Exhaust Header Guide: Types, Installation, Leak Repair & Performance Tips

Exhaust headers are among the most popular upgrades for performance-oriented vehicles, yet many drivers and engineers still wonder what they actually do.

This article explains how exhaust headers work, the differences between manifolds and headers, and what you should know about materials, installation, and maintenance—especially if you ever plan to build or order a small-batch custom header.

What Is an Exhaust Header?

An exhaust header is the first component of a vehicle’s exhaust system, attached directly to the cylinder head. Its job is to collect exhaust gases from each cylinder and channel them smoothly into one outlet pipe—with minimal resistance and maximum flow efficiency.

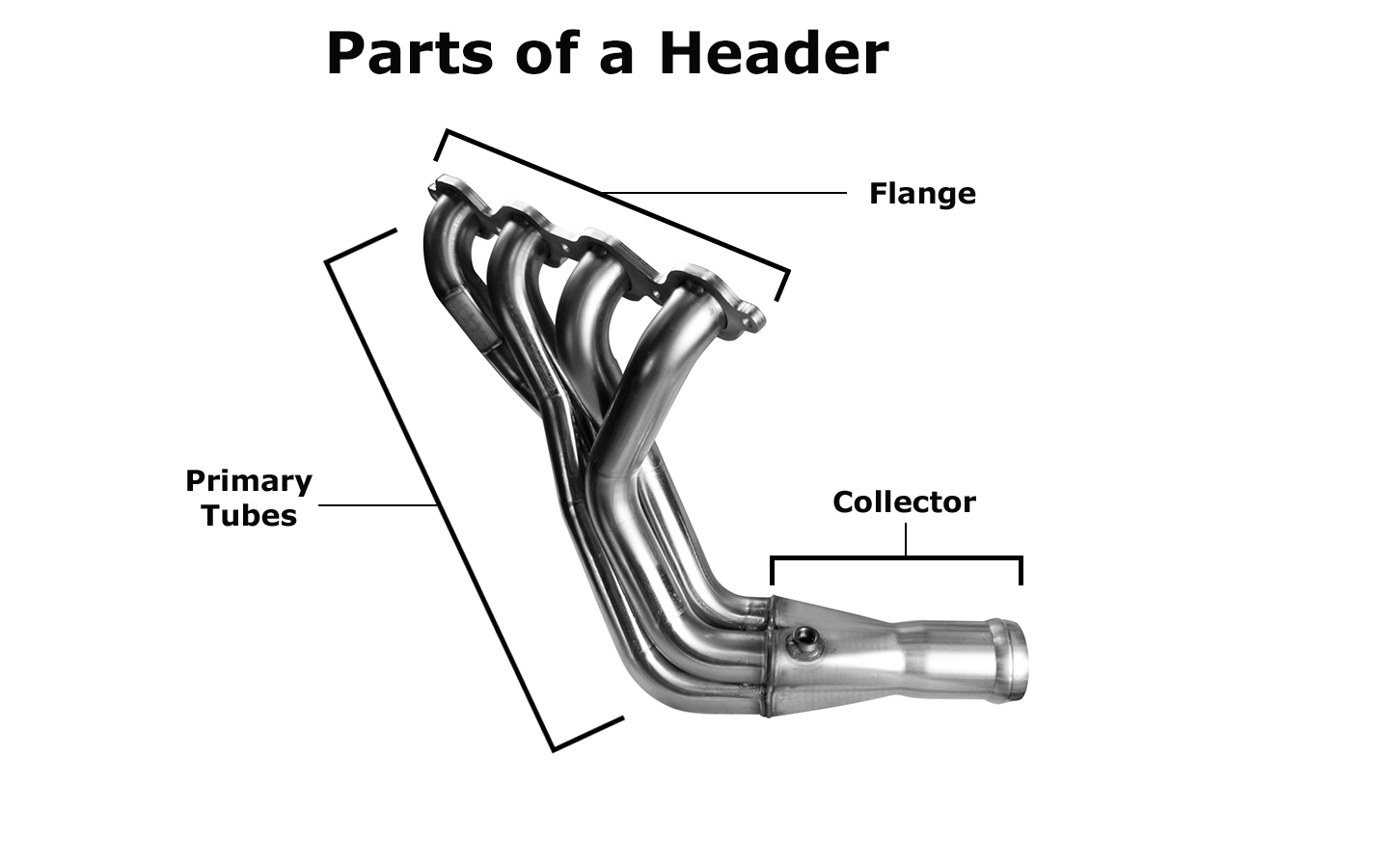

A complete exhaust header typically consists of three major elements:

Source: summitracing.co

A mounting flange — the flat plate that bolts directly to the cylinder head

Individual primary tubes — one dedicated exhaust path for each cylinder

A merge collector — where all primary tubes converge into a single outlet

Compared with factory-installed exhaust manifolds, which are usually a single cast-iron chamber designed for cost and durability, headers use separate tuned pipes for each cylinder. This independent flow path design significantly reduces back pressure and improves exhaust scavenging efficiency.

Exhaust Manifold vs. Header

While manifold and header occupy the same position in the exhaust system, their design goals are fundamentally different:

Feature | Exhaust Manifold | Exhaust Header |

|---|---|---|

Material | Cast iron | Stainless steel / titanium / mild steel |

Manufacturing | Casting | CNC bending / welding / 3D-printed collector |

Airflow | More restrictive | Free-flowing |

Design | Shared chamber | Equal-length individual tubes |

Goal | Cost, durability, noise control | Performance, efficiency, horsepower |

In simple terms — the key differences are:

Manifold is built for mass production & low cost

Header is built for high performance & optimized airflow

Headers use separate tuned tubes per cylinder instead of a shared cast chamber

The goal is to reduce backpressure and improve scavenging effect

How Exhaust Headers Are Manufactured Today

Modern performance headers are commonly produced using a combination of:

CNC mandrel bending for accuracy and smooth tube curves

TIG welding for strength and precision

Metal 3D printing for the collector section, especially in prototype or low-volume production

This hybrid approach allows manufacturers to achieve equal-length, high-efficiency layouts — even for custom or motorsport-specific designs — without the high tooling costs of traditional casting.

How Exhaust Headers Work

Every time an engine cylinder fires, it pushes out a burst of hot exhaust gas. If all cylinders share the same chamber — like in a factory exhaust manifold — those gas pulses collide with each other, which creates back pressure and slows down airflow.

An exhaust header avoids that problem by giving each cylinder its own individual pipe. When those pipes are carefully tuned to the right length and diameter, each exhaust pulse can actually help pull out the next one — this is called the scavenging effect.

→ Think of it like one cylinder “helping” the next one exhale faster.

Better scavenging = more efficient engine breathing = more power and quicker throttle response.

There are also different design styles:

Equal-length headers synchronize exhaust timing from every cylinder → best flow balance / performance

Unequal-length headers (like on Subaru WRX) create a famous “boxer rumble” sound → fun sound, but slightly less efficient

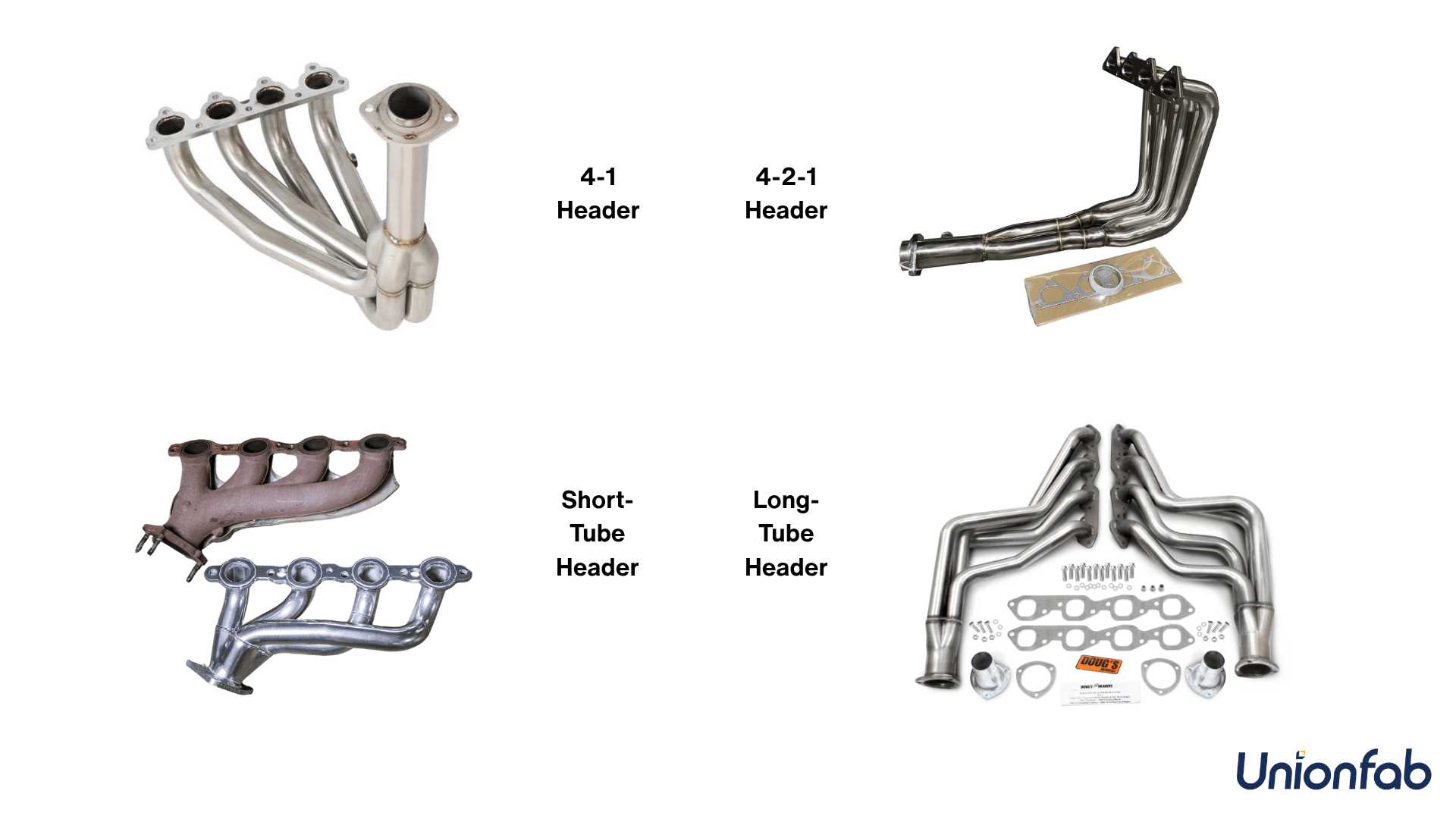

Types of Exhaust Headers

Exhaust headers are generally classified based on how the individual cylinder pipes merge and how long each pipe is, because these design factors directly affect power delivery (low-end torque vs high-RPM horsepower), installation difficulty, and sound characteristics.

Header Type | Design Summary | Power Focus | Sound Character | Installation Difficulty | Best For |

|---|---|---|---|---|---|

4-1 Header | Four primaries merge directly into one collector | High RPM horsepower | Aggressive & sharp | Medium | Racing / high-end performance |

4-2-1 Header | Two merge steps (4 → 2 → 1) | Mid-range torque | Balanced & smooth | Medium | Street + performance mix |

Short Tube | Compact fitment | Mild improvement | Slightly sportier | Easy (often bolt-on) | OEM upgrade / casual tuning |

Long Tube | Longer primaries, smoother flow | Broad power & torque gains | Loud & deep | Hard (may require tune) | Serious performance builds |

In simple terms:

4-1 headers are best for maximum top-end power and racing use.

4-2-1 headers balance mid-range torque and daily drivability.

Short tube headers are mainly used as easy bolt-on upgrades.

Long tube headers deliver the strongest overall performance but may require more space and ECU tuning.

Materials & Manufacturing Options for Exhaust Headers

Exhaust headers need to withstand extreme temperatures and continuous vibration, so the choice of material and manufacturing method directly affects durability, performance, and cost.

Common Materials

Material | Advantages | Limitations | Common Use |

|---|---|---|---|

Stainless Steel (304/409) | Durable, corrosion-resistant | Slightly heavier | Street & performance |

Mild Steel | Cheap and easy to weld | Prone to rust | Budget or temporary |

Titanium | Light, excellent heat resistance | Expensive, harder to weld | Racing / custom projects |

Modern performance headers are typically produced using:

CNC mandrel bending — ensures smooth internal bends without restricting airflow

TIG welding — provides strong and precise joints

Metal 3D printing (for the merge collector) — especially for prototype or small-batch production

A hybrid approach is common — for example, a 3D-printed collector combined with CNC-bent stainless steel tubes, offering precision and cost efficiency for custom builds.

If you’re developing a custom or low-volume exhaust header, Unionfab provides an instant online quote system where you can upload CAD files and receive manufacturing feedback within minutes — ideal for prototyping and small-batch validation.

Exhaust Header Installation Basics

Installing a header isn’t complex, but precision matters. Here’s a summary of best practices:

Let the engine cool completely before starting.

Remove the factory manifold and clean the cylinder-head surface.

Inspect flanges and gaskets; never reuse old gaskets.

Position the header loosely with all bolts finger-tight.

Tighten in sequence, starting from the center outward.

Torque to spec — usually 20–30 ft-lbs, but follow the manufacturer.

Check for leaks after the first heat cycle and re-torque if needed.

Common installation errors include uneven tightening (which warps flanges) and ignoring gasket alignment. When done properly, a header can last for years without maintenance.

Exhaust Header Leak Symptoms, Repair and Maintenance

Exhaust header leak symptoms are usually easy to detect. Common signs include:

Sharp ticking noise near the engine bay

Black soot around the flange

Faint exhaust smell inside the cabin

These indicate that exhaust gas is escaping before it reaches the rest of the exhaust system.

Basic Troubleshooting Process

If a leak is suspected:

Let the engine cool completely, then carefully inspect each joint.

Check flange flatness using a straight edge.

Replace the gasket if burnt, damaged, or compressed.

Apply high-temp sealant only if specified.

Tighten bolts gradually and evenly.

If a primary tube or merge collector is cracked, it is often better to reweld or replace the section. CNC refabrication or 3D-printed collector replacement is often faster and more precise for custom builds.

Ongoing Maintenance Tips

Re-check bolt torque every 6–12 months.

Inspect gaskets for leakage traces.

Use only pH-neutral cleaners.

Let header fully cool before cleaning.

Reapply coating or paint if corrosion appears.

A well-maintained header will not only sound cleaner but also retain performance for years.

Heat Management: Wraps, Paints & Coatings

Exhaust headers can reach over 800°C (1,500°F), which may increase engine bay temperature and affect nearby components if not properly managed.

Common thermal control methods include:

Header wrap — fiberglass/titanium tape to trap heat and reduce engine bay temperature

High-temperature exhaust paint — mainly for rust prevention and light heat control

Ceramic coating — professional-grade thermal barrier for long-term performance use

To learn more, see our dedicated article on exhaust header heat management.

Conclusion

Exhaust headers embody a blend of engineering and craftsmanship. Understanding their design, function, and materials helps both drivers and manufacturers make smarter decisions.

While factory manifolds focus on cost and noise control, a well-designed header improves efficiency, sound, and performance.

Modern CNC machining and metal 3D printing make precision manufacturing more accessible than ever.

If you’re considering a prototype or small-batch production, Unionfab can help evaluate manufacturability and material options — or you can reach out directly. New customers can also receive a 10% discount on their first order.

FAQs

What does an exhaust header do?

It allows exhaust gases to exit each cylinder more smoothly and with less back pressure, improving performance and throttle response.

Are exhaust headers legal?

It depends on local regulations — in many regions, headers are legal as long as they keep the catalytic converter intact and do not exceed noise or emissions limits.

What are the types of exhaust headers?

The most common types are 4-1, 4-2-1, short tube, and long tube headers — each designed for different power delivery and installation needs.

What is the difference between an exhaust header and a manifold?

A manifold is a single cast piece designed for cost and noise reduction, while a header uses separate tuned pipes per cylinder to improve airflow and reduce back pressure — resulting in better performance.

Do exhaust headers increase horsepower?

Yes. Depending on the engine and tuning, a properly designed header can add 5–15 horsepower by improving exhaust flow efficiency.

Should I use a header wrap or ceramic coating?

Header wrap is affordable and effective for short-term heat control, while ceramic coating provides long-term durability, heat resistance, and corrosion protection — ideal for performance builds.

How often should I re-torque header bolts?

After the first 100 miles of driving and then every 6–12 months, as vibration and heat expansion can loosen the hardware over time.

What’s the best material for a small-batch custom header?

304 stainless steel is the most balanced choice — corrosion-resistant, durable, and compatible with both CNC bending and 3D-printed collector fabrication.