SLA Rapid Prototyping Services & Guide | High-Precision 3D Printing

Bring your concept to life in 24–72 hours with industrial-grade SLA 3D printing. Explore SLA rapid prototyping materials, applications, and how to get best SLA prototyping service.

Introduction

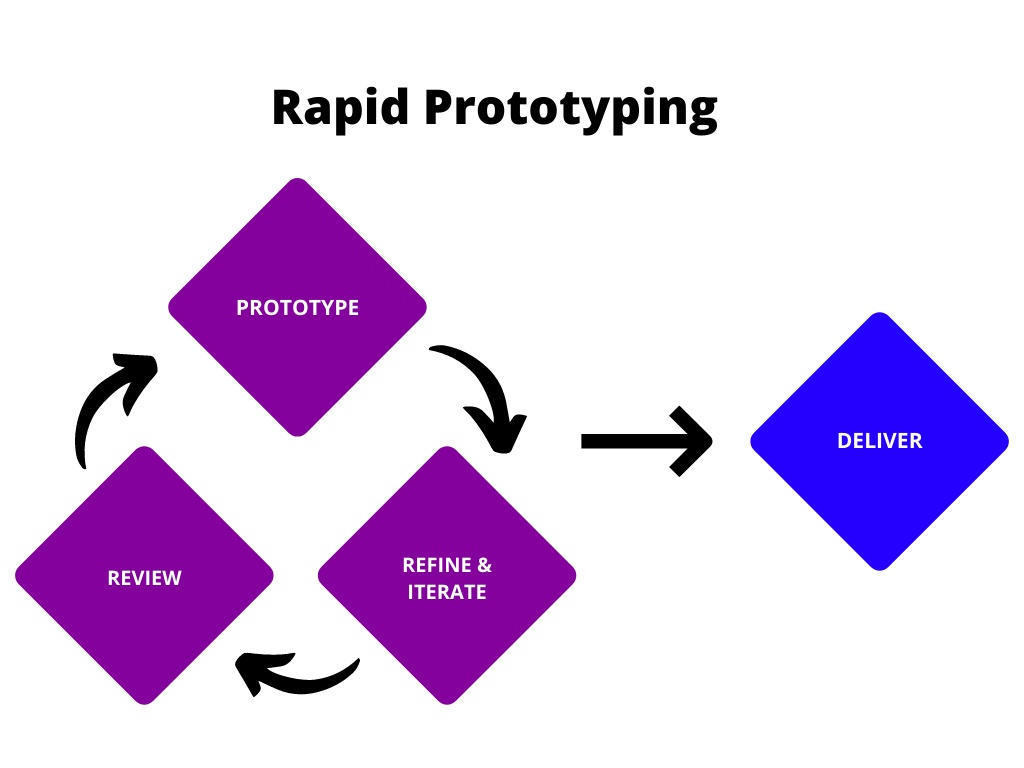

The key principle of rapid prototyping is: Fail Fast, Learn Faster.

It’s all about quickly turning ideas into tangible models so you can:

Test early and often

Identify design flaws fast

Iterate with minimal cost and time

SLA rapid prototyping, also known as stereolithography 3D printing, is a go-to technology for professionals requiring high-resolution prototypes with intricate details and smooth finishes. Compared to other 3D printing methods, SLA excels in:

Speed – Functional parts delivered in 24–48 hours

Precision – Tolerances as fine as ±0.05mm

Detail – Ideal for presentation-ready parts

⠀⠀In this guide, you'll discover:

How SLA 3D printing works

Which resins are best for your application

Ready to bring your idea to life with SLA 3D printing? Keep reading—or contact our team for tailored advice and a fast, professional quote.

What is SLA Rapid Prototyping?

SLA (Stereolithography Apparatus) is one of the earliest 3D printing technologies, first commercialized in the 1980s. It remains a top choice for rapid prototyping, especially when high precision and excellent surface quality are needed.

How SLA Works

SLA uses a UV laser to selectively cure liquid photopolymer resin layer by layer. The laser traces the resin’s cross-section, solidifying each layer to build a fully detailed 3D model.

Advantages of SLA Prototyping

Feature | SLA Advantage | Benefit for Your Project |

|---|---|---|

Precision | Up to ±0.05 mm | Ideal for intricate designs and tight tolerances |

Surface Quality | Near-mirror finish directly from the printer | Great for presentation models, CMF testing, and painted prototypes |

Geometric Freedom | Supports complex, enclosed structures | Enables flexible design with no restrictions on geometry |

Fast Turnaround | 24–72 hour lead time | Reduces iteration time and accelerates product R&D |

Why SLA is Still the Leading Prototyping Method

Despite the rise of newer technologies like FDM and SLS, SLA continues to be indispensable in fields where precision, surface quality, and speed are paramount.

1. High-Fidelity Prototypes

SLA offers layer thicknesses as fine as 25 microns, with dimensional accuracy up to ±0.05mm—making it perfect for form-fit validation and miniature components.

SLA prints naturally smooth, injection-mold-like surfaces, reducing or even eliminating the need for post-processing. This makes it the preferred choice for presentation-grade prototypes.

2. Ideal for Master Patterns in Casting/Molding

SLA is ideal for urethane casting or short-run metal molding. Its surface smoothness and dimensional stability make it perfect for master patterns in industries like automotive prototyping or consumer electronics.

3. Resin Innovation Expands SLA’s Use Cases

Modern SLA resins go beyond brittle parts, offering engineering-grade materials that provide:

High impact resistance

Temperature resistance

Biocompatibility

Transparency or elasticity

This has expanded SLA’s use to functional prototyping in industries like automotive, medical, and wearables.

SLA Prototyping in Key Industries

SLA rapid prototyping is a go-to choice for industries where visual accuracy, functional testing, and fast iteration are critical. Below are key industries where SLA excels:

Industry | Common Applications | Unionfab Case 1 | Case 2 |

|---|---|---|---|

Medical & Dental | Surgical guides, |

|

|

Consumer Products/Electronics | Concept casings, |

|

|

Industrial Design | Functional testing, |

|

|

Mold Making | Silicone mold masters, RTV patterns |

|

|

Automotive | Interior mockups, |

|

|

Art & Sculpture | Artistic sculptures, custom miniatures, prototypes |

|

|

Model Making | Architectural models, |

|

|

Resin Types & Use Cases for SLA Prototyping

Choosing the right resin is key to ensuring your SLA prototype meets both functional and visual expectations. Below is a guide to the most commonly used SLA resins and their best-fit applications.

Material Type | Key Features | Typical Applications | Example |

|---|---|---|---|

Smooth surface finish, cost-effective, fast printing | Concept models, cosmetic prototypes |

| |

High impact strength, greater durability | Functional prototypes, snap-fit assemblies, mechanical parts |

| |

Withstands >160 ~227°C, excellent rigidity | Thermal testing, under-the-hood components, mold inserts |

| |

High light transmittance, polishable surface | Optical parts, light guides, fluid dynamics models |

| |

Rubber-like flexibility, high elongation | Wearables, gaskets, soft-touch parts |

| |

Designed to burn out cleanly for investment casting | Jewelry, dental crowns, small metal parts |

|

Not sure which resin matches your project requirements? Our engineers can help you select the best material based on mechanical performance and visual expectations.

Overcoming SLA Rapid Prototyping Limitations

SLA is widely known for its precision and smooth finishes, but like any technology, it has its constraints. Here are the main challenges and how to work around them:

Limited Build Size

Limitation: Most SLA printers have a restricted build volume, limiting the size of single-piece parts.

Fix:

For larger parts, we offer part segmentation and seamless assembly, preserving strength and fit.

Unionfab also offers large-scale SLA printing up to 2000×900×700 mm.

UV Sensitivity

Limitation: SLA resins can yellow or become brittle over time due to UV exposure.

Fix: Apply UV-resistant coatings or paint finishes to extend durability—ideal for outdoor/display parts.

Higher Unit Cost

Limitation: SLA is pricier than FDM, but it's best reserved for high-detail or client-facing parts.

Fix: Use hybrid prototyping strategies—combine SLA with FDM, CNC machining, or silicone molding depending on your needs. This allows early-stage models to remain cost-effective while reserving SLA for high-detail, client-facing, or functional prototypes.

Choose the Right SLA Prototyping Service Provider

Who’s Best for Your SLA Prototype? Let’s Compare.

Not all SLA 3D printing services are created equal—and if you’re building a high-precision prototype, the right partner makes all the difference.

We’ve rounded up six top global SLA service providers and compared them on what really matters:

✅ Resin variety

✅ Maximum print size

✅ Turnaround speed

✅ Sample cost

This side-by-side chart shows who offers what—so you can make a smarter choice, faster.

2025 Top SLA Rapid Prototyping Service Providers

Why Choose Unionfab?

Unionfab is your trusted partner for industrial-grade SLA prototyping and small-batch production. With a large fleet of SLA machines and a diverse material inventory, we deliver not just precision—but also speed, consistency, and flexibility.

Instant online quotes

6 in-house factories, 500+ SLA machines for fast turnaround

Full finishing suite: sanding, painting, electroplating & more

Wide selection of engineering-grade resins

No MOQ: From single prototypes to low-volume production

⠀Looking for expert SLA support? Upload Your File for a Free Quote Today!