Guide to 3D Printing Post-Processing [+Cost Tips]

![Guide to 3D Printing Post-Processing [+Cost Tips]](https://ufc-dtc-cms.oss-accelerate.aliyuncs.com/blog/20250911/194140_o13r98r5b.png)

Learn the basics of 3D printing post-processing methods and how they are priced to choose the best finishing for your 3d printed part.

Introduction

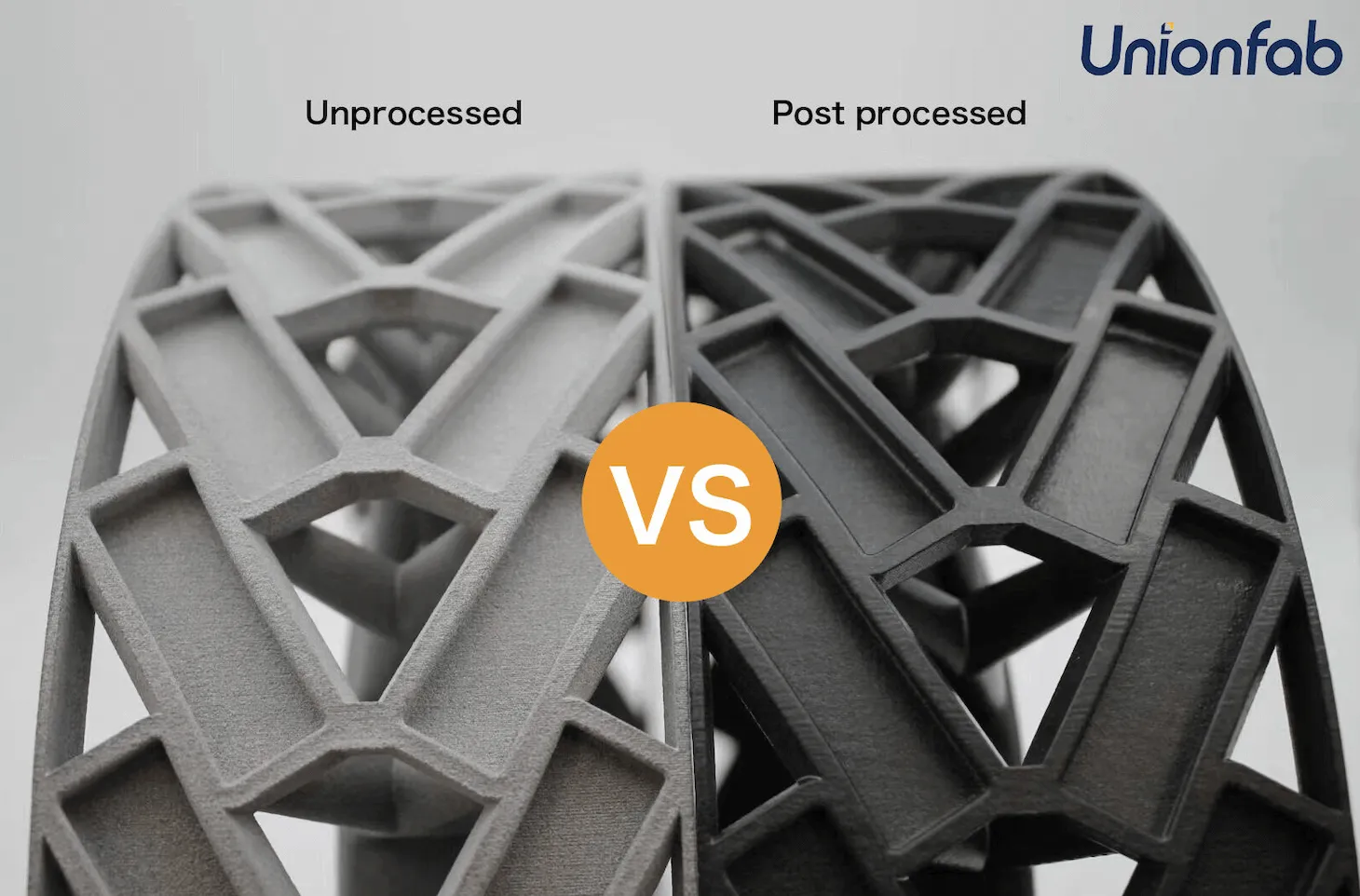

3D printing post-processing is an essential step in additive manufacturing that ensures printed parts meet the requirements for real-world use.

While 3D printing enables rapid prototyping and the creation of complex geometries, raw printed parts often display surface roughness, visible layer lines, residual supports, or limited mechanical strength. Without proper post-processing, most 3D printed components cannot be used as final products.

Put simply, 3D printing makes it possible to create a part quickly, but post-processing is what transforms that part into a functional, reliable, and high-quality product. It is the key stage that bridges the gap between prototype and production, improving surface finish, dimensional accuracy, durability, and overall appearance.

Purposes of 3D Printing Post-Processing

The goals of 3D printing post-processing can be broadly divided into two categories: enhancing physical properties and improving chemical properties of printed parts.

Each purpose directly corresponds to specific post-processing methods and is often driven by the requirements of different industries.

Purpose | Property Category | Common Post-Processing Methods | Typical Industry Needs |

|---|---|---|---|

Surface smoothing & improved aesthetics | Physical | Sanding, polishing, vapor smoothing, painting, dyeing | Medical implants, consumer products, design prototypes |

Dimensional accuracy & precision | Physical | CNC machining, grinding, support removal, infiltration | Aerospace tooling, automotive functional parts |

Enhanced mechanical strength | Physical | Heat treatment, annealing, Hot Isostatic Pressing (HIP) | Aerospace engine components, heavy-duty industrial parts |

Improved wear & corrosion resistance | Chemical | Electroplating, anodizing, powder coating, UV coating | Automotive parts, outdoor equipment, marine components |

Sealing porosity & increasing density | Chemical | Resin infiltration, epoxy coating, thermal sintering | Medical devices, pressure vessels, fluid-handling systems |

Coloring & decorative finishes | Chemical | Dyeing, painting, plating, coating | Consumer goods, fashion, electronics housings |

By aligning the right post-processing method with the desired property enhancement, manufacturers can ensure that 3D printed parts meet strict performance and visual requirements across industries.

If you want to explore the best 3D printing post-processing solution for your project, you can talk to our experts for tailored advice and cost estimates.

Types of 3D Printing Post-Processing

3D printing post-processing techniques vary depending on the material category and the target application.

In general, polymer parts require processes such as sanding, dyeing, or infiltration for better surface finish and aesthetics, while metal parts often undergo heat treatment, machining, or coating for strength and durability.

Material Category | Typical Materials | Common Printing Technologies | Common Post-Processing Methods |

|---|---|---|---|

Polymers | Nylon (PA12, PA11) | SLS, MJF | Cleaning (depowdering, bead blasting); Tumbling; Vapor smoothing; Dyeing; Epoxy/Seal coating; CNC Machining |

ABS | FDM/FFF | Sanding; Vapor smoothing; Painting; Machining | |

PLA | FDM/FFF | Sanding; Epoxy coating; Painting | |

PETG | FDM/FFF | Sanding; Painting (with primer); Flame polishing; Machining | |

TPU | SLS | Dyeing; Cutting/Drilling | |

Photopolymer Resins | SLA | Sanding & polishing; Painting/Coating | |

Metals | Stainless Steel / Tool Steels | SLM/DMLS, Binder Jetting | Heat treatment (annealing, tempering); Surface finishing (CNC, bead blasting); HIP (optional) |

Aluminum Alloys | SLM/DMLS, Binder Jetting | Heat treatment (solution/aging); Surface finishing (CNC, bead blasting); Anodizing | |

Titanium Alloys (e.g., Ti6Al4V) | SLM/DMLS | HIP; Heat treatment; Surface finishing (CNC, bead blasting) | |

Nickel-based Alloys (Inconel) | SLM/DMLS, Binder Jetting | HIP; Heat treatment |

Key Takeaways

Polymers:

● PA12/Nylon → Most common post-processing methods are bead blasting, polishing, and dyeing.

● ABS/PLA/PETG → Mainly support removal, sanding, and painting. Differences: ABS often uses acetone vapor smoothing, PLA often uses epoxy coating, PETG is suitable for flame polishing.

● TPU → Minimal post-processing, mainly dyeing and simple cutting.

● Resins → IPA cleaning + UV curing are essential, followed by polishing/painting.

Metals:

● Steels/Aluminum alloys → Common post-processing includes heat treatment, CNC machining, and surface coatings.

● Titanium alloys/Nickel-based alloys → HIP plus heat treatment are generally required, followed by machining.

● Copper alloys → Post-processing mainly focuses on oxidation protection (plating).

Before diving into each method, it is important to understand that 3D printing post-processing is not a one-size-fits-all solution. The choice of finishing technique depends on several factors, including the printing technology, material type, functional requirements, and cost constraints.

In the following sections, we will provide a detailed overview of the most widely used post-processing methods, explaining their working principles, compatibility, benefits, and limitations—helping you make informed decisions for your project.

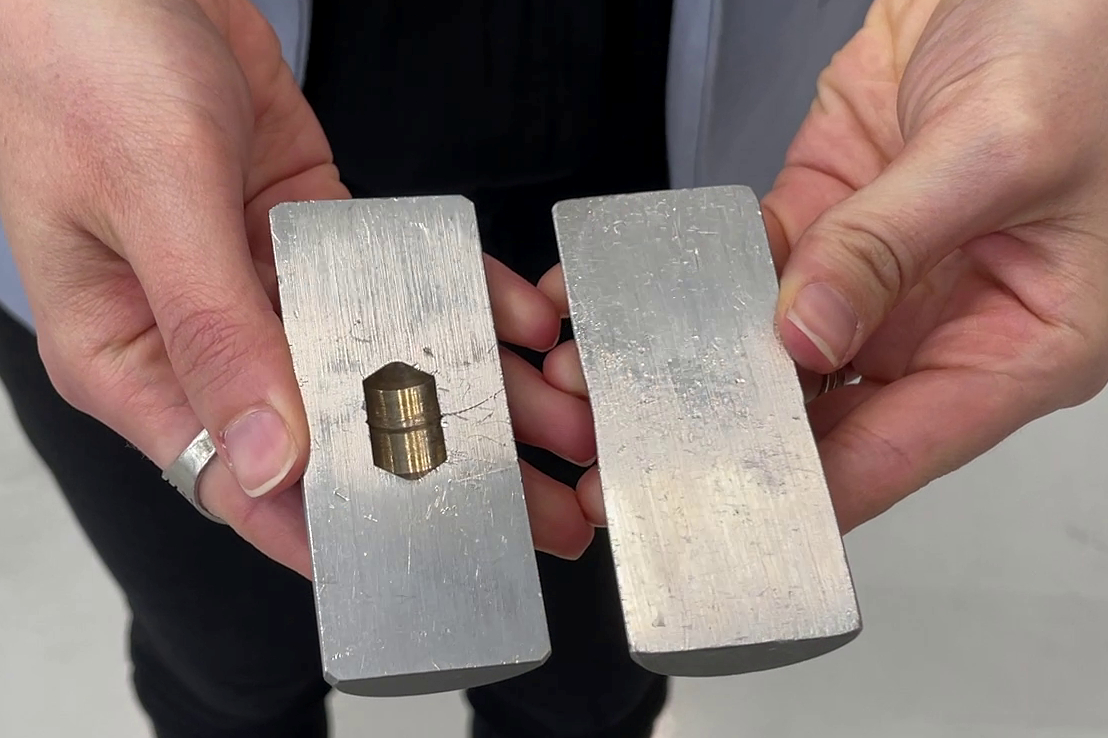

Sanding & Grinding (Polymer/Metal)

Source: makeagif.com

1. What it is

Sanding and grinding are mechanical 3D printing post-processing techniques that use abrasives to remove surface roughness, layer lines, or support marks.

2. Materials & Compatibility

Polymers: PLA, ABS, PETG, Nylon (FDM, SLS, MJF).

Metals: Aluminum, Stainless steel (SLM, DMLS).

3. Purpose

Improve surface smoothness.

Prepare parts for coating, painting, or dyeing.

Correct small dimensional deviations.

4. Process Steps

Coarse sanding → medium sanding → fine sanding or grinding → optional polishing.

Can be manual or machine-assisted.

Curious about the step-by-step approach to sanding, including grit progression and tool tips? Check out Unionfab’s detailed guide, “How to Sand 3D Prints? A Beginner's Guide” to master the sanding workflow and avoid common mistakes.

5. Cost & Efficiency

Low cost, but labor-intensive.

Time-consuming for complex geometries.

Not ideal for high-volume production.

6. Advantages

Simple and widely accessible.

Effective for improving surface finish.

7. Limitations

Limited for intricate geometries.

Risk of altering dimensions or damaging thin walls.

8. Applications

Consumer prototypes requiring smoother aesthetics.

Automotive housings and casings.

Functional prototypes before painting or coating.

Vapor Smoothing (ABS, ASA, Nylon)

Source: fabbaloo.com

1. What it is

Vapor smoothing is a chemical post-processing method where solvent vapors (e.g., acetone) melt the outer layer of a printed part to achieve a smooth, glossy finish.

2. Materials & Compatibility

Polymers: ABS, ASA, Nylon.

Printing methods: FDM, SLS, MJF.

3. Purpose

Eliminate visible layer lines.

Improve surface sealing and reduce porosity.

Enhance aesthetics for consumer products.

4. Process Steps

Expose part to solvent vapor in a controlled chamber → solvent melts surface → smooth finish upon drying.

5. Cost & Efficiency

Moderate cost; semi-automated solutions available.

Fast and suitable for small-batch production.

6. Advantages

Produces glossy, professional appearance.

Reduces porosity, making parts more liquid-resistant.

7. Limitations

Only works with solvent-sensitive materials.

Can weaken fine details if overexposed.

8. Applications

Consumer products (toys, housings), Medical casings requiring smooth surfaces, Aesthetic prototypes.

Looking for detailed guidance on implementing vapor smoothing safely and effectively? Explore Unionfab’s in-depth article, “Vapor Smoothing: Elevating 3D Printing”, which covers best practices, machine setup, and material-specific techniques.

Heat Treatment / Annealing (Metals, High-Temp Polymers)

Source: 3dspro.com

1. What it is

Heat treatment or annealing is a thermal 3D printing post-processing technique used to relieve internal stresses and improve the mechanical strength of printed parts.

2. Materials & Compatibility

Metals: Stainless steel, Aluminum, Titanium (SLM, DMLS).

Polymers: Nylon, ULTEM, PEEK (SLS, FDM).

3. Purpose

Improve strength and thermal resistance.

Enhance dimensional stability.

Relieve residual stress from the printing process.

4. Process Steps

Controlled heating → soaking/holding at target temperature → slow cooling.

For step‑by‑step instructions for annealing different materials, read Unionfab’s detailed guide, “Guide to Annealing 3D Prints [+ Why & How]”.

5. Cost & Efficiency

Medium to high cost depending on furnace setup.

Suitable for both prototypes and production.

6. Advantages

Significant mechanical property improvements.

Enables parts for demanding environments.

7. Limitations

Requires specialized furnaces.

Potential distortion if not controlled.

8. Applications

Aerospace components, Automotive engine parts, High-performance polymer applications.

Hot Isostatic Pressing (HIP)

Source: additivemanufacturing.media

1. What it is

Hot Isostatic Pressing (HIP) is a high-pressure, high-temperature post-processing method that eliminates internal porosity in metal 3D printed parts.

2. Materials & Compatibility

● Metals: Titanium, Inconel, Stainless steel, Cobalt-Chrome.

● Printing methods: SLM, DMLS, EBM.

3. Purpose

● Remove porosity and increase density.

● Enhance fatigue strength and durability.

4. Process Steps

● Place part in HIP chamber → apply high heat and isostatic pressure (inert gas) → cooling.

5. Cost & Efficiency

● High cost, suitable for critical parts.

● Slower process, usually outsourced.

6. Advantages

● Produces near-wrought material properties.

● Greatly increases component reliability.

7. Limitations

● Expensive equipment and processing cost.

● Limited availability.

8. Applications

● Aerospace turbine blades.

● Medical implants (hip/knee replacements).

● High-performance automotive parts.

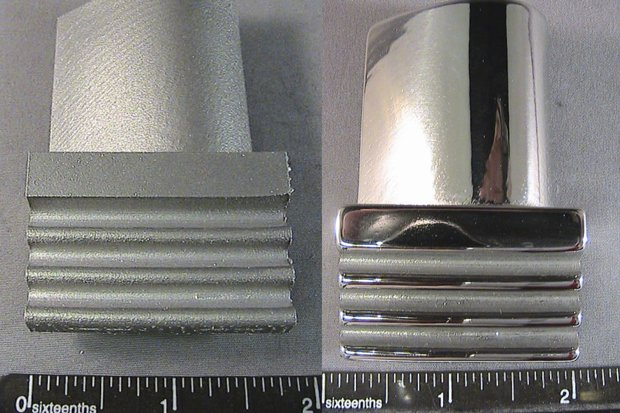

Electroplating / Anodizing

Source: 3dspro.com

1. What it is

Electroplating and anodizing are surface finishing post-processing methods that deposit a protective or decorative layer on the part surface.

2. Materials & Compatibility

Metals: Aluminum (anodizing), Steel (electroplating).

Polymers: Conductive-coated polymers can also be electroplated.

3. Purpose

Improve corrosion resistance and wear resistance.

Enhance appearance with decorative finishes.

4. Process Steps

Surface preparation → electrolyte bath → electrical current application (electroplating) or anodic oxidation (anodizing).

Curious about creating vivid, durable finishes on titanium parts? Explore Unionfab’s comprehensive guide, “Understanding Titanium Anodizing”.

5. Cost & Efficiency

Medium cost.

Scalable for batch production.

6. Advantages

Strong protective coating.

Wide range of decorative options (colors, finishes).

7. Limitations

Limited to certain materials.

May require masking to protect functional areas.

8. Applications

Automotive components, Consumer electronics housings, Aerospace fasteners and brackets.

Painting & Dyeing

Source: 3dnatives.com

1. What it is

Painting and dyeing are post-processing techniques used to add color, branding, or aesthetic finishes to 3D printed parts.

2. Materials & Compatibility

Polymers: Nylon, ABS, PLA, SLA resins.

Metals: Painted after primer or coating.

3. Purpose

Enhance appearance and customization.

Provide basic UV and surface protection.

4. Process Steps

Surface preparation → primer application (if needed) → dyeing or painting → drying.

5. Cost & Efficiency

Low to medium cost.

Fast turnaround, scalable.

6. Advantages

Wide color and finish options.

Simple and effective for consumer parts.

7. Limitations

Limited durability compared to plating or coating.

Requires additional protection for outdoor use.

8. Applications

Consumer goods and prototypes.

Industrial equipment housings.

Fashion and lifestyle products.

Infiltration & Coating (Resins, Porous Polymers)

Source: surfaceengineering.com

1. What it is

Infiltration and coating are 3D printing post-processing techniques that seal porous parts by impregnating them with resin, wax, or epoxy.

2. Materials & Compatibility

Polymers: Nylon (SLS), resin prints (SLA/DLP).

Porous ceramics and sand-printed molds.

3. Purpose

Seal porosity for liquid or gas containment.

Increase strength and durability.

Improve appearance.

4. Process Steps

Clean part → immerse or brush with resin/epoxy → curing.

5. Cost & Efficiency

Medium cost depending on coating method.

Scalable with automated infiltration systems.

6. Advantages

Improves functional performance.

Enhances mechanical properties of porous parts.

7. Limitations

Adds processing time.

May change part color or surface feel.

8. Applications

Medical and dental models.

Functional prototypes requiring airtightness.

Sand cores for casting.

Mirror Polishing

Source: tctmagazine.com

1. What it is

Mirror polishing is a finishing method that uses mechanical or chemical techniques to polish a surface until it achieves a reflective, mirror-like appearance.

2. Materials & Compatibility

Best suited for metal parts such as stainless steel, titanium, or aluminum produced by SLM/DMLS.

Occasionally applied to resin parts from SLA/DLP for aesthetic purposes.

3. Purpose

Improve surface roughness and achieve a high-quality visual appearance.

Enhance corrosion resistance and reduce friction.

4. Process Steps

Coarse grinding → fine grinding → polishing paste application → final precision polishing.

Requires polishing machines, abrasives, and sometimes chemical aids.

For a step-by-step walkthrough on achieving flawless polished metal surfaces, don’t miss Unionfab’s in-depth article, “How to Polish Stainless Steel: Step-by-Step Guide & Tips”.

5. Cost & Efficiency

High cost and time-consuming due to multiple stages.

Not efficient for large-batch production but suitable for high-value parts.

6. Advantages

Produces a highly reflective surface with superior aesthetics.

Improves durability and reduces surface friction.

7. Limitations

Complex geometries are difficult to polish evenly.

Labor-intensive, making it costly for mass production.

8. Applications

Medical implants requiring smooth, non-porous finishes.

Aerospace and automotive components for improved performance.

Luxury goods and molds requiring premium surface quality.

Bead Blasting (Polymer/Metal)

Source: rapiddirect.com

1. What it is

Bead blasting is a 3D printing post-processing method that employs high-pressure streams of small glass or ceramic beads, creating a uniform matte or satin finish while preserving part geometry—ideal for both polymer and metal prints.

2. Materials & Compatibility

Polymers: Nylon (SLS, MJF) and reinforced plastics.

Metals: Aluminum, stainless steel, titanium (from SLM, DMLS, Binder Jetting).

Also used for resin parts needing light surface cleaning.

3. Purpose

Remove powder residue, oxidation, or contaminants.

Create surface uniformity and matte texture.

Prepare parts for painting, plating, or coating.

4. Process Steps

Load part into bead blasting cabinet → subject it to bead blasting using compressed air or centrifugal force → reposition for consistent coverage.

Suitable for manual or automated systems.

For a detailed breakdown of bead blasting media options, equipment, and best practices, check out Unionfab’s comprehensive guide: “A Complete Guide to Bead Blasting.”

5. Cost & Efficiency

Medium cost, scalable for batches.

Fast processing suitable for production environments.

6. Advantages

Delivers consistent, smooth matte finishes.

Preserves tight tolerances and fine features.

Effective on complex geometries.

7. Limitations

Not suitable for achieving glossy finishes.

May slightly erode delicate or thin-walled areas.

Requires dedicated blasting equipment and dust control.

8. Applications

Aerospace and automotive components needing uniform finishes.

SLS/MJF polymer prototypes before dyeing or coating.

Medical instruments requiring clean, sterilized surfaces.

Since there are many different 3D printing post-processing methods, it can be challenging to determine which one best suits your part. Each technique offers unique advantages in terms of surface quality, mechanical performance, cost, and efficiency.

To help you quickly compare options, the following table summarizes the most common post-processing methods, their suitable materials, purposes, and typical applications3D Printing Post-Processing Comparison Table

Post-Processing Method | Suitable Materials | Main Purpose | Cost Level | Efficiency | Typical Applications |

|---|---|---|---|---|---|

Sanding & Grinding | Polymers (PLA, ABS, Nylon), Metals (Aluminum, Steel) | Surface smoothing, dimensional correction | Low | Labor-intensive, slow for complex parts | Consumer prototypes, casings, pre-coating prep |

Vapor Smoothing | ABS, ASA, Nylon (FDM, SLS, MJF) | Smooth glossy finish, reduce porosity | Medium | Fast, semi-automated possible | Consumer goods, medical casings, aesthetic models |

Heat Treatment / Annealing | Metals (Steel, Ti, Al), High-temp Polymers (Nylon, PEEK) | Stress relief, strength & thermal resistance | Medium–High | Moderate, requires furnaces | Aerospace parts, automotive engine components |

Hot Isostatic Pressing (HIP) | Metals (Ti, Inconel, CoCr, Stainless steel) | Eliminate porosity, increase density & fatigue strength | High | Slow, usually outsourced | Aerospace turbines, medical implants |

Electroplating / Anodizing | Metals (Al, Steel), Coated polymers | Corrosion resistance, decorative finish | Medium | Scalable for batches | Automotive parts, electronics housings, aerospace fasteners |

Painting & Dyeing | Polymers (Nylon, ABS, resins), Metals (with primer) | Aesthetics, branding, surface protection | Low–Medium | Fast, suitable for batches | Consumer goods, prototypes, fashion/lifestyle |

Infiltration & Coating | Polymers (SLS Nylon, SLA resins), Ceramics, Sand molds | Seal porosity, improve strength, liquid/gas containment | Medium | Moderate, scalable with systems | Medical models, functional prototypes, casting molds |

Mirror Polishing | Metals (Steel, Ti, Al), some resins (SLA/DLP) | High-reflective finish, reduce friction, corrosion resistance | High | Time-consuming, not for mass production | Medical implants, molds, luxury products, aerospace parts |

Bead Blasting | Polymers (Nylon SLS/MJF), Metals (Al, Stainless steel, Ti) | Remove residues, unify matte finish, surface preparation | Medium | Fast, scalable for production | Aerospace and automotive parts, polymer prototypes before dyeing or coating |

No single finishing method is perfect for all cases—your choice should be based on material, application, and budget.

If you are unsure which 3D printing post-processing solution best fits your project, talk to our experts for tailored guidance and cost-effective recommendations.

How Is 3D Printing Post-Processing Priced?

The cost of 3D printing post-processing varies depending on several factors, and it is important for engineers and buyers to understand how pricing is determined.

At Unionfab, we aim to provide transparent and competitive pricing so you can balance quality, functionality, and budget effectively.

Key Factors Affecting Post-Processing Costs

1. Material Type

Polymers vs. Metals: Metal finishing such as heat treatment, HIP, or electroplating is generally more expensive than polymer sanding or dyeing due to specialized equipment and higher energy usage.

2. Part Size and Geometry

Larger or more complex parts require more processing time and handling. Intricate shapes with deep cavities may need advanced finishing techniques such as vapor smoothing or infiltration.

3. Chosen Post-Processing Method

a. Basic finishing (sanding, painting, dyeing) → Low to medium cost.

b. Advanced finishing (mirror polishing, anodizing, CNC machining) → Medium to high cost.

c. High-end finishing (HIP, electroplating) → High cost, usually reserved for aerospace and medical applications.

4. Quantity and Production Scale

a. Single prototypes often involve higher per-unit costs.

b. Batch production allows economies of scale, especially for automated finishing systems.

5. Surface Quality Requirements

Cosmetic prototypes needing a mirror-like finish are more labor-intensive compared to industrial components that only require dimensional correction.

Unionfab Pricing Advantage

At Unionfab, we integrate 3D printing, CNC machining, and post-processing services under one platform. This ensures:

● Optimized workflow → Reduced lead times.

● Cost efficiency → No unnecessary outsourcing.

● Custom quotes → Tailored to your project’s material, geometry, and finishing requirements.

Start your project planning today and instantly Calculate Cost with Unionfab’s online quoting system.

Unionfab’s Post-Processing Capabilities

At Unionfab, we provide an integrated manufacturing service that combines 3D printing, CNC machining, and professional post-processing into a seamless workflow.

This one-stop solution allows us to deliver high-quality parts faster, with consistent performance and cost efficiency.

Whether you need functional prototypes, production-grade components, or polished consumer products, Unionfab ensures the right finishing process for your project.

Polymer Post-Processing Capabilities

Unionfab offers a wide range of finishing options for polymer parts produced via FDM, SLA, SLS, and MJF technologies. From simple prototypes to functional end-use components, we help enhance surface quality, durability, and appearance.

Available Post-Processing for Polymers:

Sanding & Grinding – Smoothens layer lines for functional prototypes.

Vapor Smoothing – Delivers glossy surfaces for ABS, ASA, and Nylon.

Dyeing & Painting – Adds vibrant colors or branding to consumer products.

Infiltration & Coating – Improves density and liquid resistance for SLS Nylon and resin parts.

Metal Post-Processing Capabilities

For metal 3D printed parts (SLM, DMLS, Binder Jetting, EBM), Unionfab provides industrial-grade finishing to meet the highest standards in aerospace, automotive, and medical applications.

Our expertise ensures parts not only look exceptional but also perform reliably under demanding conditions.

Available Post-Processing for Metals

Chrome Plating | Nickel Plating | Tin Plating | Zinc Plating | Powder Coating |

|---|---|---|---|---|

Painting | Anodizing | Sandblasting | Shot Peening | Polishing |

Brushing | Laser Engraving | Blueing | Heat Treatment | Texture Finishing (VDI, SPI, MOLD Texture) |

With Unionfab, you get more than just 3D printing—you get end-to-end manufacturing support with finishing solutions tailored to your industry needs.

Special Offer: Start your next project with Unionfab today and enjoy an exclusive 10% discount on your first post-processing order.

FAQs on 3D Printing Post-Processing

1. What is 3D printing post-processing?

3D printing post-processing refers to all finishing operations performed after a part is printed. These processes improve surface smoothness, mechanical strength, dimensional accuracy, and overall appearance, transforming raw prints into functional and production-ready components.

2. What is the best post-processing method for 3D printing?

The “best” method depends on your goals:

● Strength & durability → Heat treatment, annealing, or Hot Isostatic Pressing (HIP).

● Smooth surface finish → Sanding, vapor smoothing, or mirror polishing.

● Aesthetics → Painting, dyeing, anodizing, or electroplating.

● Cost-effective prototyping → Basic sanding or coating.

3. What is post-processing for FDM 3D printing?

For FDM prints, post-processing typically includes support removal, sanding, vapor smoothing (for ABS/ASA), painting, dyeing, or using XTC-3D epoxy coating to seal layer lines and create a glossy finish.

4. What tools are used in 3D printing post-processing?

Common post-processing tools include multi-grit sandpaper, sanding sponges, rotary tools, polishing compounds, spray systems for painting/dyeing, and specialized 3D print smoothing machines.

5. How do you post-process resin 3D prints?

Resin prints (SLA/DLP) require cleaning in IPA, UV curing, and optional sanding or polishing. For aesthetics and protection, resin parts are often coated, painted, or clear-finished.