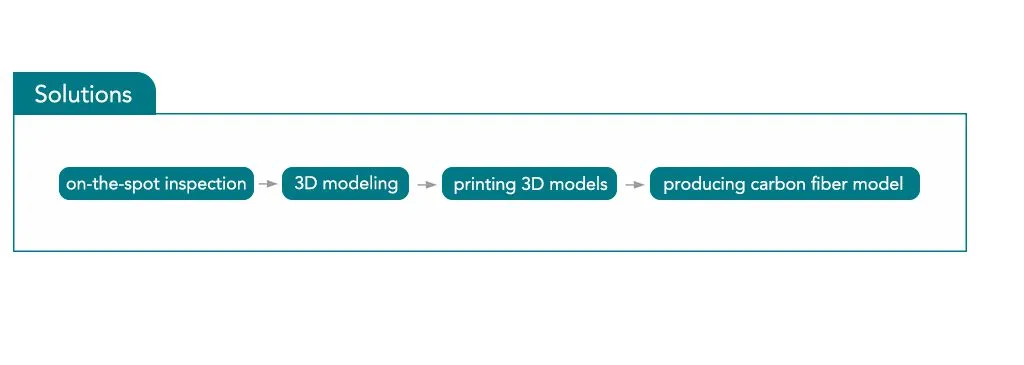

PART ONE

Technology|CAD modelling |SLA 3D Printing|Carbon Fibre Molding

PART TWO

Materials|Industrial White Photosensitive Resin|Carbon Fibre

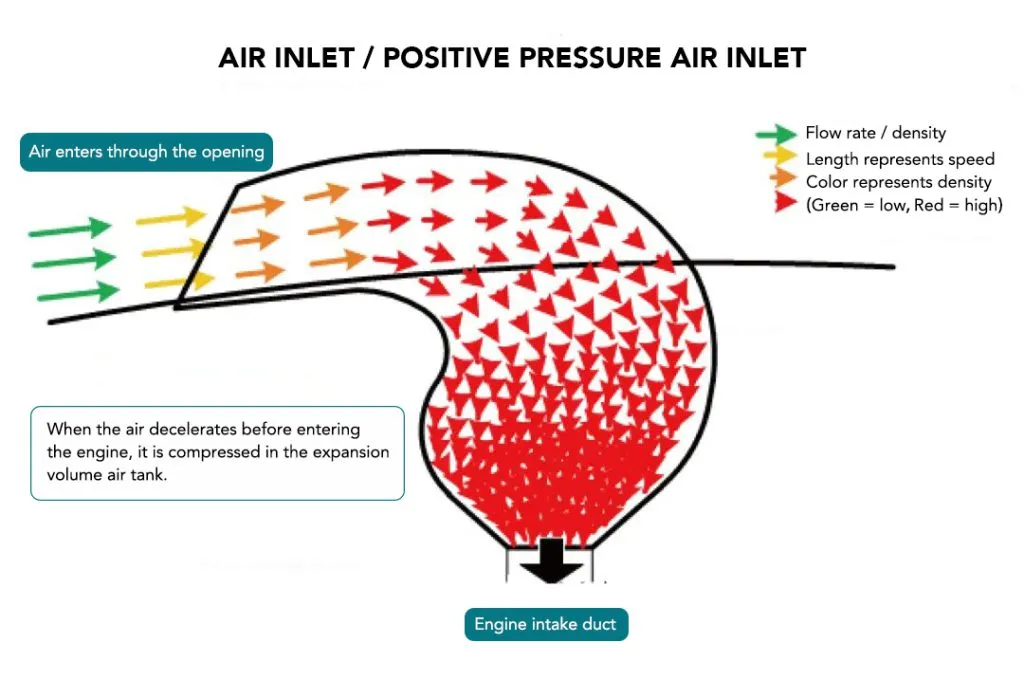

What is the effect of increasing the volume of the plenum?

The experimental results show that the engine's performance can be improved as the volume of the supercharging chamber increases from 2 times to 8 times the engine displacement. Furthermore, increasing the magnitude of the supercharging chamber to more than eight times the engine displacement can significantly improve the performance parameters.

Air Inlet / Positive Pressure air inlet

When the air decelerates before entering the engine, it is compressed in the expansion volume air tank.

Does the plenum effect increase power?

At higher engine speeds, the power increases significantly with the size of the plenum. The peak power output increased from 54kw in the 1.2L booster chamber to 63kw in the 6.01 booster chamber, with an increase of 17%. It is worth noting that the supercharging chamber size seems to have a more significant impact on the engine speed peak power than the peak torque.

SLA 3D printing workflow

After understanding customers' needs, Unionfab conducted on-site research and quickly developed a design scheme. After several modifications, we determined the final design to use the Lite600 3D printer of Unionfab to produce a high-precision white photosensitive resin prototype which passed the design and assembly verification. Finally, the 3D printed resin prototype is used as a model to complete manufacturing of carbon fibre final parts.

Unionfab has always been customer-oriented and customized the corresponding R & D strategy according to the differentiated needs of customers to provide customers with professional 3D printing technology, comprehensive solutions and high-quality pre-sales and after-sales services. The products of Unionfab have been widely used in many industrial fields, such as electronics, medical development, stomatology, shoe mould manufacturing, educational application, cultural creativity, architecture, automobile, aerospace and are spread in many directions of industrial manufacturing and consumer goods production. Unionfab’s industrial scale ranks at the forefront of the industry and has extensive industry influence and brand awareness in 3D printing.