DLP vs. SLA: Which is Best for Your Project?

This guide compares DLP and SLA 3D printing, their pros, cons, and uses, and helps you pick the best option for your needs.

Introduction

In this guide, we will examine DLP and SLA in detail, discussing their strengths, limitations, and ideal applications.

By the end, you'll be equipped with the knowledge to choose the most suitable technology to bring your ideas to life.

What is DLP?

DLP, or Digital Light Processing, is a 3D printing technology that uses light to solidify a resin layer by layer, creating a solid object.

How DLP Works

Resin Tank: A vat of liquid resin is placed in the printer.

Projection: A digital micromirror device (DMD) projects light patterns onto the resin.

Solidification: The exposed resin hardens, forming a layer of the object.

Layer-by-Layer: The process is repeated, building the object layer by layer.

Key Advantages of DLP

High Accuracy: DLP produces highly detailed and precise parts.

Fast Build Times: Compared to SLA, DLP can often build objects more quickly.

Large Build Volumes: DLP printers can accommodate larger objects.

Multiple Materials: DLP can be used with a variety of resins, including those for flexible, rigid, and transparent parts.

Key Disadvantages of DLP

Resin Cost: Resin for DLP can be more expensive than other materials.

Support Structures: DLP often requires support structures to prevent sagging or warping during the build process.

Limited Material Variety: While DLP can use a variety of resins, the range of materials may be more limited compared to other technologies.

Source: origin.io

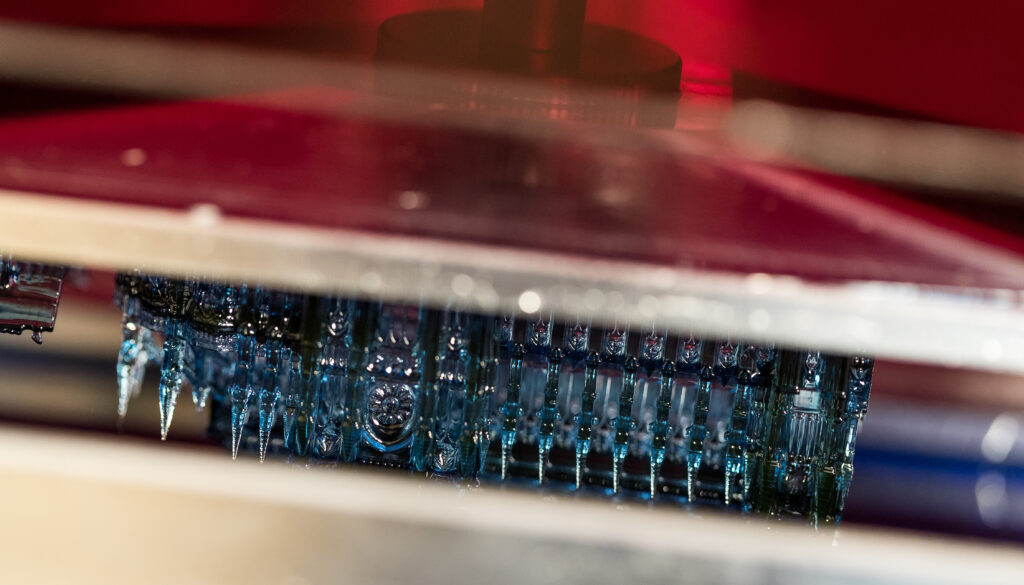

What is SLA?

SLA, or Stereolithography, is a 3D printing technology that creates objects by solidifying liquid resin layer by layer using a laser beam.

How SLA Works

Resin Tank: A vat of liquid photopolymer resin is placed in the SLA machine.

Laser Beam: A laser beam is directed onto the resin surface, curing a specific pattern.

Layer-by-Layer: The platform beneath the resin tank lowers, and the process is repeated, building up the object layer by layer.

Post-Processing: The cured object is removed from the resin tank and washed to remove excess resin. It is then cured under UV light to complete the hardening process.

Key Advantages of SLA

High Accuracy and Detail: SLA produces highly accurate and detailed parts with smooth surfaces.

Wide Range of Materials: SLA can use a variety of photopolymer resins, allowing for different properties like flexibility, strength, and biocompatibility.

Complex Geometries: SLA can create intricate and complex shapes that may be difficult with other 3D printing technologies.

Key Disadvantages of SLA

Slower Build Times: Compared to some other 3D printing technologies, SLA can have slower build times due to the layer-by-layer process.

Resin Cost: Photopolymer resins can be relatively expensive, especially for high-resolution or specialized materials.

Post-Processing: SLA requires additional steps like washing and curing, which can add to the overall time and cost.

Source: rapidmade.com

Key Differences Between DLP and SLA

The relationship between DLP and SLA lies in the fact that they are both vat photopolymerization technologies used in 3D printing. They share the same fundamental process of curing liquid resin with light to create solid layers, but differ in following dimensions:

Aspect | DLP | SLA |

|---|---|---|

Technology | Cures entire layers at once. | Cures layers point-by-point. |

Material Properties | Lower viscosity resins. | Higher viscosity resins. |

Resolution and Detail | Limited detail. | Higher resolution. |

Speed | Faster printing. | Slower but improving. |

Surface Finish | Need polishing for smoothness. | Generally smoother. |

Build Volume | Larger build sizes possible. | Typically smaller. |

Post-Processing | Often requires extra curing. | Usually requires less post-curing. |

Cost | Lower upfront cost but pricey resin material . | Comparable costs, but higher initial investment for lasers. |

Applications | Pprototyping and larger parts. | Detailed medical/dental models. |

Environmental Considerations | Needs specific ventilation for offgassing. | Different enclosure needs for laser use. |

Technology

DLP utilizes a digital light processing projector to cure entire layers of photopolymer resin at once by projecting a 2D pattern, while SLA uses a focused laser to trace and cure each layer vector-by-vector.

Material Properties

Resins for DLP require lower viscosity for the projected light to adequately penetrate layers. SLA resins can have higher viscosity without impeding the laser's curing.

Resolution and Detail

Due to laser sintering one small region at a time, SLA achieves higher resolution and can print more intricate details than DLP which is limited by its projector's pixel size when curing full layers.

Speed

DLP prints much faster by exposing complete layers simultaneously rather than SLA's point-by-point laser scanning. However, advancing technologies have significantly increased SLA speeds in recent years.

Surface Finish

SLA often results in smoother surfaces straight from the build plate since the laser selectively cures targeted spots. DLP tends to need sanding/polishing due to its layer-wide projected exposures.

Build Volume

DLP projectors allow larger build envelopes as they aren't physically constrained like the laser's scan range. But SLA build sizes have continually expanded.

Post-Processing

SLA parts typically demand less post-curing since the laser fully solidifies details within. DLP may require additional curing due to uncured resin trapped inside intricacies.

Cost

Projectors are more affordable light sources than lasers, lowering DLP's upfront cost despite more expensive resins. But overall costs are comparable between the two technologies.

Applications

SLA excels in fields like medicine/dentistry where fine feature fidelity is paramount. DLP lends itself well to prototyping and mass manufacturing larger parts.

Environmental Considerations

DLP's use of full-layer projected curing versus SLA's point-by-point laser scanning necessitates different enclosure and ventilation specifications to safely manage offgassing and exposure levels.

Ideal Applications for DLP and SLA

Both DLP and SLA are versatile technologies with their own strengths and weaknesses. Here are some ideal applications for each:

DLP

Prototyping: DLP is excellent for rapid prototyping due to its relatively fast print speeds and ability to produce complex geometries.

Jewelry and small intricate parts: The high resolution and accuracy of DLP make it well-suited for creating intricate details and small-scale objects.

Dental and medical models: DLP can be used to produce accurate dental and medical models for prosthetics, surgical planning, and education.

Consumer products: DLP is often used for creating functional prototypes of consumer products, such as toys, electronics, and household items.

SLA

Airplane/car engine parts - SLA is very good for making small parts for planes and vehicles accurately because it can repeat sizes exactly the same each print.

Molds and fixtures - SLA is best for molds, forms and things that hold pieces together well as it can make tiny inside spaces and shapes clearly.

Sculptures and decorative items - SLA's ultrasmooth and detailed prints make it perfect for copying art statues, figurines and other collectors’ items where looks matter.

Surgeon guides - SLA is regularly used to print body and bone models, customized surgery helpers and medical gear since it can copy people shapes with real precision to plan procedures and check equipment.

How to Choose the Most Suitable 3D printing Technology?

To make an informed choice between DLP and SLA, it is necessary to consider the following criteria:

What to make: Consider the size, shape, detail, and quality of the object. Small, intricate items are best suited for SLA, while larger items are more efficiently produced using DLP.

Turnaround time: SLA is slower due to its layer-by-layer laser tracing, whereas DLP quickly prints entire layers at once. Choose based on the importance of speed.

Surface smoothness: SLA generally produces smoother surfaces, while DLP prints may require sanding or polishing. Consider how much surface finish matters for your project.

Resolution: SLA excels in finer, detailed features, while DLP resolution depends on projector pixel size. Select the one that matches your resolution needs.

Budget: SLA machines tend to be more expensive upfront but use more affordable resins. DLP has a lower initial cost, but resin expenses can accumulate over time.

Programming personnel: SLA machines often require more technical expertise for setup and operation. DLP is typically easier to use with minimal programming knowledge.

Safety regulations: SLA requires proper containment and ventilation. DLP may be easier to implement in certain workspaces, depending on safety regulations.

Conclusion

This guide explained the differences between DLP and SLA 3D printing. Both use light and layers to make objects, but DLP cures whole layers at once while SLA cures layers point-by-point.

Understanding how they work differently helps you pick the right one for your project's size, details, speed needs, and more. Following the tips in this article will help you select the technology that best matches what you're making.

Unionfab: Help You Choose the Right 3D Printing Technology

Whether you need the speed and efficiency of DLP or the precision and detail of SLA, Unionfab deliver top-tier results tailored to your needs.

Contact us for professional 3D printing services. Get started on your 3D printing journey now!