How 3D Printing Innovation is Transforming Industries

Explore how 3D printing innovation is reshaping industries beyond prototyping.

Introduction

3D printing has emerged as a transformative technology, revolutionizing industries ranging from manufacturing to healthcare. As innovations continue to shape its capabilities, 3D printing is no longer just a prototyping tool; it is becoming integral to large-scale production, personalized design, and even entirely new fields of application.

This blog explores the latest trends in 3D printing, the technologies driving these changes, their current applications across industries, and what the future holds for this groundbreaking technology.

Industry Trends: The Rapid Evolution of 3D Printing

Widespread Adoption Across Industries

In recent years, 3D printing has expanded far beyond its roots in rapid prototyping. Industries like manufacturing, aerospace, automotive, and healthcare are increasingly integrating 3D printing into their operations.

The versatility of additive manufacturing (AM) allows for cost-effective production, customized solutions, and faster turnaround times. With 3D printing, companies are no longer limited by traditional manufacturing constraints, enabling them to meet market demands for more complex and personalized products.

Market Growth and Investment

In 2023, the global 3D printing market was valued at $16.75 billion, and it is expected to grow at a compound annual growth rate (CAGR) of 21% over the next several years. This growth is driven by both large-scale enterprises and small businesses adopting 3D printing for a range of applications, from product development to final production. Investors are increasingly confident in the long-term potential of 3D printing as a mainstream manufacturing process.

Sustainability and Environmental Impact

Environmental sustainability is becoming a crucial focus for the 3D printing industry. The ability to create precise parts with minimal waste is one of the technology’s greatest advantages.

Additive manufacturing produces only the material required for a part, unlike subtractive methods that generate significant material waste. This makes 3D printing an attractive option for companies seeking to reduce their environmental footprint and move toward more sustainable production practices.

Key Advances in 3D Printing

New Materials

The range of materials available for 3D printing has expanded significantly, opening up new possibilities for applications. Beyond traditional plastics, new high-performance materials such as metal alloys, ceramics, and even biocompatible materials for medical applications are now being used.

Innovations in these materials are enabling more complex and durable products, including metal 3D printing for aerospace components and bioprinting for healthcare applications.

Faster Printing Speeds and Higher Precision

One of the primary advancements in 3D printing technology is the increased speed and precision of printers. New printing methods such as continuous liquid interface production (CLIP) have reduced printing times from hours or days to mere minutes, making 3D printing more competitive with traditional manufacturing methods.

Additionally, improvements in resolution and precision are enabling the production of intricate designs with fine details, necessary for industries like aerospace, healthcare, and automotive.

Multi-Material Printing

Multi-material 3D printing has emerged as a game-changer, allowing printers to work with different materials simultaneously during the printing process. This innovation allows for more complex and functional parts to be created, particularly in applications that require multiple material properties within a single piece.

For example, automotive manufacturers are using multi-material printing to create parts with varying mechanical properties, such as flexibility and strength, in one single printed object.

Artificial Intelligence and Automation

Artificial intelligence (AI) is playing an increasingly important role in optimizing the 3D printing process. AI-driven software can predict and adjust for potential issues in printing, ensuring better results with fewer human interventions.

Coupled with automation, AI helps streamline production processes, reduce waste, and increase efficiency in large-scale manufacturing.

Applications of 3D Printing

Aerospace

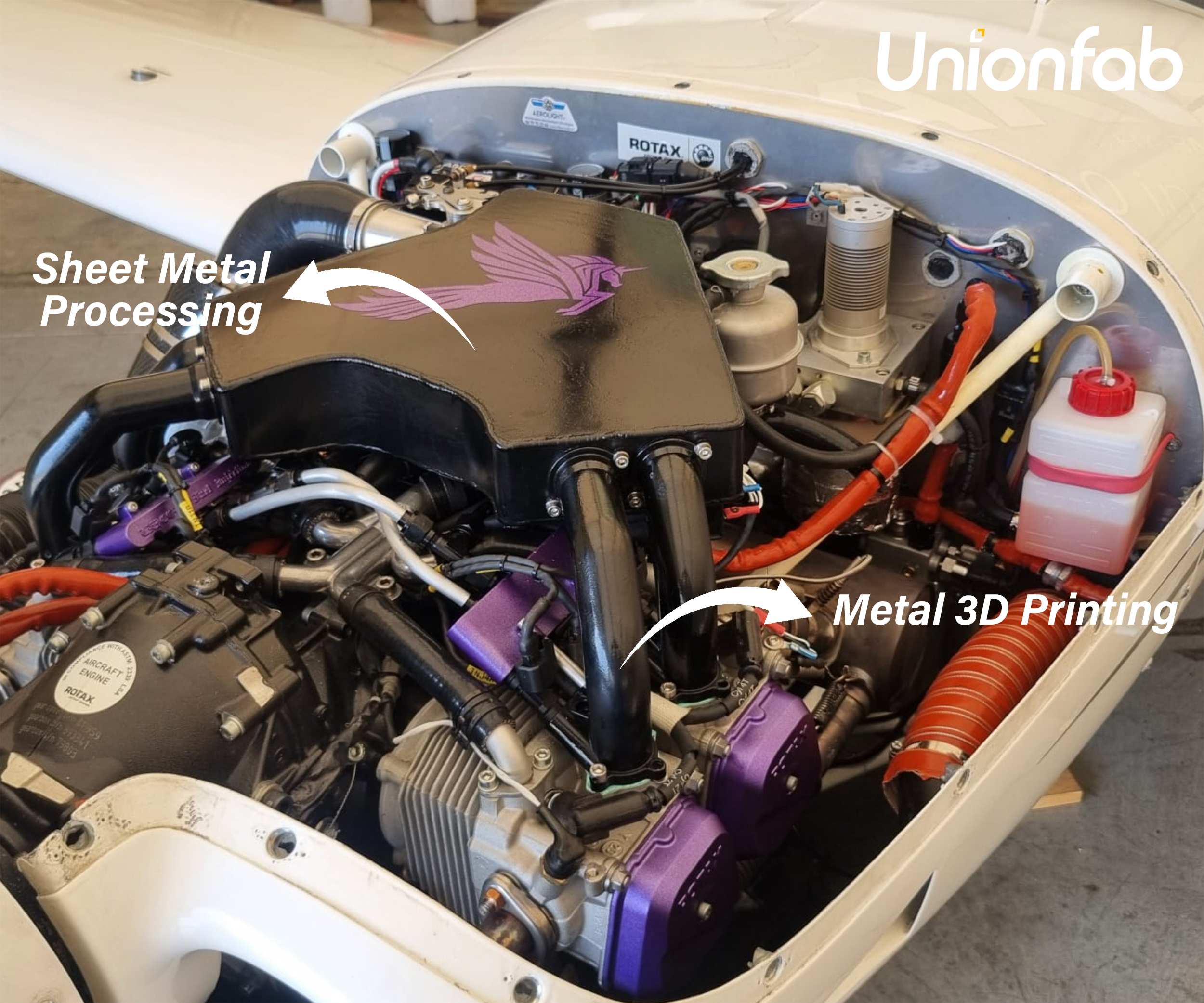

In the aerospace sector, reducing weight and enhancing precision are paramount. Selective Laser Melting (SLM) technology enables the production of lightweight, high-performance components. For example, Unicorn Aviation utilized Unionfab's SLM expertise to develop an advanced electronic fuel injection (EFI) system. The result was a weight reduction of 1 to 2 kilograms compared to traditional designs, improving fuel efficiency and sustainability.

Moreover, Unicorn’s commitment to eco-friendly aviation was further supported by using bioethanol E85 fuel, showcasing how 3D printing integrates innovation and environmental responsibility.

Source: Unionfab

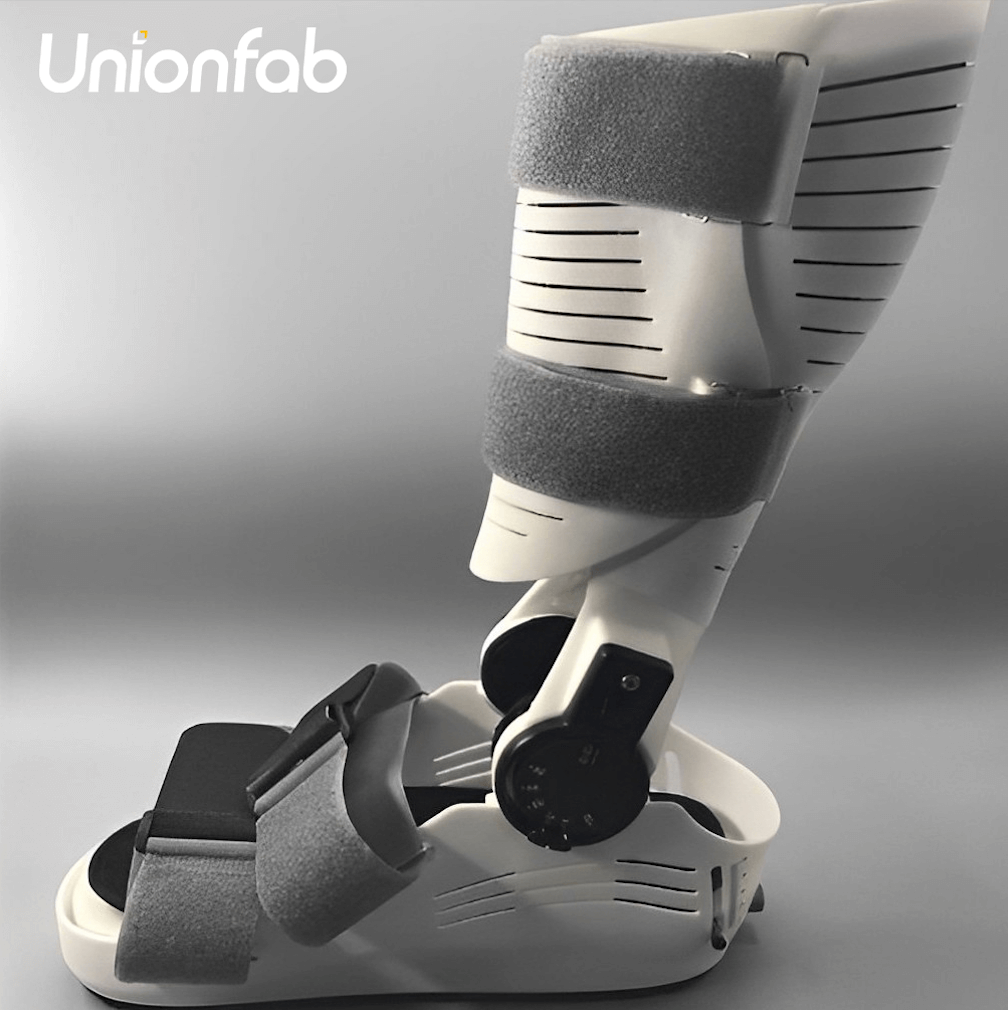

Healthcare

Personalized healthcare has become a reality with 3D printing. Using SLS Nylon PA12, Unionfab produces custom medical devices such as braces tailored to individual patients. These braces provide a perfect fit, enhanced comfort, and improved aesthetics through vapor smoothing post-processing.

Unionfab’s technology also extends to diagnostic tools, including durable and precise blood test instruments. These innovations exemplify how 3D printing addresses the stringent demands of the medical field

Source: Unionfab

Gaming and Entertainment

The gaming and entertainment industries rely on hyper-realistic props and immersive environments to captivate audiences. Unionfab’s advanced 3D printing technology has brought countless creative visions to life, from intricately detailed gaming characters to cinematic set pieces.

For example, Unionfab collaborated with developers to create life-sized, vibrant props for film and gaming, ensuring unmatched realism and artistic precision. Whether it’s complex textures or vibrant colors, Unionfab empowers creators to turn imagination into reality.

Source: Unionfab

The Path Ahead for 3D Printing Innovation

Next-Generation 3D Printing Technologies

As we look to the future, next-generation 3D printing technologies are on the horizon. Advancements in quantum computing and nanotechnology are expected to significantly enhance the capabilities of 3D printing.

These innovations could lead to even more precise, faster, and diverse printing methods, pushing the boundaries of what’s possible. The ability to print with new types of materials and at the nanoscale could transform industries like electronics, biotechnology, and manufacturing.

Scaling Up for Mass Production

One of the biggest challenges facing 3D printing is the ability to scale up for mass production. While 3D printing excels in prototyping and small-batch production, it has not yet fully reached the economies of scale seen in traditional manufacturing.

However, with continuous innovation in both hardware and materials, 3D printing has the potential to disrupt traditional manufacturing models and become a viable solution for large-scale production.

Cross-Industry Integration

The future of 3D printing will see increasing integration with other emerging technologies, including artificial intelligence, robotics, and the Internet of Things (IoT).

By combining these technologies, industries will be able to create more efficient, automated, and adaptable manufacturing processes. 3D printing could also play a key role in developing new supply chains, offering on-demand production and reducing reliance on centralized factories.

Ethical Considerations and Regulatory Challenges

As 3D printing becomes more integrated into industries, there will be increasing ethical and regulatory concerns. Issues such as intellectual property rights, product safety, and environmental impact will need to be addressed.

As new 3D printing applications emerge, particularly in sectors like healthcare and construction, clear regulations will be crucial to ensure safety and quality standards are met.

Start your 3D Printing with Unionfab

At Unionfab, we offer cutting-edge 3D printing solutions tailored to meet the unique needs of industries

Contact Unionfab today to discover how our 3D printing services can drive innovation, streamline your processes, and transform your products.

Get in touch with Unionfab for a free consultation or to explore our wide range of 3D printing capabilities. Let's innovate together!