Comparing Weight: Titanium vs. Aluminum

Compare the weight of titanium versus aluminum, uncover their distinct properties and applications, and learn how their densities impact various industries.

Introduction

Titanium and aluminum are widely used in various industries due to their lightweight strength properties. Titanium is notable for having one of the highest strength-to-weight ratios of any metal, making it desirable for applications where weight is critical. Aluminum, meanwhile, is the most widely used non-ferrous and lightweight metal due to its low density.

Composition and Basic Properties of Titanium

Chemical Composition: Titanium is a transition metal with the chemical symbol Ti and atomic number 22.

Physical Appearance: It exhibits a lustrous silver color and is known for its exceptional strength and corrosion resistance.

Biocompatibility: Titanium is highly biocompatible, making it suitable for medical implants and surgical instruments.

Heat Resistance: With a melting point of 1,668°C (3,034°F), titanium demonstrates impressive heat resistance.

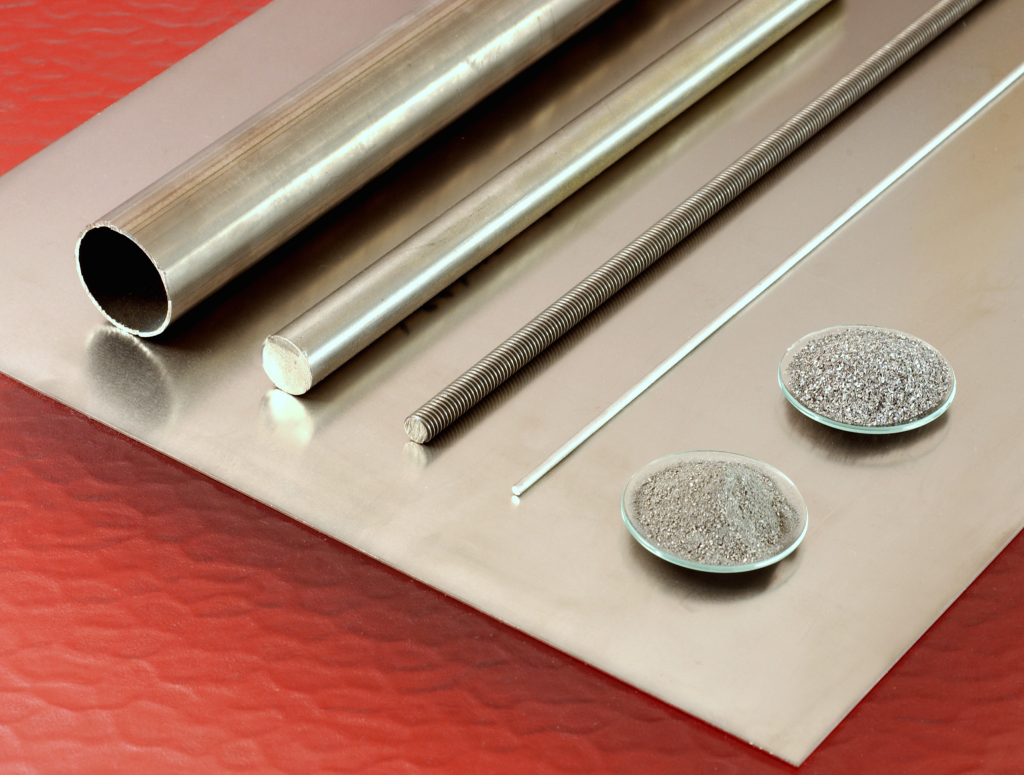

Density of Titanium

Source: https://commons.wikimedia.org/w/index.php?curid=35482877

Lightweight Nature: Titanium has a relatively low density of approximately 4.5 grams per cubic centimeter (g/cm³).

Strength-to-Weight Ratio: Despite its lightweight nature, titanium maintains remarkable strength, making it a preferred choice for weight-sensitive applications.

Applications That Benefit from Titanium's High Strength-to-Weight Ratio

Aerospace Industry: Titanium is widely used in aircraft components, such as airframes, engine parts, and landing gear, contributing to fuel efficiency and performance.

Medical Field: Titanium implants, including bone plates, dental implants, and artificial joints, capitalize on its biocompatibility and lightweight properties to promote faster healing.

Sports and Recreation: Titanium is utilized in sports equipment like bicycle frames, golf clubs, and tennis rackets, enhancing agility and maneuverability without compromising durability.

Marine Applications: Titanium's corrosion resistance and low density make it suitable for marine components such as propeller shafts and offshore structures, where weight reduction is critical for efficiency and longevity.

Composition and Basic Properties of Aluminum

Chemical Composition: Aluminum is a chemical element with the symbol Al and atomic number 13.

Abundant Metal: It is the most abundant metal in the Earth's crust and is widely distributed, making it economically viable for various applications.

Physical Properties: Aluminum is a soft, lightweight, and malleable metal with a silvery-white appearance.

Corrosion Resistance: Aluminum naturally forms a thin oxide layer on its surface, providing excellent corrosion resistance, particularly in environments with high humidity or exposure to saltwater.

Conductivity: Aluminum is an excellent conductor of heat and electricity, making it valuable in electrical transmission lines and heat exchangers.

Density of Aluminum

Source: 3dmentat/123RF

Lightweight Nature: Aluminum has a relatively low density of approximately 2.7 grams per cubic centimeter (g/cm³), making it about one-third the density of steel.

High Strength-to-Weight Ratio: Despite its low density, aluminum exhibits remarkable strength, contributing to its widespread use in lightweight structural applications.

Applications Benefitting from Aluminum's Light Weight

Transportation

Automotive: Aluminum reduces vehicle weight, enhancing fuel efficiency and reducing emissions.

Aerospace: Aluminum alloys improve aircraft performance and payload capacity.

Packaging

Beverage Cans: Aluminum ensures freshness and convenience.

Food Containers: Lightweight and durable, aluminum preserves food quality.

Pharmaceutical Packaging: Aluminum protects pharmaceutical products effectively.

Construction

Window Frames: Lightweight aluminum simplifies installation and enhances energy efficiency.

Roofing Materials: Aluminum provides durability and reduces structural load.

Curtain Walls: Aluminum offers lightweight, versatile architectural solutions.

Consumer Goods

Electronics: Aluminum casings ensure durability and heat dissipation.

Sporting Goods: Lightweight aluminum enhances sporting equipment performance.

Household Appliances: Aluminum's corrosion resistance and ease of fabrication make it ideal for appliances.

Weight Comparison: Aluminum vs. Titanium

For the same volume, titanium is approximately 66% denser than aluminum. In simpler terms, for every 3 grams of aluminum, you would need 5 grams of titanium to achieve the same volume.

This difference in density translates directly to significant weight savings when using aluminum instead of titanium for the same size object. Imagine you have two identical objects, one made of aluminum and the other of titanium. Due to its lower density, the aluminum one would weigh 30% less than the titanium object with the same volume.

This illustrates the substantial weight advantage of aluminum, especially crucial in applications where weight is a critical factor, such as:

Aerospace: Lighter airplanes require less fuel to fly, increasing efficiency and range.

Automobiles: Lighter car bodies improve fuel economy and performance.

Sports equipment: Lighter bicycles, running shoes, etc., enhance performance and user experience.

However, it's important to note that while aluminum offers significant weight savings, it might not always be the best choice. Titanium boasts superior strength and corrosion resistance, making it a preferred material for applications demanding those properties, even with its increased weight.

Additional Considerations in Titanium vs. Aluminum Weight

Choosing between aluminum and titanium goes beyond just weight. Here are some other crucial material properties to consider:

Strength: Titanium boasts significantly higher strength than aluminum. This allows designers to use less titanium to achieve the same level of strength in a component compared to aluminum. This can partially offset the weight difference.

Corrosion Resistance: Titanium excels in corrosion resistance, particularly in harsh environments like saltwater or acidic solutions. Aluminum, while offering decent corrosion resistance in specific environments, is not as durable as titanium.

Machinability: Aluminum is easier and cheaper to machine than titanium, making it a more cost-effective choice for complex shapes.

Cost: As a more complex material to extract and process, titanium is significantly more expensive than aluminum.

Conclusion

While aluminum reigns supreme in terms of weight due to its lower density, titanium remains a valuable material due to its:

High strength-to-weight ratio: Allowing for lighter designs while maintaining strength.

Superior corrosion resistance: Making it ideal for harsh environments.

Choosing between aluminum and titanium ultimately depends on the priorities of the application:

Weight is the top concern: Aluminum is the clear winner.

Strength and corrosion resistance are crucial: Titanium might be a better choice, even with its higher cost and weight.

Cost and ease of machining are significant factors: Aluminum may be preferable.

A thorough analysis of all relevant properties, not just weight, is essential for selecting the optimal material for specific needs.

Unionfab: Your Comprehensive Metal Solution

At Unionfab, we offer a wide array of materials to meet diverse project needs. From metals like aluminum and titanium to plastics, and composites, our selection ensures the right fit for any application.

With top-quality materials, expert guidance, and customization options, Unionfab is your trusted partner for superior performance and reliability.