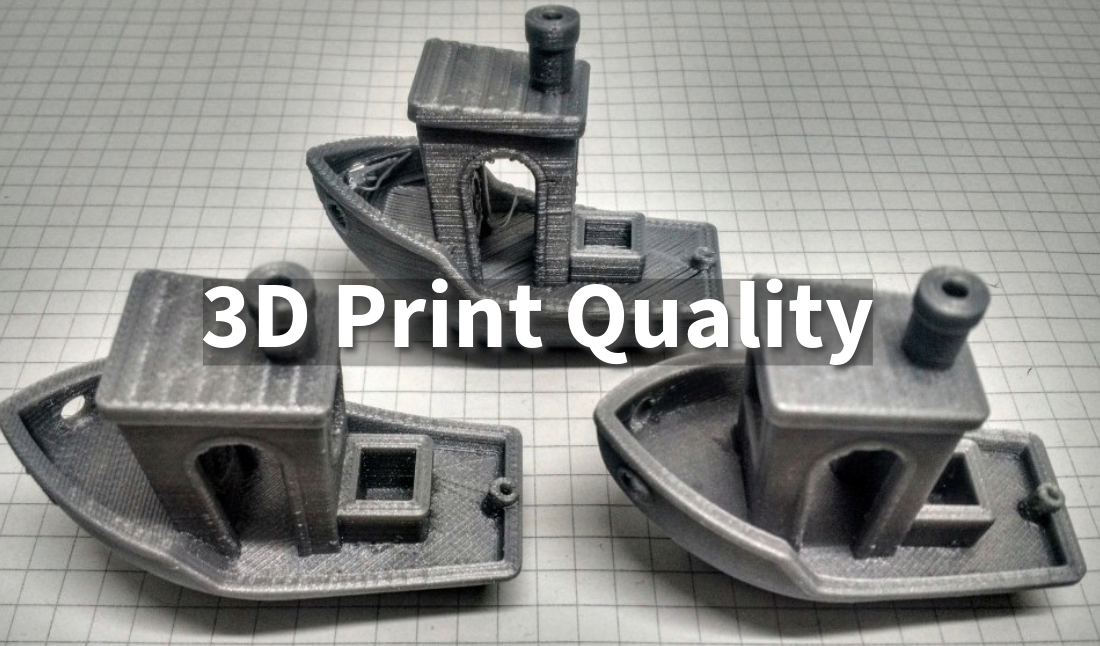

Boost Your 3D Print Quality: Tips and Tricks

Learn how to improve print quality with expert techniques, troubleshooting tips, and ideal settings for flawless results.

Introduction

Whether you're making a prototype or a final product, good print quality makes sure that all your hard work pays off with results that look nice, work well, and are reliable. Understanding what makes a good print can help you avoid problems like shifting layers, poor sticking, or rough surfaces.

In this blog, we'll explore some helpful tips and tricks to help you get the best quality from your 3D prints.

Common Factors Affecting 3D Print Quality

There are a few key factors that affect how good your 3D print turns out, like printer settings, filament quality, and the environment. Each of these is important for getting a successful print.

Printer Settings: Settings on your 3D printer, like layer height, print speed, and nozzle temperature, have a big impact on print quality. If the settings are wrong, you might have issues like poor layer sticking or surface problems.

Filament Quality: The quality of the filament you use affects how well your print turns out. Cheap or low-quality filament can have impurities or uneven thickness, which leads to weak spots or printer jams. High-quality filament makes prints stronger and more reliable.

Environmental Conditions: Things like room temperature and humidity can also affect print quality. If it's too humid, the filament can absorb moisture, causing problems like bubbling or poor sticking.

Another important factor is calibration. Calibrating your printer properly, including leveling the bed and aligning the nozzle, is crucial for getting consistent prints. A well-calibrated printer helps layers stick properly and makes sure the first layer is laid down right, which is key for avoiding problems later.

Printer Calibration Techniques

Good printer calibration is key to getting consistent and high-quality 3D prints. Here are some important calibration steps to follow:

Bed Leveling: Bed leveling makes sure that the print bed is flat and at the right distance from the nozzle. If the bed isn't level, the first layer might not stick well, causing print failures. You should do bed leveling regularly, either manually or automatically, to keep print quality high.

Nozzle Height: Nozzle height, also called Z-offset, controls how close the nozzle is to the print bed when printing the first layer. If the nozzle is too close, it can cause clogging, and if it's too far, the filament might not stick. Setting the nozzle height correctly helps create a smooth and well-stuck first layer.

Extruder Calibration: Extruder calibration means making sure the extruder feeds the right amount of filament. If too much filament is used, you get blobs and strings, while too little can lead to weak layers. By calibrating the extruder steps, you ensure strong and precise prints.

These calibration steps are really important because they help get rid of common issues like poor sticking, uneven layers, and inaccurate dimensions. Proper calibration sets a strong foundation for successful and high-quality prints.

Choosing the Right Material for Quality

Choosing the right material is very important for getting good-quality 3D prints. Here are some popular types and how they compare:

PLA, ABS and PETG are extruded layer by layer to form parts, making them ideal for functional prototypes, hobby projects, and durable components.

PLA

Properties: Easy to print, biodegradable, low cost.

Best For: Prototypes, decorative items, and low-stress applications.

Strengths: Minimal warping, a smooth surface finish, and compatibility with most 3D printers.

Limitations: Low heat and impact resistance, making it unsuitable for outdoor or functional parts.

ABS

Properties: Stronger and more durable than PLA, with good impact and heat resistance.

Best For: Functional parts, automotive components, and enclosures.

Strengths: Good post-processing capabilities (e.g., sanding, painting), durable.

Limitations: Prone to warping and emits fumes during printing, requiring a controlled environment.

PETG

Properties: A balance between PLA and ABS with excellent durability and ease of printing.

Best For: Food-safe applications, functional parts, and weather-resistant components.

Strengths: Resistant to impact, water, and UV; minimal warping.

Limitations: Requires precise settings to avoid stringing.

Optimizing Printer Settings for Quality Prints

To get the best quality prints, it's important to optimize your printer settings. Here are some key settings to focus on:

Layer Height: Layer height controls the resolution of your print. Smaller layer heights give smoother surfaces and more detail, but they take longer to print. For fine details, use a lower layer height, but for faster prints, a higher layer height is fine.

Print Speed: Print speed is how fast the printer moves while extruding filament. Faster speeds save time but can cause lower quality, like uneven layers or poor adhesion. Slower speeds usually give better results with more consistent bonding and less vibration.

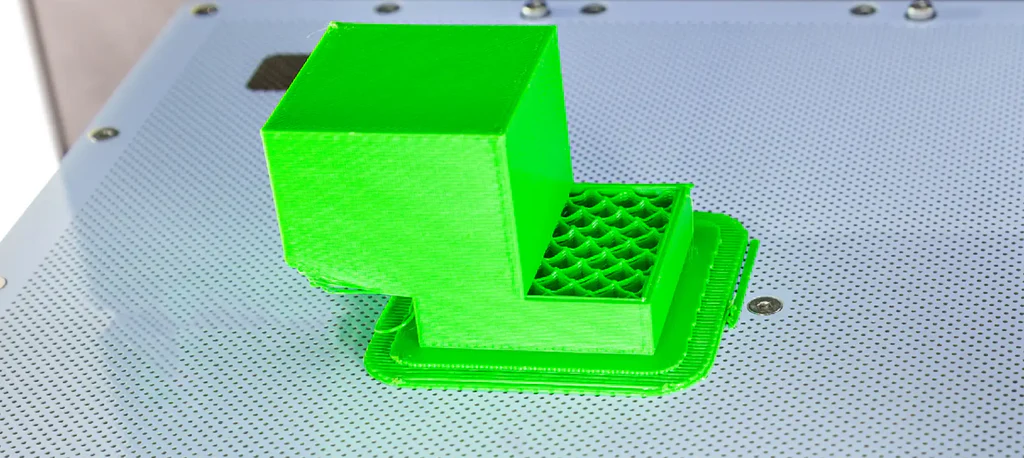

Infill Settings: Infill density and pattern affect the strength and weight of the print. Higher infill density makes the print stronger but uses more material and increases print time. Different infill patterns, like honeycomb or grid, also affect strength and flexibility. The right infill depends on the print's use—functional parts may need more infill, while decorative items can use less.

By optimizing these settings, you can improve print quality and make sure your 3D-printed parts look good and work well.

Environmental Factors

Environmental conditions can greatly affect the quality of your 3D prints. Here are some things to consider:

Room Temperature: Keeping a stable room temperature is important for consistent print quality. Sudden changes in temperature can cause warping or poor adhesion. The room should be kept at a steady temperature, away from drafts or direct airflow.

Humidity: Humidity can impact filament quality since many filaments absorb moisture from the air. This can cause problems like bubbling, weak sticking, and poor surface finish. To prevent this, store filament in airtight containers with desiccants and keep the environment as dry as possible.

Airflow: Too much airflow, like from fans or open windows, can cool the print too quickly, causing warping or uneven bonding. It's best to avoid drafts and keep the printer in a place with stable airflow. Some printers have enclosures that help control the environment, which is especially useful for materials like ABS that are sensitive to cooling.

To keep a stable printing environment, use an enclosure for your printer, keep the room temperature steady, reduce drafts, and store filament properly to avoid moisture. Controlling these factors can help you get more consistent and higher-quality prints.

Troubleshooting Common Print Quality Issues

Even if you prepare well, problems can still happen during 3D printing. Here are some common print quality issues and how to fix them:

Layer Shifting: Layer shifting happens when the layers of the print don't line up, making it look shifted or crooked. This can be caused by loose belts, obstacles, or high print speeds. To fix it, make sure the belts are tight, check for obstacles, and reduce the print speed if needed.

Layer Shifting

Source: kingroon.comWarping and Curling: Warping happens when the corners or edges of a print lift off the print bed, causing the part to bend. This usually happens because of uneven cooling or poor bed adhesion. To avoid warping, use a heated bed, apply adhesives like glue stick or painter's tape, and make sure the first layer sticks well. Enclosing the printer can also help keep the temperature steady and prevent warping.

Source: waykenrm.com

Stringing and Oozing: Stringing occurs when thin strands of filament are left between different parts of the print, usually because the nozzle leaks filament while moving. To fix this, adjust the retraction settings to pull the filament back into the nozzle during travel, and lower the nozzle temperature to stop excess filament from oozing out. These changes can help reduce stringing and give cleaner prints.

Source: ab3d.at

By knowing these common issues and how to fix them, you can improve print quality and avoid frustration from print failures.

Tips for Post-Processing to Enhance Quality

Post-processing is an important step that can make your 3D prints look much better. Here are some common post-processing techniques to try:

Sanding: Sanding smooths out the surface of a print and removes visible layer lines. Start with coarse sandpaper and move to finer grits for a polished finish. Sanding works well with materials like PLA and ABS, and it makes your prints look more professional.

Vapor Smoothing: Vapor smoothing involves exposing the print to solvent vapor, like acetone for ABS. This slightly melts the surface, creating a glossy and smooth finish. Vapor smoothing can make ABS prints look much better, but it should be done carefully since the chemicals can be dangerous.

Painting: Painting adds color and visual appeal to your prints. Before painting, sand the print and use a primer to help the paint stick. Acrylic paints are often used for 3D prints, and you can seal them with a clear coat for extra durability.

These post-processing techniques can make your 3D prints look more polished and professional. Whether you want a glossy surface, bright colors, or a smooth finish, post-processing can help you get the results you want and make your prints stand out.

Conclusion

By carefully calibrating your printer, selecting the right material, fine-tuning settings, controlling the environment, and applying post-processing methods, you can create stronger, better-looking, and highly functional 3D-printed parts. These practices will set you on the path to consistent success in your 3D printing projects.

Enhance Your 3D Print Quality with Unionfab

Ready to achieve flawless 3D prints? At Unionfab, we provide expert solutions and high-quality materials to help you bring your ideas to life.

Get an instant quote or contact us today to get started!