Unilateral Tolerance 101 [+Practical Examples]

![Unilateral Tolerance 101 [+Practical Examples]](https://ufc-dtc-cms.oss-accelerate.aliyuncs.com/blog/20250927/000936_50a08o0z9.png)

Discover unilateral tolerance: definition, examples, GD&T, Cpk, and conversion methods for reliable design and manufacturing quality.

Introduction

In manufacturing and engineering design, tolerance refers to the allowable variation in a part’s physical dimension. No machining or fabrication process can achieve a “perfect” dimension every time, so tolerances are applied to ensure that components still fit, function, and remain safe even with small deviations. Properly defined tolerances are essential for assembly compatibility, product reliability, performance, and safety.

Among different tolerance systems, unilateral tolerance is one of the most widely used. A unilateral tolerance allows variation in only one direction (either positive or negative) from the nominal dimension. This contrasts with bilateral tolerance, where variation is permitted in both directions around the nominal value.

Understanding unilateral tolerance helps engineers and quality professionals reduce risk of assembly issues, optimize cost, and improve manufacturing efficiency.

In this article, we will explain its definition, practical examples, comparisons with other systems, interpretation methods, quality control using Cpk, and conversion approaches.

What is Unilateral Tolerance?

Unilateral tolerance is a system of dimensional control where the permitted variation exists only on one side of the nominal (basic) dimension. Unlike bilateral tolerance, which distributes the variation above and below the nominal, unilateral tolerance restricts the deviation to a single direction.

Symbols and Notation

Unilateral tolerance is typically expressed as:

● 0.05 / −0.00 → variation allowed only in the positive direction

● 0.00 / −0.10 → variation allowed only in the negative direction

This makes it clear that the dimension may either stay exactly at the nominal or deviate in one specific direction only.

Why It Is Used

Engineers choose unilateral tolerances when functionality depends on preventing change in one direction. Typical cases include:

Interference fits – ensuring shafts do not exceed the hole size

Strength-critical parts – preventing thickness reduction below a safe limit

Sealing surfaces – avoiding gaps that would cause leaks

Relationship to Limit Dimensions

In unilateral tolerances, the nominal dimension coincides with one material condition (either MMC or LMC), while the other condition is defined by the tolerance limit. For example,

If variation is only negative (+0.00/−0.10), the nominal corresponds to MMC and the tolerance defines LMC.

If variation is only positive (+0.05/−0.00), the nominal corresponds to LMC and the tolerance defines MMC.Examples of Unilateral Tolerance

Unilateral tolerances are widely applied in mechanical design, especially when one direction of variation could compromise fit, function, or appearance. Below are some common examples.

Typical Component Examples

These examples show below how unilateral tolerance ensures that critical functional requirements are protected. For shafts, the tolerance prevents under-sizing that could weaken press fits. For holes, it avoids excessive clearance that would reduce stability.

For thickness, it guarantees structural integrity by disallowing material thinner than specified. In each case, the tolerance zone is shifted in the direction that preserves assembly performance, strength, or sealing reliability.

Component | Nominal Dimension | Tolerance | Allowed Direction | Functional Logic |

|---|---|---|---|---|

Shaft | Ø10.00 | ● 0.02 / −0.00 | Only larger | Shaft must never be undersized to maintain proper interference or press fit. |

Hole | Ø20.00 | ● 0.00 / −0.10 | Only smaller | Hole must not exceed nominal size to avoid excessive clearance. |

Thickness | 3.00 mm | ● 0.20 / −0.00 | Only thicker | Sheet or gasket must not be thinner than nominal to ensure strength or sealing. |

Application Scenarios

● Functional parts (mating surfaces) → shafts and holes where precise fits are required.

● Appearance-critical parts → decorative panels or covers where surface flatness or minimum thickness must be guaranteed.

Case Interpretation

● Shaft Ø10.00 +0.02/−0.00

Allowed direction: Only positive (oversize).

Logic: If the shaft is undersized, it may loosen in its mating hole; oversizing still allows interference.

● Hole Ø20.00 +0.00/−0.10

Allowed direction: Only negative (undersize).

Logic: A larger hole risks too much clearance, reducing stability. A slightly smaller hole still guarantees press-fit assembly.

● Thickness 3.00 +0.20/−0.00

Allowed direction: Only positive (thicker).

Logic: A thinner section would reduce load-bearing capacity or compromise sealing. Extra thickness improves durability.

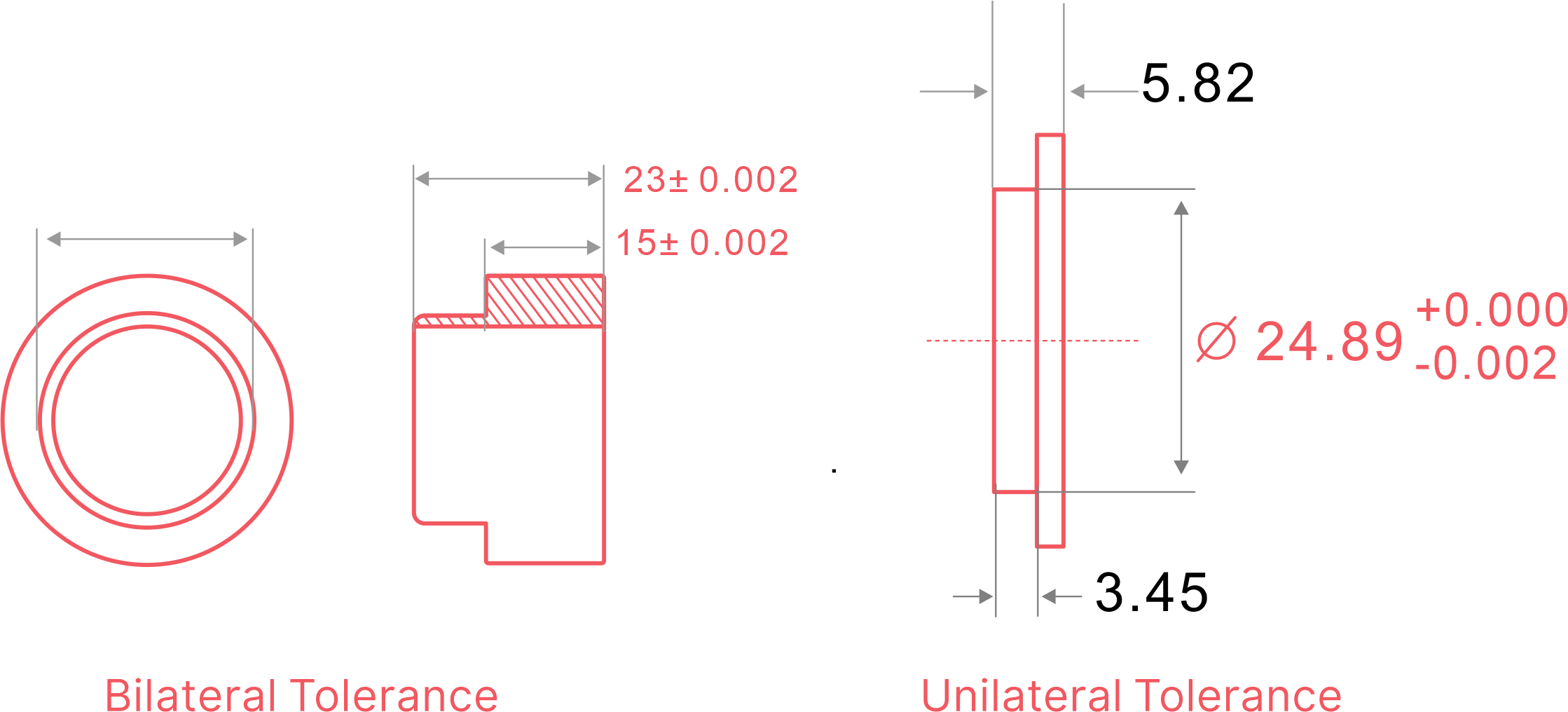

Unilateral Tolerance vs. Bilateral Tolerance

Source:Aria Manufacturing

Definition Comparison

● Bilateral Tolerance

Variation is permitted in both directions from the nominal dimension.

Example: Ø50.00 ±0.10 → allowed range = 49.90 to 50.10 mm

Can also be asymmetric, e.g., +0.15 / −0.05

● Unilateral Tolerance

Variation is permitted in only one direction from the nominal dimension.

Example: Ø20.00 +0.00 / −0.10 → allowed range = 19.90 to 20.00 mm

Comparison Table

The choice between unilateral and bilateral tolerance depends not only on dimensional control, but also on manufacturing capability, inspection effort, and overall cost efficiency.

The table below highlights the key differences to help engineers decide which tolerance type is most suitable for their design intent:

Aspect | Unilateral Tolerance | Bilateral Tolerance |

|---|---|---|

Control Direction | One-sided (above or below nominal only) | Two-sided (above and below nominal) |

Manufacturing Difficulty | Matches processes with natural bias (e.g., drilling tends to oversize) | Requires controlling both upper and lower deviations |

Inspection Method | Simple check against one boundary | Requires verifying both limits |

Cost Impact | Can reduce scrap if aligned with process trend | May increase cost if process drifts in one direction |

Design Logic | Ideal when only one direction threatens fit or function | Best when both directions matter equally (e.g., symmetry) |

Engineering Application Logic

● Choose Unilateral Tolerance when

Assembly requires interference or clearance control in one direction

Strength, sealing, or safety would be compromised if size decreases below nominal

The manufacturing process naturally drifts one way (e.g., milling removes more material, holes often oversize)

● Choose Bilateral Tolerance when

Symmetry around the nominal is functionally important

Both oversize and undersize are equally undesirable

Aesthetic, balance, or vibration-related factors require centered tolerance

Common Misconception

A common misconception is assuming that bilateral tolerance is always more lenient.

In reality, tolerance strictness depends on the total range, not the format. For example, ±0.05 mm (total 0.10 mm) and +0.00/−0.10 mm (total 0.10 mm) both allow the same deviation, but the distribution of the tolerance zone is different.

Not sure whether unilateral or bilateral tolerance best fits your design? Talk to our expert for tailored guidance on tolerance selection and design optimization.

Unilateral Profile Tolerance

GD&T Basics

In Geometric Dimensioning and Tolerancing (GD&T), profile tolerance controls the variation of a feature’s surface relative to its true profile. It defines a tolerance zone within which the actual surface must lie, ensuring both shape accuracy and functional performance.

Definition of Unilateral Profile Tolerance

A unilateral profile tolerance means that the tolerance zone is shifted to one side of the nominal (true) profile. Instead of being equally distributed inside and outside the design contour, the entire tolerance band lies either fully inside or fully outside the theoretical surface.

Application Scenarios

● Aerospace components (aerodynamic surfaces):

Airflow channels may allow slight bulging outward (to reduce drag variation) but cannot shrink inward, since contraction would disrupt flow or reduce clearance.

● Appearance-critical parts:

Decorative panels or consumer product housings must not sink below the intended design surface, but may protrude slightly outward without affecting function.

Notation Method

Unilateral profile tolerances are commonly written using asymmetric tolerance values. For example:

● 0.6 (0.1 inside / 0.5 outside)

→ The tolerance zone extends 0.1 mm inward and 0.5 mm outward relative to the nominal profile.

This makes it explicit that the surface deviation is allowed in one direction more than the other, or entirely on one side if required.How to Read Unilateral Tolerance on Drawings

Symbol Interpretation

On engineering drawings, unilateral tolerance is easy to spot:

● Upper tolerance = 0 → Only negative deviation is allowed.

○ Example: Ø20.00 +0.00 / −0.10 → dimension may shrink but never exceed nominal.

● Lower tolerance = 0 → Only positive deviation is allowed.

○ Example: Ø10.00 +0.02 / −0.00 → dimension may grow but never undershoot nominal.

Quick Judgement Method

A simple rule of thumb:

● “Only larger allowed” → The lower limit is fixed at nominal.

● “Only smaller allowed” → The upper limit is fixed at nominal.

This way, engineers and inspectors can instantly determine the permissible direction of variation without detailed calculation.

Common Misunderstandings

● Mistaking unilateral for bilateral ± tolerance

○ Some readers assume +0.00/−0.10 equals ±0.05, but in reality the entire zone lies below nominal, not centered.

● Ignoring unilateral limits in tolerance stack-up

○ In assembly tolerance analysis, forgetting a one-sided constraint can lead to clearance gaps or interference issues being overlooked.Unilateral Tolerance in Quality Control

How to Calculate Cpk for Unilateral Tolerance

In quality control, the process capability index (Cpk) is used to measure how well a process stays within tolerance limits. The standard formula is:

Cpk=min(Cpu, Cpl)

where:

● Cpu = \frac{USL - \mu}{3\sigma}]

● Cpl = \frac{\mu - LSL}{3\sigma}]

For unilateral tolerances:

● If only an upper limit (USL) exists → use Cpu only.

● If only a lower limit (LSL) exists → use Cpl only.

Example Calculation

● Nominal = 10.00 mm, Tolerance = +0.02 / −0.00

● USL = 10.02 mm, LSL = 10.00 mm

● Measured: μ = 10.01 mm, σ = 0.003 mm

Cpu=10.02−10.013×0.003=0.010.009=1.11Cpu = \frac{10.02 - 10.01}{3 \times 0.003} = \frac{0.01}{0.009} = 1.11Cpu=3×0.00310.02−10.01 =0.0090.01 =1.11

Since only the upper limit matters, Cpk = Cpu = 1.11.

Interpretation: A Cpk of 1.11 indicates the process is marginally capable. In industry, a Cpk ≥ 1.33 is often considered acceptable, while Cpk ≥ 1.67 is preferred for high-reliability or safety-critical applications. Reducing variation (σ) would improve process robustness.

Unilateral Tolerance Calculator Tools

To simplify evaluation, many online and software-based calculators can handle unilateral tolerance cases.

Common Functions

● Input: nominal dimension, tolerance direction (upper or lower), process mean (μ), and standard deviation (σ)

● Output: pass/fail judgement, process capability index (Cpk), and margin to limit

Application Scenarios

● Engineers quickly verify if a machining or molding process consistently meets one-sided limits

● Useful in first article inspection (FAI) or process validation (PPAP)

Key Considerations

● Different tools may handle one-sided tolerance differently (e.g., some still compute both Cpu and Cpl but ignore one).

● Always confirm the tool’s calculation logic before relying on results in quality reports.

Want to evaluate how tolerance choices affect your production cost? Use our cost calculator to get instant manufacturing insights.

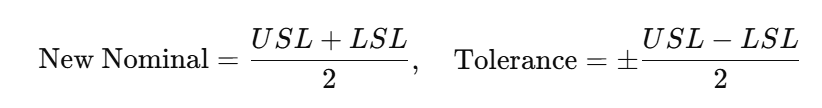

How to Convert Unilateral Tolerance to Bilateral Tolerance

Basic Method

The standard way to convert a unilateral tolerance into an equivalent bilateral tolerance is to keep the same limit dimensions but shift the nominal value to the midpoint of the tolerance zone.

Example

● Original: 10.00 +0.10 / −0.00

○ USL = 10.10, LSL = 10.00

● Converted:

○ Nominal = (10.10 + 10.00) / 2 = 10.05

○ Tolerance = ±(10.10 − 10.00)/2 = ±0.05

● Result: 10.05 ±0.05

This ensures the dimensional limits remain unchanged, even though the nominal shifts.

Application Notes

● The conversion may change the nominal dimension, which can affect tolerance stack-up and datum chain calculations.

● In assembly-critical features, always verify that the new centered nominal does not conflict with functional requirements.

● Before updating drawings or manufacturing processes, confirm with design, quality, and production teams that the converted tolerance is acceptable.Practical Applications of Unilateral Tolerance

Typical Industry Cases

● Automotive:

Shafts and holes in engines or transmission assemblies often use unilateral tolerance to ensure proper interference or clearance fit. For example, a crankshaft journal must never be undersized, otherwise it would compromise bearing performance.

● Aerospace:

Aircraft skin panels and structural joints rely on unilateral profile tolerances. Slight outward bulges may be acceptable, but inward deviations reduce aerodynamic performance or cause assembly interference.

● Mechanical Components:

Threads, seals, and gaskets frequently adopt unilateral tolerances. A sealing surface, for instance, cannot be thinner than specified, otherwise leaks may occur, but slight extra thickness may still function.

Manufacturing Perspective

From a machining viewpoint, unilateral tolerances often align with natural process bias:

● Turning & Milling: tools typically cut material away, so undersizing is more common → tolerances are set to prevent critical undersize.

● Drilling & Boring: holes tend to oversize due to tool deflection → unilateral limits prevent excessive clearance.

● Grinding: precise finishing can approach one-sided control, ensuring parts never fall below the critical minimum size.

Cost and Quality Considerations

● Improved Assembly Success Rate:

● By preventing deviations in the most critical direction, unilateral tolerance reduces the risk of rejected parts during assembly.

● Higher Manufacturing Demands:

Restricting variation to one side often requires tighter process monitoring, higher tool precision, and more frequent inspection, which may raise production cost.

● Balanced Trade-off:

Designers must weigh the benefits of functional reliability against the additional cost and cycle time introduced by stricter one-sided control.

Conclusion

Unilateral tolerance is a fundamental dimensioning approach in engineering design and manufacturing. By allowing deviation in only one direction from the nominal value, it ensures that critical functional requirements—such as assembly fit, sealing reliability, or structural strength—are not compromised.

Throughout this article, we reviewed:

Definition and notation of unilateral tolerance

Practical examples in shafts, holes, and thickness control

Comparison with bilateral tolerance in terms of logic, inspection, and cost

Applications in automotive, aerospace, and precision mechanical components

Integration with GD&T through unilateral profile tolerances

Quality control methods using Cpk and calculation tools

Conversion principles between unilateral and bilateral tolerance

When deciding between unilateral and bilateral tolerance, engineers should base their choice on functional requirements, assembly logic, and manufacturing capability, rather than assuming one is looser or stricter.

Ultimately, unilateral tolerance provides irreplaceable value for function-sensitive parts where variation in one direction would lead to product failure. For engineers seeking deeper expertise, combining unilateral tolerance with GD&T principles offers a comprehensive framework for robust design and quality assurance.

Ready to apply unilateral tolerance in real manufacturing? Start your project with Unionfab today and enjoy 10% off your first order.

FAQs about Unilateral Tolerance

1. What is the difference between a bilateral tolerance and a unilateral tolerance?

A bilateral tolerance allows variation in both directions from the nominal value (e.g., ±0.05 mm), while a unilateral tolerance allows deviation in only one direction (e.g., +0.00/−0.10 mm). Bilateral is often used when symmetry is important, while unilateral is preferred when only one direction of variation affects function.

2. What does unilateral tolerance look like on a drawing?

Unilateral tolerance is shown with one limit set to zero. For example:

● Ø10.00 +0.02/−0.00 → only larger allowed

● Ø20.00 +0.00/−0.10 → only smaller allowed

This ensures the tolerance zone lies entirely on one side of the nominal dimension.

3. What are the three types of tolerances in engineering?

● The main types are:Unilateral tolerance – deviation allowed in one direction only

● Bilateral tolerance – deviation allowed in both directions

● Limit tolerance – expressed as an upper and lower limit (e.g., 19.90–20.00 mm)

4. What is a unilateral system in GD&T?

In GD&T, a unilateral system refers to tolerance zones located entirely on one side of the true profile or nominal value. For instance, unilateral profile tolerance may allow only outward bulging of a surface while preventing inward deviation, ensuring aerodynamic or sealing performance.

5. Are there tools or calculators for unilateral tolerance?

Yes. A unilateral tolerance calculator allows engineers to input the nominal value, tolerance direction, mean (μ), and standard deviation (σ). It outputs pass/fail results, process capability (Cpk), and limits analysis. These tools are widely used in machining validation, quality assurance, and CAD/CAM integration (e.g., in SOLIDWORKS).

6. Can you give some examples of unilateral tolerance applications?

Typical unilateral tolerance examples include:

● Automotive shafts: Ø10.00 +0.02/−0.00 → prevents undersize and ensures press fit

● Aerospace skins: +0.00/−0.20 → prevents inward shrinkage that affects airflow

● Sealing gaskets: 3.00 +0.20/−0.00 → avoids leaks from undersized thickness