A Dive into SLA and FDM Technologies

3D printing has revolutionized manufacturing, offering unparalleled flexibility, innovation, and efficiency. Among the various 3D printing technologies, Stereolithography (SLA) and Fused Deposition Modeling (FDM) stand out for their unique capabilities and applications. This article explores these two techniques, comparing their costs, print quality, speed, and material usage to help you understand which might be best suited for your projects.

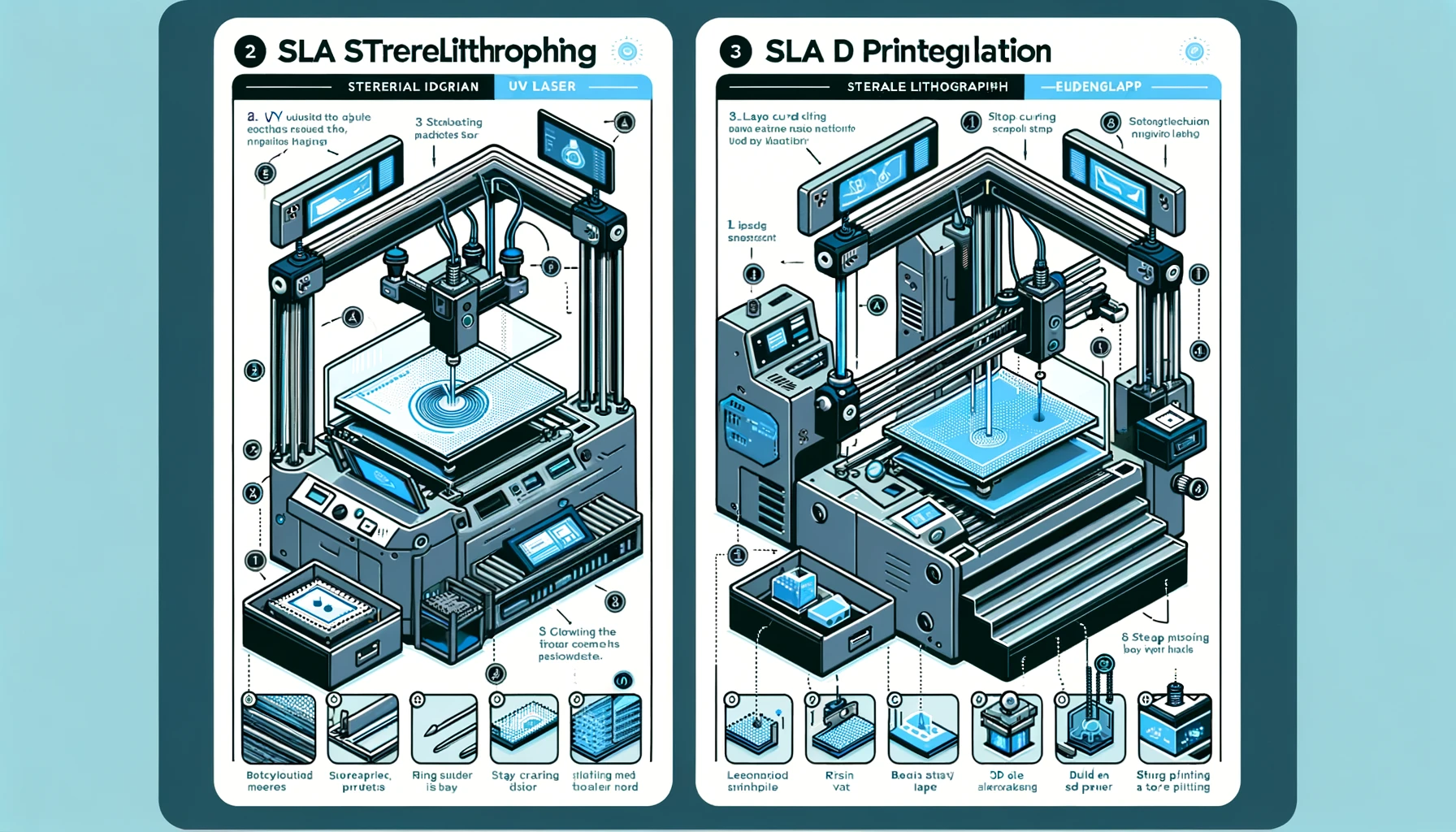

What is SLA?

Stereolithography (SLA) is one of the earliest 3D printing technologies, developed in the 1980s. It uses an ultraviolet (UV) laser to cure and solidify photosensitive resin, layer by layer, to form 3D objects.

How SLA Works

SLA printers operate by focusing a UV laser onto a vat of liquid resin, following a pre-designed 3D model. The laser beam traces a cross-section of the object onto the surface of the liquid resin, causing it to polymerize and solidify. The build platform then moves up or down, allowing the laser to cure the next layer until the entire object is printed.

Advantages and Disadvantages of SLA

Advantages:

High resolution and detail.

Smooth surface finishes.

Capability to print complex geometries.

Disadvantages:

Generally more expensive than FDM.

Limited range of materials.

Post-processing requires cleaning and curing.

SLA Software and Applications

SLA printing is supported by specialized software that prepares 3D models for printing, such as Autodesk’s Fusion 360 or Formlabs’ PreForm. Its applications range from detailed prototypes and models in industries like jewelry, dentistry, and healthcare to high-quality, small-batch production parts.

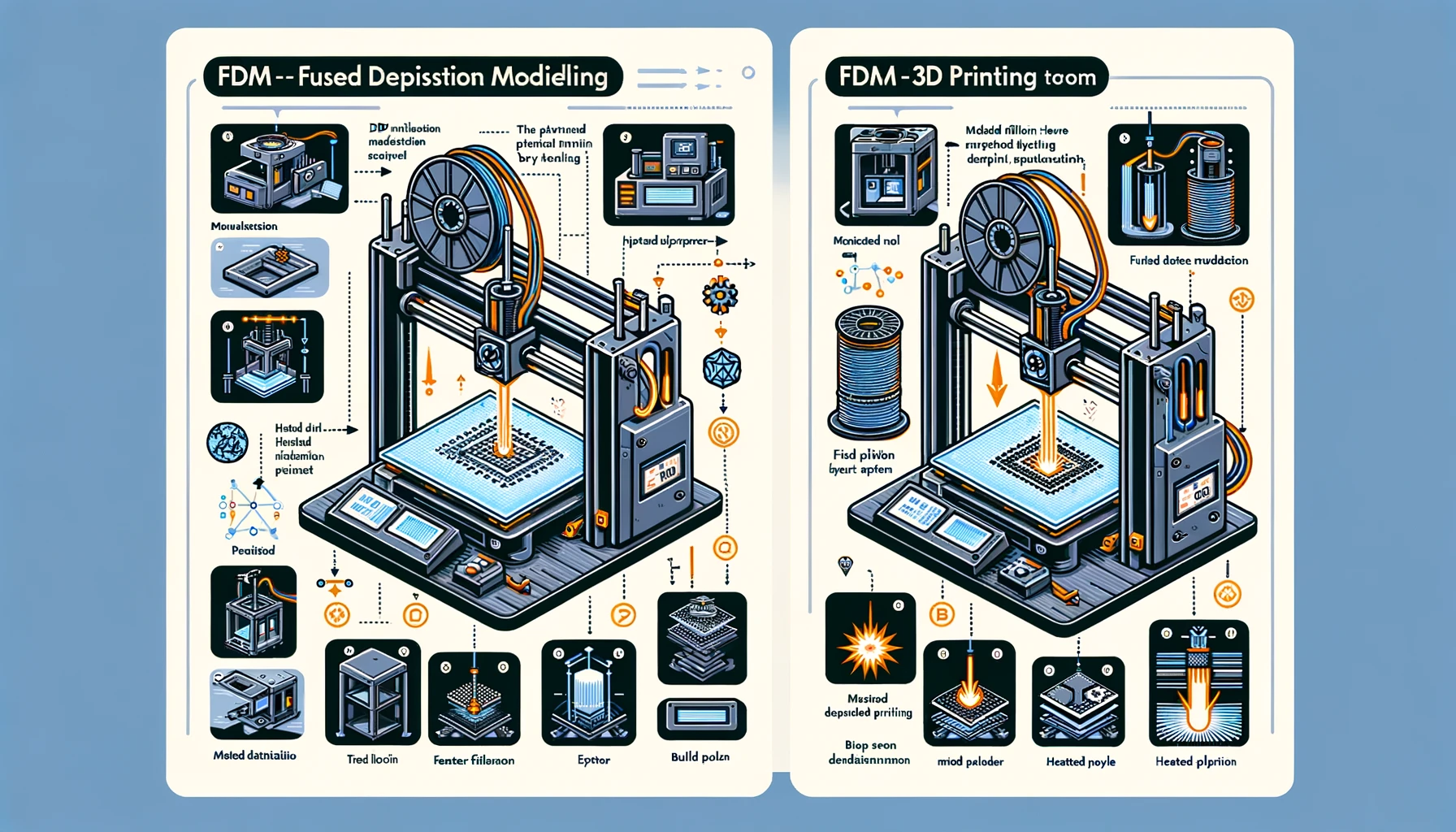

What is FDM?

Fused Deposition Modeling (FDM), also known as Fused Filament Fabrication (FFF), is a widely used 3D printing technology that extrudes thermoplastic filaments through a heated nozzle, layer by layer, to create an object.

How FDM Works

FDM printers heat a thermoplastic filament to a semi-liquid state and extrude it along specific paths to form each layer of the 3D object. The material hardens immediately after being deposited, allowing for the creation of durable and functional parts.

Advantages and Disadvantages of FDM

Advantages:

Cost-effective for low-volume production.

Wide range of materials, including specialized filaments.

Easy to use and maintain.

Disadvantages:

Lower resolution compared to SLA.

Visible layer lines and rougher surface finish.

Support structures may be needed for complex designs.

FDM Software and Applications

FDM printing is compatible with a broad selection of slicing software, such as Ultimaker Cura and Simplify3D, which translates 3D models into printable files. It’s commonly used for prototyping, educational models, hobbyist projects, and functional parts in automotive and aerospace industries.

Comparison of SLA and FDM

Printing Cost

FDM is generally more cost-effective than SLA due to the lower price of filament compared to resin and overall operational costs.

Part Strength

FDM parts are typically stronger and more suitable for functional testing and use, although SLA resins have improved in toughness and durability.

Printing Speed

FDM usually has faster printing times for larger, less detailed objects, while SLA can be quicker for highly detailed, small objects.

Surface Finish

SLA offers a superior surface finish with higher detail resolution, ideal for models requiring smooth surfaces or intricate details.

Cost-Effectiveness

FDM wins in terms of raw material costs and ease of use, making it more accessible for beginners and cost-conscious users.

Print Quality

SLA typically outperforms FDM in print quality, especially for models requiring fine features and smooth surfaces.

Material Usage

FDM allows for a wider range of materials, including composite filaments, whereas SLA materials are primarily limited to various types of resin, each suited for specific applications.

Conclusion

Both SLA and FDM have their unique strengths and weaknesses, making them suitable for different types of projects. SLA excels in producing high-detail, smooth surface finish parts ideal for prototyping and display models, whereas FDM is favored for functional, durable parts and broader material selection. Understanding these differences can guide you in choosing the right technology for your specific 3D printing needs, balancing cost, quality, and performance.

Unionfab's Experitse

To learn more about Manufacturing processes, Contact a Unionfab representative.

Unionfab provides a wide range of manufacturing capabilities for all of your prototyping and production needs. Resquest a free and instant quote.