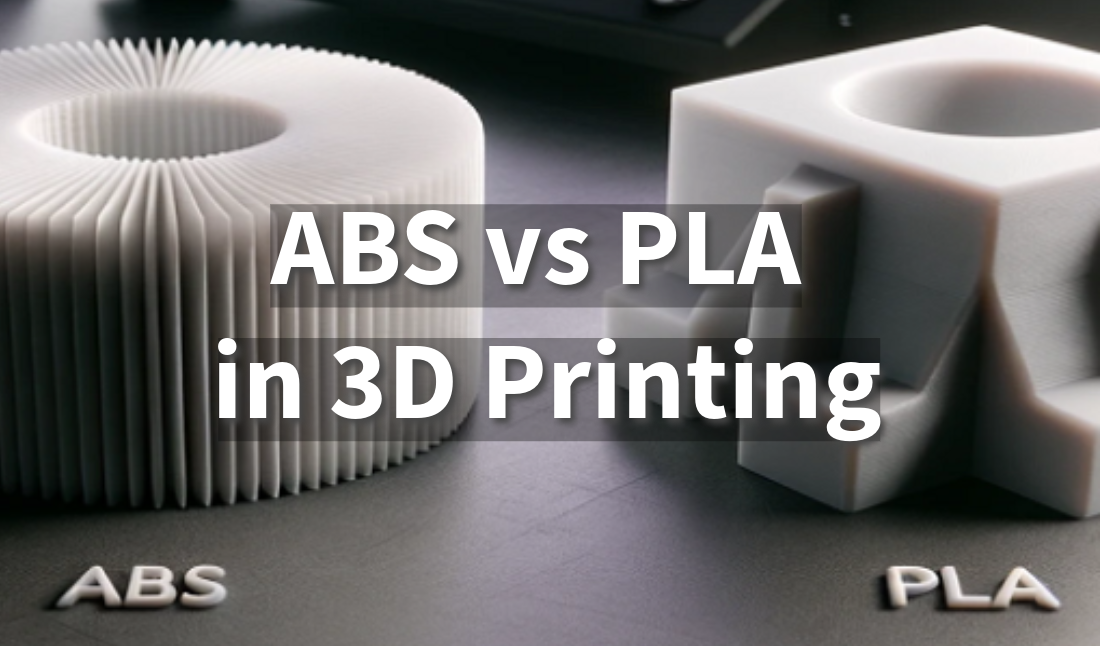

ABS vs. PLA in 3D Printing: Compare the Best 3D Printing Materials

Explore the pros and cons of ABS vs PLA for 3D printing. Find out which filament suits your project’s requirements, from strength to printability.

Introduction

3D printing has become increasingly popular over the last decade, becoming a valuable tool for hobbyists, designers, and engineers. One key factor that makes 3D printing so versatile is the variety of materials, or filaments, that can be used. Two of the most commonly used filaments are ABS and PLA. These materials each have unique properties that affect how well they work for different projects. In this blog, we will explain the key differences between ABS and PLA so you can choose the one that best fits your needs.

Overview of ABS and PLA

ABS and PLA are both thermoplastics, which means they become soft and moldable when heated and harden when cooled. However, they have important differences in their properties and uses.

ABS (Acrylonitrile Butadiene Styrene)

ABS is a strong and durable plastic that is often used for making parts that need to withstand wear and tear. It is made from a combination of chemicals that give it good strength and resistance to impact. ABS can handle higher temperatures than PLA, which makes it a good choice for objects that might get hot, such as car parts or tool handles. However, ABS can be challenging to print because it tends to warp as it cools, which means it usually needs a heated print bed to stay in place during printing.

PLA (Polylactic Acid)

PLA is a biodegradable plastic made from renewable resources like cornstarch or sugarcane. It is easier to print compared to ABS because it does not warp as much during cooling and does not require a heated bed. PLA is great for projects where strength is less important, such as decorative items, models, or prototypes. However, PLA is not as heat-resistant as ABS and can become soft if exposed to high temperatures, making it unsuitable for parts that need to handle heat.

Properties Comparison

Property | ABS | PLA |

|---|---|---|

Material Composition | Made from petroleum-based chemicals | Made from natural, renewable sources |

Mechanical Strength | Stronger, more durable | More brittle, can break under pressure |

Printability | Requires heated bed, careful temperature control | Easier to print, less warping, no heated bed required |

Heat Resistance | Can withstand higher temperatures | Likely to deform at high temperatures |

Flexibility and Brittleness | More flexible, less likely to break | Rigid but can be brittle |

Applications

When to Choose ABS: ABS is ideal for parts that need to be strong and durable, such as tool handles, mechanical parts, or items that will be used outdoors or in warm environments.

Source: 3dnatives.com

When to Choose PLA: PLA is a good choice for decorative items, models, or prototypes that do not need to handle much stress or heat. It is also a better option if you want to use a more environmentally friendly material.

Source: 3dnatives.com

Summary and Recommendations

Both ABS and PLA are popular choices for 3D printing, but they serve different purposes. ABS is stronger and more heat-resistant, making it suitable for functional parts, while PLA is easier to print and better for decorative projects. Choose the filament that best matches the needs of your project.

Unionfab - Your 3D Printing Partner

If you are looking for high-quality 3D printing services, Unionfab is here to help. We specialize in providing professional 3D printing solutions using a wide range of materials, including ABS and PLA.

Whether you need strong, functional parts or beautiful decorative pieces, Unionfab has the expertise and technology to bring your ideas to life. Contact us today to get started on your next 3D printing project!