Guide to 3D Printed Snap Fits +[Design Tips]

Design tool-free 3D printed snap-fit joints for fast, durable assembly—explore TPU, Nylon, PETG, and expert FDM/SLS tips for real-world applications.

Introduction

What is a Snap-Fit?

A snap-fit is a type of mechanical joint that enables quick assembly and disassembly using elastic deformation. It eliminates the need for screws, adhesives, or other fasteners. Widely used in electronics, consumer products, and modular components, snap-fit joints are especially well-suited for 3D printing due to their cost-effectiveness and ease of fabrication.

Common Snap-Fit Types

Cantilever (Most Common, Single-Sided Insertion)

A single flexible arm that locks into place with a one-sided insertion. Subtypes include:

Straight Cantilever: A simple straight arm with a hook or tab at the end (e.g., used in food container lids for easy locking).

L-shaped Cantilever: Features a right-angle bend, ideal for compact spaces (e.g., latches in electronics enclosures).

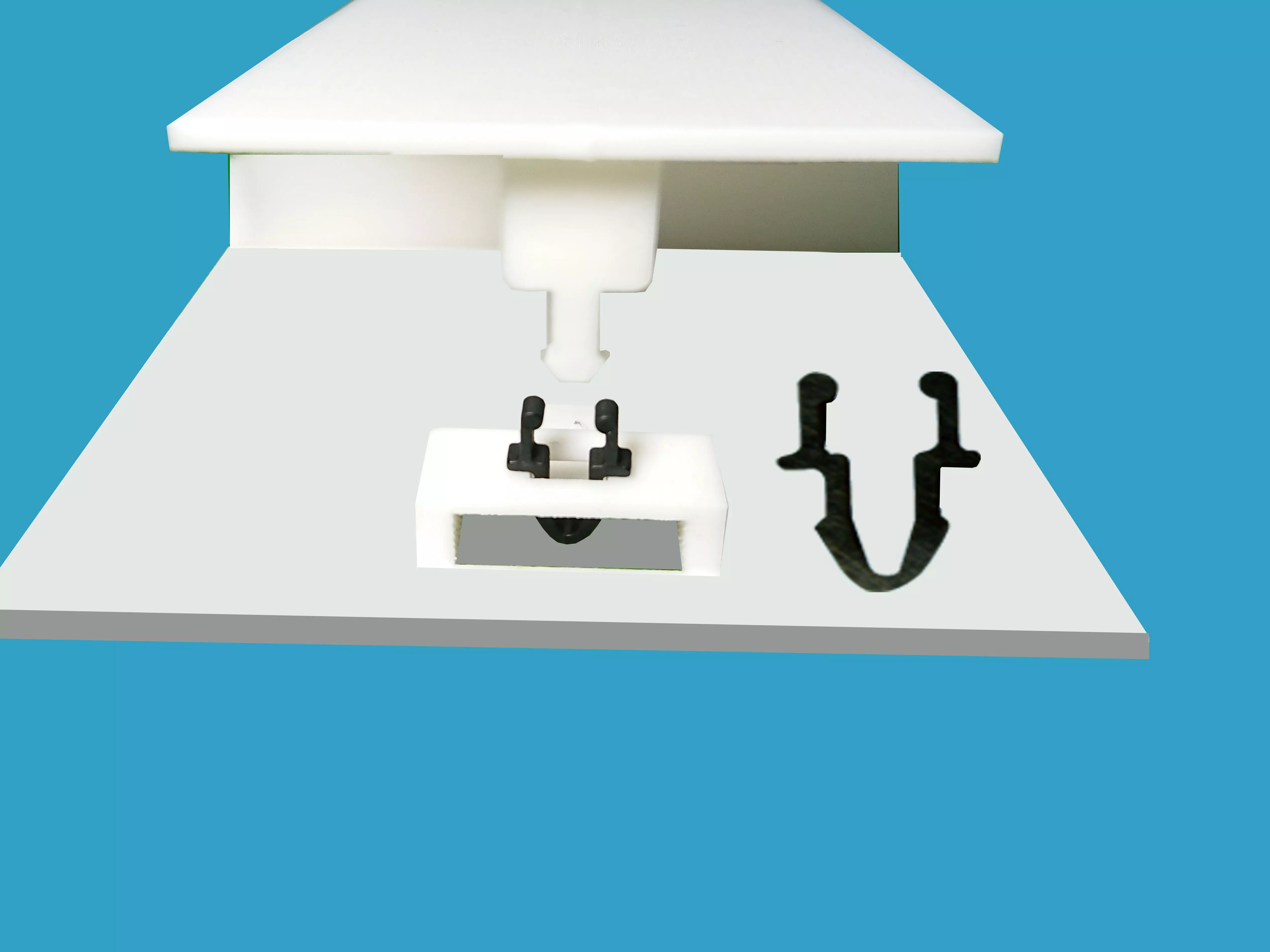

U-shaped Cantilever: Two parallel arms forming a U-shape, offering balanced flexibility (e.g., in medical device casings).

Annular (Ring Structure)

Source: hp.com

A circular snap fit that uses radial flexibility (expansion/contraction) to lock, such as bottle caps, jar lids, or pipe fittings.

Torsional

Source: hp.com

Engages through rotational deformation, requiring a twisting motion to lock (e.g., hose couplings or electrical plugs).

Latching

Source: pingood.com.tw

Two separate components (a hook and a slot) that interlock and can be manually unlocked, like safety harnesses or smartphone back covers.

Snap Fit Manufacturing Processes

Manufacturing Process | Suitability for Snap Fits | Description |

|---|---|---|

3D Printing | Highly Suitable | Ideal for rapid prototyping, custom designs, and low-volume production. Enables quick design iteration with flexible materials like TPU/Nylon. |

Injection Molding | Most Common | The standard for high-volume production, especially for plastic parts (e.g., electronics casings, toys). Offers cost efficiency at scale. |

CNC Machining | Limited | Poorly suited for flexible components (metals/hard materials lack elasticity). Best for rigid prototypes with simple geometries. |

Silicone Molding + Casting | Feasible for Low-Volume | Used to produce small batches of flexible snap fits (e.g., resin-cast clips) with moderate precision and flexibility. |

Key Takeaway:

3D printing is the most versatile for snap fits, especially in early design stages. It allows rapid testing of locking mechanisms, easy modification of flexible arms/hooks, and supports materials that mimic production-grade elasticity.

3D Printing Processes for Snap Fits

1. Fused Deposition Modeling (FDM/FFF)

How it works: Melts thermoplastic filaments (e.g., PLA, PETG, TPU) and deposits them layer by layer to build parts.

Why it’s ideal: Flexibility: Supports elastic materials (e.g., TPU) for bendable cantilever arms or torsion springs.

Speed: Rapid turnaround for prototyping, allowing same-day design iterations.

Cost: Affordable for small batches or one-off custom designs.

2. Multi Jet Fusion (MJF) / Selective Laser Sintering (SLS)

How it works:

MJF: Fuses fine nylon powder (e.g., PA12, PA11) using a fusing agent and infrared energy.

SLS: Sintering nylon powder with a high-powered laser in a powder bed.

Why they’re ideal for snap fits:

Material Strength: Nylon parts have high tensile strength and fatigue resistance—ideal for repeated snap actions.

Elastic Recovery: PA11 and PA12 exhibit excellent shape memory, supporting tight tolerances without permanent deformation.

Isotropic Properties: Near-uniform strength in all directions—critical for flexible arms or latches.

No Support Structures: Enables printing of complex or nested snap geometries.

Surface Finish: MJF offers better detail and consistency; SLS is slightly rougher but similarly strong.

Want to bring your snap fit model to life? Choose Unionfab—your professional 3D printing partner for fast, reliable results from concept to production!

Material Selection

Selecting the right material is critical to achieving durable, functional, and reusable snap-fit mechanisms. The ideal material must withstand stress concentrations, flex repeatedly without fatigue, and provide consistent shape recovery after deflection.

1. Key Material Requirements

Flexibility

The material should bend without cracking, especially in cantilever or living hinge designs where repeated deflection is expected.

Elastic Recovery

It must return to its original shape after deformation to ensure a secure, reusable snap-fit engagement.

Fatigue Resistance

The material should withstand repeated cycles of stress without permanent deformation or failure.

Layer Adhesion

In 3D printing, strong inter-layer bonding is crucial to prevent delamination, especially in parts subjected to flexing or bending.

Printability

Materials should offer good dimensional accuracy, surface quality, and consistency to meet tight snap-fit tolerances.

Impact Strength

Important for applications where snap-fits may experience sudden forces during assembly or in use.

2. Recommended Materials for Snap-Fit Manufacturing

Material | Flexibility | Elastic Recovery | Fatigue Resistance | Layer Adhesion | Printability | Impact Strength |

|---|---|---|---|---|---|---|

Nylon (PA12/11) | ⭐⭐⭐ | ⭐⭐⭐☆* | ⭐⭐⭐⭐⭐ | ⭐⭐⭐☆ | ⭐⭐☆ | ⭐⭐⭐☆ |

PETG | ⭐⭐☆ | ⭐⭐☆ | ⭐⭐☆ | ⭐⭐⭐☆ | ⭐⭐⭐☆ | ⭐⭐⭐☆ |

ABS | ⭐⭐☆ | ⭐⭐☆ | ⭐⭐☆ | ⭐⭐☆ | ⭐⭐☆ | ⭐⭐⭐☆ |

PLA | ⭐☆ | ⭐☆ | ⭐☆ | ⭐⭐⭐☆ | ⭐⭐⭐⭐⭐ | ⭐⭐☆ |

TPU | ⭐⭐⭐⭐⭐ | ⭐⭐⭐⭐⭐ | ⭐⭐⭐⭐☆ | ⭐⭐⭐☆ | ⭐⭐⭐☆ | ⭐⭐⭐☆ |

ASA | ⭐⭐☆ | ⭐⭐☆ | ⭐⭐⭐☆ | ⭐⭐⭐☆ | ⭐⭐☆ | ⭐⭐⭐☆ |

PC (Polycarbonate) | ⭐⭐⭐☆ | ⭐⭐⭐☆ | ⭐⭐⭐☆ | ⭐⭐☆ | ⭐☆ | ⭐⭐⭐⭐⭐ |

*Note: ☆=1/2⭐

3. Material Selection Tips by Use Case

Snap-fit components come in many forms, but they can all be grouped according to their functional scenarios. Below is a breakdown of typical snap-fit use cases, along with recommended 3D printing materials tailored to the performance requirements of each application.

High-cycle snap-fit clips

Recommended Materials: Nylon, TPU

Reason: Offer superior fatigue resistance and flexibility, enabling them to withstand frequent opening and closing operations without easily getting damaged.

General-purpose parts

Recommended Materials: PETG, ABS

Reason: Strike a good balance between durability and printability. They can meet the strength requirements of general usage scenarios while being easy to 3D print.

Outdoor use

Recommended Materials: ASA, PETG

Reason: Possess excellent UV and weather resistance, allowing them to be used outdoors for long periods without aging rapidly.

Prototyping / low-stress fits

Recommended Materials: PLA+, Tough PLA

Reason: Easy to print and have a fast printing speed, enabling the rapid production of prototypes. Suitable for assembly scenarios with low stress.

Flexible / soft interfaces

Recommended Material: TPU

Reason: Have high elasticity, providing a comfortable touch. Ideal for applications requiring soft and deformable interfaces.

Structural or heat-tolerant parts

Recommended Materials: PC, Nylon

Reason: Feature high strength and good thermal resistance, meeting the manufacturing requirements of parts with demands for structural strength and high-temperature tolerance.

Still unsure which material to choose? Talk to Unionfab experts to help you make final decisions.

Snap-Fit Design Guidelines

Designing effective snap-fit components in 3D printing requires balancing flexibility, strength, and dimensional accuracy. This guide covers geometry considerations, and tolerance strategies to ensure durable and functional snap mechanisms.

Dimensions & Tolerances

These geometric rules help you design snap-fits that function reliably, even under repeated use and varying print conditions.

Clearance / Gap Tolerance

Recommended: 0.2–0.5 mm, depending on the printer's dimensional accuracy and material shrinkage.

Purpose: Prevents parts from fusing or being too tight.

Adjustment: For softer or more flexible materials (e.g., PETG, TPU), tighter clearances (~0.2 mm) may work. For stiffer materials or less accurate printers, go closer to 0.5 mm.

Arm Length

Rule of thumb: 2–3× the arm thickness.

Effect: Longer arms provide greater flexibility and easier snap engagement but may be more prone to fatigue. Shorter arms are stiffer but more durable.

Design Note: Keep a consistent cross-section and avoid sudden thickness changes to reduce stress concentration.

Hook Angle

Insertion Angle: 30°–45° recommended.

Explanation:

Lower angles (30°): Easier to insert, but weaker holding force.

Higher angles (45°+): Greater retention, but harder to engage or disengage.

Tip: Consider using asymmetrical hooks—shallow angle for insertion side, steeper on the locking side.

Fillets and Radii

Why: Sharp corners at the base of the snap arm act as stress risers and can lead to failure during flexing.

Suggestion:

Add fillets with radius = 0.5–1.0× arm thickness at the base of snap arms.

Smooth transitions between hook, arm, and base improve durability.

Lead-in Angles / Chamfers

Purpose: Chamfers or tapered entries guide the snap feature into place during assembly.

Angle Range: 20°–30° lead-in on hooks and mating surfaces is ideal.

Design Bonus: Improves user experience by reducing required insertion force and misalignment risk.

Undercuts & Retention Geometry

For strong locking, integrate subtle undercuts or stepped grooves—but avoid excessive interference which can cause cracking.

Use slicer preview to verify printability of undercut features or consider using breakaway supports if needed.

Material-Specific Notes

PLA: Brittle; suitable for one-time snaps or non-critical features.

PETG: Good balance of strength and flexibility; ideal for reusable snap-fits.

ABS/ASA: Tough, weather-resistant; great for functional outdoor parts.

Nylon: Excellent fatigue resistance; best choice for high-cycle snapping.

TPU: Highly flexible; useful for interference fits or soft latching mechanisms.

Testing & Iteration Tips

Prototype quickly using draft print settings to verify tolerances and clearances.

Print in intended orientation and test snap-fit behavior in real-world conditions.

Use modifier meshes to increase infill only in snap regions for strength without wasting material.

Printing Parameters & Orientation

Choosing the right print settings and orientation is crucial for strong, functional, and reliable snap-fit components. Below are detailed recommendations to help optimize strength, flexibility, and print quality.

Layer Height

Recommended: 0.1–0.2 mm

Why it matters:

Smaller layer heights (e.g., 0.1 mm) give finer detail and smoother surfaces, ideal for tight-fitting snap features.

Larger layer heights (e.g., 0.2 mm) print faster but may create rougher surfaces and weaker layer adhesion.

Tip:

For precision snap-fits or parts that require frequent engagement, use ≤ 0.15 mm for better dimensional accuracy.

Wall/Perimeter Thickness

Recommended: ≥ 1.2 mm (3 or more perimeters)

Why it matters:

Thicker walls increase strength in flexible arms and hook regions.

Critical for preventing cracks at stress points, especially in cantilever snap joints.

Tip:

Use 3–4 wall lines, or wall thickness = 3× nozzle diameter (e.g., 0.4 mm nozzle → 1.2 mm wall).

Printing Temperature

Why it matters:

Correct extrusion temperature ensures strong inter-layer adhesion. Too low = weak layers, too high = stringing or deformation.

Material | Nozzle Temp | Bed Temp | Notes |

|---|---|---|---|

PLA | 190–210°C | 50–60°C | Keep cooling fan on for crisp detail |

PETG | 230–250°C | 70–90°C | Reduce fan speed to strengthen layers |

ABS | 230–250°C | 90–110°C | Enclosure recommended to reduce warping |

ASA | 240–260°C | 90–110°C | Good ventilation needed for fumes |

Nylon | 240–260°C | 70–90°C | Must dry before printing to avoid bubbling |

Print Orientation

Goal: Maximize snap-fit durability and avoid layer separation under stress.

Best Practices:

Align flex direction parallel to the layers (XY plane): This ensures the part bends across layers, not between them.

Avoid printing snap arms upright (Z-axis) — they are more likely to break at the layer lines.

Examples:

For a U-shaped snap: lay the part flat so the arms extend in the XY direction.

For a cantilever hook: orient the hook horizontally to align its base along the layers.

Support Settings

Why it matters:

Snap-fits often include overhangs and hooks that require support. Improper support can damage delicate features or make post-processing difficult. Recommendations:

Enable support only where needed.

Use “touching buildplate only” or support blockers to avoid internal cavities getting filled.

Design with 45° overhangs where possible to eliminate the need for supports.

Post-Processing Tips

1. Deburring and Cleaning

Purpose:

Remove stringing, rough edges, or blobs to ensure smooth snapping.How to do it:

Use a hobby knife or small file to clean up hooks and slots.

Focus on key contact areas where parts engage.

Note:

Avoid removing too much material—this may affect fit.

2. Sanding and Smoothing

Purpose:

Improve surface finish and reduce friction between snap parts.How to do it:

Sand with 400–1000 grit sandpaper for a smoother surface.

For ABS, use acetone vapor smoothing to polish surfaces.

Note:

Don’t over-sand locking features to prevent looseness.

3. Heat Treatment (Annealing)

Purpose:

Increase strength, reduce internal stress, and improve durability.How to do it:

Place parts in an oven:

PETG: 70–80°C for 1 hour

ABS: 100°C for 30–60 minutes

Nylon: 90°C for 1–2 hours

Let them cool down slowly inside the oven to avoid warping.

Note:

Use a temperature-controlled oven—not a heat gun or open flame.

4. Fit Adjustment

Purpose:

Fine-tune the fit if it’s too tight or loose.How to do it:

Sand or trim snap arms or holes slightly.

Use a drill to widen tight holes carefully.

For deformed parts, use a low-temp heat gun to reshape.

Note:

Make gradual adjustments and test frequently.

5. Lubrication (Optional)

Purpose:

Reduce friction and wear in tight or high-cycle snap fits.How to do it:

Use dry PTFE spray or silicone-based lubricants.

Apply only to hook/slot contact areas.

Note:

Avoid petroleum-based greases—they may degrade plastic and attract dust.

6. Metal Inserts (Optional)

Purpose:

Reinforce threaded holes or structural joints for repeated use.How to do it:

Use heat-set brass inserts with a soldering iron.

Glue-in inserts are suitable for light loads.

Note:

Do not place inserts on flexible snap arms—they’ll reduce elasticity.

Common Issues & Solutions

1. Snap Arm Breaks

● Likely Causes:

Arm is too thin, short, or poorly supported.

Printed vertically (stress applied along Z-axis, causing weak layer adhesion).

Brittle material used (e.g., standard PLA).

● Solutions:

Increase arm thickness, length, or add fillets at the base.

Use more ductile materials like PETG, Nylon, or TPU.

Orient the arm horizontally (in XY-plane) for stronger layer bonding.

Increase nozzle temperature to enhance interlayer adhesion.

Post-process with acetone (ABS) or enable ironing to reduce stress points.

2. Too Tight

● Likely Causes:

Insufficient clearance between mating parts.

Thermal shrinkage (especially with ABS or PETG).

Rough surfaces from blobs or print defects.

● Solutions:

Add 0.3–0.5 mm clearance between mating surfaces.

Apply chamfers or tapers to entry points.

Sand or polish surfaces for smoother fitting.

Use dimensionally stable materials for tighter tolerance fits.

3. Snap Becomes Loose Over Time

● Likely Causes:

Material fatigue from repeated snapping.

Creep or deformation under sustained load or high temps.

● Solutions:

Switch to fatigue-resistant materials (e.g., Nylon, ASA, TPU).

Reinforce design with thicker hinges, dual arms, or stop features.

Avoid prolonged exposure to heat or static loads.

4. Print Warping or Weak Snaps

● Likely Causes:

Poor bed adhesion, especially with large or thin parts.

Low infill density or inadequate wall count.

Excessive cooling (e.g., PLA prints warping or cracking).

● Solutions:

Use brims, rafts, or enclosures for better bed adhesion.

Increase wall count (≥3) and infill density (≥60%).

Reduce cooling fan speed for PETG/ABS to avoid layer separation.

5. Hooks Won’t Latch Properly

● Likely Causes:

Deformed overhangs from poor support.

Overextrusion, elephant’s foot, or inaccurate Z-offset.

● Solutions:

Add proper support structures for angles >45°.

Calibrate Z-offset and extrusion multiplier.

Use draft angles (5–10°) on hooks for smoother latching.

6. Rough or Uneven Surface Finish

● Likely Causes:

Stringing, blobbing, or inconsistent extrusion.

Wet filament or nozzle clogging.

● Solutions:

Dry filament (especially Nylon, PETG).

Tune retraction, lower print temperature (5–15°C as needed).

Use smaller nozzles (e.g., 0.25 mm) and reduce print speed.

Typical Application Scenarios

Electronics enclosures

Snap-fit designs enable tool-free assembly and disassembly, making maintenance, repairs, or upgrades faster and more convenient. Common in cases for Raspberry Pi, Arduino shields, or consumer gadgets. Snap fits help reduce screw counts and assembly time.

Consumer products

Widely used in toys, battery compartments, remote controls, wearable devices, and household appliances. Snap fits allow easy battery replacement or modular part swapping while maintaining a secure hold during use.

Modular mechanical parts

Snap-fit connectors facilitate modularity and customization in mechanical assemblies such as jigs, fixtures, robotic parts, or interchangeable tool attachments. They enable quick configuration changes without hardware tools.

Prototype testing and iterative design

Rapid prototyping benefits from snap-fit joints by allowing quick assembly/disassembly of parts for testing fit, function, and ergonomics. This is especially useful in early design validation and functional mockups before final tooling.

Automotive and industrial applications

Durable snap fits can replace screws or rivets in non-structural components like interior panels, clips, and fasteners, reducing weight and simplifying assembly lines. Materials like Nylon or ASA are preferred for durability and environmental resistance.

Medical devices and wearables

Snap fits are used for parts requiring frequent opening and closing, such as sensor housings or adjustable straps, where hygiene and user convenience are priorities.

FAQs

1. What are the three types of snap-fit joints?

The three main types of snap-fit joints are:

Cantilever Snap-Fits: The most common type, using a flexible arm that bends to engage a catch.

Annular Snap-Fits: Circular or ring-shaped features often used in caps, lids, and enclosures.

Torsional Snap-Fits: Use twisting or rotating motion to engage and disengage the joint.

2. What is the snap-fit technique?

Snap-fit is a tool-free assembly technique where two parts are joined using elastic deformation. One part has a protruding feature (like a hook or bead) that snaps into a corresponding recess on the other part, creating a secure, reusable connection.

3. What is the alternative to snap-fit?

Alternatives to snap-fit joints include:

Screws or bolts – for permanent or strong assemblies.

Adhesives – for seamless, fixed bonding.

Heat staking or ultrasonic welding – for plastic-to-plastic fusion.

Magnetic or friction fits – for modular or temporary connections.