Guide to Inconel 625[+ Property Comparison]

![Guide to Inconel 625[+ Property Comparison]](https://ufc-dtc-cms.oss-accelerate.aliyuncs.com/blog/20250616/114617_c1hye9w9a.png)

Discover why Inconel 625 excels in corrosion, heat, and fatigue resistance—ideal for aerospace, marine, and energy parts made via machining or 3D printing.

What is Inconel 625?

Inconel 625 is a high-performance nickel-based superalloy engineered for exceptional resistance to corrosion, oxidation, and extreme temperatures. Originally developed for aerospace applications, it has since become a critical material across marine, chemical processing, nuclear, and energy industries due to its strength, stability, and long-term performance in harsh environments.

Background & Development

Inconel 625 was developed by Huntington Alloys (now part of Special Metals Corporation) in the 1960s to meet the increasing demand for a material that could withstand aggressive chemical environments and high mechanical stress. Key milestones in its development include:

1964: Initial development targeting high-strength, corrosion-resistant tubing for nuclear reactor systems.

1970s: Adoption in marine and offshore engineering, where its chloride pitting and crevice corrosion resistance made it ideal for seawater environments.

1980s–1990s: Expansion into aerospace for jet engine components and ducting, due to its excellent fatigue and thermal creep resistance.

2000s–Present: Continued use in energy, chemical processing, and additive manufacturing (e.g., SLM), proving its versatility in modern fabrication methods.

Inconel 625 remains one of the most trusted alloys for mission-critical components where conventional stainless steels or other nickel alloys may fail.

Inconel 625 composition

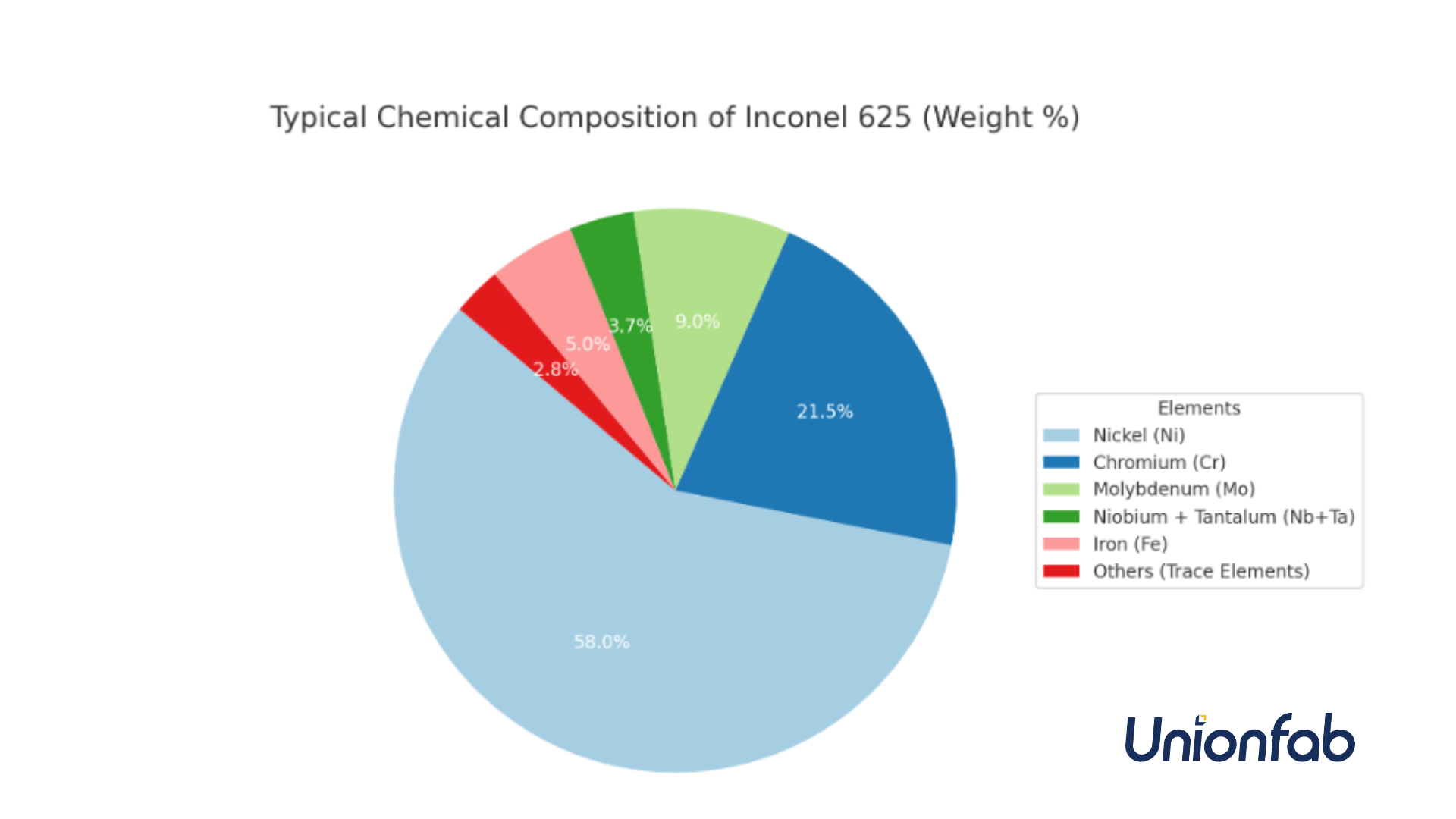

The typical chemical composition of Inconel 625 (in weight %) is as follows:

Element | Weight % | Function |

|---|---|---|

Nickel (Ni) | 58.0 min | Base element, provides corrosion and heat resistance |

Chromium (Cr) | 20.0–23.0 | Enhances oxidation and corrosion resistance |

Molybdenum (Mo) | 8.0–10.0 | Improves resistance to pitting and crevice corrosion |

Niobium (Nb) + Tantalum (Ta) | 3.15–4.15 | Provides solid solution strengthening |

Iron (Fe) | ≤ 5.0 | Impurity; naturally present in small amounts |

Cobalt (Co) | ≤ 1.0 (if reported) | May be present as a trace |

Manganese (Mn) | ≤ 0.5 | Deoxidizer |

Silicon (Si) | ≤ 0.5 | Deoxidizer |

Aluminum (Al) | ≤ 0.4 | Minor alloying element |

Titanium (Ti) | ≤ 0.4 | Minor alloying element |

Carbon (C) | ≤ 0.10 | Affects grain boundary strength |

Phosphorus (P) | ≤ 0.015 | Undesirable impurity |

Sulfur (S) | ≤ 0.015 | Undesirable impurity |

Inconel 625 Properties

Property | Typical Value / Range | Description |

|---|---|---|

Density | ~8.19 g/cm³ | Structurally strong; important for weight-sensitive applications. |

High-Temp Strength | Tensile: 1240 MPa (RT); 1000 MPa at 650–700 °C | Maintains mechanical strength at elevated temperatures. |

Creep Resistance | Stress rupture: >1000 s at 650 °C / 690 MPa | Resists long-term deformation under high heat and load. |

Fatigue Resistance | ~450 MPa (10⁷ cycles at RT) | Withstands cyclic stress; ideal for rotating/vibrating parts. |

Corrosion Resistance | Oxidation resistance up to ~980 °C; excellent passivation | Excellent in seawater, acids, and chloride-rich environments. |

Weldability | Good; suitable for TIG, laser welding | Easy to weld with good heat-affected zone stability. |

Printability | High (PBF & DED); Layer: 20–60 μm | Supports complex parts with reliable dimensional accuracy. |

Biocompatibility | Moderate; ISO 10993 compliant (non-implants) | Safe for limited body contact applications. |

Cost | ~$50–100/kg (powder/bar stock) | More affordable than some superalloys; higher than conventional steels. |

Summary:

Inconel 625 offers outstanding high-temp strength, corrosion resistance, and creep performance, making it ideal for harsh environments. It’s also easy to weld and 3D print, with good fatigue resistance—an excellent choice for aerospace, marine, and chemical applications.

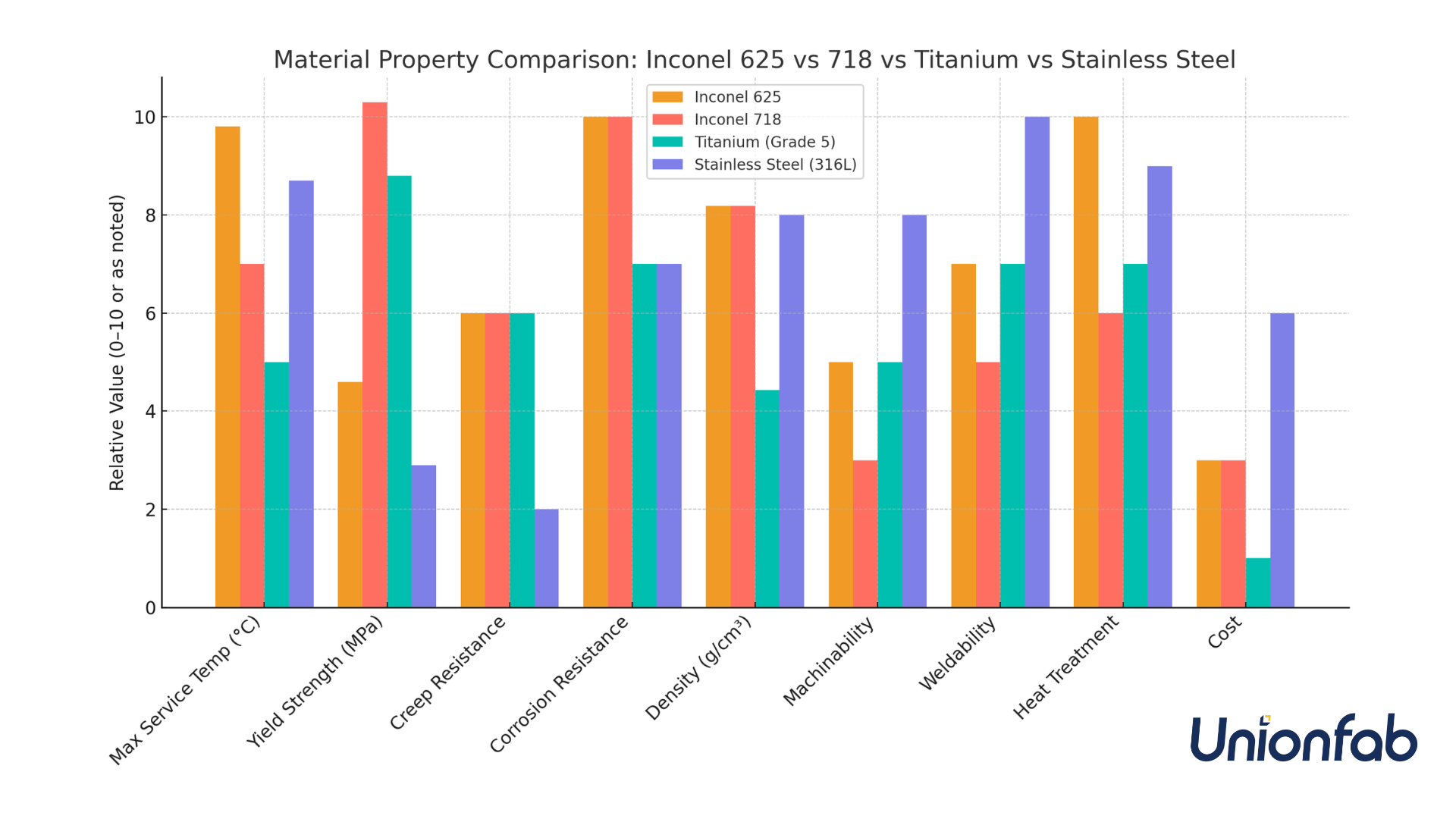

Inconel 625 vs Inconel 718 vs. Titanium vs. Stainless steel

Property | Inconel 625 | Inconel 718 | Titanium (Grade 5) | Stainless Steel (316L) |

|---|---|---|---|---|

Max Service Temp | ~982 °C | ~700 °C | ~400–600 °C | ~870 °C |

Yield Strength | Moderate (~460 MPa) | High (~1030 MPa) | High (~880 MPa) | Moderate (~290 MPa) |

Creep Resistance | Moderate | Moderate | Moderate | Low |

Corrosion Resistance | Excellent | Excellent | Good | Good |

Density | High (~8.19 g/cm³) | High (~8.19 g/cm³) | Low (~4.43 g/cm³) | High (~8.0 g/cm³) |

Machinability | Moderate | Difficult | Moderate | Good |

Weldability | Good | Moderate (prone to cracking) | Good | Excellent |

Heat Treatment | None required | Age hardened | Annealed or aged | Usually not required |

Cost | High | High | Very High | Moderate |

Application Focus | Corrosive, marine, and aerospace | High-strength aerospace & turbines | Aerospace, biomedical | General-purpose, industrial |

Summary:

Inconel 625: Excellent corrosion resistance and high-temp performance (~982 °C), easy to weld, no heat treatment needed — ideal for marine and chemical environments.

Inconel 718: Very high strength, good for aerospace and turbines, but requires heat treatment and is hard to machine.

Titanium (Grade 5): Strong and lightweight, great for aerospace and medical use, but expensive and has lower heat tolerance.

Stainless Steel 316L: Affordable, easy to machine and weld, suitable for general industrial applications, but lower strength and heat resistance.

Primary Manufacturing Methods of Inconel 625

Inconel 625 is a versatile high-performance alloy that supports a range of direct manufacturing techniques. Each method offers specific advantages depending on the application, part complexity, and performance requirements.

1. CNC Machining

CNC machining is a widely used method for producing high-precision Inconel 625 parts, especially for low-volume or complex geometries.

Inconel 625 is prone to work hardening, making it challenging to machine.

Requires carbide or ceramic cutting tools, low feed rates, and reduced cutting speeds.

Flood coolant or Minimum Quantity Lubrication (MQL) is essential to manage heat and extend tool life.

Applications: Turbine blades, nuclear components, flanges, and precision fittings.

2. Welding and Brazing

Inconel 625 is well-suited for high-integrity welding processes and is commonly used in structural assemblies and pressure vessels.

Compatible with TIG (GTAW), MIG (GMAW), plasma arc, and laser welding.

Exhibits excellent weldability without the need for post-weld heat treatment in many cases.

Stress-relief treatments are recommended for thick sections or highly constrained geometries to prevent warping or cracking.

Brazing with nickel-based filler alloys is also used in aerospace and heat exchanger applications.

3. Additive Manufacturing (3D Printing)

Advanced manufacturing via metal 3D printing enables rapid, near-net-shape production of Inconel 625 parts, especially for complex or lightweight designs.

Techniques include:

SLM (Selective Laser Melting)

EBM (Electron Beam Melting)

DED (Directed Energy Deposition)

Offers design freedom, reduced material waste, and tool-less production.

Post-processing such as heat treatment and surface finishing is often required to optimize mechanical properties.

Widely used in aerospace, energy, and medical industries for functional components and repair applications.

Inconel 625 3D Printing

1. Additive Manufacturing Techniques

Technique | Key Features | Suitability for Inconel 625 |

|---|---|---|

Laser Powder Bed Fusion (LPBF) | High precision, fine layer resolution (20–60 μm) | Most widely used; excellent for complex parts |

Directed Energy Deposition (DED) | High deposition rates, good for large repairs or near-net shapes | Suitable for large parts; less detail than LPBF |

Metal Binder Jetting | No heat during printing; sintering needed post-build | Lower mechanical properties; better for low-stress parts |

2. Challenges and Considerations

Thermal Management: Inconel 625’s high thermal conductivity affects melt pool behavior—requires precise energy input.

Cooling Rate Control: Improper cooling can cause porosity or cracking; optimized scan strategies and supports are crucial.

Post-Processing Needs:

Stress relief annealing or HIP (Hot Isostatic Pressing) improves density and mechanical strength.

Surface finishing is often required to meet dimensional and aesthetic requirements.

3. Benefits of Additive Manufacturing with Inconel 625

Complex Geometry: Enables the production of internal channels, lattices, and topologically optimized designs.

Part Consolidation: Reduces the number of assembled components, minimizing potential failure points.

Lightweighting: Suitable for aerospace and energy sectors where weight reduction is critical.

Rapid Prototyping & Small-Batch Production: Ideal for low-volume, high-performance parts where traditional methods are too slow or costly.

Start your 3D Printing with Unionfab

Unionfab, the overseas branch of Uniontech (which holds 60% of China’s 3D printing market), is China’s largest 3D printing manufacturer, specializing in rapid prototyping and on-demand production.

With 20+ years of experience, 1,000+ industrial 3D printers, and 6 smart factories, Unionfab is ISO 9001, ISO 13485, and AS 9100D certified—delivering high-quality, cost-effective solutions.

For high-performance needs, we offer Inconel 625 3D printing via SLM and DMLS, ensuring excellent resolution and material integrity. Ideal for corrosive, high-temperature, and high-stress applications in aerospace, marine, chemical, and energy industries.

Unionfab offers:

80+ industrial-grade materials

7 major 3D printing processes: SLA, SLM, SLS, MJF, FDM, DLP, PolyJet

Up to 70% cost savings compared to global competitors

One-stop production services: CNC machining, vacuum casting, injection molding, finishing

Partner with Unionfab to bring your Inconel 625 parts to life—with speed, accuracy, and industrial-grade quality.

Typical Applications of Inconel 625

Inconel 625 is a nickel-based superalloy known for its exceptional corrosion resistance, high-temperature strength, and superior fatigue and creep performance. These properties make it highly suitable for the following demanding industries:

1. Aerospace

Why Inconel 625 is ideal:

Excellent resistance to oxidation and thermal fatigue at temperatures up to ~982 °C

Maintains mechanical integrity under cyclic thermal loading

Resistant to high-velocity gas corrosion and stress cracking

Typical parts:

Jet engine exhaust ducts

Turbine housings

Compressor blades

2. Marine

Why Inconel 625 is ideal:

Outstanding resistance to chloride-induced pitting, crevice corrosion, and seawater erosion

Prevents galvanic corrosion when in contact with other metals

Suitable for long-term use in subsea and saltwater environments

Typical parts:

Subsea pipelines

Propeller shafts

Fasteners and submarine components

3. Chemical Processing

Why Inconel 625 is ideal:

Exceptional chemical resistance to acidic, alkaline, and oxidizing media

High durability in environments containing chlorides, nitrates, and organic acids

Withstands high pressure and temperature without degradation

Typical parts:

Reactor vessels

Heat exchangers

Evaporators

Piping systems

4. Nuclear & Power Generation

Why Inconel 625 is ideal:

Stability under nuclear radiation and elevated temperatures

Excellent resistance to stress corrosion cracking

Low permeability to radioactive gases and good structural retention

Typical parts:

Reactor core components

Waste containment systems

High-temperature turbine parts

5. Oil & Gas

Why Inconel 625 is ideal:

High performance in deep-well and acidic drilling environments

Strong resistance to sulfide stress cracking and chloride corrosion

Durable in high-pressure, high-temperature (HPHT) conditions

Typical parts:

Downhole tools

Valve bodies and connectors

Corrosion-resistant tubing

FAQs

Q1: Is Inconel 625 magnetic?

No, it is non-magnetic in its annealed state.

Q2: How does Inconel 625 perform in seawater?

Exceptionally well; it’s widely used in marine and offshore environments.

Q3: Can Inconel 625 be machined easily?

It’s machinable, but tool wear is significant—optimized tooling and techniques are essential.

Q4: Does Inconel 625 require heat treatment?

No, its high strength comes from solid solution strengthening, not precipitation hardening.

Q5: What’s the difference between Inconel 625 and 825?

Inconel 825 contains less molybdenum and is more economical for moderate corrosion applications.