Different Types of Coatings [+Cost Guide]

![Different Types of Coatings [+Cost Guide]](https://ufc-dtc-cms.oss-accelerate.aliyuncs.com/blog/20250929/110444_vwn98c8m7.png)

Explore the different types of coatings like powder coating, anodizing, electroplating, and more to choose the right coating for your project.

Introduction

Coatings are protective or decorative layers applied to the surface of materials to improve durability, resistance, and appearance. They are widely used in industries such as automotive, aerospace, electronics, and construction.

Choosing the right coating is crucial because each type offers unique benefits—some focus on corrosion resistance, others on wear protection, heat resistance, or aesthetics. Costs can also vary depending on the material, process, and application requirements.

In this article, we will explore the different types of coatings, their processes, advantages, applications, and cost considerations, along with practical comparison tables to help you make informed decisions.

Functions of Coatings

Coatings serve multiple functions depending on the industry and application. While the most common goal is to protect surfaces, coatings can also improve functionality and aesthetics. The main functions include:

● Corrosion Protection – Prevents metals from rusting or degrading when exposed to moisture, chemicals, or harsh environments.

● Wear and Abrasion Resistance – Extends the lifespan of components exposed to friction or mechanical stress.

● Heat and Chemical Resistance – Protects surfaces operating under high temperatures or in aggressive chemical environments.

● Electrical and Thermal Properties – Some coatings improve conductivity or act as insulators depending on the requirement.

● Aesthetic Enhancement – Adds color, gloss, texture, or decorative finishes to improve product appeal.

● Functional Surfaces – Provides special properties such as hydrophobicity, low friction, or biocompatibility for medical and advanced applications.

By combining these functions, coatings not only protect materials but also add value by making products more durable, efficient, and visually appealing.

Types of Coatings Based on Different Materials

One of the most fundamental ways to classify coatings is by the type of material used in the coating system. Based on this standard, coatings can be grouped into three categories: organic coatings, inorganic coatings, and composite coatings. Each type has unique properties, advantages, and application areas.

Organic Coatings

Organic coatings use polymers or resins as binders. They are widely applied in industrial, automotive, marine, and architectural sectors due to their flexibility, corrosion protection, and decorative potential.

Common Types of Organic Coatings

● Epoxy Coating

Excellent adhesion, chemical resistance, and durability

Often used in pipelines, marine structures, and industrial flooring

● Polyurethane Coating

Superior flexibility, weatherability, and UV resistance

Common in automotive topcoats, protective flooring, and outdoor structures

● Polysiloxane Coating

Hybrid organic–inorganic system with long-lasting gloss and color retention

Provides excellent chemical and weather resistance

Frequently applied in infrastructure, bridges, and offshore facilities

● Alkyd Coating

Cost-effective, easy to apply, with good decorative appearance

Moderate durability, suitable for general-purpose protective coatings

● Intumescent Coatings

Fire-resistant coatings that swell and form an insulating layer under heat

Protect structural steel during fire events in buildings and industrial facilities

● Zinc-Rich Coating

Note: The classification of zinc-rich coatings depends on the binder. When the film-forming material is a resin, it is an organic coating. When it is silicate, it belongs to the inorganic group.

○ Zinc-rich coatings contain more than 80% zinc powder. Their classification depends on the binder system:

Organic Zinc-Rich (Epoxy or Polyurethane based) → belongs to organic coatings because the film-forming material is resin

Inorganic Zinc-Rich (Silicate based) → belongs to inorganic coatings because the binder is a silicate compound

○ Main function: provides cathodic protection for steel, commonly used in heavy-duty corrosion control such as bridges, marine platforms, and pipelines

Inorganic Coatings

Inorganic coatings are based on minerals, oxides, or metallic layers. They are highly valued for their hardness, heat resistance, and strong corrosion protection.

Main Types of Inorganic Coatings

● Ceramic Coating

Thin, durable, and highly resistant to heat and chemicals

Used in automotive paint protection, aerospace turbines, and industrial machinery

● Oxide Coating

Produced through oxidation processes (e.g., anodizing aluminum)

Improves corrosion and wear resistance while offering decorative finishes

● Metal Coating

Metallic layers applied by electroplating, thermal spraying, or galvanizing. Common types include:Zinc Coating (Galvanizing) – strong corrosion resistance for steel structures

Aluminum Coating – excellent oxidation resistance at high temperature

Nickel Coating – enhances hardness, corrosion protection, and conductivity

Chrome Coating – decorative, shiny finish with wear resistance, used in automotive and consumer products

Composite Coatings

Composite coatings combine organic and inorganic materials to achieve multi-functional properties. By integrating polymers, ceramics, or metals, these coatings deliver both protective and functional benefits.

Examples of Composite Coatings

● Polymer-Ceramic Composites – combine polymer flexibility with ceramic hardness and heat resistance

● Metal-Matrix Composites – enhance wear and corrosion resistance while keeping high structural strength

● Hybrid Coatings with Nanomaterials – epoxy, polyurethane, or siloxane systems reinforced with silica, graphene, or other nanoparticles for enhanced durability, chemical resistance, and hydrophobic properties

Composite coatings are increasingly applied in aerospace, automotive, electronics, and medical devices where advanced performance is required.

Summary of Material-Based Coating Classification

To make the differences clearer, the table below summarizes the main types of coatings based on their material systems. It highlights typical examples, core properties, and application areas so that engineers, manufacturers, and designers can quickly identify which coating is best suited for their projects.

Category | Common Types | Key Properties | Typical Applications |

|---|---|---|---|

Organic | Epoxy, Polyurethane, Polysiloxane, Zinc-Rich (organic), Alkyd, Intumescent | Adhesion, flexibility, corrosion resistance, decorative finishes | Industrial equipment, marine, automotive, architecture |

Inorganic | Ceramic, Oxide, Metal (zinc, aluminum, nickel, chrome) | Hardness, heat resistance, wear and corrosion protection | Aerospace, automotive, construction, electronics |

Composite | Polymer-ceramic, Metal-matrix, Hybrid nanomaterials | Multi-functional properties, advanced durability | Aerospace, electronics, medical, high-performance products |

By classifying coatings according to their material systems, it becomes easier to understand their functional differences, performance levels, and best-fit applications. Next, we will look into the cost of different coatings and how to compare them effectively.

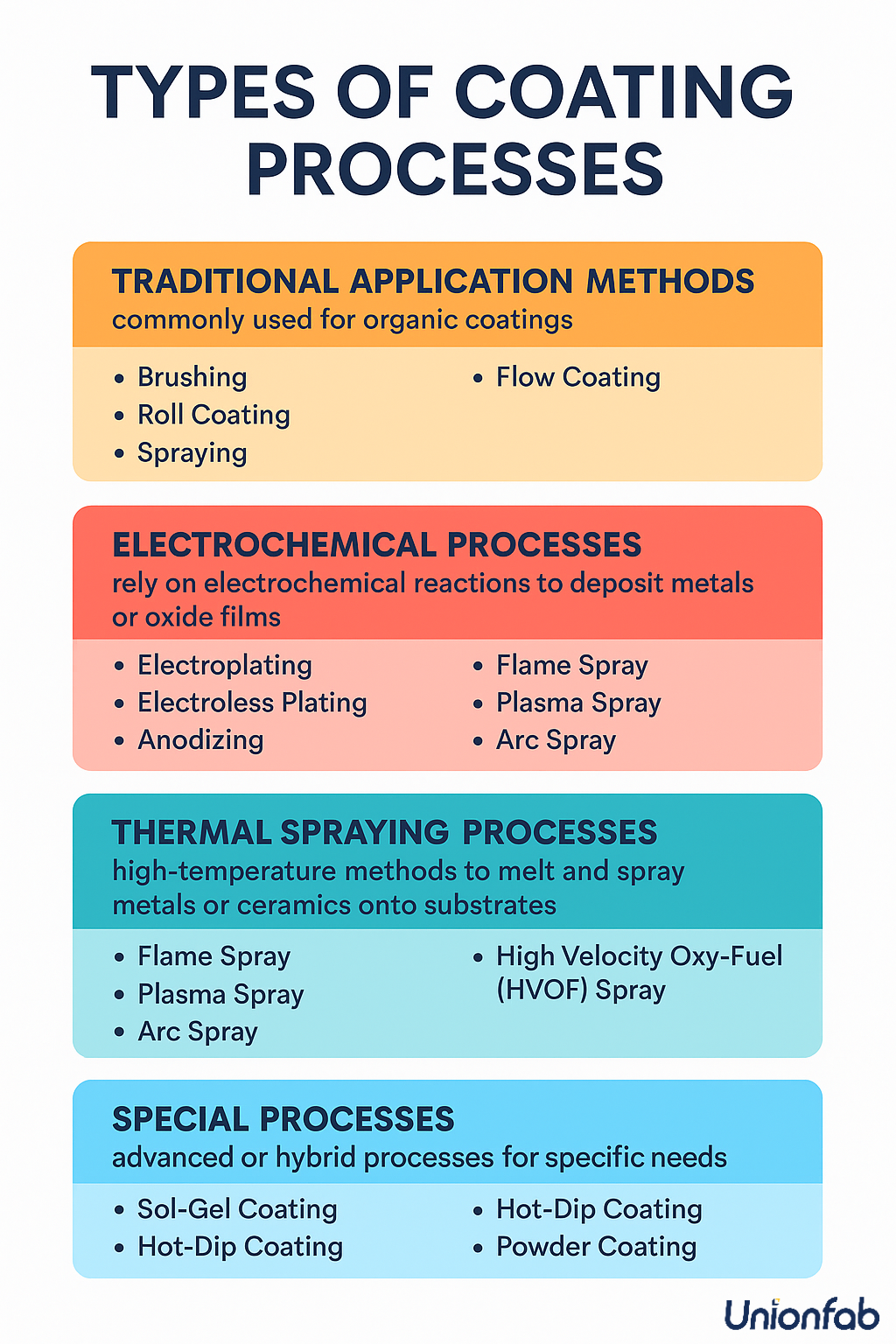

Coating Processes

Different coating processes are selected based on the type of material, required performance, and application environment. Below are the main categories of coating processes:

Traditional Application Methods

Commonly used for organic coatings:

● Brushing – Simple, suitable for small areas or repairs

● Roll Coating – Often used for floors and large wall surfaces

● Spraying – Air spray, airless spray, or electrostatic spray; provides uniform coverage with high efficiency

● Dip Coating – Ideal for small parts and mass production

● Flow Coating – Coating flows over the surface, often used for complex shapes and high-quality finishes

Electrochemical Processes

Rely on electrochemical reactions to deposit metals or oxide films:

● Electroplating

● Electroless Plating

● Anodizing

● Electrophoretic Coating (E-coating)

Thermal Spraying Processes

High-temperature methods to melt and spray metals or ceramics onto substrates:

● Flame Spray

● Plasma Spray

● Arc Spray

● High Velocity Oxy-Fuel (HVOF) Spray

Vacuum Deposition Processes

Used for high-performance thin films:

● PVD (Physical Vapor Deposition) – evaporation coating, magnetron sputtering

● CVD (Chemical Vapor Deposition) – commonly used for hard coatings such as TiN, Al₂O₃

Special Processes

Advanced or hybrid processes for specific needs:

● Sol–Gel Coating – Used for organic–inorganic hybrids and functional films

● Hot-Dip Coating – e.g., hot-dip galvanizing, hot-dip aluminizing

● Powder Coating – Electrostatic adsorption + high-temperature curing, eco-friendly and durable

Application Guide for Common Coating Materials

The table below compares different coating materials with their functions, main processes, and typical applications.

Material System | Subcategory | Main Functions | Common Coating Process | Typical Applications |

|---|---|---|---|---|

Organic Coatings | Epoxy Coating | Strong adhesion, chemical resistance, excellent protection | Brush, Spray, Roller, Powder Coating | Steel structures, storage tanks, pipeline protection |

Polyurethane Coating | Weather resistance, wear resistance, gloss and color retention | Spray, Roller, Brush | Automotive paints, floor coatings, wood coatings | |

Polysiloxane Coating | Superior weathering, UV resistance, corrosion resistance, gloss retention | Spray, Roller, Brush | Marine engineering, bridges, storage tanks, building exteriors | |

Zinc-Rich Coating | Cathodic protection, anti-corrosion | Spray, Brush, Roller (organic binder) / Inorganic silicate binder | Steel structures, ships, offshore platforms, pipelines | |

Alkyd Coating | Low cost, easy application, moderate weathering resistance | Brush, Spray, Roller | General metal parts, wood coatings | |

Intumescent Coatings | Expand and form insulating layer during fire | Spray, Brush | Steel fire protection, wood flame retardancy, tunnels, cable fireproofing | |

Inorganic Coatings | Metallic Coating | Corrosion resistance, wear resistance, conductivity, decoration | Electroplating, Hot-dip Galvanizing, Thermal Spraying | Galvanized steel, nickel-plated parts, chrome-plated decorations |

Ceramic Coating | High-temperature resistance, wear resistance, insulation | Plasma Spraying, HVOF, PVD/CVD | Turbine blades, electronic insulation layers | |

Oxide Film Coating | Corrosion resistance, hardness improvement, decorative finish | Anodizing, Chemical Oxidation | Anodized aluminum, titanium oxide film | |

Composite Coatings | Organic–Inorganic Hybrid | Scratch resistance, wear resistance, transparency | Sol–Gel, Dip Coating, Spray | Smartphone screens, optical lenses |

Metal–Ceramic Composite | Wear resistance, corrosion resistance, high-temperature resistance | Thermal Spraying, Composite Electroplating | Pumps, valves, cutting tools, aerospace components | |

Polymer–Nanocomposite | Enhanced barrier properties, conductivity, anti-aging | Solution Blending + Spray/Brush, Electrochemical Deposition | Anti-corrosion coatings, anti-static coatings | |

Self-Healing Coating | Automatic scratch repair, long-term corrosion protection | Microcapsule/Polymer Embedding + Spray/Brush | Marine engineering, oil pipelines, aerospace |

Summary

The choice of coating process depends largely on the material system and the performance requirements of the application.

● Organic coatings are widely used for general protection and decoration, offering a balance of cost and performance.

● Inorganic coatings deliver superior resistance to corrosion, wear, and heat, making them suitable for demanding industrial environments.

● Composite coatings provide multi-functional performance such as self-healing, high durability, or enhanced barrier properties, ideal for advanced applications.

Selecting the right combination of material and process ensures that coatings not only protect but also add long-term value to products.

At Unionfab, we provide a full range of coating and finishing services, including powder coating, anodizing, electroplating, and advanced finishing options. Talk to our experts today to get tailored advice for your project.

Advantages and Disadvantages of Coating

Like any surface treatment, coatings come with both benefits and limitations. Understanding these helps in choosing the right coating system for each application.

Source: Coating Systems

Advantages of Coating

● Corrosion Protection – Prevents rust and chemical damage, extending product lifespan.

● Wear Resistance – Reduces abrasion and mechanical damage in moving parts.

● Heat and Chemical Resistance – Certain coatings withstand extreme temperatures and aggressive chemicals.

● Improved Aesthetics – Enhances appearance with colors, gloss, textures, or decorative metallic finishes.

● Functional Properties – Provides hydrophobicity, conductivity, insulation, or fire resistance depending on the coating type.

● Cost-Effective Maintenance – Extends maintenance cycles and lowers long-term repair costs.

Disadvantages of Coating

● Application Cost – Advanced coatings such as PVD or ceramic can be expensive.

● Process Limitations – Some coatings require specific equipment (e.g., curing ovens, vacuum chambers).

● Environmental Concerns – Traditional paints and electroplating generate VOCs or chemical waste.

● Durability Differences – Not all coatings last equally; painting may require frequent reapplication.

● Material Compatibility – Certain coatings are limited to specific substrates (e.g., anodizing only works for aluminum, magnesium, and titanium).

Cost of Different Coatings

The cost of a coating depends on factors such as material system, coating thickness, surface preparation, and application method. Below is a general comparison of the cost levels for common organic and inorganic coatings:

Coating Type | Cost Level | Cost Drivers | Typical Cost Characteristics |

|---|---|---|---|

Epoxy Coating | Medium | Resin quality, thickness, curing process | Affordable with good long-term durability |

Polyurethane Coating | Medium-High | UV stabilizers, gloss retention, color requirements | Slightly higher than epoxy due to better weather resistance |

Polysiloxane Coating | High | Hybrid formulation, advanced weathering resistance | Premium cost for long service life |

Zinc-Rich Coating | Medium-High | Zinc content (>80%), binder type (organic or inorganic) | Cost rises with higher zinc content and silicate binders |

Alkyd Coating | Low | Simple formulation, basic application | Budget-friendly but shorter lifespan |

Intumescent Coatings | High | Fire-protective formulation, film thickness | Expensive but necessary for fireproofing standards |

Metallic Coating | Medium-High | Electroplating, galvanizing, hot-dip process | Cost depends on metal type (zinc vs. chrome vs. nickel) |

Ceramic Coating | High | Thermal spray, PVD/CVD application | High cost but offers excellent high-temp protection |

Oxide Film Coating | Medium | Anodizing or chemical oxidation | Competitive cost for aluminum protection and coloring |

Note: Organic coatings such as alkyd and epoxy are the most cost-effective, while inorganic coatings like ceramic and metallic finishes can be significantly more expensive due to specialized processes.

For accurate project pricing, use Unionfab’s Cost Calculator or talk to our experts for tailored recommendations.

Comparison of Different Coatings

The following table compares organic and inorganic coatings in terms of durability, appearance, and typical applications.

Coating Type | Material Category | Durability | Appearance Options | Best Applications |

|---|---|---|---|---|

Epoxy Coating | Organic | High – excellent adhesion and chemical resistance | Limited colors, matte/gloss | Pipelines, marine, flooring |

Polyurethane Coating | Organic | High – flexible, UV resistant | Glossy, long-term color retention | Automotive paints, floors, wood |

Polysiloxane Coating | Organic | Very High – hybrid weathering protection | Excellent gloss and color stability | Bridges, marine, infrastructure |

Zinc-Rich Coating | Organic / Inorganic (depends on binder) | Very High – cathodic protection | Grey metallic finish | Bridges, offshore platforms, pipelines |

Alkyd Coating | Organic | Medium – economical but less durable | Wide color range | General-purpose metal and wood |

Intumescent Coatings | Organic | High – expands under fire | Usually white, can be top-coated | Fireproofing of steel structures |

Metallic Coating | Inorganic | Very High – corrosion and wear resistance | Shiny decorative metallic | Galvanized steel, nickel/chrome plating |

Ceramic Coating | Inorganic | Very High – heat and chemical resistance | Glossy protective layer | Aerospace turbines, automotive exhaust |

Oxide Film Coating | Inorganic | High – anodized or oxidized finish | Can be dyed in many colors | Aluminum frames, electronics, aerospace |

Summary:

● Organic coatings (epoxy, polyurethane, polysiloxane, alkyd, intumescent) → cost-effective and versatile for general protection, decoration, and fireproofing.

● Inorganic coatings (metallic, ceramic, oxide films) → higher cost but superior durability, heat, and corrosion resistance for harsh environments.

● Zinc-rich coatings are special: they belong to organic or inorganic systems depending on the binder, but always provide exceptional corrosion protection for steel.

Conclusion

Coatings are essential for protecting materials, extending service life, and improving both functionality and appearance across a wide range of industries. From economical options such as epoxy and alkyd coatings to advanced solutions like ceramic and metallic finishes, each type offers distinct advantages and limitations.

The best coating choice depends on factors such as the application environment, base material, budget, and performance requirements. By understanding the differences between organic, inorganic, and composite coatings, as well as their cost implications, manufacturers and designers can make smarter decisions that balance durability, aesthetics, and long-term value.

FAQs

How many types of coatings are there?

There are many types of coatings used across industries, but the most common include powder coating, anodizing, electroplating, painting, ceramic coating, and PVD coating. Each type serves different purposes such as corrosion protection, wear resistance, or decorative appearance.

What are the different types of coatings for metal?

The most common types of coatings for metal are:

● Powder coating – durable, eco-friendly finish

● Anodizing – corrosion-resistant, mostly for aluminum

● Electroplating – shiny metallic finish with added protection

● Painting – versatile and cost-effective

● PVD and ceramic coatings – high-performance protective finishes

What are the classification of coatings?

Coatings can be broadly classified into:

● Protective coatings – to prevent corrosion, wear, or heat damage

● Decorative coatings – to improve appearance with color or finish

● Functional coatings – to provide specific properties like conductivity, hydrophobicity, or biocompatibility

What is the best type of coating?

The “best” coating depends on the application:

● For low-cost protection → painting

● For durability and eco-friendliness → powder coating or anodizing

● For high-performance and premium parts → ceramic or PVD coatings

No single coating is best for all cases—it should match the project requirements.

What are the different types of coatings and their uses?

● Powder Coating – durable finish for automotive and appliances

● Anodizing – corrosion-resistant finish for aluminum products

● Electroplating – decorative metallic layer for jewelry and electronics

● Painting – cost-effective option for construction and consumer goods

● Ceramic and PVD Coatings – high-performance protection for aerospace, automotive, and cutting tools

What are the types of industrial coatings?

Industrial coatings include powder coating, anodizing, electroplating, ceramic coating, and PVD. These are widely applied in automotive, aerospace, machinery, and construction industries to improve durability, reduce maintenance, and enhance performance.