Unicorn Aviation: Advancing EFI Systems for Light Aircraft with Unionfab

In his latest video, former fighter pilot Pierre-Henri "Até" Chuet showcased the incredible performance of a VL-3 aircraft, powered by an engine developed by Unicorn Aviation.

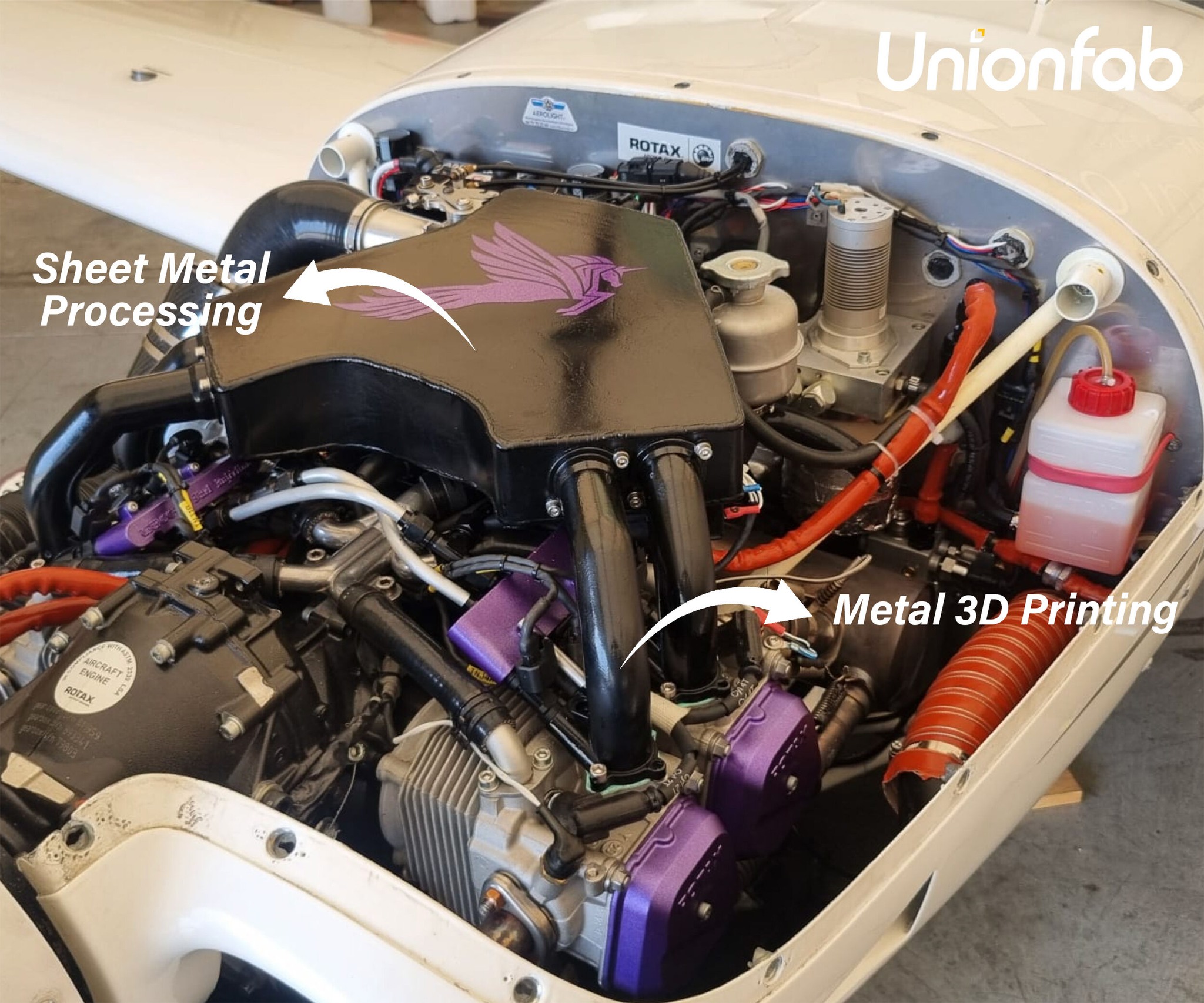

Unionfab proudly contributed to this project by manufacturing key engine components using advanced 3D printing techniques.

Parts Made: Aircraft Engine Plenums with Injector Pipes

The engine plenum for Unicorn Aviation’s advanced electronic fuel injection (EFI) system, essential for managing airflow, was manufactured using a combination of sheet metal fabrication and 3D printing technologies.

These plenums not only ensure optimal airflow but also house the injector pipes that deliver precise fuel amounts to the engine, ensuring efficiency and reliability.

Unionfab’s team, certified in AS9100D, a standard specifically developed for the aerospace and defense industries, ensured that these parts met stringent aerospace standards.

Material Choice: Aluminum Alloy for Strength and Affordability

Although Unicorn Aviation initially considered using plastic, they opted for aluminum alloy in the end.

This material provided the perfect balance between strength and weight, making it a far more durable and reliable choice for the demanding conditions of aviation. Light materials are crucial in aviation to minimize the aircraft's weight, while maintaining durability is essential for parts subjected to high temperatures and stress, such as engine components.

The use of aluminum alloy in these plenums ensures they can withstand the harsh operational conditions while also being cost-effective for mass production.

Customer Feedback

Ben, founder of Unicorn Aviation, praised the high-quality finish, precise dimensions, and smooth assembly of the parts — To ensure a perfect fit, Unionfab also provided a free assembly test.

Why 3D Printing?

Unionfab's 3D printing capabilities allowed for the production of complex, lightweight, and precise parts that would be difficult to achieve with traditional methods alone. The precision of 3D printing enables intricate designs that help reduce the weight of the engine, improving overall aircraft efficiency.

Additionally, 3D printing is a sustainable manufacturing method, reducing material waste significantly compared to subtractive manufacturing techniques. This aligns perfectly with Unicorn Aviation’s goal of reducing their environmental footprint, making the entire production process eco-friendly from start to finish.

Unionfab — Efficient Lead Time and Global Delivery

At Unionfab, we pride ourselves on delivering high-quality components within a tight timeframe. The parts were manufactured and delivered to Unicorn Aviation within just two weeks, meeting their critical project timelines.

Unionfab works with trusted logistics partners like DHL Express, FedEx, and UPS to ensure that our products reach their global customers quickly and reliably.

Order Now

At Unionfab, we leverage our in-house factories and combine cutting-edge technologies like 3D printing and CNC machining with traditional methods such as molding, casting, and sheet metal fabrication. Trust us to bring your designs to life with the highest standards of performance and reliability.

Ready to bring innovation and precision to your next project? Order directly through our website or contact one of our dedicated managers.

About the Customer: Unicorn Aviation

Unicorn Aviation specializes in advanced electronic fuel injection (EFI) systems for light aircraft, focusing on fuel efficiency, eco-friendliness, and safety. Their innovative EFI systems not only reduce CO2 emissions but also deliver superior performance and lower operating costs.