Axle Back vs Cat Back Exhaust: Which Is Better?

Discover the key differences between axle back vs cat back exhaust systems, including performance, sound, cost, and installation tips for your next upgrade.

Introduction

When it comes to upgrading a vehicle’s exhaust system, car owners often look for ways to improve both performance and sound quality. A well-designed exhaust not only enhances engine efficiency but also gives the car a more aggressive tone and sporty appearance. However, many drivers find themselves comparing axle back vs cat back systems to decide which option best fits their needs.

Both systems offer unique advantages in terms of power output, sound control, installation complexity, and cost.

This article provides a clear and professional comparison to help you understand the difference between axle-back and cat-back exhaust setups, and how to choose the right one for your car modification goals.

Exhaust System Basics

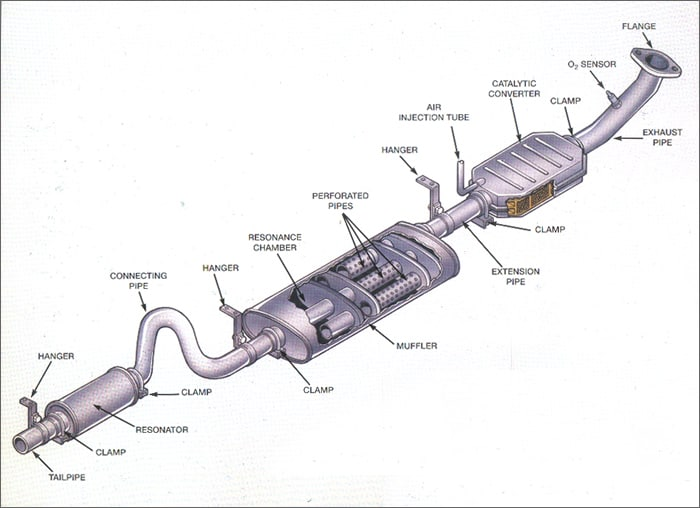

A car’s exhaust system plays a key role in removing combustion gases from the engine while maintaining smooth airflow and noise control. It directly influences the engine’s efficiency, sound, and emission levels.

A typical exhaust system includes the following components:

Source: learnmech.com

● Exhaust manifold (header): Collects exhaust gases from the engine cylinders.

● Catalytic converter: Reduces harmful emissions before gases exit the system.

● Mid-pipe or resonator section: Balances backpressure and modifies sound tones.

● Muffler: Reduces noise produced by exhaust gases.

● Tailpipe: The final section that releases gases into the atmosphere.

When car enthusiasts plan an upgrade, they usually choose from several exhaust configuration types, each covering different portions of the system:

Exhaust Type | Coverage Range | Description |

|---|---|---|

Header-back | From engine header to tailpipe | Complete exhaust replacement; maximum performance gain but high cost. |

Turbo-back | From turbocharger to tailpipe | Ideal for turbocharged engines; improves boost response. |

Cat-back | From catalytic converter to tailpipe | Enhances exhaust flow and sound while keeping emissions legal. |

Axle-back | From rear axle to tailpipe | Simpler, budget-friendly upgrade focusing mainly on sound. |

Understanding how each type works helps you clearly compare cat back vs axle back systems later in the article. By knowing what part of the exhaust each setup replaces, it becomes easier to determine which upgrade aligns best with your performance goals and budget.

What Is an Axle-Back Exhaust System?

An axle-back exhaust system is one of the most popular entry-level exhaust upgrades for car enthusiasts. It refers to the portion of the exhaust that runs from the rear axle to the tailpipe outlet, typically including the muffler, tailpipe, and exhaust tip. This upgrade replaces only the final section of the exhaust system, leaving upstream components such as the catalytic converter and mid-pipe untouched.

In discussions of axle back vs cat back exhaust, the axle-back setup is recognized for providing a clear improvement in sound and appearance while maintaining a reasonable cost and simple installation process.

Source: performancem.co.uk

Main Components of an Axle-Back System

● Muffler: Controls the noise level and exhaust tone. Different muffler designs produce varying sound profiles, from subtle to aggressive.

● Tailpipe: Directs exhaust gases out of the vehicle, influencing flow characteristics.

● Exhaust tip: Adds a refined visual finish and can slightly alter the exhaust tone.

Key Advantages

● Cost-effective: More affordable compared to full-system upgrades.

● Simple installation: Typically bolt-on, requiring no welding or major modifications.

● Enhanced sound: Produces a sportier, deeper exhaust tone.

● Improved aesthetics: Upgraded exhaust tips enhance the car’s rear appearance.

● Emission-compliant: Since it retains the catalytic converter, it usually meets emission regulations.

Limitations to Consider

● Limited performance gains: Does not significantly improve exhaust flow or horsepower.

● Minimal airflow enhancement: The upstream restrictions remain unchanged.

● Primarily for sound and style: Most benefits are auditory and visual rather than performance-based.

Suitable Users

An axle-back exhaust system is best suited for drivers who:

● Want a better exhaust sound without affecting emissions.

● Prefer an affordable and easy exhaust upgrade.

● Focus on aesthetic improvements and moderate customization.

In summary, when comparing axle back vs cat back exhaust, the axle-back option stands out as a budget-friendly and beginner-oriented modification. It enhances sound, style, and driving enjoyment without the complexity or higher costs associated with larger exhaust system upgrades.

What Is a Cat-Back Exhaust System?

A cat-back exhaust system refers to the section of the exhaust that runs from the catalytic converter outlet to the tailpipe tip. It typically replaces the mid-pipe, muffler, and tailpipe, offering a more comprehensive upgrade than an axle-back system. Because it covers a larger portion of the exhaust, it directly improves airflow efficiency, engine response, and sound performance.

In the discussion of cat back exhaust vs axle back exhaust, the cat-back system is known for delivering greater performance benefits due to its broader design coverage and optimized exhaust routing.

Source: afepower.com

Main Components of a Cat-Back System

● Mid-pipe or resonator section: Helps balance exhaust pressure and adjust sound resonance.

● Muffler: Reduces noise while controlling exhaust tone; performance mufflers often provide a deep, powerful sound.

● Tailpipe and exhaust tip: Channels gases out of the system and completes the visual styling.

Key Advantages

● Improved exhaust flow: Reduces backpressure, allowing gases to exit more efficiently.

● Potential power increase: Enhances horsepower and torque, especially when paired with other performance mods.

● Enhanced exhaust tone: Produces a louder, more aggressive sound with a deeper tone.

● Better throttle response: Smoother and quicker acceleration due to improved airflow.

● Durability options: Often built from stainless steel or titanium for long-term performance.

Limitations to Consider

● Higher cost: More expensive than axle-back systems due to larger coverage and materials.

● Complex installation: Requires more tools and may need professional fitting.

● Possible noise regulation concerns: Louder sound levels may exceed local legal limits in some areas.

Suitable Users

A cat-back exhaust is ideal for drivers who:

● Seek performance improvement beyond just sound.

● Have modified or tuned engines requiring better exhaust flow.

● Want a balanced upgrade combining power, sound, and durability.

In comparison to cat back exhaust vs axle back exhaust, the cat-back system offers a wider design scope and a more noticeable boost in performance and sound quality. It’s a premium choice for enthusiasts looking for measurable performance results, not just acoustic upgrades.

Axle-Back vs Cat-Back: Core Comparison Analysis

When deciding between exhaust upgrades, understanding the practical differences between axle back vs cat back systems is essential. Both setups improve exhaust tone and style, but their performance effects, installation complexity, and cost vary significantly.

The table below provides a clear side-by-side comparison to help you choose the right system for your needs.

Comparison Factors | Axle-Back | Cat-Back |

|---|---|---|

Replacement Range | Rear axle to tailpipe | From catalytic converter to tailpipe |

Performance Gain | Limited | Significantly improves exhaust flow and potential horsepower |

Sound Output | Enhanced tone, moderate volume | Deeper and more aggressive exhaust note |

Installation Difficulty | Simple, often bolt-on | More complex, may require professional installation |

Aesthetic Appeal | Improved tailpipe and visual style | Enhanced look with larger piping and polished finishes |

Cost | Lower and budget-friendly | Higher due to more components and materials |

Compliance | Usually keeps catalytic converter | Also retains converter but may exceed local noise limits |

Driving Experience | Better sound feedback | Improved response and overall driving dynamics |

From a performance standpoint, in the cat back vs axle back comparison, the cat-back system clearly offers greater tuning potential. It enhances exhaust flow, reduces backpressure, and may improve engine responsiveness, especially when paired with intake or ECU upgrades. Meanwhile, the axle-back setup remains a smart, affordable choice for car owners who mainly seek a better exhaust note and appearance without major modifications.

Choosing between the two depends on your priorities:

● If you value ease of installation, lower cost, and sound enhancement, the axle-back system is ideal.

● If you seek power gains, broader performance improvement, and a deeper exhaust tone, the cat-back system is the better investment.

Unionfab’s team provides custom exhaust solutions and precision manufacturing for both axle-back and cat-back configurations. Whether you’re upgrading for performance or sound, our experts can help you design and produce the most suitable exhaust system for your vehicle.

Which Materials to Choose for Your System?

The material used in an exhaust system has a direct impact on its performance, weight, durability, and resistance to heat and corrosion. Choosing the right material depends on your driving habits, environment, and performance expectations. A well-selected material ensures longer service life and better exhaust efficiency, especially under high-temperature conditions.

The table below summarizes the most common materials used in axle-back and cat-back exhaust systems, along with their benefits and recommended maintenance practices.

Material | Benefits | Maintenance Notes |

|---|---|---|

Stainless Steel (304 / 316L) | Excellent corrosion resistance and durability; maintains a clean appearance; offers great value for most vehicles. | Clean regularly to remove carbon buildup and road salt. Ideal for daily use and moderate performance setups. |

Titanium | Extremely lightweight; enhances performance by reducing total vehicle weight; superior heat resistance and unique sound quality. | Inspect welds periodically for fatigue. Best suited for high-performance or track vehicles. |

Inconel | Provides unmatched strength under extreme heat; resists oxidation and deformation; used in motorsport and aerospace applications. | Requires little maintenance but has a higher initial cost. Perfect for racing or high-power builds. |

This comparison highlights how different materials influence exhaust system performance and maintenance requirements.

● Stainless steel is the most balanced and cost-effective choice

● titanium focuses on lightweight performance

● Inconel offers the ultimate durability for high-temperature racing conditions

How to Manufacture Your System?

Building a high-quality exhaust system requires precision design, accurate fabrication, and the right choice of materials. Whether you are planning an axle-back or cat-back upgrade, the manufacturing process determines how efficiently the system will perform, how long it will last, and how well it fits your vehicle.

1. Design and 3D Modeling

The process starts with digital design using CAD (Computer-Aided Design) software. Engineers create a model of the exhaust system, testing its airflow, fitment, and heat expansion. During this stage:

● The pipe diameter and bending radius are optimized to maintain smooth airflow.

● Mounting points and brackets are positioned to align with the vehicle chassis.

● Heat distribution and backpressure are analyzed to prevent performance loss.

This stage ensures that the system will fit perfectly and perform efficiently once installed.

2. Material Selection and Preparation

After the design is finalized, materials such as stainless steel, titanium, or Inconel are selected based on performance requirements. The raw tubes are then cut, bent, and shaped according to the design specifications.

● Stainless steel is common for daily driving due to durability and cost balance.

● Titanium and Inconel are used for high-performance or racing systems.

Surface treatments such as polishing, ceramic coating, or heat-resistant painting are often applied to improve corrosion resistance and aesthetics.

3. Fabrication and Assembly

Modern exhaust systems are made using a combination of CNC bending, TIG welding, and laser cutting technologies.

● CNC tube bending ensures accurate curves and smooth internal surfaces.

● TIG welding provides strong, clean joints that resist cracking under heat.

● Components such as mufflers and resonators are welded and assembled according to the layout design.

During assembly, precise alignment is essential to prevent vibration, rattling, or air leaks.

4. Inspection and Testing

Once assembled, the exhaust system undergoes several quality checks:

● Leak testing confirms that all joints and welds are properly sealed.

● Dimensional inspection ensures fitment accuracy for specific vehicle models.

● Sound and flow testing measures exhaust tone and flow efficiency.

These tests ensure the final product delivers consistent performance, meets emission standards, and produces the desired sound level.

5. Finishing and Packaging

Finally, the exhaust system is cleaned, polished, and packed for installation. Some manufacturers offer optional surface finishes—such as brushed metal, matte black, or chrome—for better protection and appearance.

In summary, manufacturing an exhaust system is a combination of engineering precision and material science. Each stage—from digital design to final assembly—affects the system’s efficiency, durability, and sound quality.

Understanding this process helps car owners make more informed decisions when comparing axle-back and cat-back systems in terms of quality and performance.

How to Choose the Right Exhaust System for Your Car?

Selecting the right exhaust upgrade depends on your modification goals, budget, and driving style. Both systems have distinct advantages, and understanding your needs will help you make an informed choice.

In comparing axle back vs cat back exhaust, each system serves different priorities—from affordable sound upgrades to performance-focused enhancements.

1. Define Your Modification Goals

Before upgrading, clarify what you want to achieve:

● Sound optimization: If your goal is a deeper, sportier tone without major modification, the axle-back system is ideal.

● Performance improvement: For drivers aiming to boost power and torque, a cat-back exhaust provides better flow and reduced backpressure.

● Aesthetic upgrade: Both options enhance the car’s rear-end design with polished stainless-steel tips and precision welds.

At Unionfab, we help customers design and manufacture custom exhaust components that combine style and engineering precision. Using CNC machining and 3D printing, Unionfab ensures every part fits perfectly and performs reliably under real driving conditions.

2. Consider Budget and Installation Requirements

Factor | Axle-Back | Cat-Back |

|---|---|---|

Cost | Lower and affordable | Higher but offers greater performance value |

Installation | Easy bolt-on fit, DIY-friendly | Often requires professional installation |

Maintenance | Simple and quick | Slightly more complex due to additional piping |

If you are upgrading primarily for sound enhancement and want to keep costs low, the axle-back option is often the most practical.

However, if you seek performance growth and long-term tuning potential, investing in a cat-back system will yield better value.

3. Match the System to Your Vehicle and Driving Style

● Daily driving: Axle-back systems offer balanced noise levels and simplicity.

● Performance or tuned vehicles: Cat-back systems maximize exhaust flow and responsiveness.

● Track or sport applications: Cat-back systems deliver superior performance under high RPM and load.

4. Plan for Future Modifications

If you plan to upgrade further with intake tuning, ECU remapping, or turbo installation, a cat-back system is more adaptable and future-proof.

At Unionfab, we manufacture high-performance exhaust systems from materials like stainless steel, titanium, and Inconel, ensuring durability, lightweight structure, and optimal flow efficiency—ideal for both axle-back and cat-back configurations.

Get an instant quote for your axle-back or cat-back system. Compare materials, finishes, and manufacturing options in minutes with our online calculator.

Installation and Maintenance Tips

Proper installation and regular maintenance are crucial to ensuring your exhaust system performs well and lasts long. Whether you choose a cat-back or axle-back setup, understanding the installation process and material care can help you avoid noise issues, leaks, or premature wear.

1. Installation Considerations

When fitting an exhaust system, pay attention to the following details to ensure safe and effective operation:

● Pipe diameter compatibility: Match the pipe size with your vehicle’s exhaust ports to prevent flow restriction.

● Gasket and seal integrity: Use new gaskets during installation to avoid exhaust leaks.

● Resonance and vibration control: Ensure proper hanger alignment to minimize unwanted vibration or rattling sounds.

● Thermal clearance: Maintain sufficient space around heat-sensitive components like fuel lines and suspension parts.

● Tightening sequence: Secure bolts gradually from the center outward to ensure even pressure and prevent leaks.

2. Regular Maintenance Tips

Proper maintenance ensures your exhaust system performs efficiently and lasts for years. Even the best materials—such as stainless steel or titanium—can degrade if neglected. Follow these maintenance practices to keep your axle-back or cat-back system in optimal condition:

● Inspect clamps, hangers, and joints every few months to check for rust, looseness, or cracks. Replace damaged parts promptly to prevent leaks or misalignment.

● Clean exhaust tips regularly using mild metal polish to remove carbon buildup, soot, and road debris. This helps preserve appearance and prevents corrosion.

● Check for rattling or unusual noises after long drives. Persistent vibrations or metallic sounds may indicate loose fittings or exhaust resonance issues.

● Monitor for exhaust leaks, especially at welded joints or gasket connections. Leaks can reduce performance and increase noise.

● Rinse off road salt and grime in winter climates to prevent corrosion—particularly for stainless steel systems.

● Inspect rubber hangers for signs of wear or cracking, as deteriorated mounts can lead to exhaust misalignment or sagging.

Regular inspection and cleaning can significantly extend your system’s lifespan and maintain sound quality. Keeping the exhaust properly aligned and free from corrosion ensures stable backpressure and consistent engine performance over time.

Conclusion

Choosing between an axle-back and a cat-back exhaust system ultimately depends on your driving goals, budget, and performance expectations. Both systems can significantly enhance your vehicle’s character—whether through a more aggressive sound, improved power delivery, or a refined rear-end design.

When comparing cat back vs axle back, the decision comes down to priorities: power or sound. Whichever you choose, ensure that your exhaust components are precision-made and professionally fitted for maximum efficiency and longevity.

FAQs

1. Does an axle-back exhaust increase horsepower?

An axle-back exhaust may slightly improve exhaust flow, but horsepower gains are usually minimal. Its main advantage lies in sound and appearance rather than performance.

2. Is an axle-back exhaust bad for your car?

No. A quality axle-back system will not harm your car if properly installed. It maintains the catalytic converter and emissions system, ensuring compliance and safety.

3. What is the difference between axle back vs cat back exhaust?

The axle-back replaces the exhaust from the rear axle to the tip, while the cat-back runs from the catalytic converter to the tailpipe. The cat-back offers better flow and potential power gains, while the axle-back focuses on sound improvement.

4. Axle back vs cat back sound — which is louder?

Cat-back systems are generally louder and deeper because they replace more components, including the mid-pipe. Axle-back systems enhance tone but keep a milder sound level suitable for daily driving.5. Axle back vs cat back pros and cons

● Axle-Back Pros: Lower cost, easy installation, improved tone.

● Axle-Back Cons: Minimal power gains.

● Cat-Back Pros: Better exhaust flow, more power, deeper sound.

● Cat-Back Cons: Higher cost, complex installation.

6. Axle back vs cat back vs turbo back — what’s the difference?

A turbo-back exhaust replaces everything from the turbocharger to the tailpipe, offering the highest performance potential but also the highest cost and tuning requirement. It’s mainly used in turbocharged vehicles.

7. Axle back vs muffler delete — which should I choose?

A muffler delete removes only the muffler, often making the car excessively loud. An axle-back replaces both the muffler and tailpipe, improving sound quality without being too aggressive or violating noise laws.