3D Printing vs. CNC vs. Vacuum Casting: The Ultimate Comparison

This article compares and contrasts three common manufacturing methods: 3D printing, CNC machining, and vacuum casting.

Introduction

Manufacturing today offers a wide range of methods, each with its own strengths and limitations. Among them, 3D printing, CNC machining, and vacuum casting are three of the most commonly used manufacturing processes, widely adopted across industries for prototyping and functional parts.

In this article, we first provide a quick overview of how these three methods differ in their core processes, followed by an in-depth comparison across key factors such as cost, materials, part size, precision, surface finish, and lead time.

Whether you’re deciding on a production method for a prototype or a final product, this guide will help you understand the trade-offs and choose the right approach.

Quick Overview: How 3D Printing, CNC, and Vacuum Casting Differ

3D printing, CNC machining, and vacuum casting are three common manufacturing methods, each defined by a distinct way of making parts.

In simple terms, 3D printing builds parts up, CNC machining cuts parts out, and vacuum casting copies parts from a mold.

3D Printing

Source: padtinc.com

3D printing is an additive manufacturing process that creates three-dimensional objects from a digital file by laying down and fusing successive layers of material until the final part is formed.

To learn more, read our guide on Additive Manufacturing.

CNC Machining

Source: gif.com

CNC (Computer Numerical Control) machining is a subtractive manufacturing process in which cutting tools are guided by computer-controlled instructions to remove material from a solid block and form the final part.

To learn more, read our guide on CNC Machining.

Vacuum Casting

Source: YouTube video by Xometry Europe

Vacuum casting, also known as urethane casting, is a replication method that starts with a master model to create a silicone mold, into which materials are cast under a vacuum to form the final part.

To learn more, read our guide on Vacuum Casting.

In-Depth Comparison: 3D Printing vs. CNC Machining vs. Vacuum Casting

Now, let’s take a closer look at how 3D printing, CNC machining, and vacuum casting compare across key factors.

We’ll examine cost and production efficiency, materials, maximum part size, precision, surface finish, and typical lead time to help you determine the best manufacturing method for your project.

1. Cost and Production Efficiency

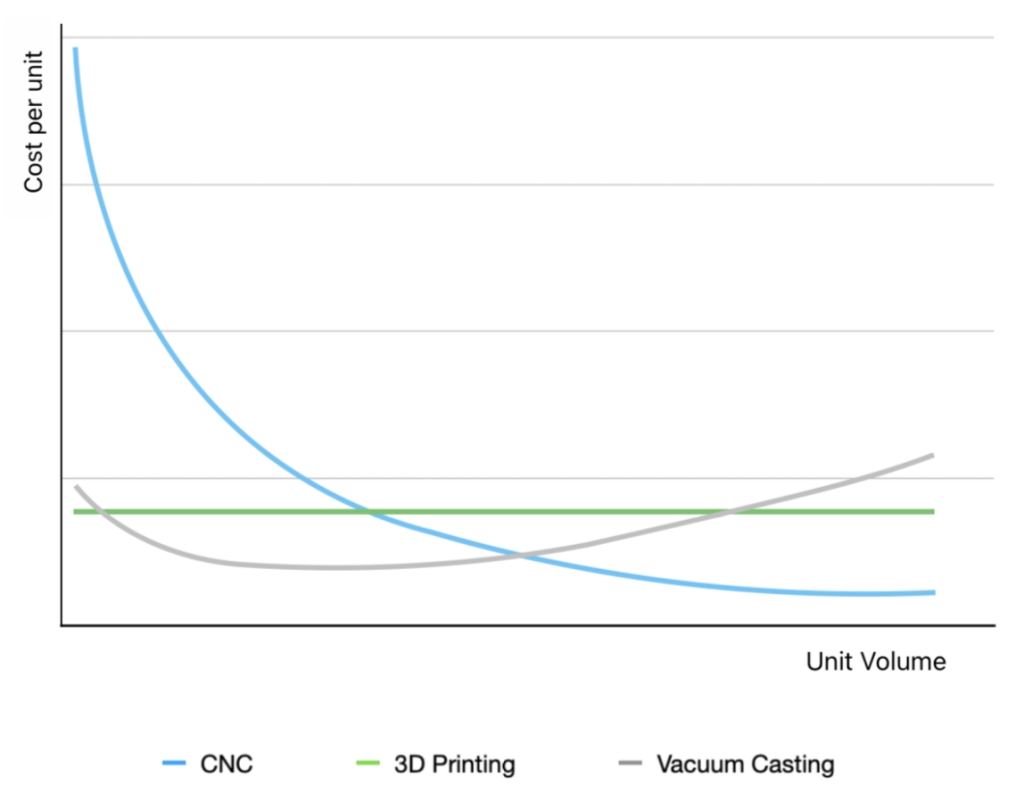

Source: Unionfab

The cost and production efficiency of each manufacturing method can vary depending on the production volume. Here’s how 3D printing, CNC machining, and vacuum casting compare across different batch sizes.

Very Low Volume Production: 5–100 Parts

(Note: For quantities fewer than 5 parts, 3D printing is typically the most practical choice due to zero tooling costs and rapid speed.)

Most Cost-Effective Choice: Vacuum Casting

Vacuum Casting: This is the "sweet spot" for this range. Once a master mold is created, you can rapidly produce high-quality copies. The cost per part drops significantly compared to machining each one individually.

3D Printing: While highly efficient because it requires no tooling, the per-part cost remains flat; it doesn't get much cheaper just because you are making 50 instead of 5.

CNC Machining: The least efficient here. High setup times and the labor-intensive process of machining every single part from scratch make it expensive for such small batches.

Low Volume Production: 100–500 Parts

Most Cost-Effective Choice: 3D Printing or CNC Machining

3D Printing: Remains practical for complex geometries where tooling would be too expensive or impossible to design.

CNC Machining: As the quantity nears 500, the initial setup cost is "amortized" (spread out) over more parts, making the price per unit more competitive.

Vacuum Casting: Efficiency begins to dip here. Silicone molds have a limited lifespan (usually 20–25 copies), meaning you would need to create multiple expensive master molds to reach these quantities.

Low to Medium Volume Production: 500–1,000 Parts

Most Cost-Effective Choice: CNC Machining or 3D Printing

CNC Machining: Becomes increasingly attractive. Once the programming and jigging are set, the fast material removal rate makes it more economical than casting for high-precision parts.

3D Printing: Excellent for this range if the parts have complex internal structures that would require expensive multi-axis machining.

Vacuum Casting: Generally not ideal. The labor cost of manual pouring and the frequent replacement of molds make it too slow and expensive for batches of this size.

Medium to High Volume Production: 1,000–10,000+ Parts

Most Cost-Effective Choice: CNC Machining

CNC Machining: The clear winner for precision at scale. Automated CNC processes can run 24/7 with minimal supervision, drastically lowering the unit price for identical, high-strength parts.

3D Printing: Less practical at high volumes. The time required to print thousands of parts is often prohibitive, and material costs do not scale down as effectively as raw metal or plastic blocks.

Vacuum Casting: Not suitable. The process is too manual and the mold degradation makes it impossible to maintain consistency across thousands of units.

Want to see exactly how much your project could cost with 3D printing, CNC machining, or vacuum casting?

Use our free cost calculator to get an instant estimate and plan your production smarter!

2. Materials

Material Options

The choice of materials varies depending on the manufacturing method. For 3D printing and CNC machining, the materials used are the final part materials—the part you produce is made directly from the raw material.

3D Printing

Plastics: ABS, PLA, Nylon, PETG, TPU, ASA

Metal powders: Stainless steel, Aluminum, Titanium (for metal 3D printing)

Resins: Photopolymer resins (for SLA/DLP)

CNC Machining

Plastics: ABS, Nylon, Polycarbonate

Metals: Aluminum, Steel, Copper, Brass, Stainless steel

Vacuum Casting

Vacuum casting is a multi-step process, and each step uses different materials:

Master Model: Created using 3D printing or CNC machining materials such as ABS, PLA, or resin

Mold: Silicone

Casting Material: Liquid urethane resins—such as ABS-like, Rubber-like, PE/PP-like, PC-like Polyurethanes—are poured into the silicone mold under vacuum. These resins cure into solid thermoset parts, replicating the shape and mechanical properties of the master model.

To explore the full range of materials available for each manufacturing method—including 3D printing and CNC machining—check out our detailed Material page.

For more details on the materials used in vacuum casting, visit our Vacuum Casting Service page.

Example: How ABS Performs Across Three Manufacturing Methods

Mechanical Property | 3D Printing (FDM ABS) | CNC Machining (ABS) | Vacuum Casting (ABS-like PU) |

|---|---|---|---|

Tensile strength | XY: 33 ± 3 MPa Z: 28 ± 2 MPa | 35 – 63 MPa | 60 – 73 MPa |

Elongation at break | XY: 10.5 ± 1% Z: 4.7 ± 0.8% | 10 – 50% | 11 – 16% |

Flexural modulus | XY: 1880 ± 110 MPa Z: 1590 ± 1 MPa | 2250 – 2280 MPa | 1200 – 2000 MPa |

*Note: The values listed above represent typical material properties for each manufacturing method. Actual mechanical performance may vary depending on material grade, processing parameters, part geometry, build orientation, and post-processing conditions.

ABS is a widely used engineering plastic, but its final appearance and performance can vary significantly depending on how it is manufactured. When comparing 3D printing, CNC machining, and vacuum casting, the key difference is not the material itself, but how ABS is processed and formed.

In other words, the same material name does not guarantee the same result. Each manufacturing process shapes ABS in a fundamentally different way.

ABS in 3D Printing (FDM)

In 3D printing, ABS is typically used in filament form and processed through FDM (Fused Deposition Modeling).

The material is melted and extruded through a nozzle

Parts are built layer by layer

Layers bond together as the material cools

Resulting characteristics:

Visible layer lines on the surface

Directional (anisotropic) strength, especially weaker along the Z-axis

Fast production and high design flexibility

This makes 3D printed ABS well suited for early-stage prototypes and functional testing, where speed and design iteration matter more than surface finish.

ABS in CNC Machining

In CNC machining, ABS starts as a solid block, sheet, or rod with uniform internal structure.

Material is removed using precision cutting tools

No melting or layering occurs

The internal material structure remains consistent throughout the part

Resulting characteristics:

Smooth surface finish

High dimensional accuracy

Stable and predictable mechanical performance in all directions

CNC machined ABS is often chosen for functional parts, housings, and components where precision, strength, and repeatability are critical.

ABS in Vacuum Casting (ABS-like Resins)

Vacuum casting uses a different approach. Instead of true ABS plastic, the process relies on ABS-like polyurethane resins designed to replicate the look and basic behavior of ABS.

A master model is first created (often by CNC or 3D printing)

A silicone mold is made from the master model

Liquid resin is poured into the mold under vacuum and then cured

Resulting characteristics:

Very smooth, uniform surfaces

Injection-molded-like appearance

Suitable for small batch production

Vacuum cast ABS-like parts are commonly used for visual models, presentation samples, and low-volume production, where appearance and consistency are more important than maximum mechanical strength.

Comparing ABS Across the Three Processes

The table below highlights how the same “ABS” material differs when produced using different manufacturing methods:

Process | How ABS Is Used | Typical Results | Best Use Cases |

|---|---|---|---|

3D Printing (FDM) | Melted filament, layered deposition | Layer lines, anisotropic strength | Rapid prototyping, design validation |

CNC Machining | Solid ABS block or sheet | High precision, smooth finish | Functional parts, mechanical testing |

Vacuum Casting | ABS-like resin in silicone molds | Excellent surface quality, uniform appearance | Visual models, small-batch production |

Key Takeaway

The differences observed between these ABS parts are not caused by the material itself, but by the manufacturing process used to shape it.

Material defines what is possible — but the process defines how the part looks, feels, and performs.

3. Part Size Limitations

When selecting a manufacturing process, it is essential to understand the maximum single-piece (integral) construction size possible in a single build.

3D Printing

In additive manufacturing, size limits are not universal; they depend entirely on the specific technology used.

Maximum Part Size: SLA (Stereolithography) is the leader for large-scale parts. At Unionfab, our industrial SLA systems can produce single-piece components up to 2100 x 700 x 800 mm.

Minimum Feature Size: SLA and PolyJet are the champions of precision, capable of resolving intricate features as small as 0.05 mm (micro resolution) up to 0.25 mm (normal resolution).

CNC Machining

For CNC Machining, size capabilities vary depending on the machine type and operation.

The table below summarizes typical maximum part dimensions and the smallest features achievable with milling, turning, and drilling.

Feature | CNC Milling | CNC Turning | CNC Drilling |

|---|---|---|---|

Maximum Part Size | X × Y × Z travel up to 11,000 × 4,700 × 2,450 mm | Diameter up to 930 mm, length up to 4,000 mm | Plate size up to 2,400 × 1,000 × 60 mm |

Minimum Feature Size | ~0.5 mm (micro-machining <2.5 mm requires specialized setup) | ~0.5 mm (common practice starts from ~1 mm) | Standard: 2.5 mm; can drill down to 0.05 mm with micro-drilling |

Vacuum Casting

For vacuum casting, the maximum part size is primarily limited by the vacuum chamber and mold design. At Unionfab, the maximum achievable part dimensions are up to 1500 × 1000 mm, making it suitable for small to medium production runs.

4. Precision

Precision indicates how closely the final part conforms to its intended dimensions and tolerances. Typical tolerance ranges for each manufacturing method are:

CNC Machining: ±0.0127 mm to ±0.127 mm, ideal for projects requiring tight tolerances and high dimensional accuracy.

3D Printing: ±0.08 mm to ±0.5 mm depending on technology, layer height, calibration, and part orientation, suitable for complex geometries with moderate precision.

Vacuum Casting: ±0.3 mm to ±0.55 mm for parts up to 150 mm, influenced by master model quality, mold accuracy, and material shrinkage; larger parts should be evaluated individually.

CNC machining offers the highest accuracy, 3D printing provides flexibility with reasonable precision, and vacuum casting balances replication fidelity with moderate tolerance requirements.

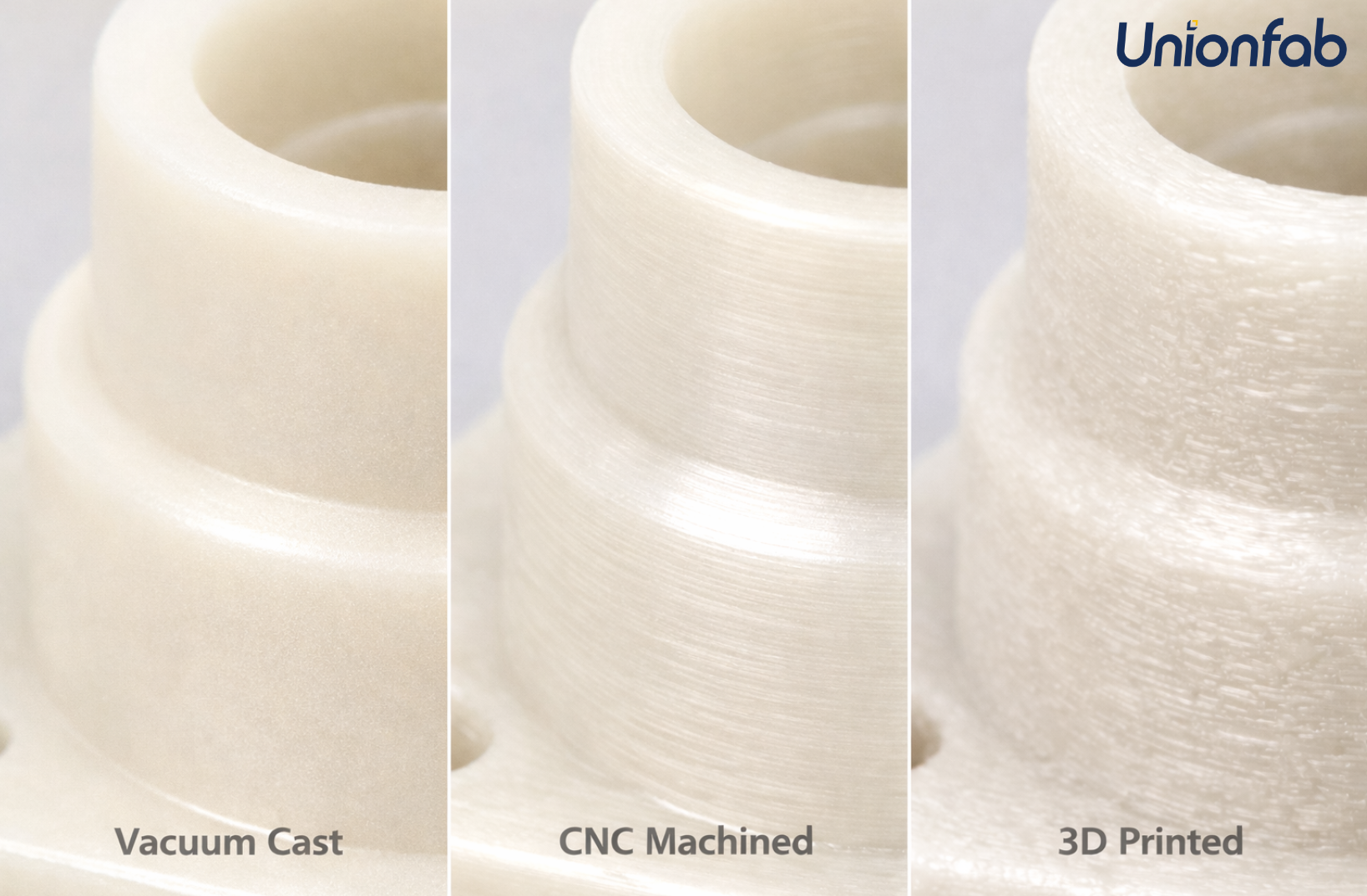

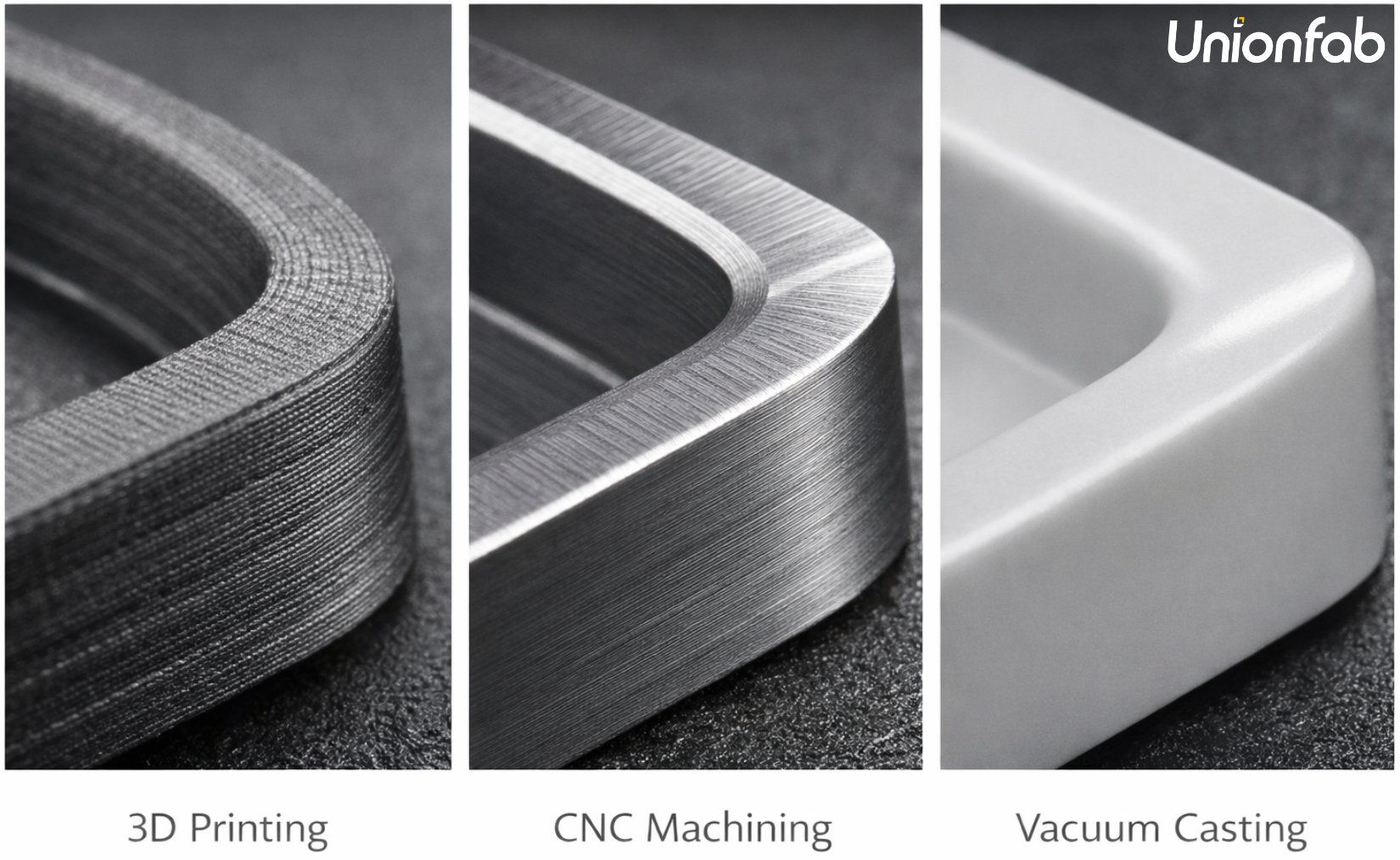

5. Surface Finish

If you’re choosing between 3D printing, CNC machining, and vacuum casting, surface finish usually comes down to two simple questions:

1. How smooth does it need to be (measurable smoothness / Ra)?

2. How “premium” does it need to look and feel in the hand?

Under normal production conditions (without heavy post-processing), here’s the practical reality:

CNC Machining

CNC typically gives you the lowest and most consistent roughness. A standard CNC surface often lands around Ra 0.8–3.2 μm, and with fine machining or polishing it can reach ≤ 0.8 μm.

Visually, it looks clean and accurate, but if you catch it under strong light you may still see very fine tool marks—a “machined” look. In the hand, it feels solid and engineered.

Best for: tight tolerances, functional parts, controlled surface quality.

Vacuum Casting

Vacuum casting is usually not the lowest Ra, but it often wins on overall look and feel. Typical roughness is about Ra 1.6–3.2 μm, and the surface tends to be smooth, uniform, and non-directional, which is why it can look close to injection-molded plastic.

The key dependency is the master pattern and mold quality—a great master produces a great surface.

Best for: presentation prototypes, cosmetic parts, “mass-production-like” appearance.

3D Printing

3D printing usually has the highest roughness and the most visible texture, often around Ra 3.2–6.3 μm depending on the process, layer height, and orientation. The surface commonly shows layer lines and a directional feel.

Sanding, coating, or smoothing can improve it, but it generally takes extra work to approach the consistency you get more naturally with CNC or vacuum casting.

Best for: fast iteration, complex geometry, early-stage prototypes.

The shortcut decision (most people use)

Want the smoothest, most controllable surface? → CNC machining

Want the best-looking, most “consumer-product” surface? → Vacuum casting

Want speed + design freedom, and can accept visible texture (or plan post-processing)? → 3D printing

Quick “Ra feel” cheat sheet (indicative)

≤ 0.8 μm: near-polished, very smooth

1.6 μm: smooth, fine-machined

3.2 μm: standard machined surface

6.3 μm: noticeably rough

≥ 12.5 μm: clearly textured

(Actual values vary by material, geometry, and process settings.)

6. Typical Lead Time

Lead time often plays a key role in selecting a manufacturing method.

3D Printing offers the fastest turnaround, with parts often completed within 1–3 days, making it ideal for rapid iteration.

CNC Machining typically requires 7–15 days, depending on part complexity, material availability, and machining time.

Vacuum Casting involves multiple steps—master model creation, mold making, and casting—resulting in lead times of 10-15 days, though multiple parts can be produced efficiently once the mold is ready.

Conclusion: Choosing the Right Manufacturing Method

Selecting the best manufacturing method ultimately depends on what matters most for your project—whether it’s speed, precision, cost, or the ability to create complex designs. Below is a clear breakdown of when each method is the most practical and what strengths it brings to your production workflow.

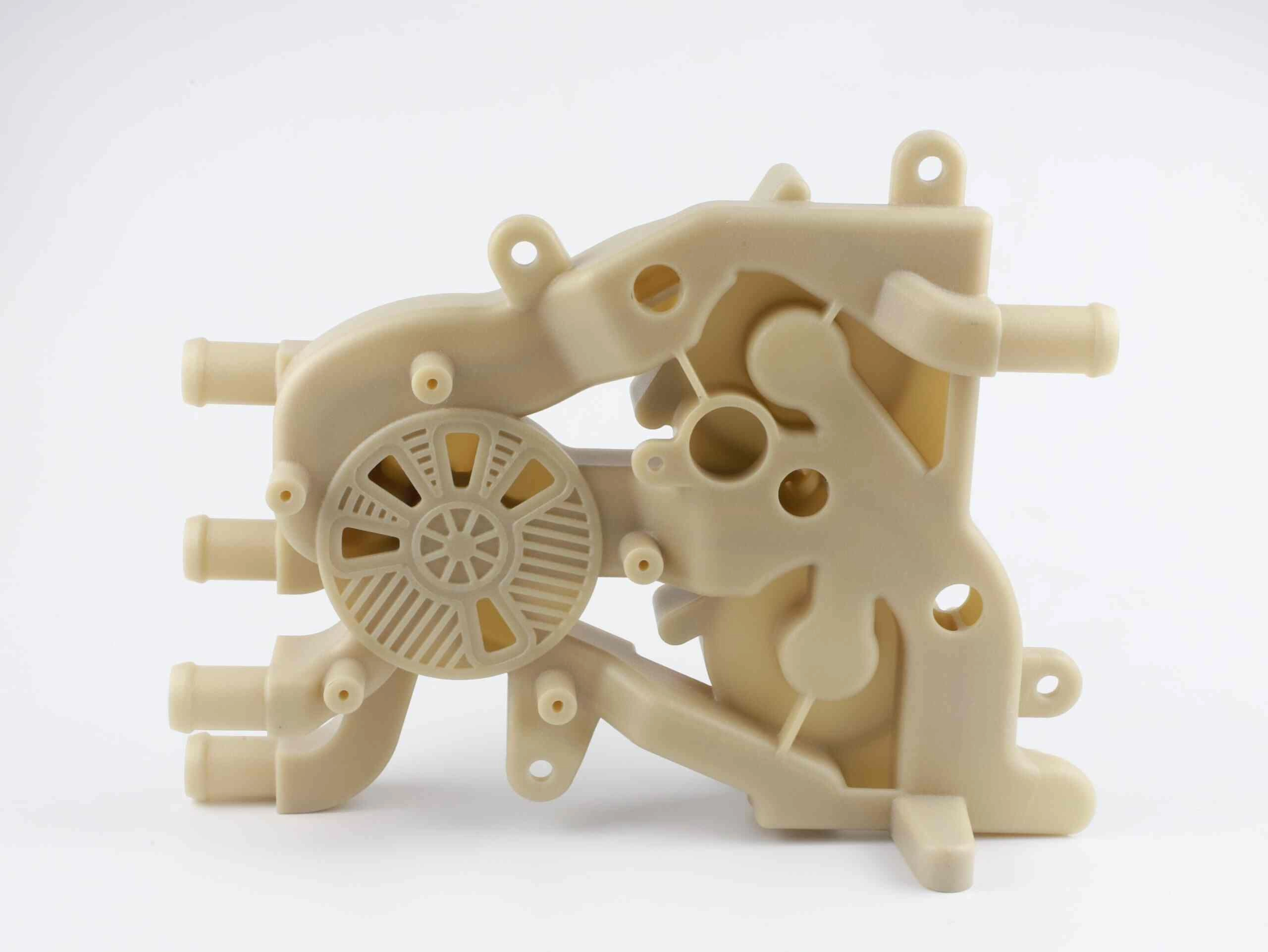

Vacuum Casting

Source: Unionfab

When to use:

Ideal for affordable prototyping and very low volume production (5–100 parts).

Strengths:

Produces prototypes with the look and feel of the final product.

Cost-effective for small quantities (5-100) with fine surface finishes.

Excels at smooth surfaces and net-shaped components that need minimal post-processing.

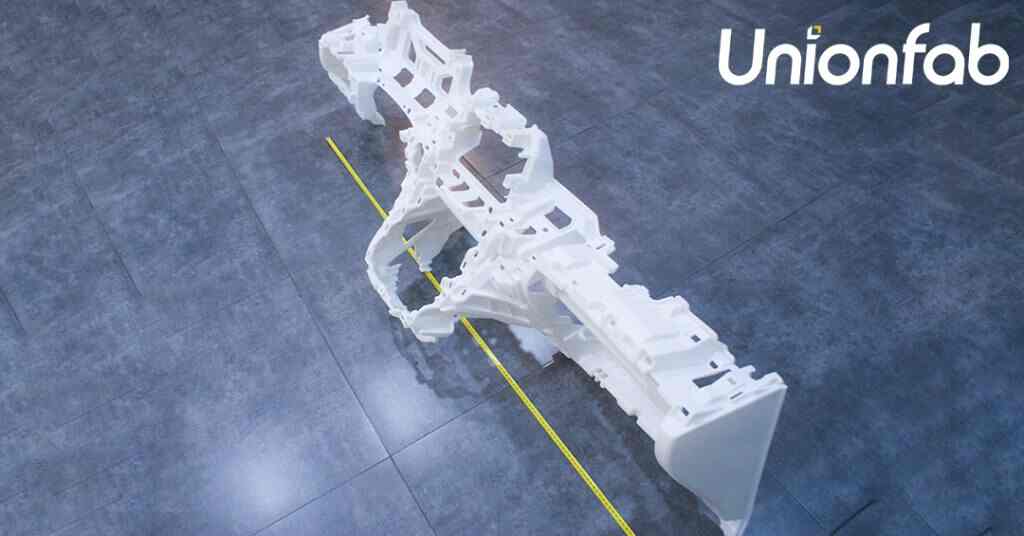

3D Printing

Source: Unionfab

When to use:

Perfect for rapid prototyping, iterations, and one-off or customized parts.

Strengths:

Allows quick design validation and rapid iterations.

Supports complex and intricate geometries that are difficult for traditional methods.

Enables high customization and personalized products.

CNC Machining

Source: Unionfab

When to use:

Best for high precision parts and medium to high volume production.

Strengths:

Known for tight tolerances and consistent quality.

Efficient for medium to high quantities of parts.

Compatible with a wide range of materials, including metals, plastics, and composites.

In Summary

Choosing the right manufacturing process depends on your specific project requirements:

For Affordable Prototyping and Very Low Volume (5-100) Production, consider vacuum casting for cost-effective replication of detailed parts and 3D printing for rapid iterations and customization.

For High Precision and Medium to High Volume Production, CNC machining excels in producing accurate, high-quality parts efficiently.

Complex Geometries and Customization are strengths of 3D printing, making it suitable for unique, intricate designs.

Additionally, for High-Volume Production Runs, injection molding leverages economies of scale to achieve cost-effective manufacturing.

Get Started with Unionfab: CNC, 3D Printing, Vacuum Casting & More

If you're looking for a reliable and experienced partner to bring your designs to life, consider Unionfab's comprehensive manufacturing services.

With a focus on precision and quality, Unionfab offers a wide range of production solutions, including CNC machining, 3D printing, and vacuum casting.

Explore Unionfab's services today to achieve your project goals with confidence! And if this is your first time using Unionfab’s services, sign up now to enjoy 10% off your first order!

FAQs

What is the difference between CNC and 3D printing?

CNC machining is a subtractive process that cuts material from a solid block, while 3D printing is an additive process that builds parts layer by layer. CNC offers higher precision and better material properties, while 3D printing provides faster prototyping and supports more complex geometries.

Is CNC harder than 3D printing?

Generally, yes. CNC machining typically requires more technical knowledge—such as toolpath programming, tool selection, and understanding cutting parameters—while 3D printing is usually more automated and beginner-friendly.

What are the disadvantages of vacuum casting?

Vacuum casting is not ideal for high-volume production since silicone molds typically last only 15–50 castings. It also requires a master pattern, has longer lead times than 3D printing, and delivers lower precision than CNC machining when tight tolerances are required.