Polycarbonate vs. Acrylic: Choosing the Ideal Material

Polycarbonate or acrylic? Discover how each material performs in 3D printing and which is best for your projects based on strength, clarity, and printability.

Introduction

Polycarbonate (PC) and acrylic are two popular thermoplastics for 3D printing functional parts and prototypes.

Polycarbonate offers strength and heat resistance, while acrylic is known for its transparency and ease of use. Choosing the right material is crucial for ensuring your 3d-printed parts perform well and last longer. The wrong material could lead to early failure or compromised designs.

This guide will help you understand the properties of polycarbonate and acrylic so you can choose the best material for your specific 3D printing needs.

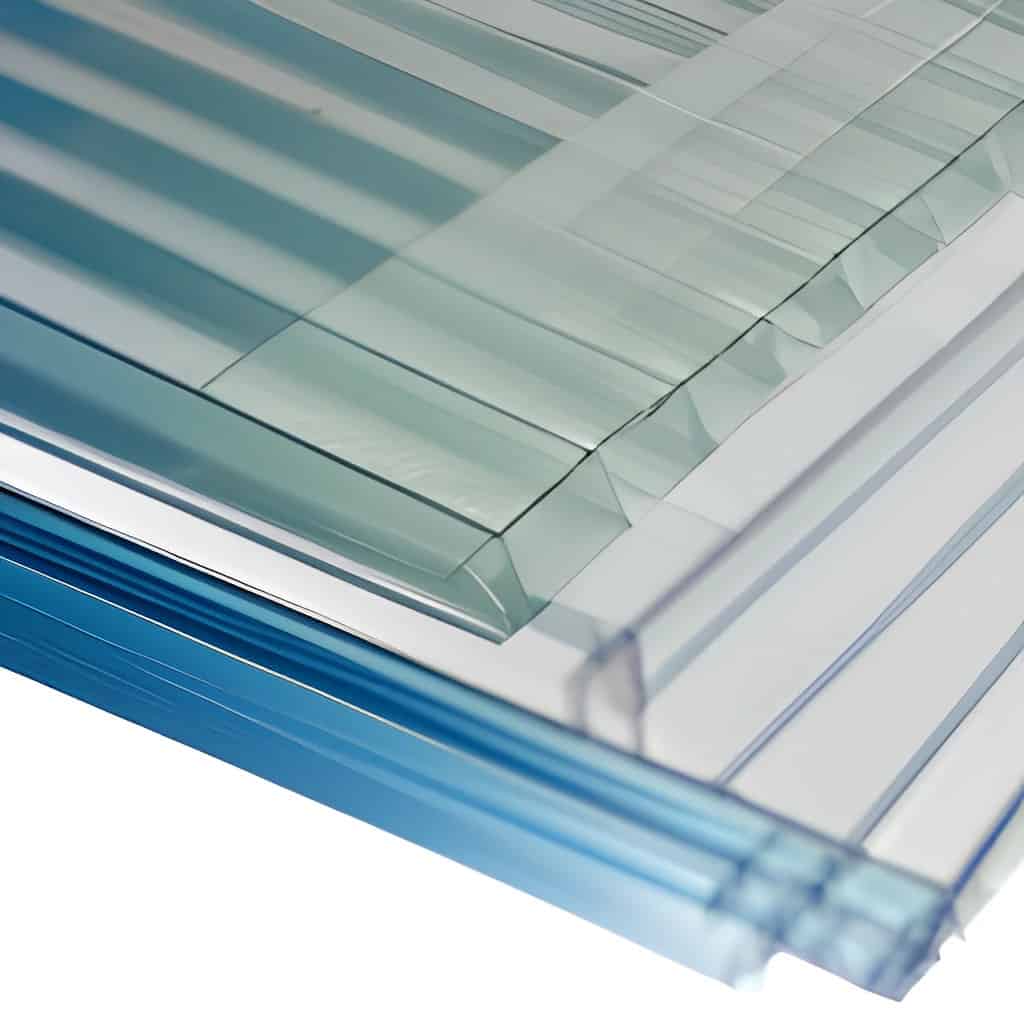

What is Polycarbonate (PC)?

Source: extechinc.com

Polycarbonate (PC) is an engineered thermoplastic that is highly impact-resistant and durable. It offers exceptional strength for its light weight, with impact resistance equal to many glasses but nearly unbreakable.

Polycarbonate maintains its strength far into the melting point zone and does not become brittle at low temperatures. It has excellent dimensional stability and weatherability.

Some key characteristics of polycarbonate include:

High impact strength - Flexible yet very difficult to break, crack, or scratch.

Strength and durability - One of the strongest commercially available plastics.

Heat resistance - Retains properties up to 150 degrees Celsius.

Common Applications of Polycarbonate (PC)

Protective screens or clear panels due to high impact resistance and strength.

Enclosures, housings, and industrial equipment parts requiring durability.

Greenhouse glazing and roofing due to weatherability and light transmission.

Corrective ophthalmic and eyewear lenses for impact protection.

Pros of Polycarbonate (PC)

Strength and durability for long-lasting applications.

Heat tolerance for higher temperature uses.

Lightweight yet robust.

Cons of Polycarbonate (PC)

More brittle than other plastics if temperatures drop below freezing.

Prone to yellowing or degrading from UV exposure without additives.

In summary, polycarbonate is an ideal high-performance plastic for 3D printing durable, impact-resistant parts and prototypes. Its versatility makes it useful for a wide range of industrial and commercial applications.

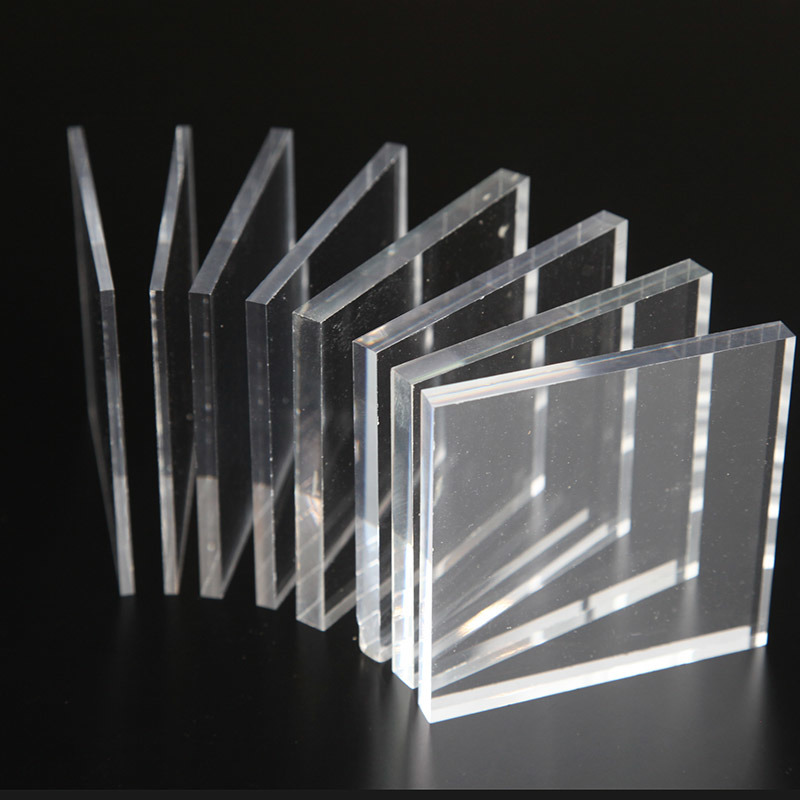

What is Acrylic?

Source: sabinplastic.com

Acrylic is a transparent thermoplastic. Its primary characteristics include high clarity, strength, and resistance to scratches and chemicals.

Acrylic is lightweight yet solid, with high resistance to weathering and ultraviolet radiation. It maintains excellent clarity and color retention both indoors and outdoors.

Some key characteristics of acrylic include:

High clarity - Enables see-through designs with crisp detail visibility.

Scratch resistance - Durable surface withstands abrasion and minor impacts.

Lightweight - Approximately 1/4 the density of glass.

Common Applications of Acrylic

Aquarium tanks, sinks, and bathtubs due to clarity and chemical resistance.

Signage, store displays for transparent visibility.

Picture frames, interior decorative panels.

Aircraft canopies and translucent roofing.

Pros of Acrylic

Superior clarity for maximum light transmission.

Workability - Easy to cut, drill, form, and thermoform.

Impact strength balanced with light weight.

Cons of Acrylic

Thermal limitations, risk of melting or deformation above 80 degrees Celsius.

More prone to scratching than polycarbonate.

In summary, acrylic is an excellent choice when transparency, light weight, or formability is important for an application. It allows the creation of detailed, clear 3d-printed designs.

Polycarbonate vs Acrylic: Key Differences

Strength & Durability

Polycarbonate is more durable and impact-resistant. It maintains properties across a wider temperature range. Acrylic is balanced between strength and workability.

Clarity & Aesthetics

Acrylic offers superior clarity for maximum light transmission and see-through visuals. Fine details are more sharply defined in acrylic parts.

Scratch Resistance & Maintenance

While acrylic is scratch-resistant, polycarbonate is more robust and tolerates abrasion better over time. Scratches on acrylic may require refinishing.

Cost & Availability

Polycarbonate material and printing costs are often higher but it is widely available. Acrylic is lower cost and easier to access in smaller quantities for hobbyists and models.

UV Resistance

Acrylic withstands UV exposure better by blocking wavelengths that cause degradation. Polycarbonate requires UV protective additives to inhibit long-term yellowing and breakdown from sunlight.

In summary, polycarbonate has better mechanical strength for functional applications or heavy-duty use, while acrylic enables clearer aesthetics and easier post-processing.

Applications: Where to Use Polycarbonate vs Acrylic

Here are some common application guidelines for choosing between polycarbonate and acrylic:

Use Polycarbonate for:

Outdoor equipment, housings or enclosures that require UV resistance and durability.

Automotive or transportation parts like lighting fixtures or console components.

Industrial equipment, machinery guards, and safety equipment.

Medical or scientific devices, medical-grade enclosures, or viewports.

Consumer electronics like phones, tablets, and laptops where heat resistance is critical.

Use Acrylic for:

Aquariums, fish tanks, terrariums, or other liquid/moisture containment.

Display cases, signage, retail fixtures where transparency is important.

Interior design elements, furniture, decorative wall partitions.

Prototyping, visual aids, and presentation models where visual clarity is key.

Crafts and architectural models where formability and weight are considerations.

When to Choose Polycarbonate or Acrylic?

When Choosing between Polycarbonate and Acrylic, Consider:

Strength

Polycarbonate is significantly stronger and more durable over the long term.

Acrylic strikes a good balance but is better suited for lighter duty applications.

Cost

Polycarbonate material and printing costs tend to be higher than acrylic.

Acrylic is more affordable for low-volume prototypes, models and non-structural parts.

Aesthetics

Acrylic has unparalleled clarity ideal for transparent or translucent designs.

Polycarbonate is clear but has a mildy yellow tintreducing translucency.

Temperature Exposure

Polycarbonate withstands continuous high heat-exposure better than acrylic.

Acrylic risks warping and deformation at temperatures over 80 degrees Celsius.

Chemical Resistance

Acrylic generally offers better resistance to chemicals that could degrade plastics.

Polycarbonate requires additives to protect against certain reactive substances.

In summary, for functional or load-bearing parts, choose polycarbonate. For prototypes, low-volume aesthetic models, and applications needing clarity, acrylic is preferable. Weighing these factors guides picking the right material.

Conclusion

In conclusion, polycarbonate is the best choice for high-performance parts due to its durability, heat resistance, and dimensional stability, making it ideal for industrial, medical, automotive, and outdoor applications.

Acrylic, on the other hand, is great for projects that need optical clarity and a polished look, like transparent displays, prototypes, and architectural models. It is a more affordable option for low-stress uses where visibility matters.

By comparing factors like strength, heat tolerance, ease of use, cost, and finishing needs, designers can decide whether durability, clarity, or flexibility are most important for their project.

Let Unionfab Help You Create

At Unionfab, we specialize in helping you choose the perfect materials for your 3D printing needs.

Whether you're working with polycarbonate for strong, durable parts or acrylic for stunning visual clarity, our expertise ensures you get the best results.

Contact us today to learn how our advanced 3D printing solutions can bring your designs to life with precision and quality. Let’s start your next project together!