Can you Powder Coat Aluminum: The Ultimate Guide

Can you powder coat aluminum? You will gain a thorough understanding of techniques involved, benefits of using this method, and its applications.

Introduction

Powder coating aluminum is a versatile and effective method for enhancing the durability, appearance, and performance of aluminum surfaces.

In this guide, we'll explore the ins and outs of powder coating aluminum, from understanding the process to its benefits and applications.

Understanding Powder Coating

What is Powder Coating?

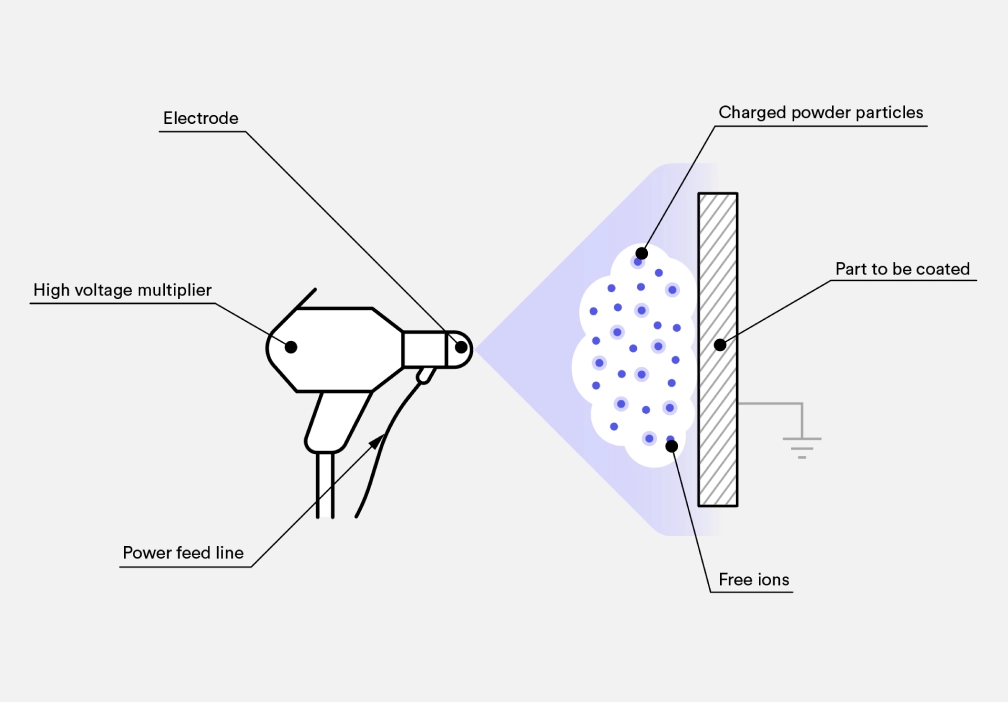

Powder coating is a dry finishing process where finely ground particles of pigment and resin are electrostatically charged and sprayed onto a surface. The charged particles adhere to the surface and are then cured under heat to form a durable and protective layer.

Types of Powder Coatings

There are two main types of powder coatings:

Thermoset Powders: These powders undergo a chemical reaction during curing, forming cross-linked molecular chains that provide excellent durability and resistance to heat and chemicals.

Thermoplastic Powders: These powders melt and flow when heated but do not undergo a chemical reaction. They offer good impact resistance and flexibility but may not be as durable as thermoset powders.

Benefits of Powder Coating Aluminum

Durability and Longevity

Powder coating forms a durable and resilient finish on aluminum surfaces, offering protection against corrosion, scratches, and abrasions.

This prolongs the lifespan of aluminum products, reducing the need for frequent maintenance or replacement.

Environmental Friendliness

Unlike liquid coatings, powder coating does not contain harmful solvents or volatile organic compounds (VOCs), reducing emissions and environmental impact.

Additionally, the overspray from powder coating can be collected and reused, minimizing waste generation and promoting sustainability.

Cost-Effectiveness

Powder coating is an efficient process that maximizes material usage and minimizes wastage, reducing overall production costs.

Its durable finish also eliminates the need for frequent recoating or touch-ups, further lowering maintenance expenses over time.

Aesthetic Appeal

With a wide range of colors, textures, and finishes available, powder coating allows for versatile customization to suit various design preferences and applications.

The smooth and uniform finish enhances the visual appeal of aluminum surfaces, adding value and aesthetic appeal to products and structures.

Preparation of Aluminum for Powder Coating

Cleaning and Pre-Treatment

Before powder coating, aluminum surfaces are thoroughly cleaned to remove dirt, oil, and contaminants, ensuring proper adhesion.

Pre-treatment methods like degreasing and phosphating further enhance adhesion and corrosion resistance, creating an ideal surface for powder application.

Sandblasting

Abrasive blasting or sandblasting removes mill scale, oxidation, and imperfections from aluminum surfaces, improving adhesion.

This process creates a clean, roughened surface profile that enhances the mechanical bond between the powder coating and the substrate.

Chemical Etching

Chemical etching cleans aluminum surfaces by removing oxides and contaminants, promoting adhesion.

It creates a microscopically rough surface texture, enhancing the mechanical bond between the powder coating and the substrate.

Masking

Masking protects specific areas of aluminum surfaces from powder coating to maintain functionality.

Materials like tape, plugs, or caps are applied to intricate or critical areas before coating to ensure they remain free of coating.

Proper masking ensures precise results and prevents the need for rework.

In summary, the thorough cleaning, pre-treatment, sandblasting, chemical etching, and precise masking of aluminum surfaces ensure optimal adhesion and functionality for powder coating applications, yielding durable and high-quality finishes.

Process of Powder Coating Aluminum

Source: hubs.com

Application Techniques

Powder coating aluminum involves various application methods to achieve desired results, including electrostatic spray deposition (ESD) and fluidized bed coating.

The choice of technique depends on factors such as the size and shape of the aluminum parts and the desired finish.

Electrostatic Spray Deposition (ESD)

ESD is the most common method for applying powder coating to aluminum surfaces. It involves electrostatically charging the powder particles as they are sprayed onto the grounded aluminum substrate.

The charged particles adhere to the surface uniformly, creating a smooth and even coating.

Fluidized Bed Coating

Fluidized bed coating is a technique primarily used for coating aluminum parts with complex shapes or intricate geometries.

In this method, the aluminum parts are preheated and then immersed in a fluidized bed of powdered coating material. The powder particles adhere to the heated surface, forming a thick and uniform coating.

Curing and Baking

After the powder coating is applied, the aluminum parts are cured and baked in an oven at high temperatures. During this process, the powder particles melt and fuse together, forming a continuous film. Curing ensures adhesion and cross-linking of the coating, resulting in a durable and resilient finish.

Quality Control and Inspection

After the powder coating is applied, the aluminum parts are cured and baked in an oven at high temperatures.

During this process, the powder particles melt and fuse together, forming a continuous film.

Curing ensures adhesion and cross-linking of the coating, resulting in a durable and resilient finish.

Finishing and Maintenance

Post-coating inspection involves a thorough check for defects like uneven coating or color discrepancies, often including film thickness and adhesion testing.

Routine maintenance for powder-coated aluminum involves periodic cleaning with mild detergent and water, avoiding harsh chemicals.

Repairing minor damage can be done with touch-up paint, while more extensive damage may require professional recoating for a seamless repair.

Applications of Powder-coated Aluminum

Architectural Uses

Powder-coated aluminum is extensively utilized in architectural applications due to its versatility and durability.

It is commonly used for building facades, windows, doors, and roofing systems, providing both aesthetic appeal and long-lasting protection against environmental elements.

Source: basystems.co.uk

Automotive Industry

In the automotive sector, powder-coated aluminum components are favored for their durability and aesthetic appeal.

They are widely used in manufacturing exterior trim, wheels, and engine parts, offering resistance to corrosion, scratches, and UV exposure while enhancing the overall appearance of vehicles.

Source: precisioncoatingtech.com

Consumer Goods

Powder-coated aluminum is a popular choice for a variety of consumer goods due to its durability, corrosion resistance, and decorative options.

It is commonly found in furniture, appliances, bicycles, and sporting equipment, providing both functionality and aesthetic appeal in everyday items.

Source: webstaurantstore.com

Industrial Applications

In industrial settings, powder-coated aluminum is valued for its robustness and resistance to harsh environments.

It is used for machinery, equipment, storage systems, and structural components, providing protection against chemicals, UV exposure, and abrasion while maintaining structural integrity over time.

Source: afterphotoshop.com

Conclusion

Powder coating aluminum provides durability, environmental benefits, cost-effectiveness, and aesthetic appeal. Proper preparation and application ensure high-quality finishes, enhancing the longevity and performance of the products.

Powder-coated aluminum is a preferred choice in architectural, automotive, consumer, and industrial applications for improving both form and function.

Unionfab Provides Professional Services to Ensure Product Quality

For professional powder coating services and expert guidance on achieving a higher quality finishes for your aluminum products, turn to Unionfab.

Also, we can provide various types of services you may need, such as CNC machining, 3D printing and finishing.

For further details, please feel free to reach out to us via our Contact Us page.