Guide to Maraging Steel [+ Properties & Applications]

![Guide to Maraging Steel [+ Properties & Applications]](https://ufc-dtc-cms.oss-accelerate.aliyuncs.com/blog/20250618/221729_27a7qa9hw.png)

Discover the properties and design guidelines of maraging steel, and how Unionfab helps you get high-strength parts with precision and speed.

Introduction

Maraging steel is a high-performance alloy known for its exceptional strength, toughness, and dimensional stability. The name "maraging" comes from a combination of “martensitic” and “aging,” referring to the material’s transformation into a martensitic structure followed by precipitation hardening (also known as aging treatment).

First developed in the 1960s for aerospace applications, maraging steel offers a unique combination of machinability in the annealed state and ultra-high strength after heat treatment. Common grades include 18Ni(300), which offers ultra-high tensile strength, excellent crack resistance, and easy machinability before aging.

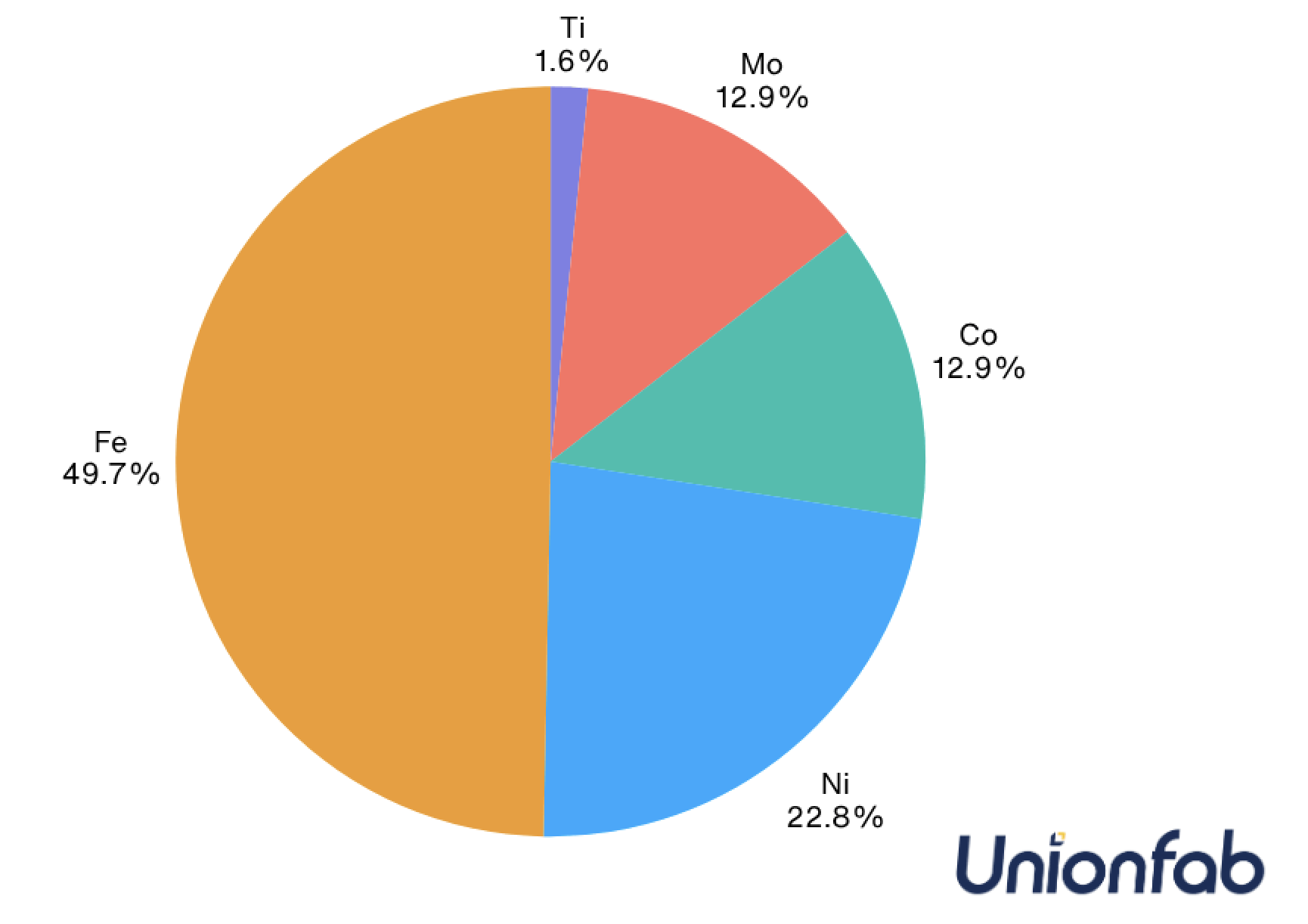

Maraging steels are typically composed of iron, nickel (17–19%), cobalt, molybdenum, and small additions of titanium and aluminum.

Chemical Composition and Mechanical Properties

The typical chemical composition of maraging steel grade 18Ni(300) is:

After aging treatment, maraging steel can achieve the following mechanical properties:

Property | Typical Value |

|---|---|

Tensile Strength | Up to 2,000 MPa |

Yield Strength | ~1,800 MPa |

Hardness (HRC) | 48–52 |

Elongation | ~8–10% |

Density | ~8.0 g/cm³ |

At Unionfab, our maraging steel materials are sourced and inspected to ensure conformity with DIN 1.2709 and AMS 6514 standards.

To explore detailed specifications, recommended applications, and processing guidelines, download our full maraging steel datasheet here: Maraging Steel - Metal 3D Printing Service | Unionfab.

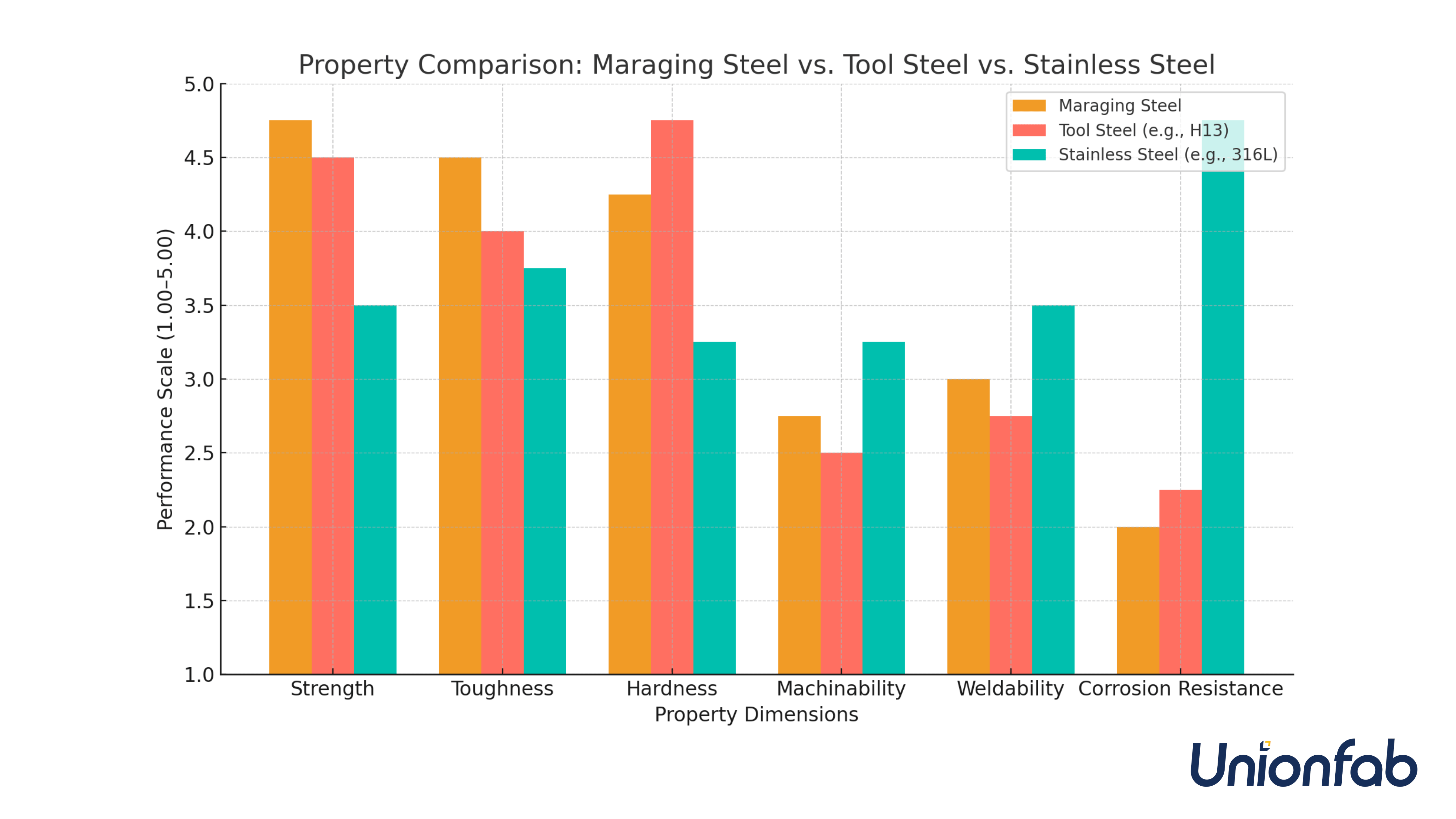

How Does Maraging Steel Compare to Other Steels?

When selecting a material for high-performance parts, it’s important to compare maraging steel with other industrial-grade steels:

Property | Maraging Steel | Tool Steel (e.g., H13) | Stainless Steel (e.g., 316L) |

|---|---|---|---|

Strength (MPa) | Up to 2,000 MPa (after aging) | 1,300–1,600 MPa | ~500 MPa |

Toughness | Excellent | Moderate | Moderate |

Hardness | Up to 50+ HRC (aged) | High | Low to moderate |

Machinability (before aging) | Good | Moderate | Good |

Weldability | Excellent | Limited | Good |

Corrosion Resistance | Moderate | Low | High |

Compared to traditional high-strength steels, maraging steel offers a rare combination of easy machinability (before aging) and ultra-high mechanical strength (after aging).

This makes it ideal for parts requiring precision and durability, especially in industries where mechanical failure is unacceptable.

Is Maraging Steel Suitable for CNC Machining and 3D Printing?

Yes — maraging steel performs excellently in both CNC machining and metal additive manufacturing, particularly in DMLS (Direct Metal Laser Sintering) and SLM (Selective Laser Melting) processes.

CNC Machining

● Before aging, maraging steel is relatively soft and easy to cut, reducing tool wear and allowing for high precision.

● After machining, the parts can be heat treated to achieve full mechanical strength.

● The low distortion during heat treatment makes maraging steel ideal for tight-tolerance parts.

3D Printing

● Maraging steel powder is widely used for metal 3D printing due to its excellent mechanical response to post-processing.

● Parts printed with maraging steel can be heat-treated after printing to reach final hardness and performance targets.

● It is especially suitable for complex geometries, mold inserts, and low-volume functional prototypes.

What Is SLM and Why Is It Ideal for Maraging Steel?

Selective Laser Melting (SLM) is one of the most effective additive manufacturing techniques for processing high-performance metal alloys like maraging steel. SLM builds parts layer-by-layer using a high-powered laser, ensuring excellent density and material properties.

Maraging steel performs exceptionally well under SLM due to:

● Excellent weldability

● Minimal cracking risk

● Consistent mechanical properties after aging

To learn more about how SLM works and why it’s ideal for precision engineering, check out our article:

Guide to SLM 3D Printing/Metal LPBF [+Cost Calculator]

Design Guidelines for 3D Printing Maraging Steel Parts

When designing components for metal 3D printing with maraging steel, several best practices can help ensure optimal quality, mechanical performance, and post-processing efficiency:

● Wall Thickness: Minimum recommended wall thickness is 0.8–1.0 mm to ensure structural integrity and consistent fusion.

● Overhangs & Supports: Features with angles greater than 45° typically require support structures. Our team can assist in optimizing your design for support minimization.

● Hole Diameter: Small holes (<2 mm) may close during printing. Consider drilling or reaming them post-printing or increasing size during design.

● Text and Embossed Features: Ensure embossed/recessed features are at least 0.3 mm deep and 1.0 mm wide for visibility.

● Tolerance Expectations: Achievable tolerances are typically within ±0.1 mm, depending on geometry and post-processing needs.

● Heat Treatment Considerations: Leave adequate allowance for post-print machining or surface finishing if tight fits are required.

Unionfab offers DFAM (Design for Additive Manufacturing) consultation to help you adapt your CAD model for optimal performance in maraging steel. We also provide simulation-based support optimization and finishing guidance for functional parts.

Why Choose Unionfab for Maraging Steel Parts?

● One-stop production: from design review to post-processing

● Support for both CNC and DMLS manufacturing

● Fast turnaround on custom 1.2709 orders

● Quality assurance backed by ISO 9001 workflows

● Engineering consultation to optimize cost and material use

Unionfab supports both CNC and 3D printing production using maraging steel, particularly grade 1.2709 (18Ni300). We provide technical consultation and offer small to large batch production services.

Key Applications of Maraging Steel

Due to its unique balance of high strength and good workability, maraging steel is widely used in industries where reliability and fatigue resistance are critical:

● Injection Molds and Die Casting: Long-lasting tooling with reduced cracking risk

● Aerospace Components: Structural parts and brackets with minimal weight and maximum strength

● Motorsport and Automotive: Gears, shafts, and powertrain components

● Defense and Security: Missile skins, pressure vessels, high-strength fasteners

● Additive Manufacturing: Tool inserts and conformal cooling channels with post-processing options

Conclusion: Why Choose Maraging Steel for Your Next Project?

Maraging steel stands out as a versatile material for both traditional and advanced manufacturing. It offers an unmatched combination of strength, dimensional stability, and post-processing flexibility — making it a top choice for engineers and manufacturers working in high-demand sectors.

Unionfab offers one-stop metal manufacturing solutions, including DMLS metal printing and 5-axis CNC machining for maraging steel parts. Our engineers will assist you with design review, material selection, and post-processing guidance.

Ready to try maraging steel for your custom parts?

Upload your design today for a free quote — Unionfab’s team will review your project and provide the best solution.

Calculate Your Cost

Frequently Asked Questions

Q1: Is maraging steel expensive?

A: It is more expensive than regular steel, but its performance per unit weight and lower failure rates often justify the cost in high-end applications.

Q2: Can I machine it without heat treatment?

A: Yes. Maraging steel is easy to machine in its annealed state, then hardened through aging afterward.

Q3: Is maraging steel corrosion-resistant?

A: It has moderate corrosion resistance, but not as high as stainless steel. Surface treatments or coatings are often recommended for corrosive environments.

Q4: Can I order small batches?

A: Yes. Unionfab supports custom low-volume production, whether through CNC or metal 3D printing.