SLS vs. MJF: Free Cost Calculator and Selection Tips

![SLS vs. MJF [ Free Cost Calculator and Selection Tips]](https://ufc-dtc-cms.oss-accelerate.aliyuncs.com/blog/20240521/211128_lyzzm58g7.png)

Discover the differences between SLS and MJF alloys to learn their unique properties, applications, and performance in 3D printing.

Introduction

Both SLS and MJF are powder-based 3D printing technologies that produce durable prototypes and end-use parts, but their processes, material options, cost, and lead times can vary greatly.

In this article, we’ll highlight the key differences between SLS and MJF to help you choose the right additive manufacturing solution for your next project.

SLS vs. MJF: Understanding the Core Differences

Both SLS (Selective Laser Sintering) and MJF (Multi Jet Fusion) are 3D printing techniques that use powder beds to create functional prototypes and end-use parts. However, they differ in how they fuse the powder material together, leading to distinct advantages and considerations for each method.

SLS vs. MJF: Printing Process Comparison

While both SLS and MJF utilize powder beds for 3D printing, the way they handle the powder and achieve fusion differs significantly.

SLS Printing Process

Source: zczz.com

Powder Preparation: Spread a thin layer of thermoplastic powder (e.g. nylon, polyamide) across the build platform.

Laser Scanning: A CO₂ laser selectively melts the powder in the part's cross-section, fusing the particles.

Platform Lowering & Recoating: The build platform lowers by one layer, and new powder is deposited.

Repeat Layers: Steps 2–3 repeat until the part is fully built.

Post-Processing: The part cools, then is excavated and cleaned of loose powder. Support structures (if any) are manually or waterjet-removed.

MJF Printing Process

Source:zhuanlan.zhihu.com

Powder Preparation: Apply a thin, even layer of thermoplastic powder (typically nylon).

Fusing Agent Application: Inkjet-style printheads deposit fusing agents onto areas defined by the CAD model.

Infrared Heating: An IR source passes over the powder bed, melting powder where the fusing agent is present to form one layer of the part.

Platform Lowering & Recoating: The build platform descends and a new powder layer is spread.

Repeat Layers: Steps 2–4 repeat until the part is complete.

Post-Processing: After cooling, the part is removed and cleaned of unfused powder. Support removal is rarely required.

Learn more about MJF 3D Printing: The Ultimate Guide [+ 2025 Service Providers] and its key benefits for functional parts.

SLS vs. MJF: Comparision of Printing Process

Feature | SLS | MJF |

|---|---|---|

Fusing Mechanism | Laser melting | Fusing agent and infrared heat |

Material Options | Wider range (nylon, polyamide, some metals) | Primarily nylon powders |

Layer Fusion | Complete melting of powder particles | Bonding through fusing agent and heat |

Surface Finish | Generally rougher | Generally smoother |

Printing Speed | Slower | Potentially faster |

SLS vs. MJF: Material Options

While both SLS and MJF utilize powdered materials for 3D printing, a key difference lies in their material options.

Similarities:

● Primary Material: Both processes primarily use nylon, specifically nylon 12 (PA 12). This versatile material offers good strength, flexibility, and heat resistance.

● Nylon Variations: Both SLS and MJF offer variations of nylon, including glass-filled nylon (PA 12 GF) for enhanced strength and stiffness.

Differences:

SLS has a wider range of material options compared to MJF. Here's what SLS offers that MJF typically doesn't:

● Metal-filled Nylons: These include carbon-filled PA for improved conductivity or aluminum-filled PA (alumide) for a lighter weight with a metallic look.

● Flexible Materials: SLS can handle some flexible materials like TPU, which is beneficial for applications requiring some give.

SLS vs. MJF: Part Quality

The quality of a 3D printed part includes various aspects: dimensional accuracy, surface finish, mechanical properties, and overall consistency.

Part Quality Achieved by SLS

● Dimensional Accuracy: SLS offers high dimensional accuracy due to the precise laser control. Parts closely match the digital design with minimal deviations.

● Surface Finish: SLS parts typically have a rougher surface texture directly related to the size and shape of the powder particles used. This might require additional finishing techniques for a smoother aesthetic.

● Mechanical Properties: SLS parts are known for their strength, durability, and heat resistance. The complete melting of powder particles creates strong inter-particle bonds, making them suitable for functional applications.

● Consistency: SLS offers good overall consistency in part quality due to the controlled laser melting process. Material properties tend to be consistent throughout the part.

Part Quality Achieved by MJF

● Dimensional Accuracy: MJF also delivers good dimensional accuracy. However, due to the use of a fusing agent and heat, there might be a slightly higher chance of dimensional deviations compared to SLS.

● Surface Finish: MJF parts generally boast a smoother surface finish right out of the printer. The fusing agent can fill in gaps between particles, reducing the grainy texture associated with SLS parts.

● Mechanical Properties: While still good for many applications, MJF parts might have slightly lower overall strength compared to SLS. The bonding process using a fusing agent might not be as strong as complete material melting in SLS.

● Consistency: MJF parts generally exhibit good consistency. However, there's a possibility of slight variations in material properties depending on the distribution of the fusing agent within the powder bed.

SLS vs. MJF: Comparision of Part Quality

Feature | SLS | MJF |

|---|---|---|

Dimensional Accuracy | High | Good (might have slight variations) |

Mechanical Strength | Strong and durable | Strong, but potentially less than SLS |

Surface Finish | Rougher texture (requires post-processing) | Smoother texture |

SLS vs. MJF: Post-Processing Requirements

While both SLS and MJF produce 3D printed parts directly from a powder bed, they might require some post-processing steps to achieve the desired final quality.

Post-Processing Steps Required for SLS Parts

● Cooling: The build chamber needs to cool down slowly to prevent warping or cracking of the parts due to thermal stress.

● Part Removal: The completed part is excavated from the surrounding unsintered powder. Depending on the complexity, this might involve manual removal or using compressed air.

● Support Structure Removal: SLS parts often require support structures for overhanging features. These supports are typically removed manually with tools or with a waterjet cutting system. Waterjetting requires additional equipment and expertise.

● Bead Blasting: This optional step involves blasting the part with tiny glass or ceramic beads to achieve a smoother surface texture.

● Dyeing: SLS parts are typically white or off-white. Dyeing can be used to achieve a desired color for aesthetic purposes.

● Machining or Finishing: Additional machining or finishing techniques like sanding or polishing might be necessary to achieve precise dimensions or a desired surface finish.

Post-Processing Steps Required for MJF Parts

● Cooling: Similar to SLS, the build chamber needs to cool down gradually to minimize the risk of warping.

● Part Removal: The completed part is removed from the surrounding unsintered powder. Due to the potentially weaker bonds between particles in MJF, this might be easier compared to SLS.

● Support Structure Removal: Support structures, if used, can often be removed manually with less force compared to SLS parts because of the potentially weaker bonds.

● Bead Blasting (Optional): Bead blasting can be used for MJF parts as well, but due to the potentially smoother surface finish achieved with the fusing agent, it might not always be necessary.

● Dyeing: Similar to SLS, dyeing can be used to add color to MJF parts.

SLS vs. MJF: Comparision of Post-Processing

Feature | SLS | MJF |

|---|---|---|

Cooling | Required | Required |

Part Removal | Can be challenging, might require compressed air | Potentially easier due to weaker particle bonds |

Support Structure Removal | Requires tools or waterjetting | Often easier to remove manually |

Bead Blasting | Optional, but common for smoother finish | Optional, might not be necessary for some parts |

Dyeing | Possible | Possible |

Machining/Finishing | Might be necessary for precise dimensions | Might be necessary for precise dimensions |

SLS vs. MJF: Cost Comparison

The cost of 3D printing a part using SLS or MJF depends on multiple factors, including part complexity, part volume, material selection, and post-processing needs. Here’s a breakdown of each consideration as it relates to SLS and MJF.

Machine and Material Costs

SLS machines generally require a higher upfront investment due to the more complex hardware and broad material compatibility. SLS supports a range of nylon powders and specialty blends — including metals and glass-filled composites — which can drive up material expenses. In contrast, MJF machines typically involve a lower initial cost and primarily process nylon powders like PA12 and PA12 GF, often resulting in lower material costs overall.

Printing Speed

SLS technology uses laser sintering, which can be relatively slow depending on part height and complexity. This often translates into a higher cost per hour of printing time. MJF, by using agents and infrared light to quickly fuse powder, is capable of producing similar parts faster, reducing the per-hour printing expense.

Material Usage and Recovery

Both SLS and MJF allow for partial recovery and reuse of unsintered powder after each build cycle. However, SLS powder is more prone to degradation after repeated use, especially when working with specialty materials, while MJF tends to maintain powder properties across multiple reuse cycles. These differences can influence ongoing material consumption and long-term project budgets.

Post-Processing

Post-processing plays a significant role in overall costs. SLS parts often require waterjetting to remove powder, followed by additional finishing techniques such as bead-blasting or dyeing, which adds time and expense. MJF parts typically require less intensive post-processing — manual powder removal is often sufficient, which simplifies labor and lowers post-processing costs.

Key Takeaways

Feature | SLS | MJF |

|---|---|---|

Machine Cost | Higher | Lower |

Material Cost | Can vary depending on material selection | Primarily uses nylon, might be lower |

Printing Speed | Slower | Potentially faster |

Material Usage | Can be partially recovered and reused | Can be partially recovered and reused |

Post-Processing Cost | Potentially higher due to waterjetting | Potentially lower due to simpler removal methods |

How to Choose SLS vs. MJF

When deciding between SLS and MJF, it’s important to align the process with your specific application requirements. Here are a few key factors to help you make the right choice:

● If you value surface finish, precision, and production efficiency → Choose MJF

Multi Jet Fusion (MJF) provides smoother surfaces, greater part consistency, and faster build times. This makes it ideal for projects where part aesthetics, fine details, and short lead times are top priorities.

● If you need a broad material selection, complex geometries, or lower costs → Choose SLS

Selective Laser Sintering (SLS) supports a wider range of materials and excels at producing intricate shapes without support structures. It’s often more cost-effective for small-batch and one-off designs.

● If you require full-color 3D-printed parts → Choose MJF

MJF is currently the only one of the two processes that offers full-color printing. This is especially valuable for visual models, prototypes for marketing, and customized end-use products.By carefully weighing these considerations, you can select the process that best matches your performance needs, design complexity, and budget. The result will be a more efficient, cost-effective 3D printing experience tailored to your goals.

SLS vs. MJF: Applications

The choice between SLS and MJF depends on the desired outcome of your project.

Applications Suitable for SLS

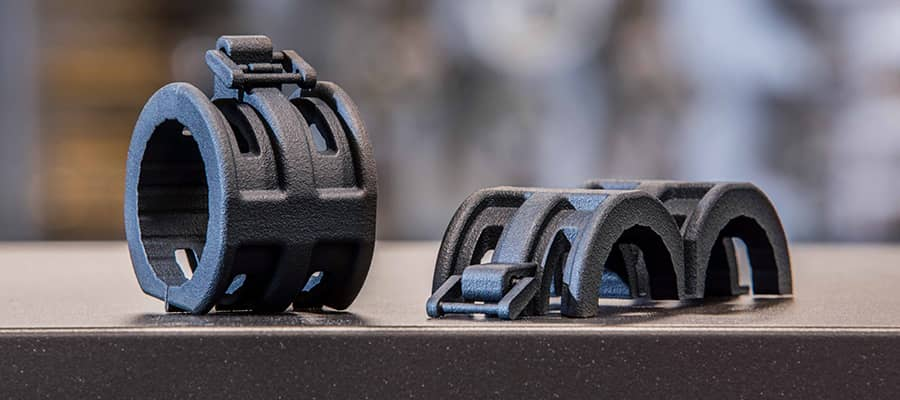

● Functional Prototypes: Due to their high strength and durability, SLS parts are ideal for prototypes undergoing rigorous testing or requiring functional performance under stress.

● End-Use Parts: SLS excels in creating robust end-use parts for various industries like aerospace, automotive, and medical. Examples include gears, brackets, and housings.

● Applications Requiring High Heat Resistance: SLS parts can withstand high temperatures, making them suitable for applications like jigs and fixtures used in manufacturing processes.

● Wide Material Selection: SLS offers a wider range of materials beyond nylon, including some metals. This allows for creating parts with specific properties like biocompatibility or electrical conductivity.

Source: protolabs.com

Applications Suitable for MJF

● Visual Prototypes: MJF parts generally have a smoother surface finish, making them ideal for creating visually appealing prototypes for design validation or presentations.

● Low-Volume Production Runs: MJF can be cost-effective for producing small batches of end-use parts, especially for simpler geometries.

● Applications Prioritizing Aesthetics: The smoother finish and potential for dyeing make MJF suitable for applications where appearance matters, like consumer goods or wearables.

● Rapid Prototyping: Due to potentially faster printing speeds, MJF can be a good choice for quickly iterating on prototypes during the design process.

Source: hubs.com

Conclusion

Both SLS and MJF are powerful 3D printing technologies with distinct advantages. SLS excels in functionality with its durable parts and wider material range, ideal for prototypes and end-use parts.

MJF offers a smoother finish, potentially faster printing, and simpler post-processing, making it a good fit for visual prototypes and low-volume production runs.

Experience Advanced 3D Printing Technology

In addition to SLS and MJF, Unionfab offers other 3D Printing Services, including SLA, FDM, SLM, PolyJet and Large Scale Printing. With advanced technology and quality services, Unionfab help make your project perfect!

FAQs

Q1: What is the main difference between SLS and MJF?

A: SLS (Selective Laser Sintering) uses a laser to sinter powdered material layer by layer, while MJF (Multi Jet Fusion) applies fusing agents and heat for faster, smoother, and more color-accurate parts. MJF is generally better for fine detail and surface finish, while SLS excels at complex geometries and material variety.

Q2: Which process is more cost-effective?

A: SLS is often more cost-effective for complex, low-volume parts or one-off prototypes. MJF tends to be more efficient and affordable for larger production runs due to its high-speed printing and uniform part quality.

Q3: Can both processes produce durable, end-use parts?

A: Yes. Both SLS and MJF can produce strong, functional parts suitable for end-use applications. However, MJF parts generally have slightly better isotropic mechanical properties and smoother surfaces right out of the printer.

Q4: Does MJF support color printing?

A: Yes. Multi Jet Fusion is one of the only industrial-grade 3D printing technologies that can produce full-color parts, making it ideal for prototypes, marketing models, and customized products.

Q5: How do I choose between SLS and MJF?

A: It depends on your priorities. If you need faster production, smooth finishes, or color capability, MJF is the better option. If your focus is on design freedom, broad material choices, or lower per-part cost for complex shapes, SLS is a great fit.