Guide to 3D Printed Bearings [+Material Selection Tips]

![Guide to 3D Printed Bearings [+Material Selection Tips]](https://ufc-dtc-cms.oss-accelerate.aliyuncs.com/blog/20250612/231236_0cubshkbh.png)

Learn how to design and choose 3D printed bearings for your projects. Discover material options, compare with CNC, and explore real-world applications—all with expert insights from Unionfab.

Introduction

3D printed bearings are increasingly being explored as viable alternatives to traditionally machined components. With the growth of additive manufacturing and material science, engineers and designers now have more freedom to develop lightweight, low-friction, and corrosion-resistant bearing solutions with fast turnaround times.

In this guide, we explore what 3D printed bearings are, how they compare to CNC-machined bearings, and how you can use them effectively in various applications.

What is a Bearing?

A bearing is a mechanical component that supports and guides moving parts such as shafts, enabling either rotational or linear motion while minimizing friction and wear.

Think of it as a combination of a pulley and lubricant — helping motion become smooth, efficient, and durable.

Composition of Bearings

A typical bearing consists of the following parts:

Component | Function |

|---|---|

Inner Ring | Mounted on the shaft and rotates with it |

Outer Ring | Fixed in the housing and remains stationary |

Rolling Element (balls/rollers) | Roll between the rings to reduce friction |

Cage (Retainer) | Evenly spaces the rolling elements to avoid collision |

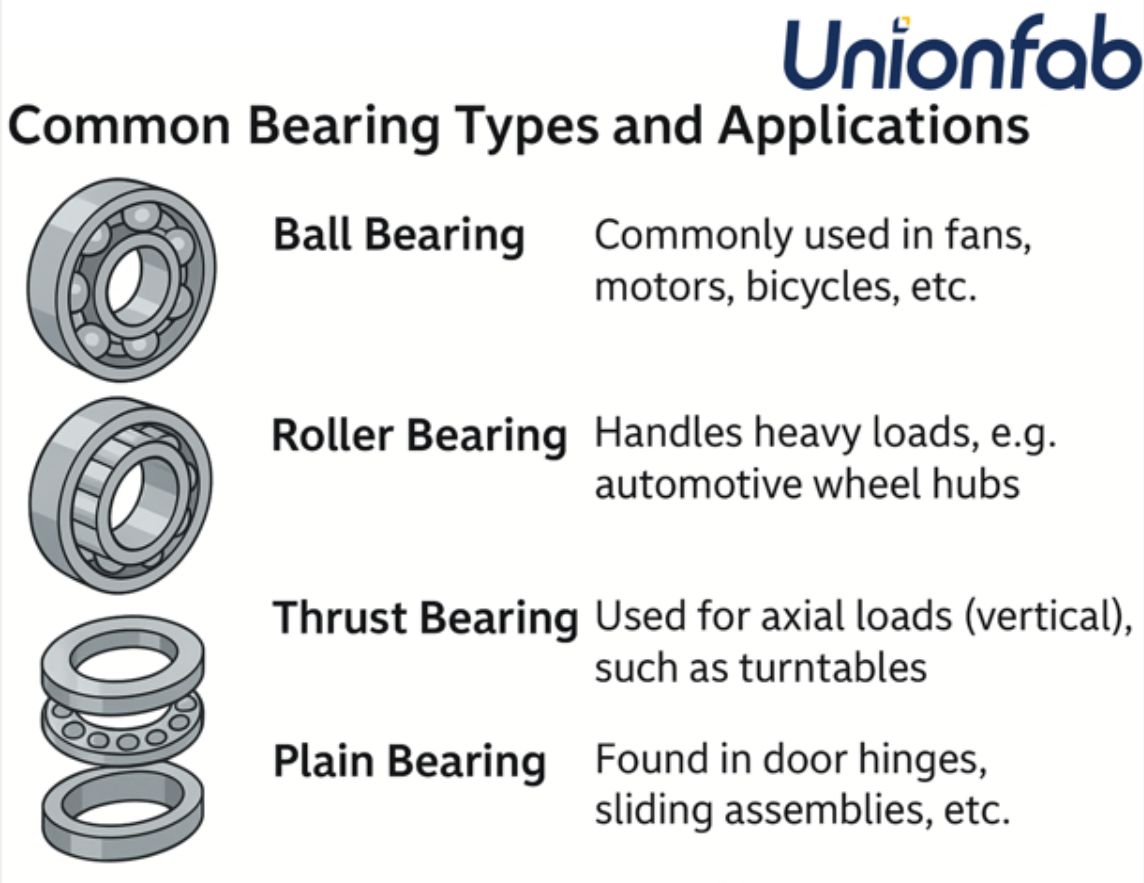

Typical Genres of Bearings

Type | Common Applications |

|---|---|

Ball Bearing | Fans, motors, bicycles |

Roller Bearing | Heavy loads, impacts (e.g., automotive hubs) |

Thrust Bearing | Axial forces (e.g., swivel chairs, turntables) |

Plain Bearing | Sliding fit (e.g., door hinges) |

Traditional Manufacturing of Bearings

Bearings can be made from metals or plastics using several well-established manufacturing methods.

Metal Bearings: Heat Treatment + Grinding

Item | Description |

|---|---|

Features | The most mature and precise method, suitable for high-load and high-speed use |

Process | Bar stock → Forging/Turning → Heat Treatment → Precision Grinding → Assembly |

Applications | Industrial machinery, automotive, wind power, aerospace |

Pros | High precision, durability, mass production-ready |

Cons | Complex process, long lead time, expensive |

Metal Bearings: Powder Metallurgy

Feature | Description |

|---|---|

Process | Metal powder → Pressing → Sintering → Oil Impregnation → Assembly |

Applications | Home appliances, small motors, printers |

Pros | Low cost, self-lubricating, good for volume production |

Cons | Lower precision and strength, not ideal for high-speed loads |

Plastic Bearings: Injection Molding

Feature | Description |

|---|---|

Process | Injection/Turning of inner & outer rings + balls → Assembly |

Applications | Food equipment, chemical machinery, low-load use |

Materials | POM, PTFE, PA, PEEK, self-lubricating plastics |

Pros | Corrosion-resistant, lightweight, lubrication-free |

Cons | Lower load capacity, less precision than metal bearings |

How Are Bearings Made with 3D Printing?

● SLS (Selective Laser Sintering): Provides higher strength and detail for functional plastic parts.

● MJF (Multi Jet Fusion): Good for production-quality components with uniform mechanical properties.

● DMLS/SLM (Direct Metal Laser Sintering / Selective Laser Melting): Suitable for manufacturing metal bearings with high strength, excellent precision, and complex internal geometries. These metal AM methods are ideal for low-to-medium volume production or complex custom parts where conventional machining is impractical.

● EBM (Electron Beam Melting): Another metal 3D printing process that uses an electron beam to melt metal powder. It is particularly suited for titanium or other high-performance alloys and can produce strong, dense components for demanding industrial environments.

Unlike traditional methods, 3D printing allows the integration of complex geometries, internal channels, or even moving elements in a single print without assembly.

3D Printed vs. CNC Machined Bearings: A Practical Comparison

While CNC machining is known for precision and material versatility, 3D printed bearings offer flexibility and cost savings for specific scenarios. Here's a quick comparison:

Feature | 3D Printed Bearings | CNC Machined Bearings |

|---|---|---|

Material Options | PA12, TPU, composites | Metals, engineering plastics |

Precision | Moderate (0.1 - 0.3mm) | High (up to 0.01mm) |

Cost Efficiency | Lower for low volumes | Economical at high volumes |

Custom Geometry | Easily achievable | Limited without high cost |

Lead Time | 1-3 days (fast) | 5-10 days (longer) |

Lubrication Need | Self-lubricating possible | Often requires lubrication |

3D printed bearings are best suited for custom-fit, low- to medium-load applications where fast iteration, lightweight design, or environmental resistance are key.

Recommended Materials and Their Performance

Choosing the right material is crucial for optimal bearing performance. Below are common 3D printable materials used for bearings:

Nylon-Based Materials (PA12 and Composites)

PA12 is one of the most widely used materials in industrial 3D printing due to its excellent mechanical properties. It offers high strength, flexibility, and wear resistance. When reinforced with carbon fiber or glass fiber, PA12 composites gain added stiffness, heat resistance, and dimensional stability—making them suitable for more demanding load-bearing applications such as in automotive or industrial tools.

Printing Tips: For best results, use a layer height of 0.1–0.2mm, 100% infill for strength, and post-process with annealing. Use a hardened steel nozzle for composites.

TPU (Thermoplastic Polyurethane)

TPU is a flexible, rubber-like material ideal for applications requiring impact resistance, vibration damping, and noise reduction. While not suitable for high-precision fits or heavy loads, TPU bearings are excellent in soft-contact mechanisms and flexible enclosures. Their shock-absorbing nature also makes them a common choice in robotics and wearable tech.

Printing Tips: Recommended nozzle temperature is 210–230°C, print slowly (20–30 mm/s), and use low retraction settings to prevent stringing.

Metal Alloys (Stainless Steel, Titanium, Aluminum)

Metal 3D printing opens up the possibility to create high-performance bearings using alloys like 316L stainless steel, Ti6Al4V titanium, or AlSi10Mg aluminum. These materials are suitable for applications requiring high load resistance, corrosion protection, and thermal stability.

Printing Tips: DMLS or EBM is recommended. Ensure proper heat treatment post-printing to optimize hardness, fatigue strength, and precision.

Choosing the optimal material can be complex—let Unionfab’s experts guide you to the right solution.

Design Tips for Bearing 3D Printing

Proper design plays a crucial role in ensuring performance and manufacturability of 3D printed bearings:

● Allow for Tolerance: Add clearances to accommodate the printer’s tolerance range (typically ±0.1–0.3mm for plastics).

● Choose the Right Orientation: Print in a way that optimizes layer bonding for load-bearing directions.

● Avoid Overhangs in Critical Areas: Use chamfers or fillets where possible to ensure cleaner layers and minimize post-processing.

● Consider Assembly: If printing moving parts together, maintain enough clearance to avoid fusion.

● Use Symmetrical Designs: This ensures balanced rotation and wear distribution.

How to Choose A Reliable 3D Printing Service Provider

Selecting the right manufacturing partner can directly impact the success of your 3D printed bearing project. Here's what to look for:

● Material Expertise: Can they guide you in selecting the right material based on load, friction, and environment?

● Technology Range: Do they offer both plastic and metal AM technologies like SLS, MJF, and DMLS?

● Engineering Support: Do they help optimize your designs for printability and performance?

● Quality Control: Do they provide certifications, dimensional inspection, and surface finishing?

● Lead Time & Flexibility: Can they deliver prototypes quickly and scale up if needed?

Get Started with Unionfab: Custom 3D Printed Bearings for Your Project

At Unionfab, we offer fast, affordable, and professional 3D printing services for custom bearing solutions. Whether you need prototypes, short-run production, or specialized materials, our engineering team is ready to support you.

Why Choose Unionfab?

● Access to both polymer and metal 3D printing

● Dedicated engineering consultation

● Consistent part quality and dimensional accuracy

● Proven experience across industries

Contact Unionfab today to get a free quote or consultation on your 3D printed bearing needs.

Conclusion

3D printed bearings are unlocking new possibilities in lightweight design, custom geometry, and fast prototyping. With proper design, material selection, and manufacturing support, they can serve effectively in a wide range of applications—from robotics to industrial machinery. As technology advances, more functional end-use parts will be achieved through additive manufacturing, including high-performance bearings.

Frequently Asked Questions

Are 3D printed bearings durable enough for industrial use?

Yes, with the right material and design, 3D printed bearings can withstand moderate to high loads and perform reliably in many industrial environments.

Can I print both plastic and metal bearings?

Yes. Plastic options like PA12 and TPU are ideal for lightweight needs, while DMLS-printed metals like stainless steel are used for demanding, high-load applications.

What is the typical tolerance for 3D printed bearings?

Plastic parts: ±0.1–0.3mm; metal parts: ±0.05–0.1mm. Post-processing can improve fit and finish.

Can Unionfab help me choose the right material?

Absolutely. Our engineers will help evaluate your design, environment, and performance needs to recommend the most suitable material.