Urethane Casting: A Comprehensive Introduction

Understand what is urethane casting, process of casting urethane as well as its benifits and applications.

Introduction

The purpose of this article is to offer a comprehensive understanding of urethane casting, its materials, and the detailed process involved.

We will also compare urethane casting with injection molding and discuss the applications and advantages of urethane casting.

What is Urethane Casting

Definition of Urethane Casting

Urethane casting, also known as vacuum casting, is a versatile manufacturing process that involves creating parts by pouring liquid urethane into a mold, which then hardens into the desired shape.

This method is particularly effective for producing prototypes, small production runs, and parts that require detailed features.

Urethane casting is known for its ability to produce high-quality, detailed parts quickly and cost-effectively without the need for expensive tooling.

Urethane Casting vs. Injection Molding

Aspect | Urethane Casting | Injection Molding |

|---|---|---|

Production Volume | Low to medium | High |

Cost | Lower upfront costs | Higher upfront costs |

Lead Time | Shorter | Longer |

Ideal For | Prototypes, small runs | Large-scale production |

Production Volume

Urethane casting is ideal for low to medium production volumes, commonly ranging from a few units to several hundred parts. This makes it excellent for prototyping, custom parts, and limited runs.

Injection molding, however, suits high-volume production, typically involving thousands to millions of parts.

Cost

Urethane casting has lower upfront costs due to cheaper silicone molds compared to the expensive steel molds of injection molding. This cost-effectiveness is beneficial for smaller runs where high injection molding costs aren't justified.

Despite higher per-part costs, overall expenses for low to medium volumes are lower in urethane casting.

Lead Time

Urethane casting offers shorter lead times, beneficial for rapid prototyping and quick turnarounds.

Silicone mold creation is faster and simpler than the metal molds needed for injection molding, resulting in a quicker design-to-production timeline. Injection molding's longer setup time is due to the complexity and precision required in mold creation.

Overall, urethane casting provides a flexible, cost-effective, and fast solution for low to medium volume production, ideal for creating detailed and high-quality parts.

Urethane Casting Materials

Urethane casting involves the use of two main categories of materials: those required for the mold and those required for the production process.

Materials Required for the Mold

Silicone Rubber: Silicone rubber is commonly used to create molds for urethane casting due to its flexibility, durability, and ease of use. Silicone molds can capture intricate details and are reusable for multiple casting cycles.

Release Agents: Release agents are applied to the mold surface to prevent the urethane casting resin from sticking to the mold. They ensure easy demolding and help prolong the lifespan of the silicone mold.

Materials Required for the Production Process

Urethane casting resin is the primary material used to create the actual parts. It is a versatile polymer known for its durability, flexibility, and ability to mimic the properties of production-grade plastics.

This resin offers versatile properties, adaptable for diverse applications, crafting both rigid and flexible parts as needed. Common variants like ABS-like, PC-like, and rubber-like resin mimic ABS plastic, polycarbonate, and rubber, respectively, ensuring durability, clarity, and flexibility.

Additives and Fillers

Urethane casting compounds often include various additives and fillers to enhance specific material properties.

These additives can include:

Rigidity Enhancers: Additives made of materials like glass or mineral fillers that increase the stiffness of the urethane casting resin, making it suitable for structural applications.

Clarity Enhancers: Additives such as transparent resins or nanoparticles that improve the optical clarity of the resin, ideal for applications requiring transparency or specific optical properties.

Thermal Stabilizers: Additives like heat-resistant polymers or ceramics that improve the thermal resistance of the resin, enabling it to withstand high temperatures without degrading.

By adjusting the formulation with these additives, manufacturers can customize the urethane material to meet the precise requirements of different projects, ensuring optimal performance and quality in the final parts.

Process of Casting Urethane

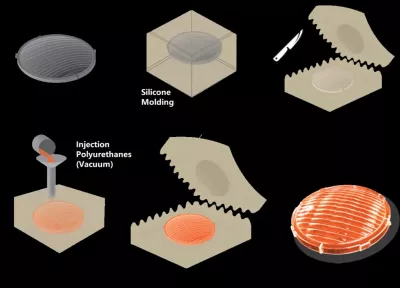

The urethane casting process involves several key steps to produce high-quality parts with detailed features.

Below is a detailed breakdown of each step, along with illustrative images to enhance understanding.

Source: firstpart.com

Step 1. Mold Creation

A master pattern is created, usually via 3D printing or CNC machining, which serves as the template for the silicone mold.

The master pattern is carefully designed to ensure that the final part will have the desired shape and details.

Step 2. Mixing Urethane

The urethane resin is mixed with a curing agent, following precise ratios to ensure the proper material properties.

This mixture must be homogeneous to avoid inconsistencies in the final part.

Step 3. Pouring

The mixed urethane is poured into the silicone mold.

This step is often done under vacuum to eliminate air bubbles, which can cause defects in the final part.

Ensuring a bubble-free pour is crucial for achieving a smooth and accurate surface finish.

Step 4. Curing

The filled mold is placed in an oven or left at room temperature to cure, solidifying the urethane.

The curing time and conditions depend on the specific urethane formulation and the desired properties of the final part.

Step 5. Demolding

Once cured, the mold is carefully opened to remove the finished part.

The silicone mold is flexible, which helps in releasing the part without damaging it.

Proper demolding techniques are essential to maintain the integrity of both the mold and the cast part.

By following these steps and using the appropriate tools, urethane casting can produce high-quality, detailed parts suitable for a wide range of applications.

Types of Urethane Castings

Urethane casting can produce a variety of part types, each tailored to meet specific requirements and applications.

Here are the primary types of urethane castings, along with their distinct properties and uses.

Rigid Urethane Castings

Rigid urethane castings are used for parts requiring structural integrity and stiffness.

These parts can withstand high stress and are often utilized in applications where durability and load-bearing capabilities are essential.

Applications: Mechanical components, housings, brackets, and structural supports.

Properties: High strength, durability, and dimensional stability.

Flexible Urethane Castings

Flexible urethane castings are ideal for parts that need flexibility and impact resistance.

These parts are designed to absorb shock and maintain their shape under stress, making them suitable for dynamic applications.

Applications: Gaskets, seals, bumpers, and protective covers.

Properties: High flexibility, impact resistance, and elasticity.

Clear Urethane Castings

Clear urethane castings are utilized in applications requiring transparency or specific optical properties.

These parts are often used where visibility and aesthetic appearance are important.

Applications: Lenses, display components, prototypes, and custom lighting fixtures.

Properties: Optical clarity, UV stability, and smooth surface finish.

Each type of urethane casting offers unique benefits, making urethane a versatile material for a wide range of industries and applications.

By selecting the appropriate type of urethane casting, manufacturers can ensure that their parts meet the specific needs of their projects.

Applications of Urethane Casting

Urethane casting offers versatility across various industries, making it suitable for a broad range of applications:

Prototyping

Urethane casting enables the creation of functional prototypes with production-like quality.

This allows manufacturers to test and iterate designs before committing to full-scale production, accelerating the product development process.

Source: prototypes.prioritydesigns.com

Short-Run Production

Cost-effective for producing limited quantities of parts without investing in expensive tooling.

This makes urethane casting an ideal solution for small production runs, where traditional manufacturing methods like injection molding may not be economically viable.

Source: prototypes.prioritydesigns.com

Industrial Applications

Urethane casting is widely used in industrial settings for manufacturing machinery parts, protective covers, and custom components.

Its versatility and durability make it suitable for various applications where strength and reliability are paramount.

Source: precisionurethane.com

Consumer Products

Commonly found in custom enclosures, toys, and decorative items.

Urethane casting allows for the production of aesthetically pleasing and functional consumer products with intricate details and high-quality finishes.

Source: facfox.com

From prototyping to short-run production and industrial to consumer applications, urethane casting offers a cost-effective and versatile solution for creating high-quality parts across diverse industries.

Advantages of Urethane Casting Parts

Parts produced via urethane casting offer several significant benefits:

Cost-Effectiveness

Urethane casting requires a lower initial investment compared to other manufacturing processes like injection molding.

The cost of creating molds for urethane casting is significantly lower, making it a cost-effective solution for producing small to medium volumes of parts.

Versatility

Urethane casting is highly versatile and can accommodate a wide range of materials and part designs.

Whether producing rigid or flexible parts, urethane casting can meet diverse project requirements, making it suitable for various industries and applications.

Precision and Detail

Urethane casting is capable of producing intricate and highly detailed parts with excellent dimensional accuracy.

This precision allows for the creation of complex geometries and fine features, making it ideal for applications where tight tolerances are required.

Durability

Urethane parts are robust and can withstand various environmental conditions, including temperature fluctuations, moisture, and chemicals.

This durability ensures that urethane castings maintain their structural integrity and performance over time, making them suitable for demanding applications in industries such as automotive, aerospace, and electronics.

Overall, the cost-effectiveness, versatility, precision, and durability of urethane casting make it a preferred manufacturing method for producing high-quality parts across a wide range of industries and applications.

Conclusion

Urethane casting is a highly adaptable and efficient manufacturing process, particularly beneficial for prototyping and low to medium volume production.

It offers significant advantages in terms of cost, versatility, and speed compared to traditional injection molding.

Achieve Flawless Manufacturing with Unionfab

Whether used for prototyping or short-term production, Unionfab can provide reliable solutions for your manufacturing needs.

Also, we can provide various types of services you may need, such as vacuum/urethane casting and injection molding mentioned in this article.

For further details, please feel free to reach out to us via our Contact Us page.