Inconel vs. Titanium vs. Stainless Steel[+Full Alloy Comparison Chart]

Compare Inconel, Titanium, and Stainless Steel for 3D printing—explore properties, printability, applications, and how to choose the right metal.

Overview of Inconel, Titanium and Stainless Steel

What is Inconel?

Inconel is a family of nickel-chromium-based superalloys known for their exceptional strength and resistance to extreme heat and corrosion.

Key Characteristics:

Excellent high-temperature strength

Outstanding oxidation and corrosion resistance

Good fatigue and creep resistance under harsh conditions

What is Titanium?

Titanium is a lightweight, strong metal known for its high strength-to-weight ratio and excellent corrosion resistance.

Key Characteristics:

High strength with low density (lightweight)

Excellent corrosion resistance, especially in seawater and bodily fluids

Biocompatible and non-toxic

What is Stainless Steel?

Stainless Steel is an alloy of iron with chromium and other elements, valued for its corrosion resistance and durability.

Key Characteristics:

Strong and durable

Highly resistant to rust and corrosion

Good weldability and versatility in applications

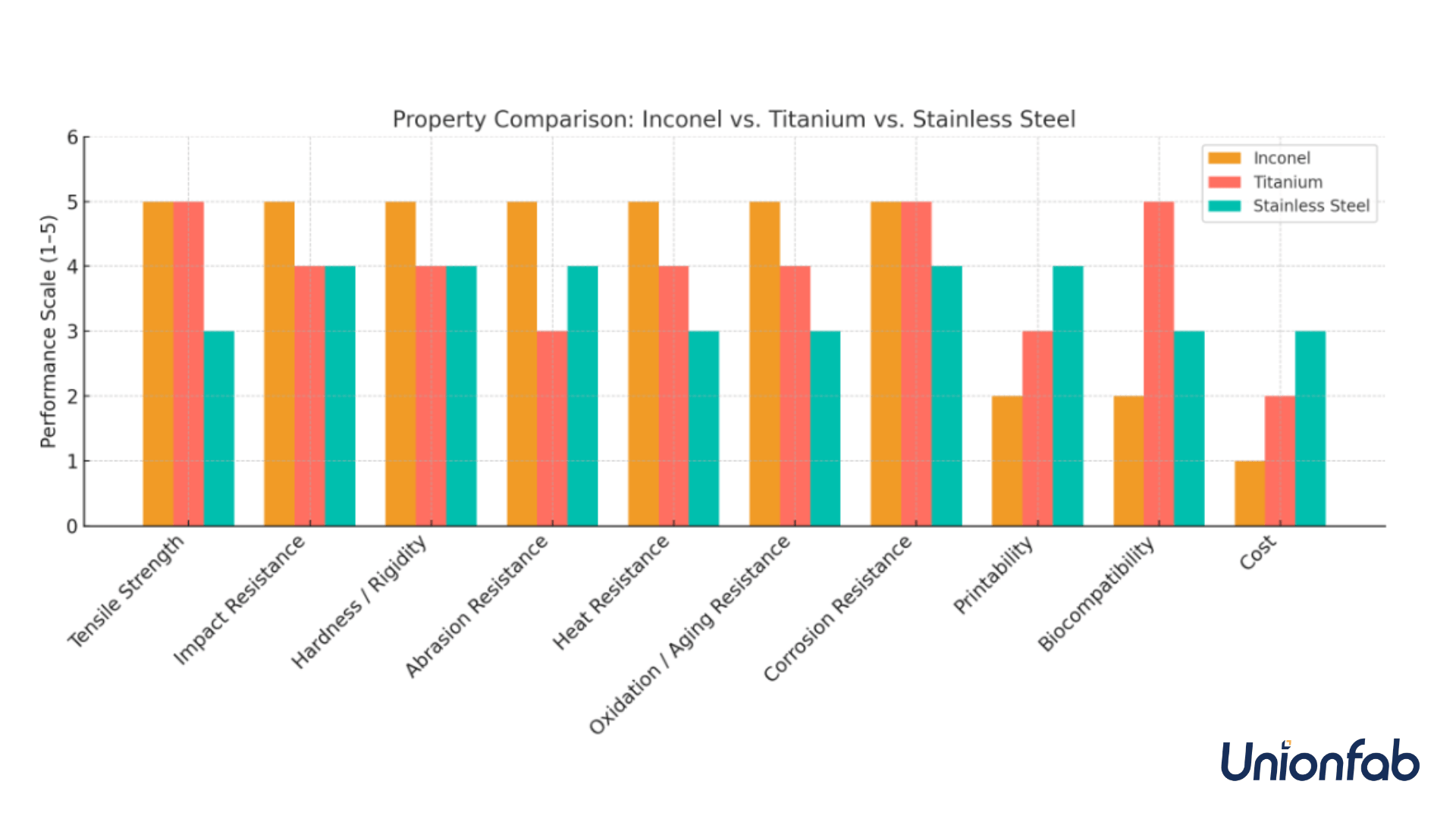

Key Performance Comparison

Choosing the right alloy—Inconel, Titanium, or Stainless Steel—requires a clear understanding of how each material performs in demanding conditions.

The following table provides a side-by-side comparison of key performance attributes, helping engineers, designers, and procurement teams make informed decisions based on functionality, durability, weight, and workability.

Performance Comparison Table

Property | Inconel | Titanium | Stainless Steel |

|---|---|---|---|

Density (g/cm³) | ~8.4–8.7 | ~4.5 | ~7.8 |

Tensile Strength (MPa) | ~800–1,200+ | ~900–1,100 | ~500–750 (up to 1,300 for some grades) |

Impact Resistance | High (especially at high temps) | Medium-High | High |

Hardness / Rigidity | Very High (Rockwell B85–C40+) | Medium-High | Medium-High |

Abrasion Resistance | Excellent | Moderate | Good |

Heat Resistance (°C) | Excellent (up to ~1000°C or higher) | Good (~400–600°C, depending on alloy) | Moderate to Good (~300–600°C) |

UV Resistance | Excellent | Excellent | Excellent |

Oxidation / Aging Resistance | Excellent (high-temp corrosion resistant) | High (forms protective oxide layer) | Good (depends on alloy and finish) |

Chemical / Corrosion Resistance | Excellent (even in harsh acids) | Excellent (especially in saltwater) | Good to Excellent (varies by grade) |

Printability (metal AM) | Difficult (requires high-end systems) | Moderate (better with EBM or SLM) | Easier (more common in DMLS/SLM systems) |

Biocompatibility | Limited (some Inconel alloys) | Excellent (widely used in implants) | Variable (316L is medical grade) |

Cost | Very High | High | Low-Medium |

Key Takeaways

● Inconel: Best for extreme heat, hardness, and corrosion resistance, but heavy, expensive, and hard to print. Limited biocompatibility.

● Titanium: Lightweight, biocompatible, and corrosion-resistant, with good strength. Moderate printability and high cost.

● Stainless Steel: Cost-effective, versatile, easier to print, with decent performance across most properties. Biocompatibility varies by grade.

Primary Manufacturing Techniques

Inconel, Titanium, and Stainless Steel each present unique challenges and advantages in manufacturing. This section compares their compatibility with traditional methods and additive manufacturing (AM), highlighting how each material performs under different production techniques.

Traditional Methods

Inconel: Typically forged or cast for high-performance components in aerospace and energy. CNC machining is difficult due to work-hardening and poor machinability, requiring special tooling and low speeds.

Titanium: Commonly forged or cast, especially in aerospace and medical sectors. Processing must limit oxygen exposure to prevent brittleness. It’s also challenging to machine due to galling and rapid tool wear.

Stainless Steel: Highly machinable and widely used across industries. Easily rolled, cast, or CNC machined, making it ideal for both industrial and consumer products.

Additive Manufacturing

Inconel: Best printed using SLM or EBM, allowing complex geometries and high strength. SLM offers fine detail; EBM is better for larger parts with reduced stress.

Titanium: Well-suited for SLM and EBM. Oxygen control is critical. SLM yields precise parts; EBM enables faster builds and better stress relief.

Stainless Steel: Compatible with SLM and DMLS, offering a cost-effective, accessible option for both prototypes and production. It prints reliably due to stable powder behavior and lower melting point.

Summary

Each material aligns best with specific manufacturing strategies:

Inconel is extremely durable and excels in additive manufacturing, where its machining challenges are bypassed.

Titanium offers high performance but requires careful control in both traditional and AM processes due to its reactivity and machining complexity.

Stainless Steel is the most versatile, offering smooth workflows in both traditional and additive methods, making it ideal for a broad range of applications.

How to Print (3D Printing Considerations)

3D printing metals requires careful consideration of thermal properties, equipment capabilities, and environmental control. Inconel, Titanium, and Stainless Steel each pose different levels of difficulty during printing.

This section explains what makes each material easier or harder to print and how to manage those challenges effectively.

Inconel

Printing Inconel is highly challenging due to its very high melting point (>1300°C), requiring powerful lasers or electron beams.

An inert gas atmosphere (typically argon) or vacuum environment is essential to prevent oxidation.

Low thermal conductivity increases thermal gradients, leading to residual stress and cracking, which necessitates precise process control.

Titanium

Titanium also has a high melting point (~1660°C), demanding careful thermal management during printing.

EBM is often preferred for large parts due to its ability to reduce internal stresses, while SLM is ideal for detailed, small-scale features.

Environmental control is critical; oxygen and moisture levels must be kept very low to preserve material integrity and prevent defects.

Stainless Steel

Stainless steel is relatively easy to print, with a lower melting point (~1400–1450°C) that suits standard SLM and DMLS systems.

It has good powder flow and stable thermal behavior, making it reliable for structural, functional, and tooling components.

It is forgiving to minor variations in environmental conditions, making it ideal for consistent production.

Key takeaways:

Inconel is the most difficult to print due to its high temperature and stress issues.

Titanium offers excellent strength but requires tight oxygen control.

Stainless Steel is the most user-friendly, with stable performance and fewer printing constraints.

Understanding these differences helps in choosing the right material and printing method for specific needs.

Post-processing Requirements

Post-processing plays a key role in achieving the final mechanical properties, surface quality, and dimensional accuracy of metal 3D-printed parts. Inconel, Titanium, and Stainless Steel each have different post-processing needs due to their unique material characteristics.

This section outlines the typical finishing steps required for each metal and the reasons behind them.

Inconel

Hot Isostatic Pressing (HIP) is commonly applied to eliminate internal porosity and increase density.

Heat treatment is often required to restore or enhance mechanical properties like strength and fatigue resistance.

Due to its poor machinability, CNC finishing is time-consuming and requires high-performance tools and cutting strategies.

Surface finishing methods like grinding or polishing are often used to improve surface quality.

Titanium

HIP and heat treatment are also recommended to ensure high mechanical performance and structural integrity.

Support removal must be carefully performed to avoid surface damage or oxidation.

Surface finishing techniques such as sandblasting, chemical etching, or anodizing are common to improve aesthetics and corrosion resistance.

Machining is delicate due to the risk of galling and tool wear, requiring sharp tools and proper cooling.

Stainless Steel

Post-processing is flexible and cost-efficient. Heat treatment is optional but can be used for stress relief or strength enhancement.

Surface finishing includes polishing, electropolishing, and passivation to improve corrosion resistance and appearance.

Stainless steel has good machinability, making CNC post-processing efficient and suitable for tight-tolerance parts.

Lower residual stress compared to Inconel or Titanium reduces the need for intensive thermal post-treatment.

Applications by Industry

Inconel, Titanium, and Stainless Steel are key materials used across industries due to their distinct properties. Each is suited for specific applications—from aerospace to medical and automotive—based on their strength, corrosion resistance, and durability.

1. Aerospace & Space Exploration

Inconel: Jet engine turbine blades, exhaust systems, and rocket nozzles—tolerates extreme heat and pressure.

Titanium: Aircraft structural frames and fasteners—high strength-to-weight ratio helps reduce fuel consumption.

Stainless Steel: Hydraulic lines and support brackets—offers corrosion resistance and robustness.

2. Medical Devices & Healthcare

Inconel: Surgical instruments requiring repeated sterilization cycles and mechanical strength.

Titanium: Permanent implants such as hip joints and dental roots—biocompatible and corrosion-resistant.

Stainless Steel: Surgical tools and temporary implants—strong, affordable, and easy to sterilize.

3. Chemical & Pharmaceutical Processing

Inconel: Reactor vessels and valves exposed to acidic or high-temperature environments.

Titanium: Chlorine dioxide systems, acid production equipment—resistant to aggressive chemicals.

Stainless Steel: Mixing tanks, pipelines, and drug processing equipment—hygienic and corrosion-resistant.

4. Automotive & Motorsport

Inconel: Turbochargers, exhaust manifolds—excellent thermal and oxidation resistance.

Titanium: High-performance engine components like valves and connecting rods—lightweight and strong.

Stainless Steel: Fuel systems, mufflers, and structural brackets—durable and economical.

Summary

In summary, Inconel is ideal for high-temperature and corrosive conditions, Titanium offers excellent strength and lightness, and Stainless Steel provides versatile corrosion resistance and cost-efficiency. Choosing the right material ensures better performance and reliability in various industries.

Choosing the Right Alloy

Selecting between Inconel, Titanium, and Stainless Steel depends on several critical factors. Below is a breakdown by application scenario, guiding you to the most suitable material based on environmental conditions, mechanical needs, cost, and more.

1. High-Temperature Environments

Recommended: Inconel

● Why: Excellent strength retention above 1000°C, ideal for jet engines, turbines, exhaust systems.

● Avoid: Titanium (weakens above ~600°C), standard stainless steel (may oxidize above 600°C).

2. Corrosive or Chemical Exposure

Recommended: Titanium for chloride, saltwater, acids; Inconel for extreme chemicals, acids, and oxidizers.

● Why: Both offer superior corrosion resistance. Titanium for marine and biomedical; Inconel for chemical processing.

● Avoid: Stainless steel in chloride-rich or highly acidic environments (can pit and corrode).

3. General Structural or Load-Bearing Parts

Recommended: Stainless Steel (cost-effective); Titanium (when weight is a concern)

● Why: Stainless Steel is strong, affordable, and easy to process. Titanium offers strength with significant weight savings.

● Avoid: Inconel unless high temperature or extreme strength is needed (due to cost and machining difficulty).

4. When Weight is Critical

Recommended: Titanium

● Why: Excellent strength-to-weight ratio; perfect for aerospace, automotive racing, and implants.

● Avoid: Inconel and Stainless Steel (both much denser).

5. Budget-Conscious Projects

Recommended: Stainless Steel

● Why: Best balance of performance and affordability; ideal for non-extreme, everyday use.

● Avoid: Inconel (high cost) and Titanium (moderate to high cost).

4. Biocompatibility Needed

Recommended: Titanium: Implants, prosthetics, surgical tools; Stainless Steel: Surgical instruments, food-grade containers.

● Avoid: Inconel (rarely used due to cost and limited biocompatibility).

7. Machinability and Ease of Fabrication

Recommended: Stainless Steel

● Why: Widely supported in conventional machining and welding. Inexpensive tooling.

● Avoid: Inconel (requires CNC and advanced tools), Titanium (difficult to cut and weld without galling).

Decision Matrix Summary

Use Case | Best Choice |

|---|---|

Extreme heat | Inconel |

Corrosive chemicals | Inconel / Titanium |

Lightweight performance | Titanium |

General use, cost-effective | Stainless Steel |

Biocompatible needs | Titanium / SS |

Machining or large-scale production | Stainless Steel |

Harsh marine environments | Titanium |

Conclusion

Inconel, Titanium, and Stainless Steel each offer unique strengths for metal 3D printing. Inconel is ideal for extreme heat and corrosion, Titanium balances strength and weight, and Stainless Steel is versatile and cost-effective. Choosing the right material depends on your specific performance and application needs.

Achieve Perfect Products with Unionfab

At Unionfab, we specialize in advanced metal 3D printing to help you bring even the most demanding designs to life — faster, stronger, and more efficient than ever. To calculate the printing price of your project, use our online 3d printing cost calculator below.

FAQs

Why is Inconel so expensive?

Inconel costs a lot because it contains expensive metals like nickel and chromium, is very hard to machine, and performs extremely well in tough environments like aerospace and power plants.

Is titanium better than cobalt?

It depends. Titanium is lighter and corrosion-resistant, great for implants and aircraft parts. Cobalt is harder and better for tools and high-wear parts.

Will titanium drill stainless steel?

Pure titanium won’t drill stainless steel well. But titanium-coated drill bits can, especially if you use the right speed and cooling. Cobalt or carbide bits are usually better choices.