Wire EDM Explained: Your Complete Guide to Precision Machining

Want to machine parts with extreme precision, no mechanical stress, and excellent surface finish? Wire EDM is your answer. In this guide, we’ll show you how it works, what it’s good for, and how to get the most out of it.

Introduction

Wire EDM (Wire Electrical Discharge Machining) is a vital technology for producing highly accurate, intricate, and stress-free components. Unlike conventional cutting tools, Wire EDM uses electrically charged wire to erode material without physical contact—enabling unmatched detail and edge quality.

In this guide, we’ll walk you through:

What Wire EDM is and how it works

Its advantages over traditional and alternative cutting methods

The materials it supports and the industries where it excels

Best practices for getting the most out of the process

Let’s dive into the precision world of Wire EDM—where complexity meets control.

What is Wire EDM?

Wire Electrical Discharge Machining (Wire EDM) is a highly precise, non-contact CNC machining process that uses controlled electrical sparks to cut through metal.

Instead of relying on mechanical force like milling or turning, Wire EDM removes material by creating tiny electrical discharges between a thin wire and the workpiece—allowing for extremely accurate, low-stress cutting.

Because the wire never physically touches the material, there is no mechanical pressure, no vibration, and minimal thermal distortion, making it ideal for cutting delicate, hard, or heat-sensitive components.

What Materials Can Be Cut with Wire EDM?

Wire EDM is capable of machining any electrically conductive material, including:

Hardened steel and tool steel

Titanium and nickel-based superalloys (e.g., Inconel)

Tungsten carbide

Copper and copper alloys

Graphite and certain conductive ceramics

How Does Wire EDM Work?

Wire EDM works much like controlled lightning in a tank. Rather than cutting with force, it removes metal with a stream of rapid, precise electrical sparks—allowing for intricate, high-precision cuts that traditional machining can't achieve.

Wire EDM Process Flow

CAD Design ➜ CNC Programming ➜ Workpiece Setup ➜ Submerged Cutting ➜ Finished Part

CAD Design: Engineers create a digital model of the part.

CNC Programming: Toolpaths are defined based on the part geometry.

Setup: The workpiece is fixed in place and submerged in dielectric fluid.

Cutting: A thin, electrically charged wire moves precisely along the programmed path, cutting the material via electrical discharges.

Finishing: The part is cleaned, inspected, and ready for use—with tight tolerances and smooth surface finish.

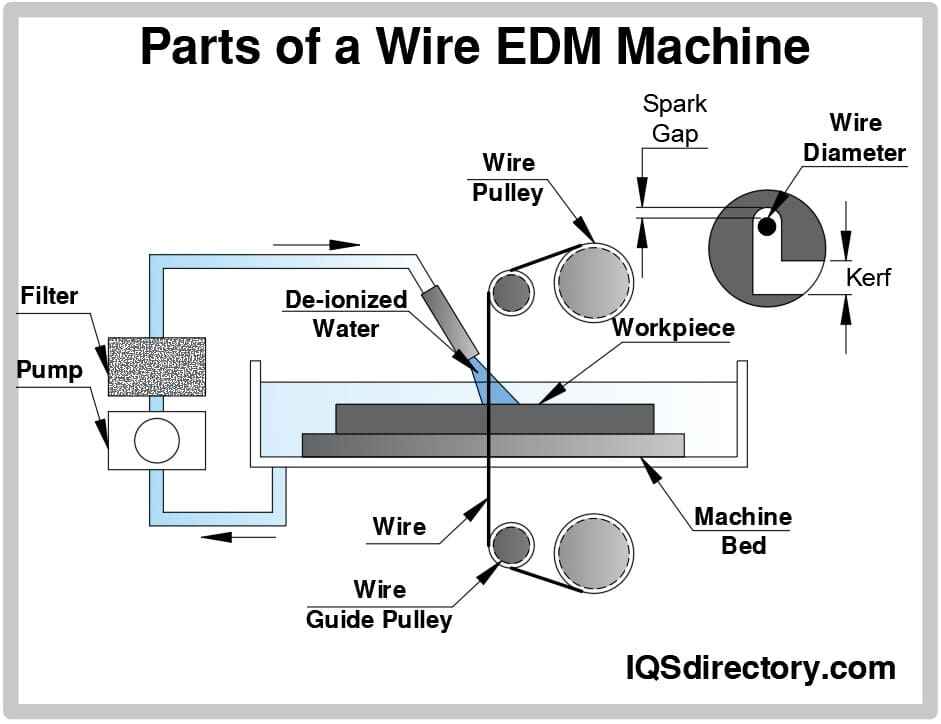

The Principle

No Mechanical Contact: The wire never physically touches the part. Instead, a small gap—called the spark gap—is maintained.

Spark Discharge: The power supply sends short, pulsed bursts of energy across this gap, creating tiny sparks that vaporize metal.

Kerf Width: The total width of the cut, known as the kerf, depends on wire size and spark gap (typically ~0.1–0.3 mm).

Core Components of a Wire EDM Machine

Component | Function |

|---|---|

Power Supply | Generates high-frequency voltage (100–300V) to produce electrical sparks |

Wire Electrode | Thin brass, tungsten, or molybdenum wire (Ø 0.05–0.30 mm) |

Dielectric Fluid | Deionized water that insulates, cools, and flushes debris |

Workpiece Fixture | Holds the conductive part in place during submerged machining |

CNC System | Controls the wire movement and cutting path with extreme precision |

Key Terminology You Should Know

Spark Gap: The controlled distance between wire and part (~0.01–0.05 mm) where sparks form

Kerf: The width of the material removed by the EDM process

Dielectric: Non-conductive fluid (deionized water) that cools the work zone and flushes particles

Wire Tension: Affects accuracy and wire stability during cutting

Pulse Duration: Determines how much material is eroded with each spark

Wire Speed: Controls how fast new electrode wire feeds through the cut

Advantages of Wire EDM

Wire EDM offers a unique set of benefits that make it a go-to solution for precision manufacturing—especially when working with hard materials, tight tolerances, and complex geometries.

1. Exceptional Precision & Surface Quality

Wire EDM is renowned for its ultra-high accuracy, achieving tolerances as tight as ±0.005 mm and surface finishes as smooth as Ra 0.8 μm. This level of detail significantly reduces or eliminates the need for secondary finishing like polishing or grinding.

2. No Mechanical Stress or Tool Pressure

Because the cutting process is completely non-contact, there’s no force, friction, or vibration applied to the part. This makes it ideal for:

Fragile structures

Thin walls

High-precision featuresIt also avoids distortion—critical in aerospace, medical, and microfabrication applications.

3. Cuts Hard and Tough Materials with Ease

Wire EDM can process materials that are notoriously difficult for conventional machining, including:

Hardened steel and tool steel

Titanium alloys

Tungsten carbide

Inconel and other superalloys

Copper, brass, and other conductive metals

4. Handles Extremely Complex Geometries

Need internal corners, deep slots, or intricate 3D contours? Wire EDM makes it possible to cut:

Micro-holes

Sharp internal angles

Narrow channels

Intricate outlinesWith unmatched accuracy—something traditional tools often can’t achieve.

5. No Custom Tooling Required

Unlike milling or turning, Wire EDM doesn’t rely on shaped cutters. Everything is driven by the CNC program and wire path:

Fast changeover between jobs

Minimal setup time

Cost savings on tooling

6. Ideal for Prototyping & Small-Batch Production

Wire EDM is well-suited for rapid prototyping and low-volume runs, offering:

Fast turnarounds

Low tooling investment

High flexibility in part design iteration

Whether you're creating surgical instruments or turbine blades, Wire EDM combines speed, precision, and versatility—making it a vital tool for advanced manufacturing.

Wire EDM Tolerances

One of the defining strengths of Wire EDM is its exceptional dimensional accuracy. Whether you're producing fine-featured prototypes or mission-critical aerospace parts, Wire EDM offers tolerances that rival or exceed those of traditional CNC machining.

Typical Wire EDM Tolerances

Standard tolerance: ±0.01 mm (±0.0004 in)

Tight tolerance (with fine-tuning and multiple skim passes): ±0.005 mm (±0.0002 in)

Ultra-precision setups (on stabilized parts and machines): down to ±0.002 mm (±0.00008 in)

These tolerances are achievable without generating mechanical stress or thermal distortion, making Wire EDM ideal for high-precision parts with tight dimensional requirements.

What Affects Wire EDM Tolerance?

Several factors influence the achievable accuracy:

Factor | Impact |

|---|---|

Wire Diameter | Finer wires can cut smaller features, but may vibrate more. Common sizes range from 0.10–0.30 mm. |

Wire Tension | Proper tension minimizes deflection and corner rounding. |

Skim Passes | Multiple finishing passes reduce roughness and improve dimensional control. |

Workpiece Thickness | Thicker parts may experience slight taper unless compensated via CNC. |

Dielectric Fluid Quality | Clean, deionized water ensures stable sparking and consistent erosion. |

Thermal Stability | Holding tight tolerances requires a temperature-controlled environment and stable machine calibration. |

When Tight Tolerances Matter

Wire EDM is the go-to solution for parts that require:

Interlocking fits and zero-play assemblies

Micro-scale channels, gears, and medical devices

Tight corner radii and small feature profiles

Precision dies, injection mold inserts, and stamping tools

Even complex geometries—like thin walls, sharp internal corners, or deep narrow slots—can be cut with precision that conventional machining struggles to match.

Need high accuracy for your project? Unionfab’s Wire EDM services support tolerances down to ±0.005 mm with inspection reports on request. Upload your drawing for a free manufacturability review.

Materials & Typical Applications

Wire EDM’s ability to cut electrically conductive materials with extreme precision makes it indispensable across industries that demand performance, complexity, and consistency.

What Materials Can Be Cut with Wire EDM?

Wire EDM is compatible with a wide range of conductive metals, including those that are too hard, brittle, or heat-sensitive for traditional machining methods.

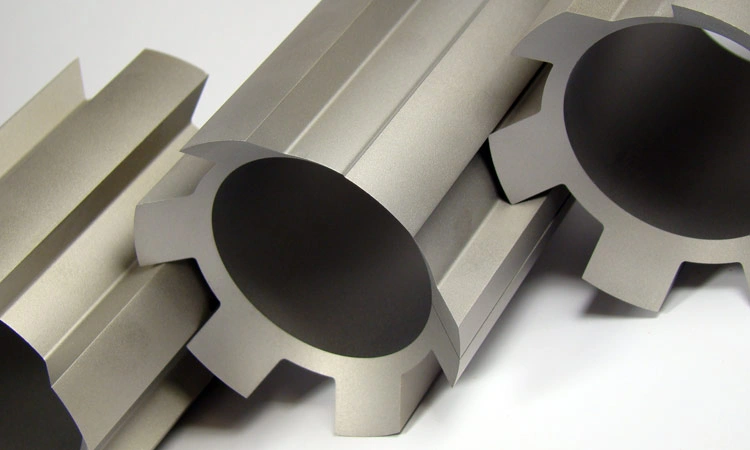

Material Type | Typical Grades/Notes | Common Uses |

|---|---|---|

Stainless Steel | Surgical tools, aerospace brackets | |

Tool Steel | A2, D2, H13, P20 | Dies, molds, punches |

Titanium Alloys | Grade 2, Grade 5 (Ti-6Al-4V), Grade 23 | Implants, turbine parts |

Nickel Alloys | Inconel 625, 718, Hastelloy, Monel (Contact us for a quote) | Jet engines, heat exchangers |

Tungsten Carbide | Sintered carbide blocks or inserts | Cutting tools, wear parts |

Copper Alloys | copper, brass, bronze | Electrical connectors, leadframes |

Graphite | Used for EDM electrodes | Mold cavities, semiconductor tooling |

As long as the material conducts electricity, Wire EDM can handle it—with minimal thermal distortion or tool wear.

Wire EDM vs Other Cutting Methods

When choosing a cutting process, precision, material compatibility, speed, and edge quality are critical factors. This section compares Wire EDM with other common cutting methods, helping engineers and buyers make the right decision based on project requirements.

Comparative Overview

Criteria | Wire EDM | Laser Cutting | Waterjet Cutting | Plasma Cutting | Conventional EDM |

|---|---|---|---|---|---|

Material Type | Conductive only | Most materials | Most materials | Conductive only | Conductive only |

Precision | ★★★★★ (±0.005 mm) | ★★★☆☆ (±0.1 mm) | ★★☆☆☆ (±0.2 mm) | ★☆☆☆☆ (±0.3–0.5 mm) | ★★★★☆ |

Surface Finish | Excellent (Ra 0.8 µm) | Good | Fair | Rough | Good |

Heat-Affected Zone | Minimal | Moderate | None | High | Moderate |

Cut Complexity | Excellent (3D & Internal) | Good (2D & contours) | Moderate | Poor (limited geometry) | Moderate (3D shapes) |

Cutting Speed | Slow | Fast | Fast | Very fast | Slow |

Tool Wear | Low | None | None | Moderate | High (on electrode) |

Cost (per part) | Medium | Low | Medium | Low | Medium-high |

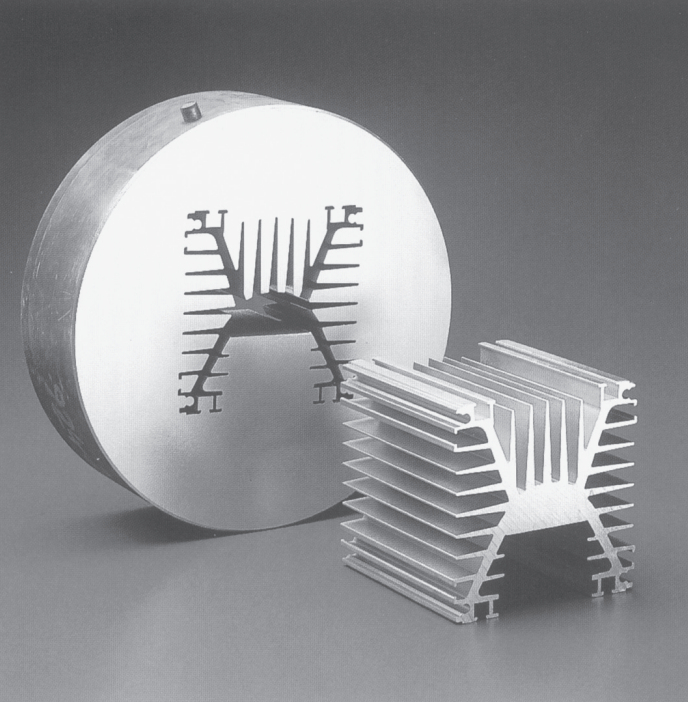

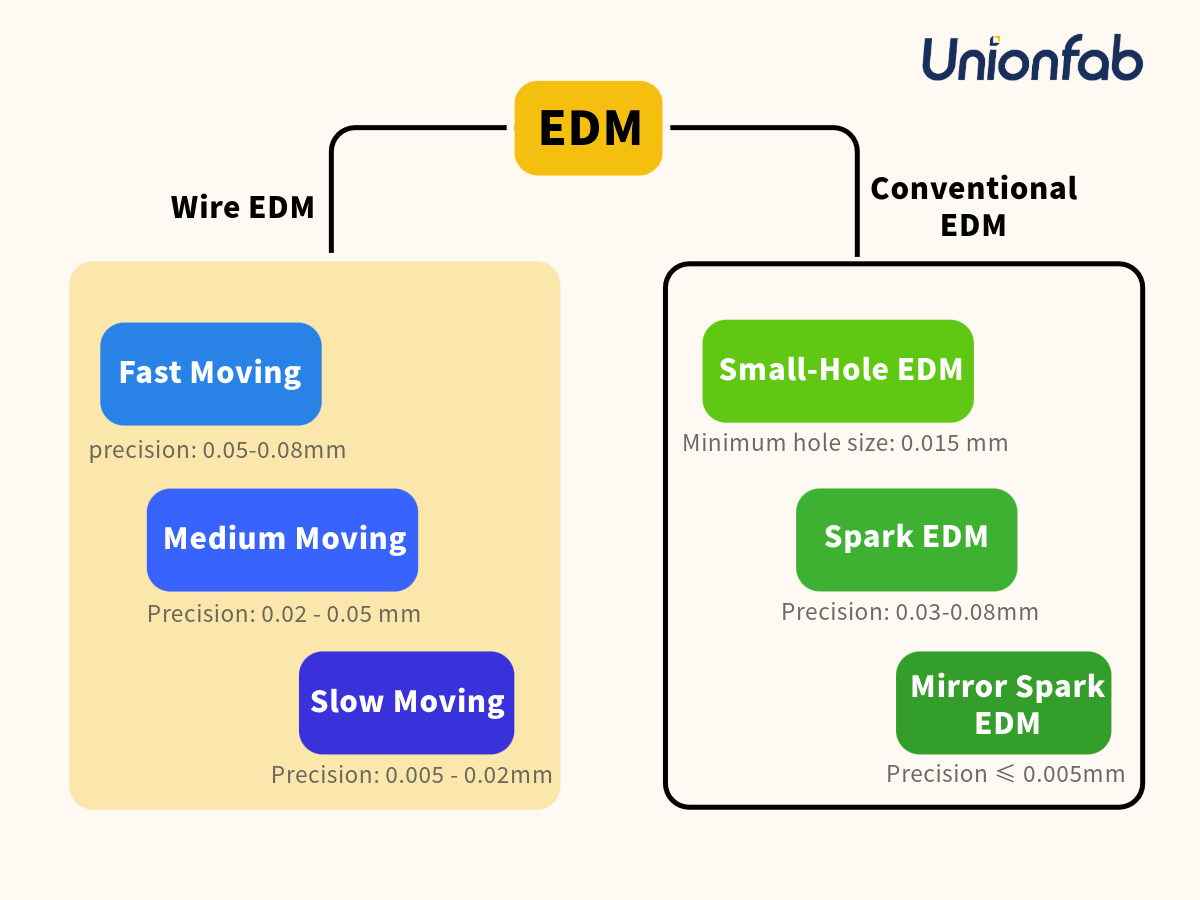

Wire EDM vs. Conventional EDM

Both Wire EDM and conventional EDM are spark erosion processes, but they differ significantly in application. Conventional EDM (also called sinker or die-sinker EDM) uses shaped electrodes to erode cavities into a workpiece, making it ideal for 3D shapes, mold cavities, and internal geometries.

Wire EDM, by contrast, excels at cutting profiles, slots, and through-holes with speed and precision, especially in flat or plate-like workpieces.

These two methods are often used together in tool and die manufacturing, each serving a specific stage of the process.

Wire EDM vs. Laser Cutting

Laser cutting uses a high-energy beam to melt or vaporize material, making it fast and suitable for thin sheets and general-purpose cutting. However, when it comes to tight tolerances and edge smoothness, Wire EDM has a clear advantage. It produces cleaner cuts with no heat-induced warping, especially in thick, hard, or reflective metals like titanium or Inconel, where lasers may struggle. In short:

Laser cutting is faster,

Wire EDM is more precise, with minimal heat-affected zones and better edge definition.

Wire EDM vs. Waterjet Cutting

Waterjet cutting uses a high-pressure stream of water mixed with abrasives and excels at cutting a wide variety of materials—including non-conductive materials like plastics, stone, or rubber—which Wire EDM cannot process. However, waterjet systems often leave rougher edges and lower dimensional accuracy, especially in intricate features.

Wire EDM, on the other hand, is the method of choice for complex geometries, fine internal contours, and tiny features that require exceptional accuracy and minimal material disturbance.

Wire EDM vs. Plasma Cutting

Plasma cutting is commonly used for fast, rough cuts in thick, conductive materials like steel plates. It offers high throughput at a relatively low cost. But the process results in angled edges, more burr, and lower precision, making it unsuitable for tight-tolerance parts.

Wire EDM is much slower but produces straight, clean, burr-free cuts with negligible thermal impact, which is vital for high-spec components in aerospace, medical, or precision tooling applications.

When to Choose Wire EDM

Wire EDM is the best choice when your application requires:

Unparalleled accuracy (±0.005 mm or better)

Sharp internal corners, micro-holes, or narrow slots

Hard-to-machine materials like carbide or hardened steel

Minimal heat distortion and stress-free machining

One-off parts, prototypes, or low-volume high-precision runs

Wire EDM Techniques and Best Practices

To get the most out of Wire EDM, manufacturers must understand how key process variables—like wire selection, cutting speed, and flushing conditions—affect precision, efficiency, and surface quality.

Balancing Cutting Speed and Accuracy

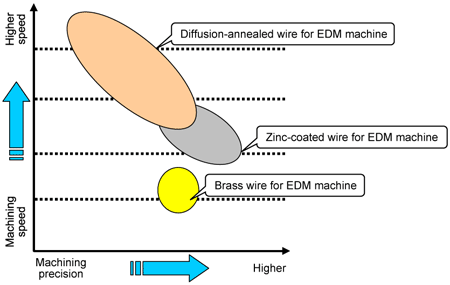

Wire diameter directly affects both speed and accuracy. Thin wires (e.g., Ø 0.10 mm) can move faster and are ideal for micro-details but may introduce vibration or corner rounding. Thicker wires (e.g., Ø 0.25 mm) provide better stability and edge control, making them suitable for precise contours.

To achieve an optimal cut:

Increase wire tension to stabilize thin wire during tight cuts

Reduce pulse duration and lower feed rates for better surface finish

Use multi-pass cutting (rough cut + skim passes) for improved tolerance

Using Coated/Diffusion-Annealed Wire for Wire EDM

Wire selection is fundamental to performance. Brass wire is the standard choice for most applications, but for higher speed and better surface quality, coated wires (e.g., zinc-coated or diffusion-annealed) are often preferred. These wires reduce electrical resistance and wire breakage, allowing faster cutting speeds (up to 30% faster) and improved edge finishes.

Tip: Use lower-cost uncoated wire for roughing passes and premium wire for final finishing—this reduces cost without compromising quality.

Surface Finish Optimization

Wire EDM can achieve surface finishes as fine as Ra 0.8 μm, but this depends heavily on machine settings and post-processing. To enhance results:

Perform multiple skim cuts after the roughing pass

Monitor deionized water purity to prevent contamination artifacts

Consider post-EDM finishing like:

Vibratory deburring

Passivation

Electro-polishing (especially for medical and aerospace parts)

Note: Higher amperage = faster cut, but coarser finish. For a smoother surface, slow down and refine.

Preventing Common Issues

Some of the most frequent problems in Wire EDM include:

Wire breakage: Often caused by excessive speed, poor flushing, or low-quality wire

Inconsistent cuts: Can result from contaminated dielectric, misaligned wire guides, or incorrect polarity

Tapered or inaccurate profiles: May indicate unstable wire tension or worn fixtures

Regular maintenance, machine calibration, and routine wire guide inspection are critical for long-term reliability.

Automation & Efficiency

Modern Wire EDM machines support advanced automation features, including:

Auto wire threading (reduces downtime between cuts)

Multi-axis CNC control for complex 3D geometries

Custom fixturing to hold multiple parts simultaneously for batch runs

Remote monitoring & scheduling to optimize machine uptime

These capabilities not only boost throughput but also make Wire EDM highly competitive for low-volume and mid-volume precision manufacturing.

Cost Control Strategies

Wire EDM is not always the cheapest process—but smart strategies can help reduce cost-per-part:

Use rough/finish sequencing with different wires

Nest multiple parts in one setup when possible

Optimize CNC programming to reduce non-cutting movements

Schedule jobs to minimize idle machine time

In Wire EDM, consistency is king—and consistency comes from understanding the interplay of process variables. Mastering these techniques can help turn precision into productivity.

Ready to Take Your Precision to the Next Level?

At Unionfab, we provide advanced Wire EDM services powered by decades of manufacturing experience and a commitment to detail.

Upload your design, and we’ll help you bring it to life with accuracy down to the micron.

✅ Instant quotes available for qualified files

✅ Support for high-performance metals and small-batch runs

✅ Expert support to optimize cost, material, and design

👉 Explore Our CNC Machining Capabilities ›

Precision starts here. Let’s build what others can’t.