Powder Coating vs Anodizing [+Selection Guide]

![Powder Coating vs Anodizing [+Selection Guide]](https://ufc-dtc-cms.oss-accelerate.aliyuncs.com/blog/20250723/223746_fplehw860.png)

Compare powder coating vs anodizing in terms of cost, durability, and material compatibility. Use our expert-backed selection guide to choose the right finish for your project.

Introduction

Choosing the right surface finish is essential for CNC machined parts. Powder coating and anodizing are two of the most reliable options, each offering unique advantages in protection, appearance, and performance.

This guide compares powder coating vs anodizing—helping you decide which finish best suits your material, design, and end-use environment.

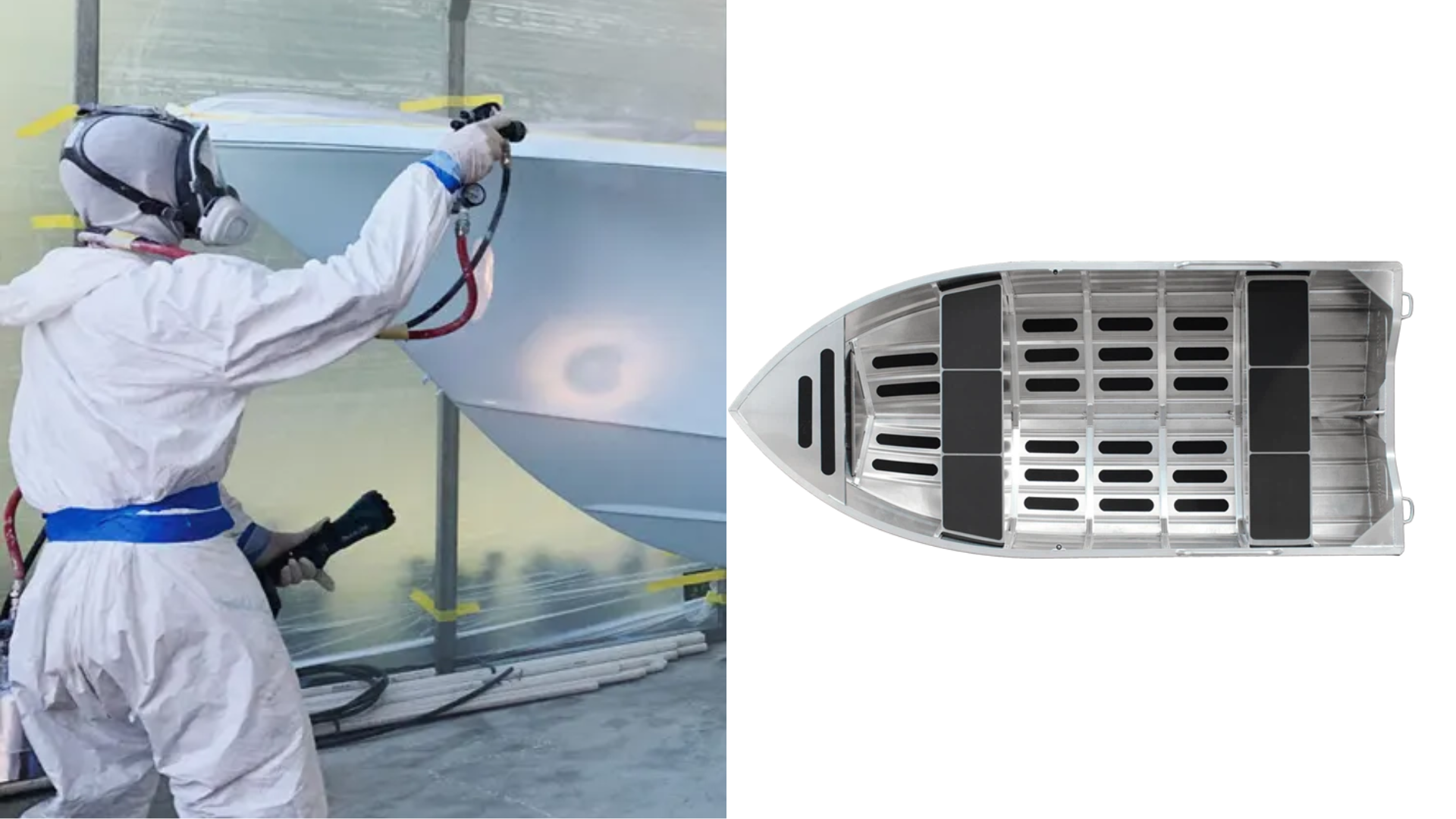

What is Powder Coating?

Source: surfaceprep.com

Powder coating is a dry finishing method where a powder is electrostatically applied to a metal part, then cured in an oven to form a solid, protective layer. It works well with aluminum, steel, and magnesium.

The finish offers excellent corrosion resistance and comes in many colors, textures, and gloss levels. It's widely used in consumer electronics, industrial parts, and automotive components. However, its thickness (50–150 μm) may reduce fine detail accuracy.

What is Anodizing?

Source: protocase.com

Anodizing is an electrochemical process that builds up a protective oxide layer on the surface of a metal—most commonly aluminum. The part is submerged in an acid-based electrolyte and exposed to an electric current, creating a controlled, bonded oxide layer.

This process enhances corrosion resistance, increases surface hardness, and improves wear resistance. Anodized finishes are thin (5–25 μm), preserve fine part details, and maintain a metallic appearance. While color options are more limited than powder coating, anodizing produces long-lasting, stable finishes. It is not suitable for steel or non-aluminum metals.

Types of Anodizing

Type I – Chromic Acid Anodizing

Produces a thin oxide layer; mainly used for aerospace parts. Offers basic corrosion resistance.

Type II – Sulfuric Acid Anodizing

Most common for decorative purposes. Provides moderate wear and corrosion resistance and allows for dyeing.

Type III – Hard Anodizing (Hardcoat)

Creates a thick, dense oxide layer for maximum hardness and abrasion resistance. Ideal for high-performance industrial applications.

Powder Coating vs Anodizing: A Technical Comparison

The table below compares key properties of the same metal—typically aluminum—after undergoing powder coating or anodizing. It highlights how each finishing method affects surface characteristics, performance, and durability across different functional dimensions.

Property | Powder Coating | Anodizing |

|---|---|---|

Compatible Materials | Aluminum, steel, magnesium, more | Mainly aluminum |

Corrosion Resistance | Excellent | Excellent (varies by type) |

Wear Resistance | Good | Very high (especially Type III) |

Color Options | Wide variety | Limited, mostly metallic and black |

Surface Thickness | 50–150 μm | 5–25 μm (Type II) |

Appearance | Smooth, opaque finish | Metallic look retained |

Detail Retention | Moderate | Excellent |

Dimensional Impact | Can affect tight tolerances | Minimal impact |

UV Stability | Good (depends on powder type) | Good (especially clear coatings) |

Chemical Resistance | Good | Moderate to excellent |

Environmental Impact | Low VOC, powder recyclable | Water-based, minimal waste |

Cost | Moderate | Lower for basic types |

Maintenance | Easy to clean, durable | Durable, but color can fade over time |

Aluminum Powder Coating vs Anodizing

Aluminum is compatible with both powder coating and anodizing, but each finish offers different benefits.

Powder Coating on Aluminum:

● Adds a colorful, protective layer

● Ideal for aesthetic components and outdoor exposure

● Provides uniform coverage even on complex shapes

Anodizing on Aluminum:

● Enhances natural oxide layer without adding thickness

● Retains metallic look and part detail

● Offers better hardness and scratch resistance

In Summary:

Feature | Powder Coating | Anodizing |

|---|---|---|

Finish Thickness | 50–150 μm | 5–25 μm |

Look | Opaque, customizable | Natural metallic, limited colors |

Tolerance Sensitivity | Moderate impact | Minimal impact |

Choose powder coating if visual flexibility and environmental durability matter. Opt for anodizing when precision, surface hardness, and metallic aesthetics are more critical.

Powder Coating vs Anodizing: Durability

Both processes improve part life, but their protective mechanisms differ:

Powder Coating Durability:

● Offers a thick outer layer

● Highly resistant to moisture, UV, and physical wear

● Can chip if coating is damaged or improperly applied

Anodizing Durability:

● Converts the surface into a hard oxide layer

● Very high abrasion and wear resistance (especially Type III)

● Cannot peel or flake

Use Case Summary:

Environment | Preferred Finish |

|---|---|

General Outdoor | Powder Coating |

High Friction or Precision Fit | Anodizing |

Corrosive or Saltwater | Both (depends on material and exposure time) |

For maximum wear resistance, especially on aluminum, anodizing—particularly hard anodizing—is superior. Powder coating is preferred for impact resistance and aesthetic surfaces.

Powder Coating vs Anodizing: Cost

Cost depends on part geometry, volume, and finish requirements.

Powder Coating Costs:

● Higher labor and setup for masking, spraying, and curing

● Cost-effective for large parts and colorful or textured surfaces

● Slightly more expensive for complex shapes

Anodizing Costs:

● More affordable for aluminum in medium to high volumes

● Shorter lead time, especially for Type II decorative anodizing

● Type III (hard anodizing) involves higher process control and cost

In Summary:

Scenario | Cost-Effective Option |

|---|---|

Large aluminum batch with standard look | Anodizing (Type II) |

Custom colors and finishes | Powder Coating |

High wear resistance needed | Anodizing (Type III) |

Unionfab can help you select the optimal surface finish based on performance and cost goals. We provide transparent quotes tailored to project needs.

Application Scenarios: When to Choose Which?

When to Use Powder Coating

Powder coating is ideal when visual appearance, surface coverage, and corrosion protection are priorities. It is especially effective for:

● Structural parts exposed to harsh environments

● Consumer products with color and texture requirements

● Outdoor enclosures, frames, and brackets

● High-volume production where consistent color and finish are needed

When to Use Anodizing

Anodizing is best for parts that require high wear resistance, minimal dimensional change, and a clean metallic appearance. It is commonly used for:

● Precision aluminum components with tight tolerances

● Aerospace and defense applications

● Heat sinks and electronic housings

● Decorative aluminum parts needing long-term color stability

Unionfab’s Finishing Capabilities

Unionfab offers in-house powder coating and anodizing services integrated with our CNC machining and 3d printing services. We support a wide variety of metals, including aluminum, stainless steel, nickel-based alloy, titanium alloy etc.

If you need expert advice on surface finishing for your metal parts — from choosing the right coating to ensuring durability and aesthetics — our team is here to help.

Contact Unionfab today to discuss your finishing needs and get tailored recommendations.

FAQs

Do these finishes affect part dimensions?

Yes. Powder coating adds measurable thickness that can interfere with tight fits. Anodizing alters the surface minimally and is often preferred for dimensionally critical parts.

Can powder coating chip or crack?

Powder coating is durable, but if surface preparation is poor or the part faces high impact, chipping may occur.

Do anodized colors fade?

Anodized colors are UV-stable but can fade over extended periods or with chemical exposure. Sealing improves longevity.

Which method is more eco-friendly?

Both are considered environmentally friendly. Powder coating uses no solvents and recycles excess powder. Anodizing is water-based and generates low waste.

Does Unionfab support custom color requests?

Yes. We offer a range of custom colors and finishes for both powder coating and anodizing, depending on material and volume.