Metal 3D Printing Cost – Free Cost Calculator & Full Breakdown

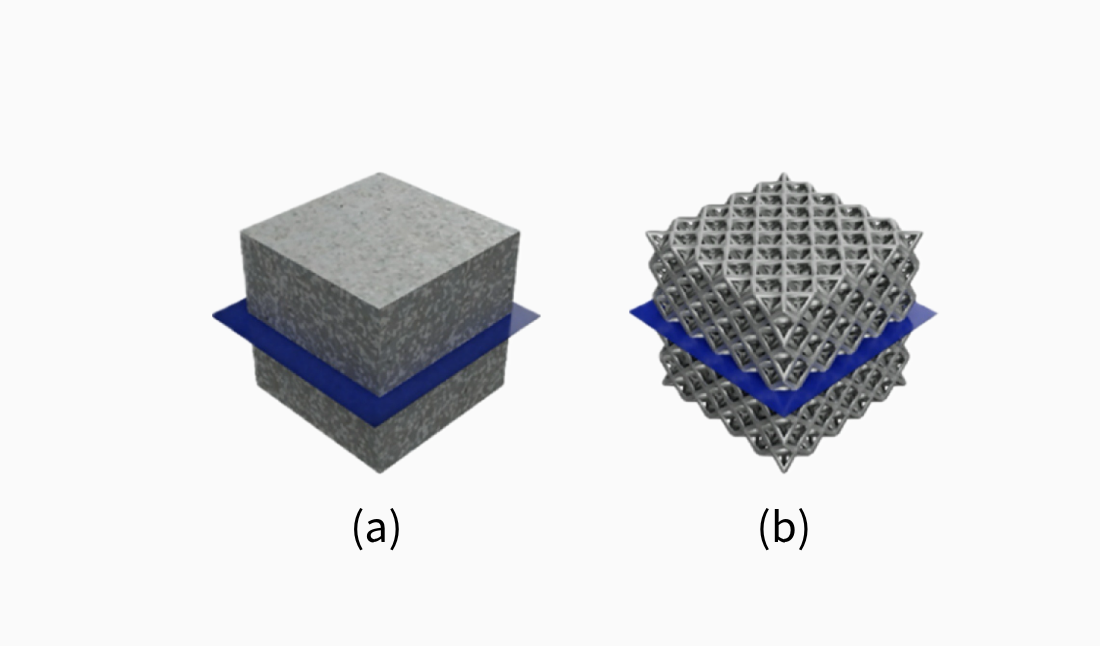

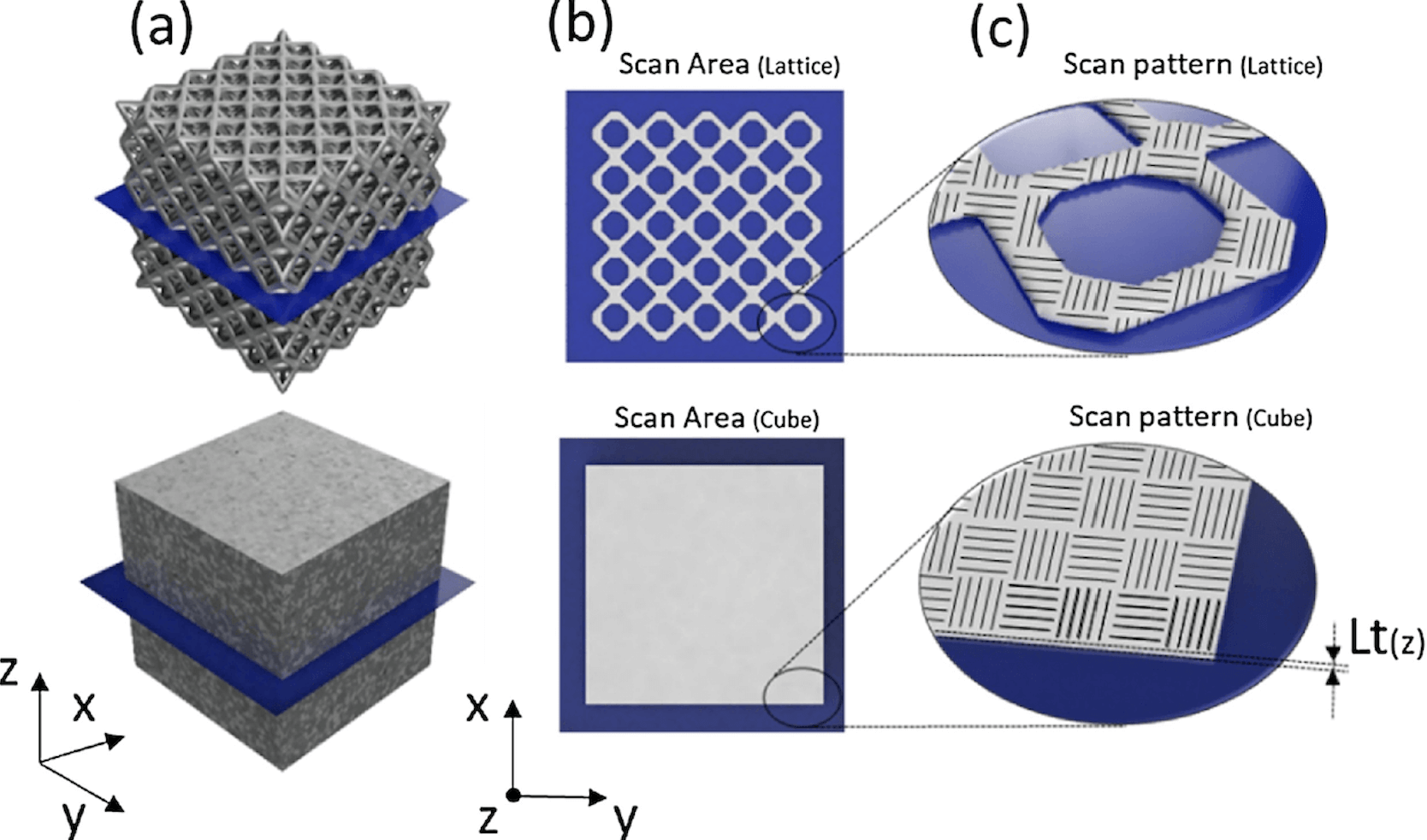

Here are two 3D models of the same part but in different shapes: a solid cube (a), and a lattice structure (b). Which one do you think is easier to print and costs less using metal? It's easy to mistake that the simple solid cube is easier to print and costs less, while the complex lattice is harder to print and costs more.

Source: sciencedirect.com

But it is exactly the opposite way: generally speaking, the lattice structure is easier to 3d print and costs less than the cube using the same material. Here’s why:

Less material: the lattice has many gaps, using less material while maintaining strength, whereas the cube requires more material to fill.

Faster printing: the lattice has smaller print areas per layer, reducing print time; the cube needs to fill each layer, taking longer.

Better cooling: the lattice distributes material evenly, reducing overheating or warping and lowering failure rates.

No supports needed: the lattice is cleverly designed with built-in support, while the cube may require extra support, increasing costs and post-processing time.

However, lattice is just one of the many factors that affect 3D printing costs. There are many other factors not mentioned. Today, let’s uncover the mysteries of metal 3D printing cost together.

What is Metal 3D Printing?

Metal 3D printing is an additive manufacturing method that uses metal materials to create parts layer by layer from digital designs. By melting or binding metal powder, it allows for the production of complex, customized components that are often difficult or impossible to achieve with traditional manufacturing methods.

How Metal 3D Printing Works

In metal 3D printing, the most commonly used technologies are SLM/DMLS and Binder Jetting, which are used to fuse metal powder into solid parts. SLM/DMLS uses a laser to melt the powder, while Binder Jetting applies a binder to the powder, followed by sintering to solidify the part. Both technologies build the part layer by layer, allowing for intricate designs.

Advantages of Metal 3D Printing

Metal 3D printing offers several key benefits:

Customization: High precision for producing complex geometries tailored to specific needs.

Material Efficiency: Minimal material waste compared to traditional subtractive methods.

Speed: Faster prototyping and production, reducing lead times.

Design Flexibility: Ability to produce parts with complex internal structures or unique shapes.

Strength and Durability: Metal parts are stronger and more durable than plastic, making them ideal for high-performance applications where strength is crucial.

Typical Applications of Metal 3D Printing

Metal 3D printing is commonly used in:

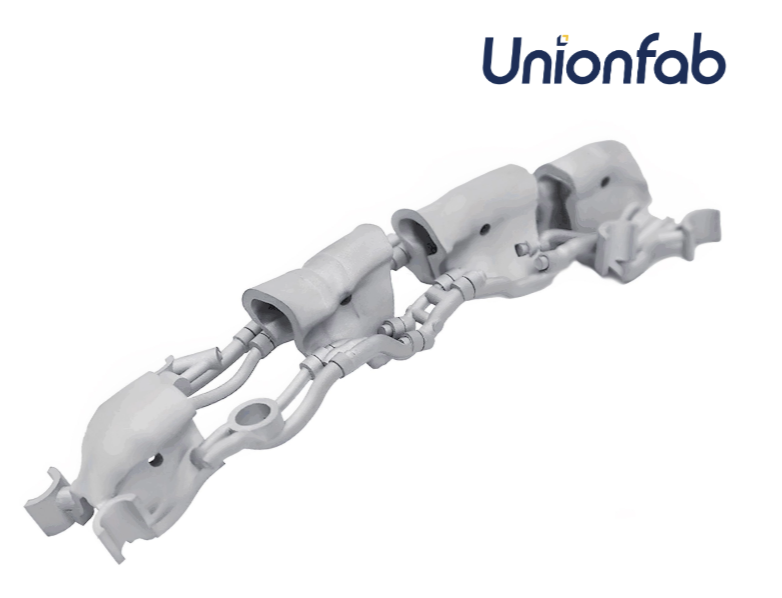

Aerospace: Lightweight, high-strength parts.

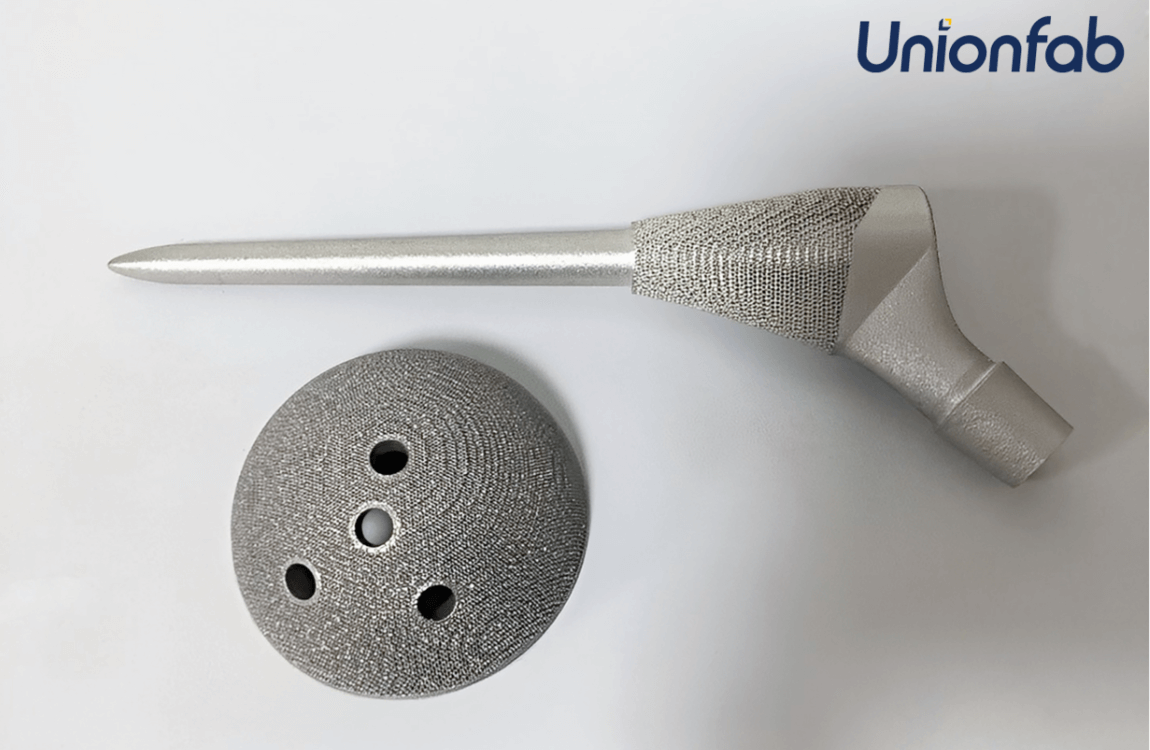

Medical: Custom implants and prosthetics.

Automotive: Prototypes and functional parts.

Tooling: Custom jigs, fixtures, and production tools.

Metal 3D Printing Technologies

SLM/DMLS and Binder Jetting are two widely used metal 3D printing technologies, each offering unique benefits for different applications.

Selective Laser Melting (SLM) / Direct Metal Laser Sintering (DMLS)

Source: SLM Solutions

Selective Laser Melting (SLM), also known as Direct Metal Laser Sintering (DMLS), is a metal 3D printing technology that uses a high-powered laser to melt and fuse metal powder into solid layers.

The process begins by spreading a thin layer of metal powder on the build platform, which is then scanned and melted by the laser to create the desired shape. After each layer solidifies, the platform lowers, and a new layer of powder is applied. This process continues until the entire object is built.

SLM/DMLS parts are known for their high strength, density, and precision, making them ideal for applications that require robust components. They offer faster turnaround times compared to traditional methods, enabling manufacturers to reduce lead times and bring products to market quicker.

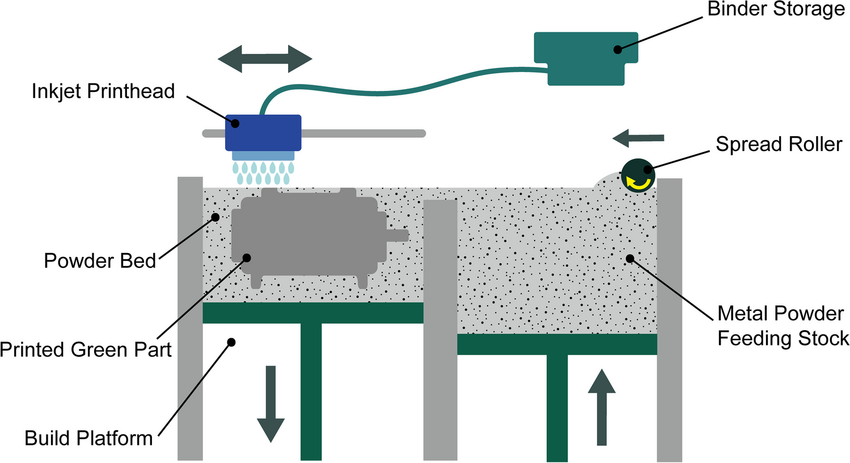

Binder Jetting (BJ)

Source: researchgate.com

Binder Jetting is another metal 3D printing technology that uses a liquid binder to bond metal powder particles together layer by layer. The binder is deposited onto the powder bed, and once the entire object is built, the part is removed from the bed and undergoes a sintering process. During sintering, heat is applied to solidify the material, resulting in a strong and durable part.

While Binder Jetting is generally faster and more cost-effective than SLM/DMLS, it requires additional post-processing steps, including sintering, to achieve the final part strength. It’s a popular choice for creating parts with complex geometries at a lower cost, especially for larger volumes.

SLM/DMLS vs Binder Jetting: Key Differences

Aspect | SLM/DMLS | Binder Jetting |

|---|---|---|

How it works | Uses a laser to melt and fuse metal powder layer by layer. | Deposits a binder onto metal powder and sinters the part later. |

Material | Fully melted metal powders, primarily titanium, stainless steel, and aluminum. | Un-sintered metal powders, |

Accuracy | Very high and detailed. | Slightly lower than SLM, |

Speed | Slower, as the laser melts each layer individually. | Faster, as it only binds powder without melting it. |

Strength of Parts | Strong parts, | Green parts are weaker initially |

Post-Processing | Heat treatment and | Sintering and possibly infiltration (adding another material to fill pores) required to fully solidify and improve strength |

In Summary

Go for SLM if you need high strength, precision, and durability in parts where post-processing should be minimal.

Choose Binder Jetting if speed and cost-effectiveness are more important than absolute strength, or if you're working with larger volumes and don’t mind the additional sintering process.

If you want to learn more about how Metal Binder Jetting and DMLS compare, check out our guide on their key differences here.

Metal 3D Printing Materials

The table below compares common metals used in 3D printing across six aspects to help you choose the most suitable material for your needs.

Materials | Strength (★★★★★ = Highest) | Temperature Resistance (★★★★★ = Highest) | Weight (★★★★★ = Heaviest) | Cost (★★★★★ = Most Expensive) | Key Benefits | Common Uses |

|---|---|---|---|---|---|---|

★★★★ | ★★★ | ★★★ ~7.9g/cm³ | ★★ | ✔High strength and durability ✔Good temperature resistance ✔Relatively low cost | ● Medical devices ● Automotive ● Food processing | |

★★ | ★ | ★ ~2.7g/cm³ | ★ Best | ✔Extremely lightweight ✔Low cost | ● Automotive ● Aerospace ● Electronics ● Heat exchangers | |

Titanium (TC4) | ★★★★ | ★★★★ | ★★ ~4.4g/cm³ | ★★★★ | ✔Exceptional strength-to-weight ratio ✔High temperature resistance ✔Outstanding biocompatibility | ● Aerospace ● Medical implants ● High-performance parts |

Nickel Alloys (Inconel 625, 718) | ★★★★★ Best | ★★★★★ Best | ★★★★ ~8.2g/cm³ | ★★★★★ | ✔Outstanding high-temperature performance ✔Maintains strength under stress | ● Aerospace ● Turbomachinery ● High-temperature industrial parts |

Cobalt Chrome | ★★★★ | ★★★★ | ★★★★ ~8.5g/cm³ | ★★★★ | ✔High strength ✔Excellent wear resistance | ● Medical implants ● Dental applications ● Wear-resistant parts |

Bronze | ★★ | ★★ | ★★★★ ~8.7g/cm³ | ★★ | ✔Durable and wear-resistant ✔Good thermal and electrical conductivity | ● Marine parts ● Bearings ● Decorative items |

Key Takeaways:

Most Common Material: Stainless Steel (316L) dominates metal 3D printing due to its balance of strength, corrosion resistance, and cost-effectiveness.

Lightweight Option: Aluminum is ideal when weight reduction is critical, such as in aerospace and automotive parts.

High-Performance & Biocompatible: Titanium is preferred for aerospace components and medical implants requiring strength and biocompatibility.

Extreme Temperatures: Nickel alloys (Inconel) are best for parts exposed to very high temperatures, like turbines and industrial equipment.

Wear Resistance: Cobalt Chrome excels in dental and medical implants where wear resistance is key.

Durable & Conductive: Bronze is suitable for marine parts, bearings, and decorative components due to its durability and conductivity.

How to Calculate the Cost of Metal 3D Printing

Understanding the total cost of metal 3D printing involves several factors beyond just the printing process itself. The overall cost is a combination of material, post-processing, and other factors, with each aspect contributing to the final price.

The total cost can be calculated as follows:

Total Cost = Printing Cost (material price × part weight) + Post-Processing Cost + Packaging Fees + Shipping Fees + Customs Duty

Now, let's take a closer look at each of these components:

Printing Cost

The printing cost is the most significant cost in metal 3D printing. It is determined by:

Material Price: The unit price of the metal material, typically measured per gram or kilogram. The price of materials like 316L stainless steel, titanium alloys, and aluminum alloys varies significantly based on their properties.

Part Weight: Calculated as model volume × material density, this depends on the size and geometry of the part.

Example:

Here’s an example to help you better understand the formula:

● Model Volume: 10 cm³

● Material Used: 316L Stainless Steel

● Density of Material: 7.9 g/cm³

● Material Price per Gram: $0.4/g

Total Printing Cost = Model Volume × Material Density × Material Price per Gram

Total Printing Cost = 10 cm³ × 7.9 g/cm³ × $0.4/g = $31.6

(*Note: The material price listed here is for illustrative purposes only. The actual cost may vary depending on material quantity and other factors, such as batch production. However, in most cases, the more you print, the lower the total cost.)

Factors That Influence Printing Cost:

● Part Design and Geometry: More intricate geometries, such as lattice structures, use less material, which reduces the overall material costs. However, complex designs may require additional processing time, which can increase the cost.

● Size and Volume of the Part: Larger parts or parts with high volume increase material consumption, leading to higher printing costs.

● Batch Production: If you're printing in bulk, the cost per part usually decreases due to economies of scale, as material usage and printing time are optimized across multiple parts.

● Technology Used: Different printing technologies influence the cost:

SLM and DMLS are more expensive because they use high-powered lasers and fine metal powders.

Binder Jetting is often cheaper for large-scale metal printing due to its process and material efficiency.

If you'd like to quickly estimate your 3D printing costs, Unionfab’s cost calculator makes it simple. Click below to get started!

Post-Processing Cost

Post-processing costs vary depending on several factors, including the type of post-processing required, the size and complexity of the part, the material used, and the printing technology applied. Below are three common methods for pricing post-processing services:

● Hourly Rate: This is commonly used when post-processing tasks involve time-intensive procedures like surface treatments or mechanical machining.

● Per Part Rate: For simpler post-processing steps, such as polishing or basic finishing, a fixed fee per part is applied.

● Weight or Volume Rate: For processes that require significant resources, such as heat treatment, some providers charge based on the weight or volume of the part.

Factors That Influence Post-Processing Cost:

Several factors impact the overall cost of post-processing, which can significantly affect your project’s total cost. Here are some key considerations:

● Complexity of the Part: More intricate designs may require additional steps, such as manual finishing or more detailed machining, increasing the cost.

● Post-Processing Method: Processes like heat treatment, polishing, or coating can vary greatly in cost. High-precision tasks or specialized coatings will naturally cost more.

● Material Type: Certain materials, like titanium or Inconel, may require more time and resources to process, leading to higher costs compared to materials like stainless steel or aluminum.

● Technology Used: The printing method (e.g., SLM, DMLS, Binder Jetting) can affect the post-processing requirements. Parts from SLM/DMLS may need more intensive post-processing than parts from Binder Jetting, which could affect pricing.

Packaging Fees

Packaging fees are an important consideration in the overall cost of metal 3D printing, especially for parts that are heavy, have intricate geometries, or are particularly sensitive to impact during transit. Given the nature of metal parts, proper packaging is essential to avoid any damage during shipping, especially when they have delicate features or are made of materials that can be prone to surface damage.

● Standard Packaging (Free): For smaller and less complex metal parts, standard packaging is typically sufficient. This includes corrugated boxes with bubble wrap or foam padding to cushion the items during transit.

● Protective Packaging (Paid): More complex or heavier metal parts, or parts with intricate geometries, may require additional protective packaging to ensure safe delivery. This can include wooden crates or custom-made flight cases. Below is a cost breakdown:

1. Wooden Crates:

For small to medium-sized metal parts, simple wooden crates generally range from $50 to $300.

For larger or more complex metal parts, the cost of crates can increase to $500 or more, depending on the size, material, and reinforcement required.

2. Custom-Made Flight Cases:

Basic custom flight cases for smaller metal parts can cost around $200 to $500.

For larger, highly specialized metal parts requiring tailored padding and advanced materials, prices for custom flight cases can range from $800 to $2,000 or more.

Shipping Fees

Shipping fees are another important factor in the total cost of metal 3D printing, especially for international shipments. Shipping costs can vary depending on the size, weight, and destination of the metal parts. Different carriers (e.g., FedEx, UPS, DHL) will offer varying rates based on the urgency and delivery service selected.

Customs Duty

For international shipments of metal 3D printed parts, customs duties may apply according to the destination country's import regulations. These duties typically range from 5% to 20% of the total product value, depending on the specific tariffs and regulations of the destination country.

How to Reduce Metal 3D Printing Costs

Reducing 3D printing costs is a strategic process that involves optimizing design, selecting the right materials, and improving production efficiency. Here are some practical tips to help you save money on your 3D printing projects:

Optimize Your Design

Simplify the Geometry: Complex designs take more time and material to print. Simplifying unnecessary details can significantly lower costs.

Use Hollow Structures: Replace solid parts with lattice or hollow structures to save material without compromising strength.

Consolidate Parts: Combine multiple components into a single design to reduce assembly time and production cost.

Reduce Model Volume

Scale Down When Possible: Smaller models require less material and shorter print times. If the part doesn't need to be full-sized, consider scaling it down.

Thin Walls and Reduced Infill: Use thinner walls and low-density infill to save on material usage.

Choose the Right Material

Cost-Effective Materials: Opt for materials that meet your requirements without overspending. For example, use aluminum instead of titanium for lightweight applications with moderate strength requirements.

Minimize Material Waste: Design with material efficiency in mind, especially for expensive metals like Inconel or titanium.

Choose the Right Printing Technology

Different 3D printing methods have varying cost structures. For instance:

Binder Jetting: Better for high-volume production with lower material costs but requires additional sintering.

SLM/DMLS: More expensive but ideal for high-strength, intricate parts.

Optimize Post-Processing

Simplify Post-Processing Requirements: Choose finishes that meet, but don’t exceed, the functional needs of your part.

Batch Processing: Group similar parts together to minimize setup costs for post-processing tasks.

Comparison of Metal 3D Printing Service Providers

When choosing a metal 3D printing service provider, it’s important to consider various factors such as the technologies they offer, available materials, build volume, pricing, and customer reviews. The table below compares leading service providers based on these aspects to help you make an informed decision.

Service Provider | One-line Profile | Technology | Material | Max. Build Volume | Online Instant Quoting System | *Sample Cost | Trustpilot Score |

|---|---|---|---|---|---|---|---|

Xometry | A US-based Global Factory-less 3D Printing Supply Chain Platform | SLM/DMLS Binder Jetting | SLM/DMLS: Aluminum AlSiMg Stainless Steel 17-4PH Stainless Steel 316L Binder Jetting: 316i (316SS/Brz) 420i (420SS/Brz) Stainless Steel 316L | SLM/DMLS: 250 x 250 x 250 mm Binder Jetting: 400 x 250 x 250 mm | ✅ | $575.26 | (Click to See Customer Feedback) |

Unionfab | A China-based Global 3D Printing Service Provider with Six In-house Factories | SLM/DMLS Binder Jetting | SLM/DMLS: Aluminum (AlSi10Mg, 6061) Titanium (TC4) Stainless Steel 316L Stainless Steel 17-4PH Maraging Steel Inconel 625 CuCrZr Binder Jetting: Stainless Steel 316L Stainless Steel 17-4PH | SLM/DMLS: 400 x 300 x 400 mm Binder Jetting: 400 x 250 x 250 mm | ✅ | $45.49 | (Click to See Customer Feedback) |

Facfox | A China-based Global Factory-less 3D Printing Supply Chain Platform | SLM/DMLS Binder Jetting | SLM/DMLS: Aluminum (Alsi10Mg) Titanium(Ti61Al4V) Stainless Steel 316L Stainless Steel 17-4PH Maraging Steel Inconel 718 Inconel 625 Cobalt Chrome(CoCrMo) Binder Jetting: CJP Fullcolor Sandstone | SLM/DMLS: 500 x 500 x 1000 mm Binder Jetting: 254 x 381 x 203 mm | ✅ | $46.93 | (Click to See Customer Feedback) |

Additive3dasia | A Singapore-based 3D Printing Company | SLM/DMLS | SLM/DMLS: Stainless Steel 316L Aluminum AlSiMg Titanium Alloy Ti6Al4V Miraging Steel (MS1-18Ni300) | Not Mention | ❌ | / | / |

Zelta3d | A Singapore-based 3D Printing Company | SLM/DMLS | SLM/DMLS: Stainless Steel 316L Aluminum AlSiMg | Not Mention | ✅ | $92.07 | / |

Addimen | A Spain-based 3D Printing Company | SLM/DMLS | SLM/DMLS: Stainless Steel 316L Martensitic Steel Aluminum AlSiMg Titanium Alloy Ti6Al4V Cu Inconel 718 | Not Mention | ❌ | / | / |

Jellypipe | A Germany-based Global Factory-less 3D Printing Supply Chain Platform | SLM/DMLS | SLM/DMLS: Stainless Steel 316L Stainless Steel 17-4PH Aluminum AlSi9 Cu3 Titanium TiAl6V4v Martensitic Nickel Steel Corrax (Corrosion-Resistant Tool Steel) Inconel 718 | Not Mention | ✅ | $439.56 | / |

(Continued)

Service Provider | One-line Profile | Technology | Material | Max. Build Volume | Online Instant Quoting System | *Sample Cost | Trustpilot Score |

|---|---|---|---|---|---|---|---|

Rapidobject | A Germany-based Global 3D Printing Service Provider with Factories | SLM/DMLS | SLM/DMLS: Stainless Steel 316L Aluminum AlSiMg Inconel 718 Titanium Bronze | Not Mention | ✅ | $583.56 | / |

*Note: The Sample cost is calculated via the online instant quoating systems of each company above.

Volume: 74.62 cm³; Material: Stainless Steel 316L; Tech: Selective Laser Melting (SLM)

In summary,

Xometry, Unionfab, and Facfox provide both SLM and Binder Jetting technologies, and offer a broader range of materials compared to other competitors.

Facfox offers the largest build volume for SLM, while Xometry and Unionfab provide the largest build volume for Binder Jetting.

Xometry, Unionfab, and Facfox have higher ratings on Trustpilot, with real customer feedback available.

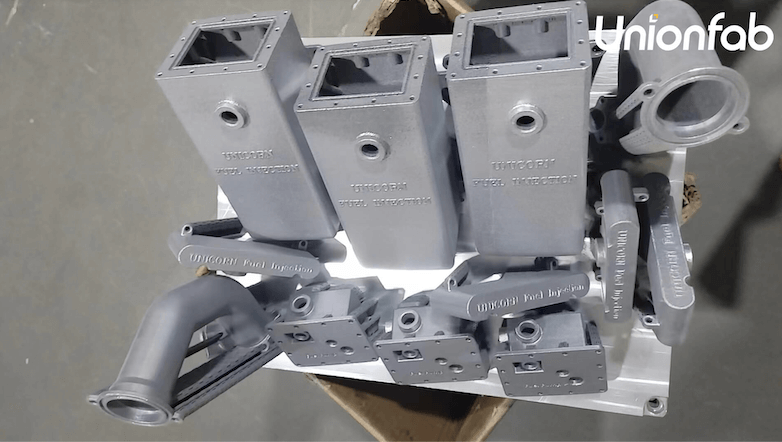

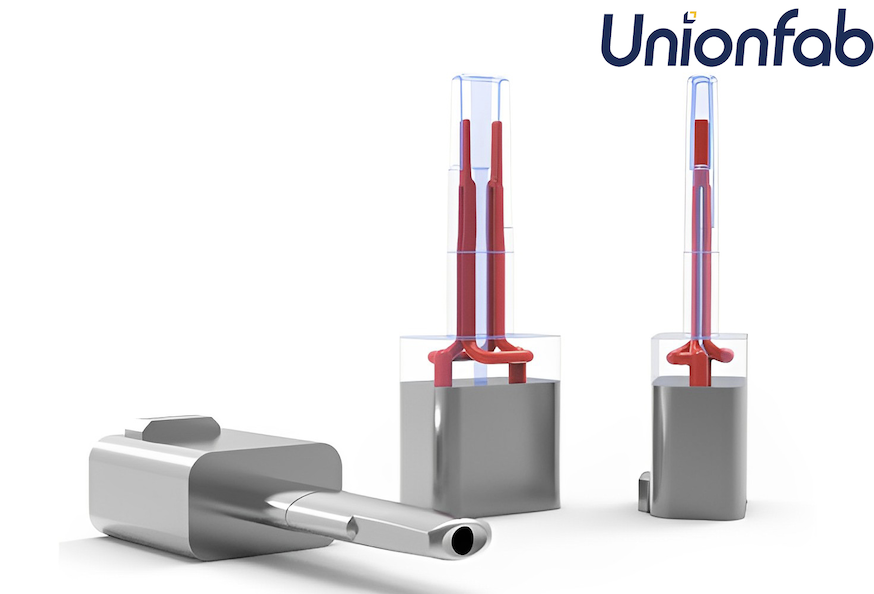

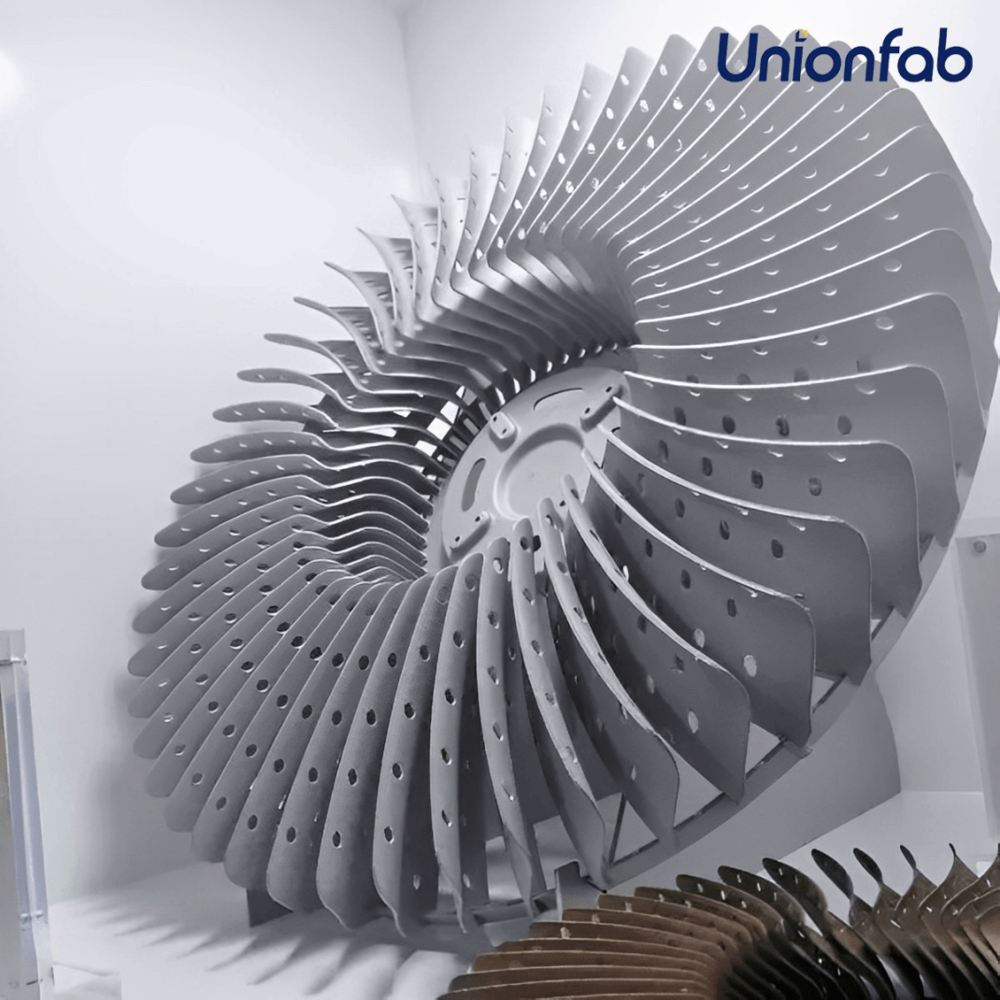

Metal 3D Printing Case Studies by Unionfab

At Unionfab, we’ve successfully applied metal 3D printing across a wide range of industries. Below, you’ll find examples of our completed projects showcasing the versatility and precision of metal 3D printing in automotive, aerospace, industrial, medical, and design applications.

Industry | Case |

|---|---|

Automotive |

|

Aerospace |

|

Industrial |

|

Medical |

|

Design |

|

Unionfab's Metal 3D Printing Service

Unionfab offers advanced metal 3D printing services with a range of materials and technologies, including SLM/DMLS and Binder Jetting. With state-of-the-art equipment and high-quality standards, we ensure precise and reliable results for your metal parts. Whether you need complex geometries or high-performance materials, our services provide a variety of options to meet your needs.

Below is a summary of our metal 3D printing capabilities:

Feature | SLM / DMLS | Binder Jetting |

|---|---|---|

Materials | Aluminum (AlSi10Mg, 6061), Titanium (TC4), Stainless Steel 316L, Stainless Steel 17-4PH, Maraging Steel, Inconel 625, CuCrZr | Stainless Steel 316L, Stainless Steel 17-4PH |

Build Size | up to 400 × 300 × 400 mm | up to 400 x 250 x 250 mm |

Layer Thickness | 0.035 mm | 0.05 mm |

Dimensional Tolerance | ±0.2 mm | ±0.3 mm |

Minimum Wall Thickness | 0.5 mm | 2.0 mm |

Pass Rate | 99.5% | 99.5% |

Lead Time | As fast as 4-5 days | As fast as 4-5 days |

On-Time Delivery Rate | 98% | 98% |

Certification | ISO 9001, ISO 13485, AS 9001D | ISO 9001, ISO 13485, AS 9001D |

Post-Processing Service

At Unionfab, we offer more than just high-quality printing. Our comprehensive finishing services, including sandblasting, electroplating, polishing, and more, are designed to improve the smoothness, strength, and appearance of your parts. This ensures that every component is ready for production and customized to meet your specifications.

Quality Assurance Report

In addition to affordable 3D printing, we provide quality assurance services to ensure the highest standards. If requested, we can include a detailed QA report with your shipment to guarantee consistency and reliability.

New to Unionfab? Enjoy a special discount! Sign up now and get 10% off your first order!

FAQs

Is Metal 3D Printing Worth It?

Metal 3D printing is worth it for businesses needing high-precision, complex, and customized metal parts. Although it can be more expensive upfront, the benefits, including faster prototyping, reduced waste, and greater design flexibility, often justify the cost.

What is a Metal 3D Printing Cost Calculator?

A metal 3D printing cost calculator helps you estimate the cost of your project quickly. By uploading your 3D model, the calculator factors in material, part weight, complexity, and post-processing requirements to give you an accurate price.

What is the Cost of Metal 3D Printing per Gram?

Metal 3D printing costs are typically calculated per gram of material. For example, stainless steel may cost around $0.4 per gram, while materials like titanium range from $2 to $4 per gram, depending on the type.

What is the Cost of Metal Powder for 3D Printing?

The cost of metal powder for 3D printing varies depending on the material. Stainless steel powders can cost between $60 to $100 per kilogram, while premium materials like titanium or Inconel can range from $500 to $1000 per kilogram.