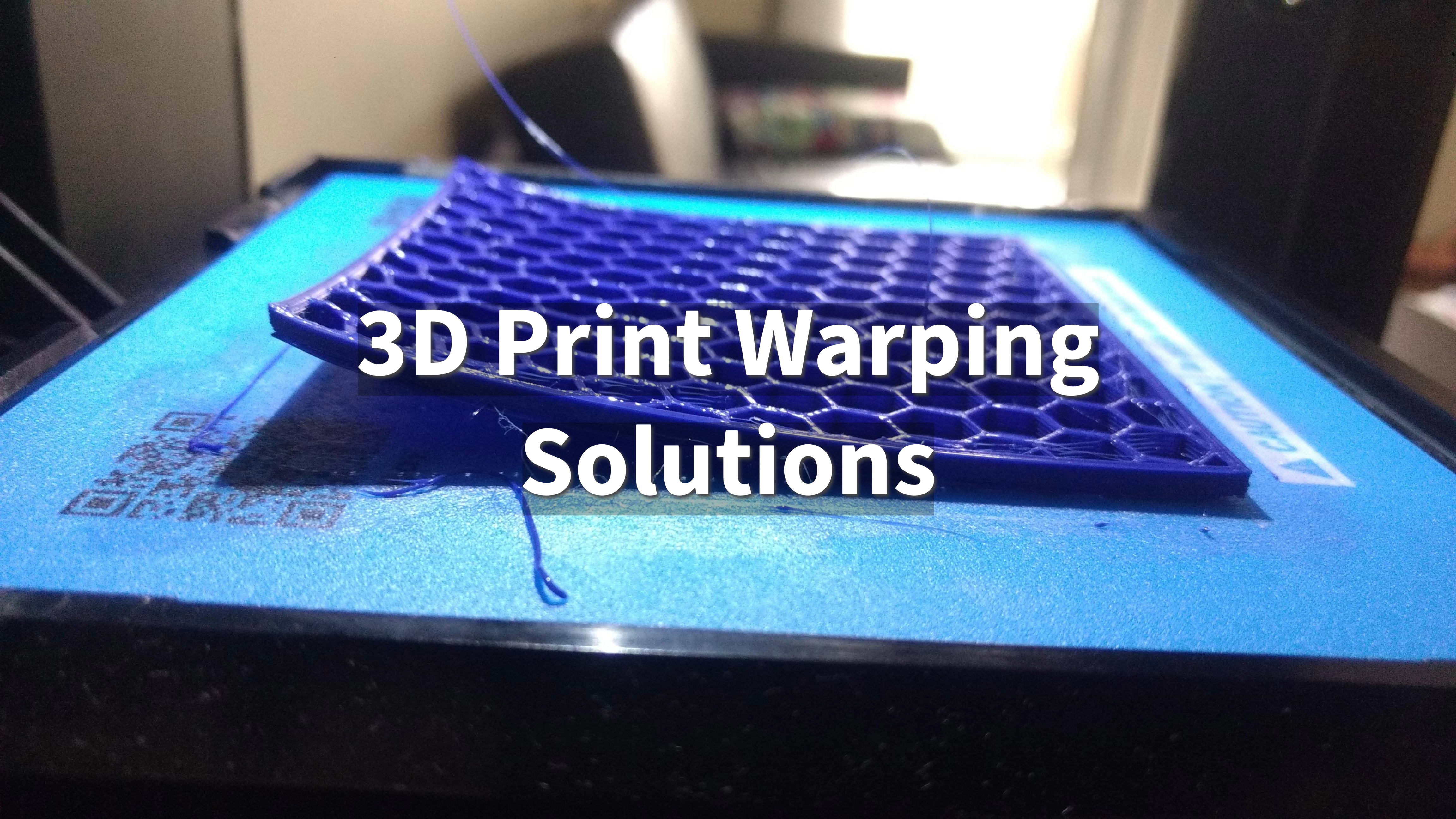

3D Print Warping Solutions: Tips and Techniques

Warping is a common 3D printing issue. Find out what causes it and explore easy-to-apply solutions for achieving smooth, warp-free prints.

Introduction

3D printing is a great way to make custom designs, prototypes, and unique products. But one of the biggest problems people face is warping. Warping happens when parts of a 3D print cool down unevenly, c ausing them to bend or lift up. This can ruin the print and waste both time and materials.

Warping is more common with certain materials like PLA, ABS, and PETG. PLA usually warps less, but ABS and PETG can be more difficult to work with because of how they react to heat. Knowing why warping happens and how to prevent it is important for getting good results with 3D printing.

Understanding Warping in 3D Printing

Source: flashforge.com

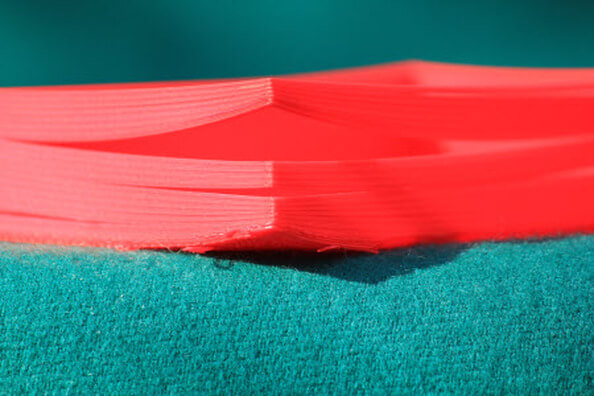

Warping is when a 3D print bends or lifts up because it cools unevenly. As the material cools, it shrinks a little, which can cause the edges of the print to lift off the build plate. This happens because different parts of the print cool at different rates, which creates stress that leads to warping.

Warping can really hurt the quality of your print. Warped prints often don't stick well to the build plate, which makes them less accurate and weaker. This affects how the final product looks and can make it less useful if it needs to be strong.

Causes of 3D Print Warping

Warping can be caused by several things, including:

Insufficient Bed Adhesion

If the print doesn't stick well to the build plate, the edges are more likely to lift off as it cools.

Uneven or Fluctuating Print Bed Temperature

If the bed temperature isn't consistent, different parts of the print can cool at different rates, causing stress and warping.

Incorrect Cooling Times or Fan Settings

Cooling the print too quickly or unevenly can cause warping. Setting the fan correctly and cooling at the right speed can help prevent this.

Material Choice and Environmental Factors

Some materials, like ABS, shrink more as they cool, which makes them more likely to warp. Drafts or changes in room temperature can also lead to uneven cooling and warping.

Effective Techniques to Prevent Warping

Improving Bed Adhesion

Making sure the print sticks well to the build plate is key to preventing warping. You can use glue sticks, painter's tape, or special build plates to help the print stay in place.

Temperature Settings

Setting the right bed and nozzle temperatures is important. For materials like ABS, keeping the bed warm can help prevent the lower layers from cooling too fast and warping.

Cooling Adjustments

Proper fan settings are important for controlling how fast the print cools. For materials that warp easily, lowering the fan speed during the first few layers can help avoid quick cooling and reduce stress.

Environmental Control

Reducing drafts and keeping the room temperature steady can help prevent warping. Using an enclosure around the printer can also help keep the temperature stable and protect the print from outside factors.

Choosing the Right Materials and Tools

Best Materials for Minimizing Warping

Some materials are less likely to warp than others. PLA is a good choice because it doesn't shrink as much when cooling. PETG is also a good option since it is strong and less prone to warping compared to ABS. For more advanced needs, nylon blends can be used as they resist warping well.

Recommended Adhesion Aids, Bed Surfaces, and Enclosures

Using the right tools can help prevent warping. Adhesion aids like glue sticks, hairspray, or painter's tape can help the print stick better. Special bed surfaces like PEI sheets or glass plates also help keep the print in place. Enclosures are useful for materials like ABS, as they keep the temperature steady and reduce drafts.

Troubleshooting and Quick Fixes

What to Try if You Notice Warping Early in the Print: If you see warping starting early, try adding more adhesive to the build plate or adjusting the bed level to get better contact. You can also pause the print and raise the bed temperature slightly to help keep the edges down.

When to Adjust Settings Versus Restarting the Print: If warping keeps happening despite small changes, you might need to restart the print with new settings. Try increasing the bed temperature, lowering the fan speed, or using an enclosure. If the warping is minor, adjusting the cooling rate or adding more adhesive during the print might be enough to save it.

Conclusion

Warping is a common problem in 3D printing, but it can be managed. By understanding the causes and using the right techniques, you can reduce the risk of warping and get better prints.

Trying different materials, adhesion aids, temperature settings, and environmental controls will help you find what works best for your needs. Practice and adjustments are key to getting good at 3D printing and minimizing warping issues.

Unionfab: Your Partner for Perfect Prints

Struggling with 3D print warping? Trust Unionfab for high-quality, warp-free prints every time.

Discover our reliable 3D printing services today and take the first step toward flawless results!