Heat Creep in 3D Printing: What It Is and How to Prevent It

Learn how heat creep impacts your 3D printing and practical solutions to ensure smoother prints.

Introduction: What Is Heat Creep in 3D Printing?

Defining Heat Creep

Source: 3dprinteracademy.com

Heat creep is a phenomenon that occurs in 3D printing when heat from the hot end of the printer travels up into the cooler areas of the filament path.

This can cause the filament to soften or melt prematurely, leading to clogs and poor print quality.

Relevance to 3D Printing

Heat creep is particularly important in 3D printing because it can disrupt the extrusion process. When filament softens too early, it can cause jams in the nozzle, resulting in failed prints.

This issue is common in printers with long or poorly insulated hot ends, making it a challenge for both beginners and experienced users.

Causes of Heat Creep

Overview of Heat Management in 3D Printers

Effective heat management is essential in 3D printing to ensure that each component operates at the correct temperature. The hot end must reach high temperatures to melt the filament, while other parts, like the heat sink, need to stay cool to prevent heat from traveling upwards. Proper cooling prevents heat creep and ensures smooth filament extrusion.

Role of Hotend, Heat Sink, and Filament

Hotend

Source: 3djake.de

The hot end is where the filament is melted. It needs to maintain a specific temperature to ensure the filament flows smoothly. If the hot end is poorly insulated, heat can escape and travel up the filament path, causing heat creep.

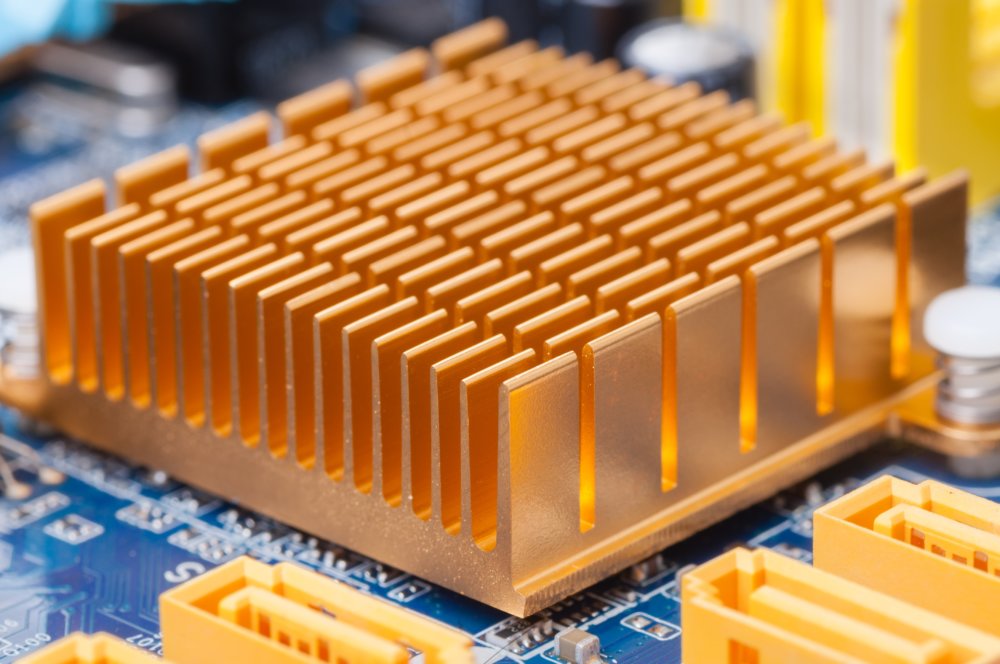

Heat Sink

Source: 3erp.com

The heat sink is designed to cool the filament as it moves away from the hot end. If the heat sink fails to dissipate heat effectively, it can lead to an increase in temperature further up the filament path, resulting in premature softening.

Filament

Different types of filament have varying thermal properties. Some materials are more susceptible to heat creep than others. For example, filaments with lower melting points can soften quickly if they encounter excess heat.

Common Causes of Heat Creep

Improper Cooling Insufficient cooling around the heat sink can allow heat to rise, increasing the risk of heat creep. Fans must be functioning correctly to maintain appropriate temperatures.

Filament Softening If the filament is exposed to heat for too long, it may start to soften before reaching the nozzle. This can happen if the filament path is too long or poorly designed.

Thermal Conductivity Issues Some components may not effectively insulate heat. High thermal conductivity materials can transfer heat too readily, allowing it to escape from the hot end and cause problems upstream.

Signs and Symptoms of Heat Creep

Recognizing heat creep issues in your 3D prints is crucial for maintaining print quality. Here are some common signs and symptoms to watch for:

Inconsistent Extrusion

One of the first signs of heat creep is inconsistent extrusion. You may notice that the filament does not flow smoothly through the nozzle. Instead, it may start and stop unexpectedly, leading to gaps or uneven layers in your print.

This inconsistency can severely impact the final appearance and strength of the printed object.

Nozzle Jams

Frequent nozzle jams are a clear indication of heat creep. If the filament is softening too early, it can create a blockage in the nozzle. This can cause the printer to skip steps or even stop printing altogether.

If you find yourself needing to clear the nozzle regularly, heat creep may be the culprit.

Material Oozing

Another symptom of heat creep is material oozing from the nozzle when the printer is not in operation.

If you notice filament leaking out, it could mean that the filament is softening due to excess heat in the hot end or filament path. This can lead to stringing and other quality issues in your prints.

How Heat Creep Affects 3D Printing

Print Failures

Heat creep can lead to significant print failures by disrupting the extrusion process. When the filament softens prematurely, it can cause clogs in the nozzle, resulting in under-extrusion or complete stoppage of material flow. This often leads to failed prints, wasted materials, and frustration for the user. Additionally, once a print begins to fail, it can be challenging to recover or salvage, especially if it occurs mid-print.

Impact on Filament Types

Different filament types respond differently to heat creep:

PLA: This material is sensitive to temperature and can soften quickly when exposed to heat. As a result, PLA is particularly prone to heat creep issues, leading to clogs and poor print quality if the hot end is not adequately cooled.

PETG: PETG has a higher melting point than PLA but can still experience heat creep. If the filament gets too warm, it may not flow properly, leading to similar extrusion issues as seen with PLA. The balance between heat and cooling is crucial for successful PETG prints.

ABS: While ABS can tolerate higher temperatures, it is also affected by heat creep. If the filament softens too early, it may lead to warping or layer adhesion problems, especially in longer prints, where consistent temperature management is vital.

Problems with Print Quality

Heat creep can significantly impact print quality, especially during longer prints. As the print progresses, any heat creep can cause layer inconsistencies, leading to:

Weak Layer Bonds: Inconsistent extrusion may result in weak adhesion between layers, compromising the structural integrity of the print.

Surface Defects: Inconsistent flow can create rough surfaces or unwanted artifacts, detracting from the overall appearance of the final product.

Dimensional Inaccuracy: Heat creep can also lead to variations in dimensions, making it difficult to achieve precise measurements in your finished prints.

How to Prevent Heat Creep

Preventing heat creep is essential for maintaining consistent print quality. Here are some effective strategies to combat this issue:

Cooling Fan Adjustments and Proper Placement

Optimize Cooling Fans: Ensure that cooling fans are functioning properly and directed at the heat sink. This helps dissipate heat effectively and keeps the filament cool as it moves through the printer.

Fan Placement: If your printer allows, adjust the placement of fans to maximize airflow around the heat sink. This can help reduce heat buildup and minimize the risk of heat creep.

Use of Thermal Barriers

PTFE Tubes: Utilizing PTFE (polytetrafluoroethylene) tubes can create a thermal barrier between the hot end and the cooler sections of the filament path. These tubes have low thermal conductivity, which helps prevent heat from traveling upwards.

Insulation: Consider adding insulation around the hot end to keep heat contained. Insulating materials can help maintain the necessary temperatures without allowing excessive heat to escape.

Hotend Upgrades and Heat Sink Maintenance

Hotend Upgrades: Consider upgrading to a high-quality all-metal hot end designed to handle higher temperatures more effectively. These hot ends often have better heat management features that reduce the risk of heat creep.

Heat Sink Maintenance: Regularly clean and inspect the heat sink for dust or debris that might hinder airflow. A clean heat sink can dissipate heat more efficiently, reducing the likelihood of heat creep.

Fixing Heat Creep Problems

When you encounter heat creep issues in 3D printing, it's essential to troubleshoot and resolve them quickly to maintain print quality. Here’s a step-by-step guide to help you fix heat creep problems effectively.

Troubleshooting Heat Creep Issues

Identify Symptoms: Look for signs of heat creep, such as inconsistent extrusion, nozzle jams, or material oozing.

Check Cooling Fans: Ensure that the cooling fans are operational and directed towards the heat sink. If they are not functioning properly, replace or adjust them.

Inspect the Hotend: Examine the hotend for any signs of blockage or excessive heat. If the heat sink is too hot to touch, it may be a sign of heat creep.

Step-by-Step Guide on Cleaning and Maintaining the Hotend

Power Down the Printer: Always turn off and unplug your printer before performing maintenance.

Disassemble the Hotend: Carefully remove the hotend from the printer. Follow your printer's manual for specific instructions on disassembly.

Clean the Nozzle: Use a small needle or cleaning tool to clear any blockages in the nozzle. You can also soak the nozzle in acetone or a similar solvent if it’s clogged with stubborn residues.

Inspect the Heat Sink: Check for dust and debris around the heat sink. Use compressed air or a soft brush to clean it thoroughly.

Reassemble the Hotend: Once everything is clean, reassemble the hotend and ensure all components are securely attached.

Test the Printer: After reassembly, run a test print to check if the heat creep issue has been resolved.

Filament Selection Tips

Choose High-Quality Filaments: Select reputable brands that offer filaments designed to withstand higher temperatures and reduce the risk of softening.

Consider Temperature Tolerance: When selecting filament, be aware of its temperature tolerance. Materials like PLA are more prone to heat creep, while others like ABS and PETG may be more resilient.

Store Filament Properly: Keep filament in a cool, dry place to prevent it from absorbing moisture, which can affect its thermal properties.

Best Practices for Heat Management in 3D Printing

Effective heat management is crucial for achieving high-quality prints while avoiding heat creep. Here are some best practices to maintain consistent temperature control and improve your 3D printing experience.

Tips for Consistent Temperature Control

Monitor Temperatures: Use a reliable thermometer or temperature monitoring system to keep track of the hot end and heat sink temperatures during printing.

Calibrate Your Printer: Regularly calibrate your printer's temperature settings to ensure that the hot end reaches the desired temperature without overheating.

Use a PID Controller: Implement a PID (Proportional-Integral-Derivative) controller to maintain stable temperatures in the hot end. This helps reduce temperature fluctuations that can lead to heat creep.

Proper Airflow Management and Hardware Upgrades

Optimize Fan Placement: Ensure that cooling fans are positioned correctly to direct airflow around the heat sink and hot end. Proper airflow helps dissipate heat effectively.

Upgrade Cooling Fans: Consider upgrading to more powerful fans or adding additional fans to improve cooling efficiency, especially if you're printing with materials prone to heat creep.

Insulate the Hotend: Use thermal insulation around the hot end to prevent heat from escaping and affecting the filament path.

Recommended Print Settings to Avoid Heat Creep

Lower Print Speeds: Reducing print speeds can help manage heat buildup by allowing more time for the filament to cool as it moves through the printer.

Adjust Temperature Settings: Set the hot end temperature according to the filament manufacturer's recommendations. Avoid exceeding these temperatures, as it can lead to heat creep.

Use Cooling Settings: Enable part cooling fans in your slicer settings. This helps cool the filament as it is extruded, reducing the risk of heat creep.

Layer Height Considerations: Opt for a larger layer height for longer prints, as this reduces the amount of time the filament spends in the hot zone.

Conclusion

Heat creep is a significant challenge in 3D printing that can lead to print failures and quality issues.

By understanding its causes—such as improper cooling, filament softening, and thermal conductivity problems—you can take proactive measures to prevent it. Recognizing signs like inconsistent extrusion, nozzle jams, and material oozing is crucial for troubleshooting.

Implementing best practices for heat management, including consistent temperature control, proper airflow, and careful filament selection, will enhance your printing experience.

By following these guidelines, you can minimize heat creep and achieve high-quality prints consistently.

Trust Unionfab for Expert 3D Printing Solutions!

Don’t let heat creep ruin your 3D prints! At Unionfab, we specialize in providing high-quality 3D printing services with advanced technology that ensures precise temperature control for perfect prints every time.

Whether you need professional advice or custom 3D printing solutions, our team is here to help you achieve flawless results. Get in touch with Unionfab today and take your 3D printing to the next level!