What is a CMM: The Power of Precision Measurement

Find out what a CMM machine is, its uses, and the importance of CMM inspection.

Introduction

What is a CMM (Coordinate Measuring Machine)?

A coordinate measuring machine, or CMM, is a precision instrument used to inspect and measure physical features of manufactured parts and assemblies.

CMMs can check dimensions, shapes, angles, depths, roughness, and other characteristics with high accuracy.

The Importance of Precision Measurement

In manufacturing, it is very important that products are made to precise specifications and tolerances.

If parts do not have the correct dimensions, they may not fit or work properly when assembled. Precision measurement is needed to ensure quality.

What is a CMM?

Definition of CMM

Source: Unionfab

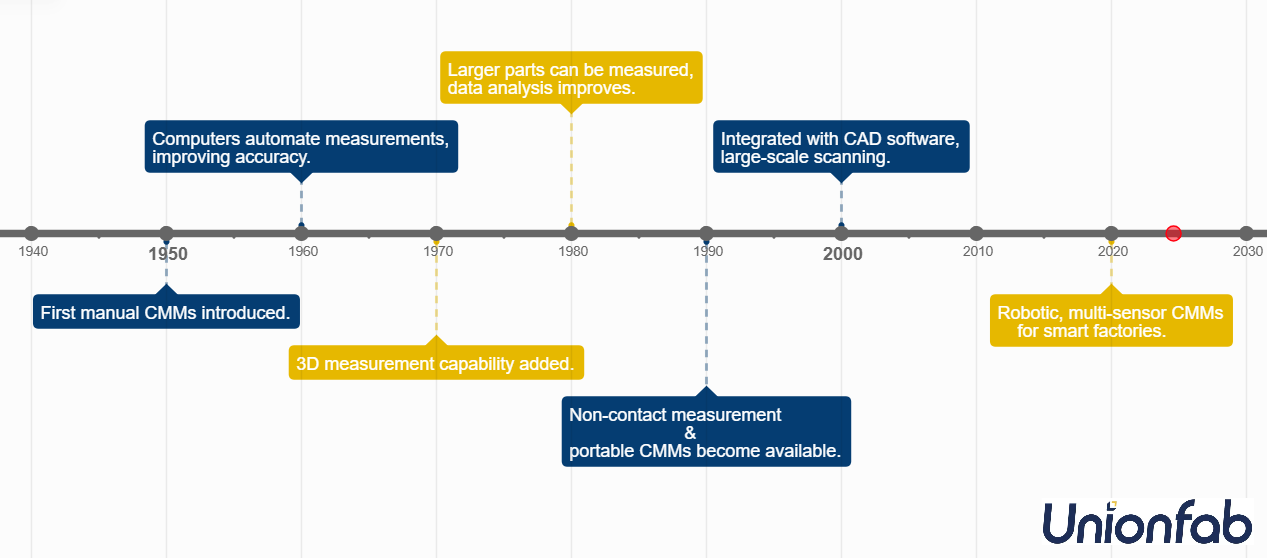

A Coordinate Measuring Machine (CMM) is a device used to measure the physical geometrical characteristics of an object.

It was developed to enable highly precise dimensional measurements to be taken on site in a manufacturing environment, replacing less accurate manual methods.

Types of Coordinate Measuring Machines

Bridge Machine

Bridge machine features a bulky fixed-bed design with beams on either side of the measurement volume. The probe moves along rigid bridges on tracks for X and Y scanning. Commonly found in large production facilities for heavy parts.

Cantilever Machine

Resembles a large adjustable spanner with one rigid beam extending over the work table. The probe mounts on the extending beam which moves left/right and in/out for X and Y scanning. It saves space compared to bridge machines.

Gantry Machine

Portable Arm CMM

Resembling a robotic arm, it has joints that flex to position the probe.

It is used where space is limited, to inspect directly on the production line or in tricky work areas. Very flexible, but less accurate than fixed machines.

How CMM Machines Work

Key Components

Probes: These are the "fingers" of the CMM. They touch the object being measured and send information about the point of contact to the machine.

Sensors: These are like the machine's "eyes." They detect the position of the probe and convert it into digital information that the computer can understand.

Basic Measurement Methods

There are two main ways a CMM measures objects:

Contact Measurement: This is like using a ruler to measure the length of a pencil. The probe physically touches the object to determine its shape and size.

Non-Contact Measurement: This is like using a camera to measure the size of an object. The CMM uses sensors, like lasers, to measure the object without touching it. This method is often used for delicate or fragile items.

What is CMM Inspection?

Explanation of CMM inspection

CMM Inspection is the process of using a Coordinate Measuring Machine (CMM) to check if an object meets the required specifications.

The Role of CMM Inspection in Ensuring Accuracy

CMM inspection is crucial for ensuring that products are made correctly. By measuring objects with extreme accuracy, CMMs help to:

Identify errors: CMMs can detect even tiny mistakes in the size or shape of an object.

Improve quality: By finding and correcting errors, manufacturers can produce higher quality products.

Save time and money: Early detection of problems can prevent costly rework.

Applications in 3D Printing and CNC

Role in Quality Control for 3D Printed Parts

3D printing is a fantastic way to create objects layer by layer. However, it's important to make sure these parts are the correct size and shape.

This is where CMMs come in. By precisely measuring 3D printed parts, CMMs help identify any errors or imperfections, ensuring that the final product meets the required standards.

Role in Precision Measurement for CNC Machined Components

CNC machines are used to create parts with extreme accuracy. To verify that these parts are made correctly, CMMs are used to measure them with precision.

This helps to guarantee that the parts fit together perfectly and function as intended.

Benefits of CMM Machines

Accuracy and Reliability

CMM machines are known for their exceptional accuracy. They can measure objects with incredibly small margins of error.

This reliability is crucial for ensuring that products meet the highest quality standards.

Efficiency and Error Reduction

CMMs can perform measurements much faster than humans and with far fewer mistakes.

This boosts efficiency in production and helps to reduce the number of faulty products.

Challenges and Considerations

Potential Limitations of CMM Technology

While CMMs are incredibly precise, they do have limitations. For example, they might struggle to measure very small or very large objects accurately. Additionally, they might have difficulty measuring objects with complex shapes or textures.

Maintenance and Calibration Needs

Like any complex machine, CMMs require regular care. They must be cleaned and maintained to ensure they continue to work accurately. Additionally, CMMs need to be calibrated regularly to make sure their measurements are correct.

Conclusion

CMMs are amazing machines that help make sure things are built correctly. They're like super-accurate rulers that can measure tiny details.

From building cars to creating 3D printed toys, CMMs play a big role in making sure everything fits together perfectly.

Unionfab: Your Partner for Quality Part Production

Need precise measurements for your project? Unionfab’s manufacturing services include CMM inspection to ensure your product meets the highest quality standards. For an additional fee, you can request a detailed CMM inspection report.

Your Vision. Our Expertise. Perfectly Engineered.

Bring your designs to life with our advanced 3D printing and CNC machining capabilities.

Get an instant quote now or contact us today to discuss your requirements!