Custom Fuel Rails + [Cost Calculator & Free DFM]

![Custom Fuel Rails + [Cost Calculator & Free DFM]](https://ufc-dtc-cms.oss-accelerate.aliyuncs.com/blog/20250731/102345_65yzatmrd.png)

Learn how to design and manufacture custom fuel rails using CNC or 3D printing. Compare materials, processes, and get a free design review to optimize performance.

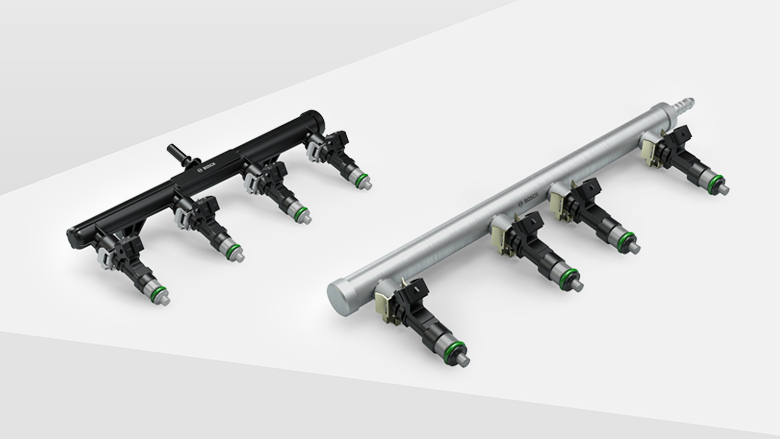

Introduction: What is a Fuel Rail

Source: Bosch.com

A fuel rail is an essential part of an internal combustion engine's fuel system. It functions as a high-pressure conduit that delivers fuel from the fuel pump to the engine’s fuel injectors.

Positioned above or near the intake manifold, the fuel rail ensures that each cylinder receives an equal and consistent supply of fuel, which is critical for optimal combustion, power output, and efficiency.

Fuel rails are present in both Port Fuel Injection (PFI) and Direct Injection (DI) systems. PFI systems inject fuel into the intake ports, while DI systems deliver fuel directly into the combustion chamber at much higher pressures.

As such, fuel rails in DI applications must be robust enough to withstand extreme operating conditions. Most fuel rails are made from high-strength metals such as aluminum or stainless steel to provide structural integrity, corrosion resistance, and long service life.

Why It Matters for Engine Performance

A properly designed and manufactured fuel rail helps maintain consistent combustion, improves throttle response, and ensures maximum efficiency. Even minor flaws in fuel delivery can lead to power loss, poor fuel economy, or long-term engine damage.

Why Custom Fuel Rails Are Often Required

In cases of aftermarket tuning, forced induction, or non-standard engine configurations, OEM fuel rails may not suffice. Custom fuel rails allow precise integration, optimized flow, and support for high-performance injectors and sensors.

Fuel Rail Function and Key Performance Requirements

Fuel rails serve five primary functions in an engine:

● Uniform Fuel Distribution: A fuel rail must deliver a consistent amount of fuel to each injector regardless of engine speed or load.

● Pressure Regulation: It must maintain stable fuel pressure under varying driving conditions, especially in high-performance or turbocharged engines.

● Corrosion Resistance: The rail must be resistant to ethanol blends, additives, and exposure to high heat and moisture.

● Leak-Free Operation: Precision machining and effective sealing are vital to prevent fuel leaks.

● Integration: Many fuel rails must accommodate pressure sensors, regulators, and return lines.

In high-performance applications, inconsistency in fuel delivery can lead to misfires, poor fuel economy, and even engine damage. Therefore, high manufacturing precision and quality control are essential.

Unionfab provides precision metal 3d printing and tight tolerance CNC machining that ensures all sealing surfaces and mounting features are dimensionally accurate. Let Unionfab help you create art without limits.

What Materials Are Used to Make Fuel Rails?

Material selection for fuel rails is driven by the need for strength, thermal stability, and chemical resistance. Below is a comparison of commonly used materials:

Material Type | Description | Key Benefits | Applications |

|---|---|---|---|

Aluminum (6061) | Lightweight, corrosion-resistant | Easy to machine; supports anodizing | Aftermarket, motorsport, tuning |

Stainless Steel (304/316) | High strength and corrosion-resistant | Handles high pressure and harsh fuels | OEM, Direct Injection, industrial |

Aluminum is commonly used for performance applications due to its weight advantage and flexibility in machining.

Stainless steel is preferred for higher pressure systems or environments with aggressive fuels and chemicals.

Unionfab offers CNC machining and 3D printing for both aluminum and stainless steel and can advise on the best material for your specific engine and performance requirements. Need support? Contact our engineers for material or finish suggestions.

How Are Custom Fuel Rails Manufactured?

Fuel rails can be manufactured using several techniques. The most suitable method depends on the application, performance expectations, and budget.

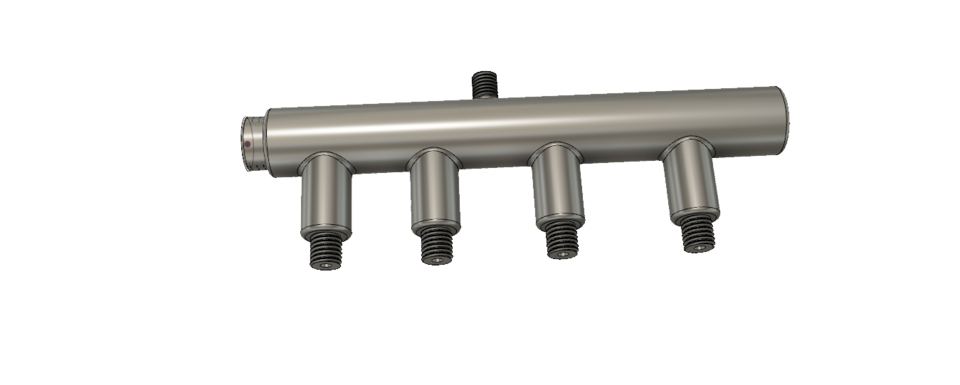

CNC Machining Fuel Rails

Source: Youtube @Turbo_V6

CNC machining is the most precise and reliable method for producing fuel rails. This subtractive process starts with a solid block of material (usually aluminum or stainless steel) and removes material layer by layer using cutting tools controlled by a digital design.

Advantages:

● Tight tolerances (±0.01 mm), ideal for sealing surfaces and threaded ports

● Compatibility with various metals, including aluminum and stainless steel

● Clean internal passages and ports, reducing turbulence and flow loss

● Flexibility in design customization

● Suitable for prototypes, low-volume batches, or production runs

Unionfab uses multi-axis CNC equipment capable of producing complex fuel rail geometries with consistent quality.

3D Printing Fuel Rails

Source: GrabCAD.com

Additive manufacturing (3D printing) is becoming more common in prototyping and design validation phases. While it’s not yet widely used for full-production metal fuel rails, it is beneficial for:

● Rapid prototyping of custom designs

● Creating internal geometries that are difficult to achieve via machining

● Early-stage testing with polymer or metal prototypes

The most commonly used 3D printing technologies for fuel rail development include:

● Fused Deposition Modeling (FDM): Ideal for basic functional prototypes using engineering-grade thermoplastics such as ABS or Nylon.

● Selective Laser Sintering (SLS): Useful for more durable plastic parts with complex internal features, often using PA12.

● Direct Metal Laser Sintering (DMLS) / Selective Laser Melting (SLM): Suitable for producing metal fuel rail prototypes from stainless steel or aluminum alloys, especially when testing for fit or thermal behavior.

However, pressure tolerance and surface finish may not meet production standards, especially in DI systems. 3D printing is best for fitment tests and design evaluation.

CNC vs. 3D Printing

Feature | CNC Machining | 3D Printing |

|---|---|---|

Material Range | Aluminum, stainless steel | Polymers, limited metals |

Pressure Tolerance | High | Low to medium |

Surface Finish | Excellent | Moderate |

Speed | Fast for production | Fast for prototyping |

Design Flexibility | High for outer features | High for internal features |

Cost Efficiency | Better for medium/high volume | Better for one-off designs |

Design Considerations for Custom Fuel Rails

Designing an effective custom fuel rail requires attention to several technical parameters:

● Engine Layout: Inline, V-type, or flat engines require different mounting geometries

● Injector Spacing: Must match cylinder head configuration and intake ports

● Internal Bore Size: Affects fuel flow capacity and pressure consistency

● Mounting Features: Bracket locations, bolt patterns, and stiffness

● Ports and Threads: For regulators, return lines, and sensors

Unionfab provides design-for-manufacturing (DFM) assistance to optimize fuel rail geometry, reduce manufacturing cost, and improve reliability.

Need support? Contact our engineers for technical guidance.

Surface Treatments and Finishing Options

Post-machining finishing enhances durability, appearance, and resistance to fuel and environmental exposure.

Anodizing

Anodizing is ideal for aluminum rails. It increases corrosion resistance and allows for cosmetic customization. Anodized rails are available in various colors such as black, blue, red, or silver.

Polishing and Bead Blasting

These processes improve surface aesthetics and eliminate tool marks. Bead blasting gives a matte finish, while polishing provides a smooth, reflective surface.

Protective Coatings

For stainless steel fuel rails, coatings can enhance chemical resistance and long-term durability. Coatings may also improve compatibility with aggressive fuels or industrial environments.

When to Use a Custom Fuel Rail

You may need a custom fuel rail if:

● Your engine build includes aftermarket injectors, forced induction, or performance tuning

● OEM fuel rails are no longer available or don't fit

● You're designing a prototype or unique engine configuration

● You need to optimize fuel delivery for specific flow requirements

Custom fuel rails ensure perfect fitment, maximize performance, and avoid compromises.

Unionfab helps you design and produce the right solution for your needs. Let Unionfab help you create art without limits.

Conclusion

Fuel rails are critical to engine performance, fuel efficiency, and long-term reliability. By understanding the materials, manufacturing processes, and design factors involved, engineers and product developers can make better decisions for their fuel system components.

Whether you're creating a prototype or building a high-performance application, Unionfab provides the manufacturing expertise and flexibility to help bring your designs to life.

FAQs

Q: What is a fuel rail?

A fuel rail distributes pressurized fuel from the pump to the engine's injectors.

Q: What happens if a fuel rail fails?

Fuel leaks, pressure drops, engine misfires, and poor performance can result.

Q: Can I 3D print a fuel rail?

Yes, but it's best suited for design validation or low-pressure applications.

Q: How much does a fuel rail cost?

Typical CNC-machined fuel rails cost $50–$300 depending on design, material, and quantity.

Q: Can Unionfab manufacture from my CAD file?

Yes. We accept standard CAD formats and offer a free manufacturability review.

Q: What is the lead time for a custom fuel rail?

Lead times range from 5–12 business days depending on design complexity and finishing.