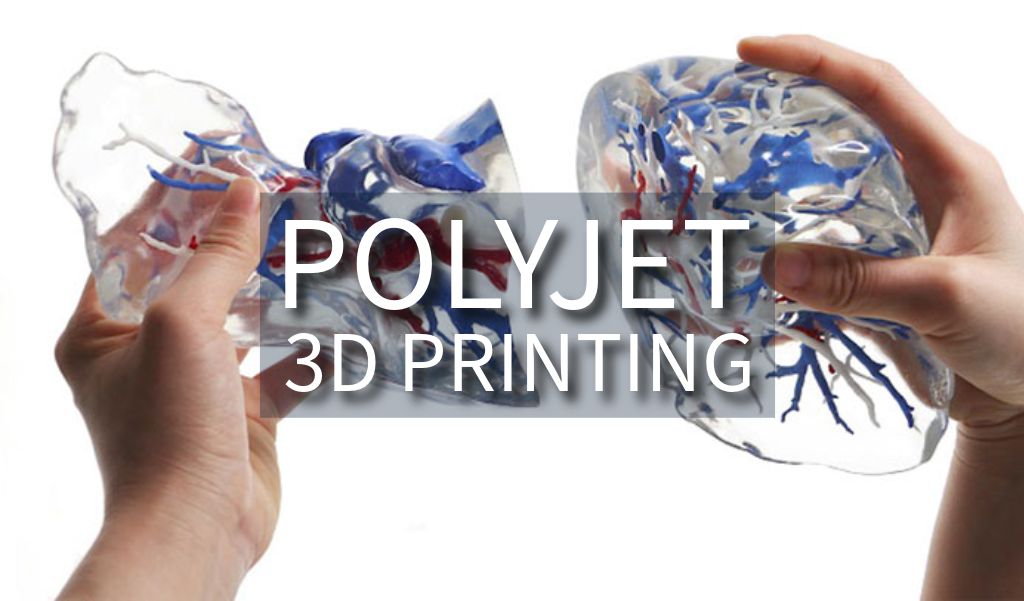

How PolyJet 3D Printing Enables Realistic Prototyping

Unlock the potential of PolyJet 3d printing by exploring its process, strengths and weaknesses, and applications.

Introduction

PolyJet 3D Printing utilizes inkjet-like printing heads to deposit layers of photopolymer resin, cured with UV light for precise creations.

PolyJet's power lies in its ability to print objects in a variety of colors and even combine different materials within the same build, making it ideal for creating realistic prototypes, functional parts with diverse properties, and everything in between.

What is PolyJet 3D printing?

Definition

PolyJet 3D printing is a revolutionary technology categorized as material jetting. Think of it as an inkjet printer for 3D objects, but instead of ink cartridges, it utilizes photopolymer resins.

These liquid resins are deposited in precise layers by specialized inkjet printheads. A UV light source then cures each layer, solidifying the resin and building the 3D object one layer at a time.

Key Benefits of PolyJet Printing

High Resolution and Exceptional Detail

PolyJet excels at creating intricate and detailed objects. With layer thicknesses as thin as 16 microns (thinner than a human hair), it can capture even the finest features in your design.

Multi-Material Capabilities

Unlike many 3D printing methods, PolyJet allows you to print with multiple materials within a single build. This helps create complex parts with varying properties in different areas.

Vibrant Color Printing

PolyJet printers can print in a wide range of colors, allowing for the creation of highly realistic prototypes or even functional parts that incorporate color coding for better identification or aesthetics.

Support Structures Made Easy

PolyJet uses a water-based support material that is easily removed after printing, eliminating the need for complex post-processing steps often required in other methods.

Broad Range of Applications

The high precision, multi-material capabilities, and smooth surface finishes make PolyJet ideal for various industries, including prototyping, product design, medical modeling, and even dental applications.

PolyJet Printing Process

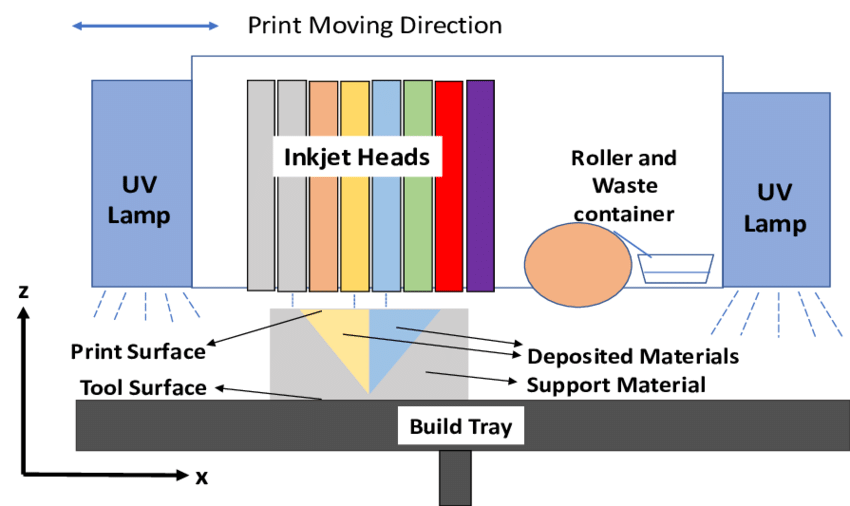

Source: researchgate.net

Liquid Photopolymer Jetting: The process starts with specialized printheads jetting tiny droplets of liquid photopolymer resin onto a build platform. These resins come in various properties, allowing for customization of the final part's characteristics.

Precise UV Curing: Following each layer deposition, a UV light source instantly cures the resin, solidifying it into a permanent structure. This layer-by-layer curing builds the object one tiny slice at a time.

Support material extrusion and removal: PolyJet printing often utilizes a unique, water-based support material. This temporary material is deposited alongside the main resin to provide support for overhangs and intricate geometries during printing. Unlike some other methods, dissolving the water-based support material is a simple post-processing step.

Post-processing Options: While PolyJet prints are often known for smooth surface finishes, some applications might require additional post-processing steps depending on the desired outcome.

PolyJet Printing: Materials and Properties

Types of Resins Used by PolyJet Printing

Rigid Opaque Resins: These are the most common materials of PolyJet, offering excellent strength, dimensional stability, and a smooth surface finish. They come in a variety of colors, perfect for creating prototypes or functional parts with a rigid structure.

Transparent Resins: PolyJet offers a range of transparent resins that mimic the clarity of materials like acrylic (PMMA). These are ideal for applications requiring clear parts or showcasing internal details.

Flexible Resins: PolyJet's flexible resins offer varying degrees of flexibility, allowing for the creation of parts that can bend or compress without breaking.

Digital ABS and Polypropylene: These advanced materials simulate the properties of commonly used thermoplastics like ABS and polypropylene. This allows for the creation of prototypes that closely resemble the final product in terms of strength, heat resistance, and feel.

Biocompatible Resins: For medical and dental applications, PolyJet offers biocompatible resins that meet specific regulations for use in the human body.

Properties of PolyJet Printing

Surface Finish and Resolution Capabilities: PolyJet has exceptional resolution, with layer thicknesses as low as 16 microns. This translates to incredibly smooth surface finishes, ideal for creating highly detailed prototypes and intricate models.

Material Properties: The wide variety of resins available in PolyJet allows for the creation of parts with a diverse range of mechanical properties. From rigid and high-strength to flexible and rubber-like, PolyJet caters to various functional needs.

Options for Color: PolyJet printers can print in a wide range of colors, allowing for the creation of highly realistic prototypes or even functional parts that incorporate color coding.

Advantages of PolyJet Printing

Realistic Color and Surface Textures

PolyJet's ability to print in a vast array of colors and utilize different resin types allows for the creation of prototypes with incredibly realistic color tones, textures, and finishes.

This is invaluable for product design, marketing, and even medical applications where visual accuracy is paramount.

Multi-materials and Composite Parts

PolyJet can print objects using a variety of materials within a single build. This is beneficial for creating parts with different properties like rigidity, flexibility, transparency, and opacity, all in one go.

Smooth Detail and Flexible Materials

PolyJet has an incredible resolution, capable of printing unmatched details and smooth surface finishes. This makes it ideal for intricate prototypes, detailed models, and even functional parts with tight tolerances.

Additionally, the availability of flexible resins allows for the creation of parts that can bend or compress, expanding the range of applications.

Biological Compatibility

PolyJet offers a range of biocompatible resins that meet specific regulations for use in the human body. This makes it a valuable tool for creating medical models, surgical guides, and even prototypes for dental implants or prosthetics.

Design Freedom for Complex Geometries

PolyJet excels at creating objects with complex geometries and intricate details. The high resolution and support material system allow for the printing of overhangs, undercuts, and other features that might be challenging with other methods.

Disadvantages of PolyJet Printing

Higher Per-Part Cost

Compared to some widely used methods like Fused Deposition Modeling (FDM) or Stereolithography Apparatus (SLA), PolyJet printing can be significantly more expensive per part. This stems from two main factors:

Specialized Materials: PolyJet utilizes a wide range of photopolymer resins that are more intricate and often pricier than the filaments used in FDM or the liquid resins used in SLA.

Intricate Printing Process: The jetting process with multiple printheads and UV curing adds complexity, increasing overall production costs.

Build Volume Limitations

PolyJet printers typically have smaller build volumes compared to some FDM machines. This restricts the size of parts you can create in a single build.

Large or complex objects might require sectioning into smaller pieces for printing and subsequent assembly, adding time and complexity.

Post-Processing Considerations

The water-based support material in PolyJet, although a major advantage for ease of removal, still requires a post-processing step. Depending on the print's intricacy, removing support structures can be time-consuming and require careful handling to avoid damaging the final part.

Material Property Limitations

The diverse range of PolyJet resins provides a lot of properties. However, these resins might not always match the strength and durability of some engineered polymers used in traditional manufacturing.

Applications of PolyJet 3D Printing

Prototyping and Product Design

Hyper-realistic Prototypes

PolyJet excels at creating prototypes that mimic the final product's look and feel with exceptional detail and color accuracy. This allows for better design iteration, user testing, and marketing efforts.

Functional Prototypes

With multi-material capabilities, PolyJet can create prototypes that incorporate features like rigid and flexible sections, simulating the final product's functionality for a more comprehensive evaluation.

Medical and Dental Applications

Medical Models

PolyJet's ability to create detailed anatomical models from medical scans is invaluable for surgical planning, patient education, and developing customized medical devices.

Dental Applications

From creating clear aligner molds in orthodontics to printing custom dental implants and prosthetics, PolyJet plays a vital role in modern dentistry.

Other Applications

Jewelry and Art

The ability to print in a vast array of colors and fine details makes PolyJet ideal for creating intricate jewelry pieces and artistic prototypes.

Film and Animation

PolyJet-printed models are used in stop-motion animation and for creating realistic props and figurines.

Engineering and Manufacturing

PolyJet is valuable for creating functional prototypes for testing and complex jigs and fixtures for production.

Conclusion

PolyJet 3D printing is a powerful tool for creators and innovators. Its ability to produce high-resolution, multi-material parts with exceptional detail and smooth finishes makes it ideal for various areas.

For applications requiring exceptional detail, multi-material capabilities, and high-fidelity prototypes, PolyJet is better. However, for projects needing large, strong, or high-temperature resistant parts, other 3D printing methods might be a better fit. Understanding the pros and cons of PolyJet 3D printing helps make informed decisions.

Try Unionfab’s 3D Printing Service

Unionfab offers a comprehensive range of 3D Printing Services, including PolyJet, SLA, and FDM.

At Unionfab explore the world of 3D printing with a variety of support options and expert finishing services. A team of specialists is ready to assist you in maximizing the potential of your designs and unlocking the full power of 3D printing.