Age Hardening Guide [+Free Engineering Toolkit]

![Age Hardening Guide [+Free Engineering Toolkit]](https://ufc-dtc-cms.oss-accelerate.aliyuncs.com/blog/20250807/214026_zhnvmmclg.png)

Learn how age hardening improves metal strength, hardness, and fatigue life. Get clear design tips, best-fit materials, and manufacturing insights to enhance part performance instantly

What Is Age Hardening

Age hardening, also called precipitation hardening, is a heat treatment process that makes certain metals stronger and harder. It works by forming tiny particles (called precipitates) inside the metal. These particles make it harder for the metal to bend or change shape, which improves its strength.

This method works especially well for metals that contain copper, magnesium, or nickel. It’s often used in high-performance products like airplane parts, car components, and medical tools.

Compared to other heat treatments like annealing or normalizing, age hardening gives more stable and reliable results. Since it increases strength without adding weight, it’s great for light metals such as aluminum and titanium.

The process is also easy to control and repeat, which makes it a good choice for mass production where each part needs to perform the same.

How the Process Works

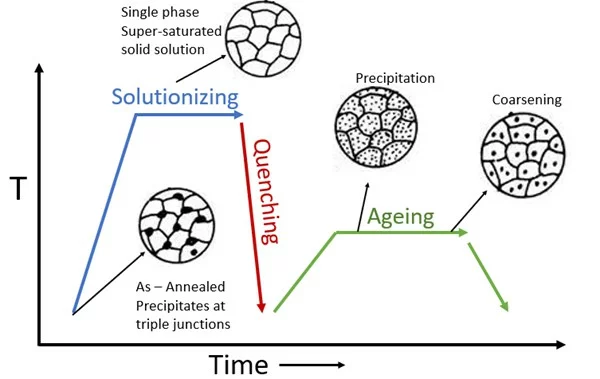

The following process diagram illustrates the age hardening (also known as precipitation hardening) process in metallurgy. It consists of three main stages: Solutionizing, Quenching, and Ageing, with the relationship between Temperature (T) and Time shown on the axes.

Source: WayKen.com

1. Solutionizing

● What happens: The alloy is heated to a high temperature to dissolve secondary phases and form a single-phase supersaturated solid solution.

● In the diagram: Temperature increases to a plateau. The microstructure becomes uniform, with no precipitates.

● Purpose: To eliminate pre-existing precipitates or segregation and prepare the material for subsequent strengthening.

2. Quenching

● What happens: The material is rapidly cooled (usually by water, oil, or air) to retain the supersaturated solid solution created during solutionizing.

● In the diagram: The temperature drops steeply. Precipitates are avoided.

● Result: The material is in a metastable state with no precipitates — it's still relatively soft at this stage.

3. Ageing

● What happens: The material is held at a moderate temperature for a certain time to allow controlled precipitation of strengthening phases.

● In the diagram:

○ Early stage (precipitation): Fine, evenly distributed precipitates form inside the grains, increasing strength and hardness.

○ Peak-aged stage: Maximum mechanical properties are achieved.

○ Over-ageing (coarsening): The precipitates grow larger and coarser, leading to a decline in strength.

● Purpose: To improve mechanical performance (strength, hardness) by forming finely dispersed precipitates that hinder dislocation motion.

Summary of Microstructural Changes:

Stage | Microstructure | Mechanical Property |

|---|---|---|

As-Annealed | Precipitates at grain boundaries | Relatively soft |

Solutionized | Uniform solid solution, no precipitates | Still soft |

Quenched | Supersaturated solution, no precipitates | Soft, metastable |

Aged (Peak) | Fine, uniform precipitates | Maximum strength |

Over-aged | Coarse precipitates, reduced density | Strength decreases |

This process is widely used in aluminum alloys, titanium alloys, nickel-based alloys, and other systems where increased strength is desired without compromising too much ductility.

Suitable Metals for Hardening

Age hardening is only effective for specific alloys that respond well to precipitation. These materials are widely used in CNC machining and 3D printing due to their strength and performance after heat treatment.

Metal / Alloy Type | Common Grades / Examples | Ageing Temperature (°C) | Ageing Time | Typical Strength Gain |

|---|---|---|---|---|

Aluminum Alloys | 6061, 2024, 7075 | 120–190°C | 4–24 hours | Up to 2× tensile strength compared to annealed |

Titanium Alloys | Ti-6Al-4V | 480–650°C | 2–8 hours | 20–30% increase in yield strength |

Nickel-Based Alloys | Inconel 718, Monel K-500 | 600–800°C | 4–24 hours (multi-stage) | High-temperature strength + creep resistance |

Copper Alloys | Beryllium Copper (C17200) | 300–325°C | 2–3 hours | Up to 4× hardness and high spring strength |

Magnesium Alloys | AZ91, WE43 | 150–250°C | 4–16 hours | Moderate strength gain (~15–30%) |

Notes:

● Actual ageing parameters vary based on exact alloy composition, desired properties, and processing conditions.

● Pure metals cannot be age hardened, because they do not form the necessary precipitates. Age hardening only works in specific alloy systems with the right chemistry and microstructure

● Some systems (like Inconel) may require multiple ageing steps at different temperatures.

● Pre-ageing treatments (e.g., solutionizing, quenching) are assumed before ageing starts.

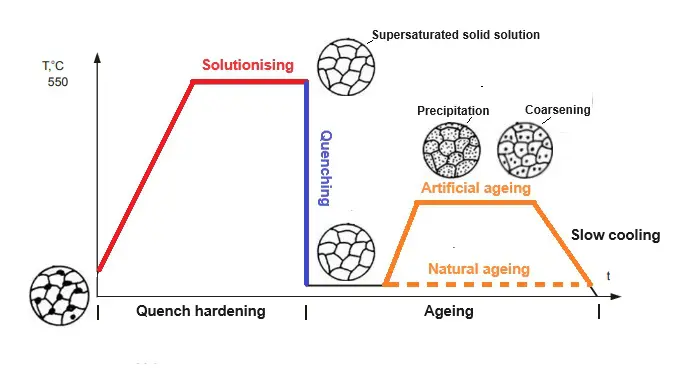

Common Age-Hardenable Alloys:Artificial vs Natural Ageing

Source: fractory.com

When heat-treatable alloys are quenched, they are left in a supersaturated solid solution—a state ready for strengthening. The next step is ageing, which helps form fine particles (called precipitates) inside the metal, making it stronger.

But how we age the metal makes a big difference. There are two main types of ageing: Natural Ageing and Artificial Ageing.

What’s the Difference?

Feature | Natural Ageing | Artificial Ageing |

|---|---|---|

Temperature | Room temperature (20–30°C) | Elevated temperature (typically 100–200°C) |

Speed | Slow – takes hours to days | Fast – minutes to hours |

Control | Hard to control | Easy to control (precise time/temp settings) |

Strengthening Effect | Moderate | Stronger (peak strength possible) |

Common Alloys | 6061-T4 aluminum | 7075-T6 aluminum, high-strength alloys |

Energy Use | Low (no heating needed) | Higher (requires heating equipment) |

Risk of Over-ageing | Unlikely | Possible if overheated or aged too long |

Which One Should You Use?

● Choose Natural Ageing if:

○ You don’t need extreme strength

○ You want to save energy and simplify processing

○ You’re working with alloys that naturally strengthen well at room temperature

● Choose Artificial Ageing if:

○ You need high, consistent strength

○ You want fast processing with predictable results

○ You’re in industries like aerospace or automotive

In some special cases, a material may be naturally aged first, then artificially aged, but this is not always necessary.

Summary

Both natural and artificial ageing help improve metal strength—but in different ways.

● Natural ageing is slower and simpler.

● Artificial ageing is faster, stronger, and more precise.

Your choice depends on performance needs, production timeline, and material type.

Benefits and Applications of Ageing

Ageing—whether natural or artificial—is a crucial step in the heat treatment process for many metal alloys. It offers not just stronger materials, but also improved performance, longer service life, and better reliability in demanding environments.

Key Benefits

Enhanced Strength and Hardness

Ageing promotes the formation of fine precipitates that block dislocation motion, significantly increasing the strength and hardness of the material.

Improved Fatigue Resistance

Aged alloys are more resistant to repeated loading and mechanical stress, making them ideal for parts under cyclic strain.

Dimensional Stability

Artificial ageing, in particular, helps stabilize the material’s internal structure, reducing distortion over time

Customizable Mechanical Properties

By adjusting the ageing temperature and time, engineers can fine-tune the alloy to achieve a desired balance between strength and ductility.

Cost-Effective Performance Upgrade

Compared to alloy redesign or adding expensive elements, ageing offers an affordable way to boost performance using standard materials.

Common Applications

Industry | Example Components | Reason for Using Ageing |

|---|---|---|

Aerospace | Wing spars, fuselage frames, landing gear | High strength-to-weight ratio; fatigue resistance |

Automotive | Suspension arms, wheels, engine brackets | Lightweight yet strong; stable performance under heat |

Consumer Electronics | Laptop shells, mobile phone bodies | Precision form, high surface quality, good wear resistance |

Construction | Structural panels, frames, connectors | Long-term stability and load-bearing strength |

Marine & Transport | Boat hulls, railcar parts | Corrosion resistance and structural strength in harsh environments |

Age Hardening in Manufacturing

In modern manufacturing, age hardening is an essential post-processing step for both CNC-machined and 3D-printed metal parts.

Common Use Cases:

● CNC Machining: Strengthens parts post-machining without affecting dimensions. Ideal for brackets, shafts, and enclosures.

● Metal 3D Printing: Restores strength in SLM/DMLS printed parts, ensuring real-world usability.

Manufacturing Considerations:

● Plan for rough machining → heat treatment → final finishing

● Coordinate heat treatment with stress relief to prevent distortion

● Consider geometry and support structures for thermal stability

Early planning in design ensures smoother processing and better results. Heat treatment is not an afterthought but a critical part of part development.

Unionfab's Heat Treatment Support

Unionfab offers full-service support for age hardening as part of its CNC machining and metal 3D printing solutions. Our capabilities include artificial ageing treatments for widely used alloys such as 6061 aluminum and 17-4PH stainless steel.

We provide expert consultation on material selection and help clients design parts with the right thermal treatment plan in mind.

Unionfab’s production workflow integrates heat treatment into the manufacturing schedule to minimize delays and ensure optimal material performance.

Why Choose Unionfab:

● Integrated machining + post-processing

● Standardized thermal treatment protocols

● In-house hardness testing and quality control

● One-stop delivery from CAD model to finished part

Upload your files today to receive a custom quote with age hardening included.

FAQs

What is the meaning of age hardening?

Age hardening is a heat treatment process that improves the strength and hardness of specific metal alloys by forming fine precipitates within the material's crystal structure. These precipitates block dislocation motion and increase mechanical performance.

What are the three steps in age hardening?

The three steps are:

Solution treatment – heat to dissolve alloying elements

Quenching – rapidly cool to form a supersaturated solution

Ageing – allow fine precipitates to form, increasing strength

What is the difference between age hardening and quenching?

Quenching is a rapid cooling step used within the age hardening process. On its own, quenching doesn’t strengthen the metal. Age hardening includes quenching, followed by controlled ageing to achieve improved mechanical properties.

What is the difference between age hardening and annealing?

Age hardening increases strength and hardness, while annealing softens metal to improve ductility and relieve internal stress. They are used for opposite purposes in manufacturing.

Is age hardening the same as precipitation hardening?

Yes. Age hardening and precipitation hardening refer to the same process. Both describe strengthening alloys by forming fine precipitates during the ageing phase of heat treatment.

Can aluminum alloys be age hardened?

Yes. Many aluminum alloys, such as 6061 and 7075, are specifically designed to benefit from age hardening, achieving high strength-to-weight ratios for aerospace and structural applications.

What steel grades are age hardenable?

Age-hardenable steels include 17-4PH and 15-5PH stainless steels. These steels combine corrosion resistance with high strength and are widely used in aerospace, tooling, and medical parts.