Induction Hardening【+Prevent Gear Failures】

Step into induction hardening best practices with detailed guidance on process parameters, material selection, and CNC integration to extend part life and optimize manufacturing efficiency.

Introduction

High-wear components such as gears, shafts, and cams often face surface fatigue, wear, and premature failure, leading to costly repairs, downtime, and rework. Manufacturers need a reliable solution to enhance durability while maintaining the mechanical integrity of these critical parts.

Induction hardening provides a precise and efficient method to strengthen the surface of metal components without compromising the ductile core. By combining rapid electromagnetic heating with controlled quenching, it significantly improves wear resistance and fatigue life.

What Is Induction Hardening?

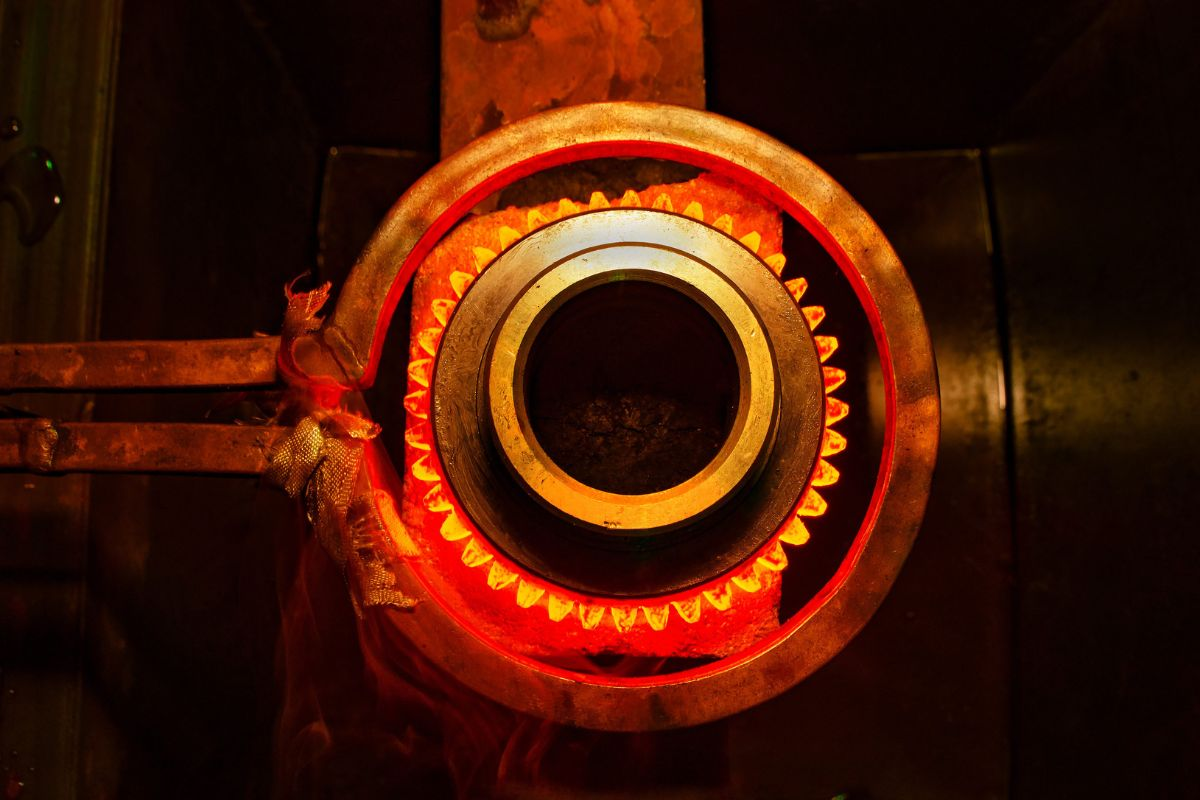

Source: leadrp.net

Induction hardening is a surface heat treatment process for metals. The process involves placing a metal part inside an induction coil.

A high or medium frequency alternating current (AC) is passed through the coil, which quickly generates heat on the part's surface, bringing it to the required temperature for hardening.

The part is then immediately and rapidly cooled (quenched), typically with a water-based liquid, hardening only the surface layer.

Physical Principles

The success of induction hardening relies on three key principles:

Electromagnetic Induction Heating:

When AC flows through the induction coil, it creates a changing magnetic field. This field induces electrical currents, called "eddy currents," inside the conductive metal part.

As these currents flow against the material's electrical resistance, they generate intense heat (Joule heat), allowing for rapid, non-contact heating.

Skin Effect:

The higher the frequency of the AC, the more the eddy currents concentrate near the surface of the conductor.

This physical phenomenon, known as the skin effect, allows engineers to precisely control the depth of heating by selecting the right frequency. High frequencies result in a shallow hardened layer, while medium frequencies create a deeper one.

Martensitic Transformation:

For materials like steel, when the surface is heated quickly above a critical temperature, its crystal structure changes to austenite.

The immediate rapid cooling (quenching) that follows prevents the structure from returning to its original, softer state. Instead, it transforms into martensite, a very hard and fine needle-like structure.

This transformation is the reason for the significant increase in surface hardness.

The Process and Key Elements

Standard Process Steps

A complete induction hardening cycle typically includes four steps:

Loading and Positioning:

The part is accurately placed within the induction coil. The gap between the part and the coil is critical for uniform and efficient heating.

Induction Heating:

The power supply is turned on to heat the part for a set time at a specific power level. This step usually takes only a few seconds.

Quenching:

Immediately after heating, a cooling liquid is sprayed onto the part or the part is dipped into a quench tank to cool it rapidly.

Tempering:

After quenching, the hardened layer is very hard but also brittle. A low-temperature heating process called tempering is often performed to reduce stress and increase toughness while maintaining high hardness.

Critical Process Parameters

Frequency:

Determines the depth of the hardened layer.

The higher the frequency, the shallower the hardened depth on the part's surface; conversely, the lower the frequency, the deeper the hardening.

Power Density:

Affects the heating speed.

The higher the power density, the less time is needed for heating, which increases production speed; it also helps prevent the part's core from being damaged by excess heat.

Heating Time:

Works with power to determine the final temperature and heat depth. The longer the heating time, the deeper the hardened layer on the part's surface becomes; however, too much time can cause the part to bend or crack.

Quenching Rate:

Affects the final hardness and quality of the hardened layer.

The faster the quenching rate, the higher the final surface hardness will be.

Air Gap:

The distance between the coil and the part, which influences heating efficiency.

The smaller the air gap, the faster the part heats up and the less electricity is used; but if the gap is too small, it can create sparks that damage both the part and the equipment.Classifications of Induction Hardening

Induction hardening can be categorized in several ways, which helps in choosing the right process for a specific part and production need.

By Process Method

Single-Shot Hardening (Static Hardening):

The entire area to be hardened is heated all at once and then quenched. The part and coil remain stationary during heating. This method is very fast and suitable for short or complex parts like gears and bearings. It requires a high-power supply.

Scanning Hardening (Progressive Hardening):

Only a small section of the part is heated at a time. The part or the coil moves at a constant speed, so the heating zone "scans" across the surface until the entire length is hardened. This method is ideal for long parts like shafts and guideways and requires less power.

By Power Source Frequency

High Frequency (HF) (100 kHz - 500 kHz+)

Creates a shallow hardened layer (0.5 mm - 2.0 mm). Used for small, precise parts like small gears and valves.

Medium-High Frequency (MF/SAF) (10 kHz - 100 kHz)

Creates a medium-depth layer (1.5 mm - 5.0 mm). This is the most common range, used for parts like automotive crankshafts and drive shafts.

Medium Frequency (MF) (1 kHz - 10 kHz)

Creates a deep hardened layer (>4.0 mm). Used for large, heavy-duty parts like rolling mill rolls and large pins for construction machinery.

Dual Frequency

An advanced process combining two frequencies to achieve an optimal hardness profile, especially useful for complex shapes like gear teeth.

By Hardening Location

External Hardening: Hardening the outer surface of a part. This is the most common application, used for shafts, pins, and gears.

Internal Hardening: Hardening the inside surface of a hollow part, like a cylinder or tube. This requires a specially designed internal coil.

Category | Type | Key Features | Typical Applications |

|---|---|---|---|

Process Method | Single-Shot | Heats all at once, fast cycle, high power | Gears, bearings, short shafts |

Scanning | Heats progressively, for long parts, low power | Long shafts, guideways, rods | |

Frequency | High (HF) | Shallow depth (0.5-2.0mm) | Small, precision parts |

Medium (MF/SAF) | Medium depth (1.5-5.0mm), most common | Crankshafts, drive shafts, gears | |

Medium (MF) | Deep depth (>4mm) | Large, heavy-duty parts, rolls | |

Location | External | Hardens outer surfaces, very common | Shafts, gears, pins |

Internal | Hardens inner bores, needs special coils | Cylinders, tubes, sleeves |

Materials Applicable to Induction Hardening

Two Core Requirements for Induction Hardening

A material must meet two essential requirements to be suitable for induction hardening.

1. Physical Requirement: Ability to Be Heated by Electromagnetism

Induction hardening uses an electromagnetic field to heat the part. Therefore, the material must conduct electricity.

It is also best if the material is magnetic (like steel), as this makes the heating process faster and more efficient. Non-conductive materials like plastics and ceramics cannot be used.

2. Metallurgical Requirement: Ability to Be Hardened by Quenching

Hardening occurs during the rapid cooling (quenching) step that follows heating.

The material's internal structure must be able to transform and become hard through this heat-and-quench cycle.

This property is primarily found in steel and cast iron with sufficient carbon content. Carbon is the key element for hardening. Other metals, such as aluminum and copper, cannot be hardened this way.

CNC Machining and Induction Hardening

Induction hardening is a common and reliable process for CNC machined parts. When the correct metal is used, it can greatly increase the surface hardness and wear resistance of a part.

Common CNC Machining Materials Suitable for Induction Hardening

Material Category | Common Grades / Examples | Suitability Analysis |

|---|---|---|

Medium-Carbon Steel | 1045, 1050 | Most common choice: Ideal for hardening, cost-effective, and widely used for shafts, pins, and gears. |

Alloy Steel | 4140, 4340 | Stronger choice: Alloys allow for deeper and more consistent hardening, suitable for high-strength parts. |

Tool Steel | O1, A2, S7 | High-hardness choice: Designed for heat treatment to achieve extreme surface hardness for molds and wear parts. |

Martensitic Stainless Steel | 410, 420, 440C | Specialty choice: One of the few stainless steel types that can be hardened, used when hardness and corrosion resistance are needed. |

Ductile Iron | Grade 65-45-12, Grade 80-55-06 | Economical choice: Often used for cast parts that are then CNC finished, such as camshafts, to create a wear-resistant surface. |

3D Printing and Induction Hardening

Using induction hardening on 3D printed parts is a more complex and less common process. It requires very strict controls, and only specific 3D printed metals are suitable.

A critical prerequisite:

The printed part must be stress-relieved (annealed) before hardening. This removes internal stress from the printing process and prevents the part from cracking during quenching.

3D Printing Metals Suitable for Induction Hardening

Tool Steels:

Grades like H13 and M2 are the most suitable. They are often 3D printed for custom tools and mold inserts and require heat treatment, like induction hardening, to function correctly.

Maraging Steels:

Grades like MS1. These materials are designed for heat treatment to achieve very high strength. Induction heating can be part of their specialized hardening process.

Some Alloy Steel Powders:

Special steel powders similar to traditional alloys like 4140 are available. After printing and proper pre-treatment, they can be induction hardened.

Important Note: Common 3D printing metals like 316L Stainless Steel, Aluminum alloys (e.g., AlSi10Mg), and Titanium alloys (e.g., Ti6Al4V) are not suitable because they lack the "quench-hardening" property.

If you are unsure if the material you have chosen for your project is suitbale for induction hardening or not, talk to Unionfab Experts to check it out.

Advantages and Limitations of Induction Hardening

When planned and executed correctly, induction hardening offers significant performance benefits that make it a preferred choice for many precision-engineered parts.

Key Advantages

Fast and Efficient:

Heating times are measured in seconds, making it ideal for high-volume production.

Precise and Controllable:

Only specific areas of a part can be heated and hardened.

High Quality:

The process creates a fine, hard surface layer with minimal part distortion.

Energy-Efficient and Eco-Friendly:

Heat is generated directly within the part, using less energy. It is a clean process with no smoke or fumes.

Easy to Automate:

The simple process can be easily integrated into automated production lines.

Limitations and Challenges

High Initial Investment:

Induction heating equipment can be expensive to purchase.

Complex Coil Design:

Each different part shape requires a custom-designed coil, which can be costly and time-consuming to develop.

Sensitive to Part Shape:

Very complex shapes can be difficult to heat evenly.

Limited to Certain Materials:

The process works best on materials that can be hardened by heat treatment, such as medium-to-high carbon steels and cast iron.

Unionfab’s Integrated CNC/3DP + Induction Hardening Service

Achieving optimal part performance requires more than just excellent manufacturing—it demands a holistic approach.

At Unionfab, we provide a seamless, end-to-end solution that integrates precision CNC machining and advanced metal 3D printing with critical finishing services like induction hardening.

By managing the entire workflow, we eliminate complexity and ensure every component achieves its specified hardness and durability.

Experience the Unionfab difference with transparent pricing and a special welcome offer:

● Instant Online Quoting:

Discover your project's cost in seconds. Our free calculator provides a comprehensive estimate, including all post-processing services you select.

● 10% Welcome Discount:

We invite you to experience our commitment to quality with a 10% discount on your first order.

FAQs

How long does induction hardening take?

The process typically takes a few minutes per part, depending on material, size, and required case depth.

What are the disadvantages of induction hardening?

High setup costs, potential cracking, and limitations on complex shapes or low-carbon steels are common drawbacks.

What materials can be induction hardened?

Medium carbon steels, certain alloy steels, select stainless steels, and some cast irons are suitable.

What is the difference between quenching and induction hardening?

Quenching is a rapid cooling step used in induction hardening; induction hardening includes both localized heating and quenching to harden the surface.

Can induction hardening cause deformation?

Minimal distortion may occur, but proper fixturing and process control at Unionfab minimize this risk.