Metal Binder Jetting vs. DMLS Guide [+Cost Calculator]

![Metal Binder Jetting vs. DMLS Guide [+Cost Calculator]](https://ufc-dtc-cms.oss-accelerate.aliyuncs.com/blog/20251121/132054_i0ppiu1jr.png)

Learn the differences between Metal Binder Jetting and DMLS 3D printing, including process, materials, cost, and services to find the right solution.

Introduction

Metal Binder Jetting (MBJ) and Direct Metal Laser Sintering (DMLS) are two leading metal 3D printing technologies. Metal 3D Printing produces parts layer by layer from metal powders such as titanium, aluminum, and stainless steel, enabling complex, high-strength components with excellent design freedom.

MBJ is ideal for cost-effective, medium-to-large batch production of geometrically complex parts, while DMLS delivers high-precision, performance-critical components.

This blog explains what MBJ and DMLS are, highlights their differences, and helps you choose the right metal 3D printing process for your project.

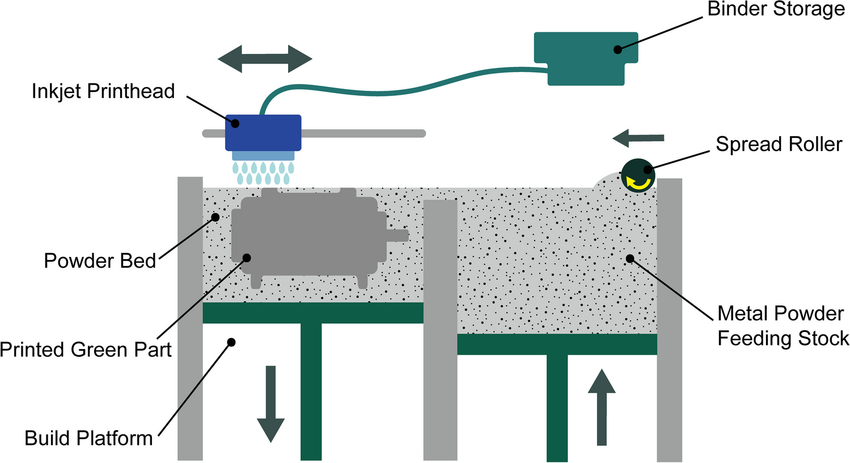

What is Metal Binder Jetting?

Source: researchgate.com

Metal Binder Jetting is a type of additive manufacturing in which a liquid binder is used to join layers of fine metal powder, forming what’s known as a “green part,” which refers to the unfinished printed component before it undergoes any post-processing. The printed part is then strengthened through steps like sintering or infiltration to achieve its final mechanical properties.

How it Works

Metal Binder Jetting turns digital designs into high-strength metal parts through a precise, multi-step process. It combines the speed of inkjet printing with the power of sintering to produce complex geometries efficiently.

The Metal Binder Jetting process involves several key steps:

Powder Spreading: A thin and even layer of metal powder is spread across the build platform.

Binder Deposition: A printhead selectively deposits a liquid binder according to the digital 3D model, bonding the powder in specific areas.

Layer Recoating: The build platform lowers slightly, and a new layer of powder is spread on top. The process repeats until the full part is printed.

Curing: The printed “green parts” are gently cured in an oven to strengthen the binder and make handling easier.

Depowdering: Unbound powder is removed, leaving behind the fragile green parts. The unused powder can be recycled for future builds.

Sintering: The parts are heated in a high-temperature furnace, causing the metal particles to fuse and form a dense, solid structure.

Optional Infiltration and Finishing: Depending on material requirements, parts may undergo infiltration with another metal or receive surface finishing to enhance density, strength, and appearance.

To better visualize how Metal Binder Jetting works in practice, watch this short animation that walks through each stage of the process:

Pros & Cons

Like any advanced metal 3D printing process, Metal Binder Jetting comes with its own strengths and limitations. Understanding these advantages and challenges can help you determine whether this technology is the best fit for your production goals and part requirements.

Pros

Cost-effective for large-scale production compared to powder bed fusion methods.

Capable of producing large, geometrically complex parts without support structures.

Room-temperature printing reduces warping and allows larger machine sizes.

Flexibility in materials, including stainless steel composites and bronze-infiltrated metals.

Cons

Post-processing (debinding and sintering) is time-consuming and adds cost.

Finished parts may have higher porosity, affecting mechanical properties.

Not ideal for applications requiring extremely high density or precision.

Typical Applications

Metal Binder Jetting is ideal for industries requiring high-volume production or complex geometries at lower cost. Applications include:

Automotive components, including lightweight brackets and mounts.

Aerospace parts where complex shapes are needed, but ultra-high strength is less critical.

Tooling, molds, and prototypes for large-scale manufacturing.

Medical devices and implants requiring customized shapes.

Materials Available for Metal Binder Jetting

Metal Binder Jetting works with a variety of metals and specialized materials, offering flexibility for different applications and performance requirements. Here’s a look at some commonly used options:

Stainless Steel: Ideal for functional prototypes and industrial components.

Titanium: Strong yet lightweight, suitable for aerospace and medical applications.

Copper: Excellent thermal and electrical conductivity for specialized uses.

Ceramics: Applied in niche industries, such as electronics, for specialized parts.

If you want to explore the full range of materials available for MBJ, check out Metal Binder Jetting Materials.

And for a more detailed explanation of Metal Binder Jetting, see our in-depth guide.

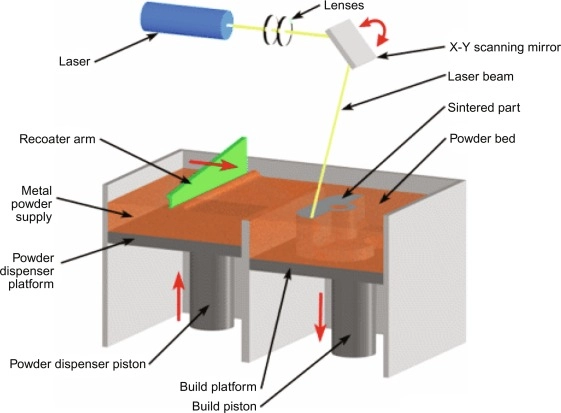

What is DMLS?

Source: sciencedirect.com

Direct Metal Laser Sintering (DMLS) is a metal 3D printing technology that builds complex components layer by layer from fine metal powders using a high-powered laser. It produces fully dense, high-precision parts suitable for industries like aerospace, automotive, and medical engineering.

DMLS vs. SLM

Some of you may have come across the term SLM (Selective Laser Melting) alongside DMLS (Direct Metal Laser Sintering) when exploring metal 3D printing. These terms are often used interchangeably today, but their names actually come from different historical and brand contexts:

SLM – Selective Laser Melting

Origin: Germany, Fraunhofer ILT

What it means: Emphasizes completely melting metal powders layer by layer.

Usage: Originally a generic term for the technology, now also associated with companies like SLM Solutions, EOS, Trumpf, and Concept Laser.

DMLS – Direct Metal Laser Sintering

Origin: Germany, EOS GmbH

What it means: Created for EOS’s commercial metal 3D printing line, following the naming style of its plastic SLS (Selective Laser Sintering) products. The word “sintering” was kept historically, though the process actually fully melts the metal powder.

Usage: A brand-specific term used by EOS, widely referenced in literature and industrial applications.

Key point:

Both DMLS and SLM rely on high-energy lasers to fuse metal powders layer by layer, producing fully dense, high-precision parts. The main differences are historical and branding-related. In practice, they represent the same advanced metal 3D printing process.

In short:

DMLS is the EOS brand name, while SLM originates from Fraunhofer research. Technically, they deliver very similar results in precision, density, and performance, and in most industrial settings, the terms can be treated interchangeably. You can consider DMLS and SLM as essentially the same technology, both capable of producing high-quality, precise, and strong metal parts.

How It Works

The Direct Metal Laser Sintering (DMLS) process converts metal powder into high‑performance parts through a series of precise, layered steps:

Powder Spreading: A thin, uniform layer of metal powder is laid across the build platform.

Laser Scanning: A high‑powered laser scans each region defined by the digital model, selectively melting or fusing the powder.

Layer Recoating: Once one layer is merged, the platform lowers and a new powder layer is spread—this repeats until the full part is built.

Sintering: The laser’s energy raises the temperature to fuse metal particles, creating strong bonds and forming a fully dense structure.

Complex Geometry: Thanks to the layer‑by‑layer method, DMLS can produce internal lattice structures and integrated cooling channels with ease.

For a visual walkthrough of the process, watch this short clip:

Pros & Cons

Understanding the advantages and limitations of DMLS helps you evaluate whether this technology is the right choice for your project requirements.

Pros

Enables the creation of complex, lightweight, and topology-optimized geometries.

Produces dense, high-strength metal parts with excellent material properties.

Minimizes residual stress and internal defects in high-performance components.

Reduces waste by using only the material required for the part.

Supports a wide range of engineering-grade metals, including aluminum, titanium, and stainless steel.

Cons

Higher production cost compared to traditional manufacturing or polymer 3D printing.

Longer build times for large or highly detailed parts.

Post-processing (such as heat treatment or machining) may be required to achieve final surface finish and dimensional accuracy.

Typical Applications

DMLS/SLM is ideal for producing intricate, high-performance parts that must withstand extreme conditions. Common applications include:

Aerospace: Lightweight structural components, heat exchangers, and turbine parts.

Automotive: Engine components, heat management systems, and resonant metamaterials for noise reduction.

Medical: Custom implants, surgical tools, and dental prosthetics.

Industrial: Tooling inserts, molds, and parts for energy and defense applications.

Materials Available for DMLS/SLM

DMLS/SLM works with a wide range of metal powders, offering flexibility for different performance requirements and part characteristics. Here’s a look at some commonly used options:

Aluminum Alloys: Lightweight and corrosion-resistant, suitable for parts that require both strength and reduced weight.

Titanium Alloys: Strong and durable, ideal for producing complex, high-strength components.

Stainless Steels: Reliable and versatile, featuring excellent mechanical strength and corrosion resistance.

Tool Steels and Maraging Steels: High hardness and dimensional stability make them suitable for molds and tooling.

Nickel-Based and Copper Alloys: Excellent thermal, electrical, and heat resistance properties for specialized applications.

If you want to learn more about the specific materials used in DMLS/SLM, check out DMLS/SLM Materials.

In-Depth Comparison: Metal Binder Jetting vs. DMLS

To give you a clear perspective on these two leading metal 3D printing technologies, we’ll examine their performance across several key aspects that are often critical when selecting a printing process.

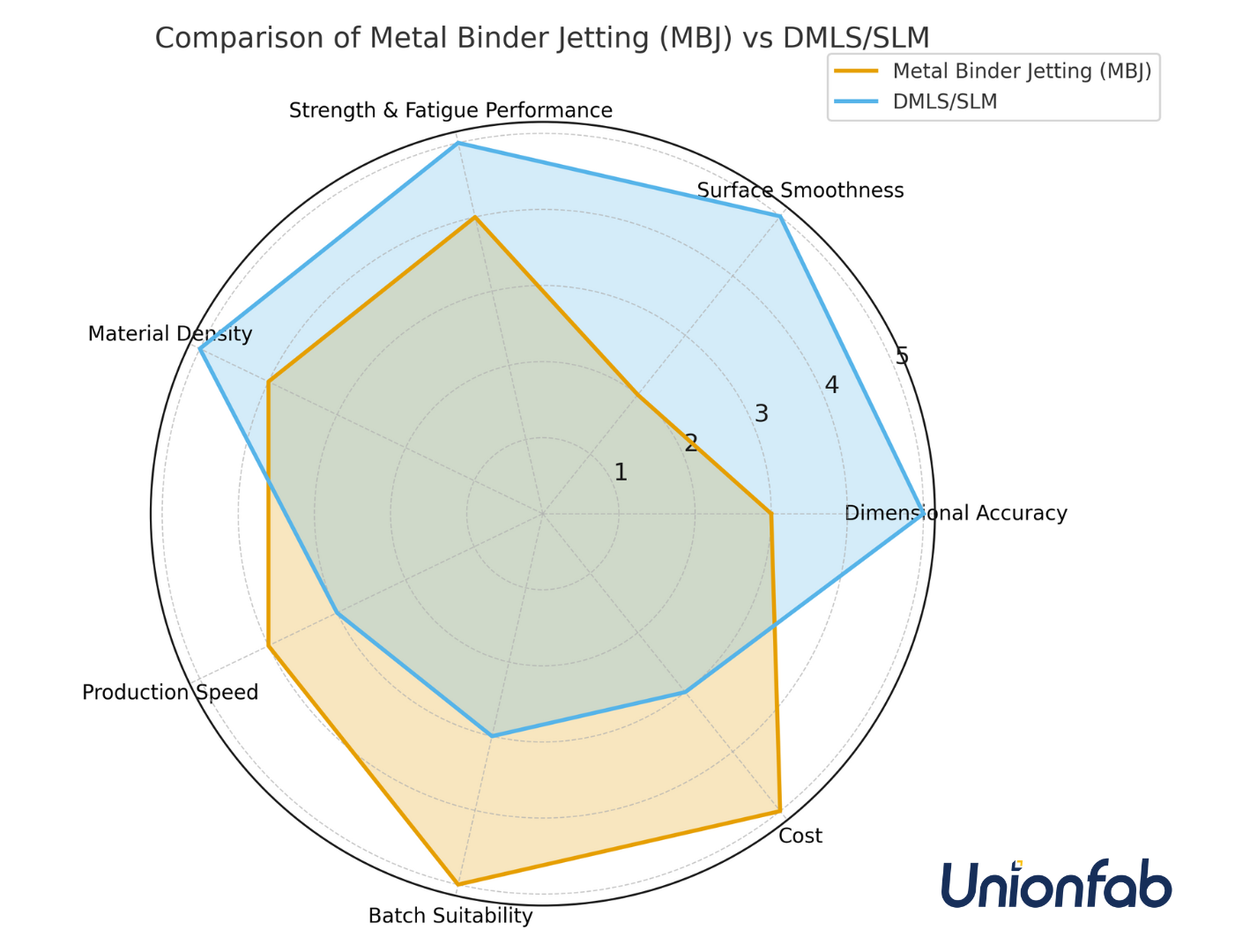

The radar chart below highlights a quantitative comparison of Metal Binder Jetting (MBJ) and DMLS/SLM across seven measurable dimensions.

Source: Unionfab

*Note: A higher "Cost" score for MBJ reflects better cost-effectiveness for large batches, not higher costs.

From the radar chart above, we can see that MBJ excels in batch production and cost-efficiency, whereas DMLS offers superior precision, surface smoothness, strength and fatigue performance, and material density.

The table below complements the radar chart with a more detailed side-by-side comparison, including additional factors such as available materials and surface finishing options.

Aspect | Metal Binder Jetting (MBJ) | DMLS/SLM |

|---|---|---|

Dimensional Accuracy | Good; slight shrinkage during sintering | Excellent; high precision for intricate parts |

Surface Smoothness | Rougher; often needs post-processing | Smooth; minimal finishing required |

Strength & Fatigue Performance | Medium-to-high after sintering | High strength and fatigue performance |

Material Density | High, up to ~99.6% | Nearly fully dense, minimal porosity |

Materials Available | Common metals; growing options | Wide selection of high-performance alloys |

Production Speed | Fast for large batches; post-processing adds time | Direct process; faster for small batches |

Suitability for Medium & Large Batch Production | Ideal for medium-to-large batches; ultra-high precision not required | Best for small batches; high cost for large volumes |

Surface Finish & Post-Processing Options | Requires sintering; optional machining/polishing | Often near-final finish; minimal post-processing |

Cost | Cost-effective for medium-to-large batches | Higher cost; justified for high-performance parts |

The table above provides a concise overview of the main characteristics and differences between Metal Binder Jetting and DMLS/SLM. To give a deeper understanding, the following sections break down each aspect in detail.

1. Printing Quality

Printing quality plays a crucial role in selecting the right metal 3D printing process. Here’s what you need to know about the main factors:

a. Dimensional Accuracy

● DMLS/SLM: Offers high precision due to direct melting and layer-by-layer fusion of metal powder. Ideal for intricate geometries and components requiring tight tolerances.

● Metal Binder Jetting (MBJ): Accuracy is slightly lower because the printed green part may shrink during sintering, but still suitable for many engineering applications.

b. Surface Smoothness

● DMLS/SLM: Produces smoother surfaces with fewer post-processing requirements.

● MBJ: Surface roughness is higher due to powder-binder interaction, often requiring additional finishing after sintering.

c. Strength & Fatigue Performance

● DMLS/SLM: High strength directly from printing; excellent fatigue performance.

● MBJ: Medium-to-high strength after sintering; suitable for functional parts but less ideal for high-stress applications.

d. Material Density

● DMLS/SLM: Nearly fully dense parts with minimal porosity.

● MBJ: Achieves high density (up to ~99.6% with optimized sintering), but generally slightly less than DMLS.

2. Materials Available

● DMLS/SLM: Wide selection including Aluminum (AlSi10Mg), Titanium (TC4), Stainless Steel 316/L, 17-4PH, and Maraging Steel. Suitable for high-performance and specialty alloys.

● MBJ: Growing material base; commonly used metals include X1 Metal 420i (420 Stainless + Bronze), X1 Metal 316i, 316L, and 17-4PH. Best for large-volume, cost-sensitive applications.

3. Production Speed

● MBJ: Faster layer-by-layer deposition; however, debinding and sintering can extend total production time to 7–15 days. Very efficient for medium to large batch production.

● DMLS/SLM: Direct process without additional post-printing consolidation; faster overall for small batch production (4–5 days).

4. Suitability for Medium & Large Batch Production

● MBJ: Ideal for medium-to-large batch production, especially when parts do not require ultra-high precision. Allows nesting and full use of build volume.

● DMLS/SLM: Best for small-batch, high-precision applications. Production cost for large batches is higher.

5. Surface Finish & Post-Processing Options

● DMLS/SLM: Often achieves near-final surface finish; post-processing can include minimal machining or polishing.

● MBJ: Requires debinding and sintering, plus optional machining or polishing to reach desired surface quality.

6. Cost

● MBJ: More cost-effective for large batches; metal powder is less expensive, reducing material costs significantly.

● DMLS/SLM: Higher cost for small, high-precision batches; justified by performance in challenging applications.

Choosing the Right Technology for Your Project

Selecting the most suitable metal 3D printing technology depends on your project requirements, production volume, and desired material properties. Here’s a practical guide to help you decide between Metal Binder Jetting (MBJ) and DMLS/SLM.

When to Choose Metal Binder Jetting

Metal Binder Jetting is ideal in scenarios where:

Medium to large batch production is needed, especially for parts that do not require ultra-high precision.

Faster throughput and cost-efficiency are priorities. The metal powders used are generally less expensive, and the process allows nesting to maximize build volume.

Complex geometries without extreme structural demands are required, such as brackets, housings, or prototypes where some porosity is acceptable.

When to Choose DMLS

Direct Metal Laser Sintering (DMLS) or Selective Laser Melting (SLM) is preferred when:

High precision and intricate designs are critical, including organic or topology-optimized structures.

Mechanical performance and density are essential, such as in aerospace, medical, and automotive components.

Small to medium batch production is planned, where the higher per-part cost is justified by material performance and component reliability.

Summary Recommendation

Criteria | Recommended Technology | Reasoning |

|---|---|---|

Production Scale | MBJ | Cost-effective and efficient for medium to large batches |

Precision & Complexity | DMLS | Provides high accuracy and dense, strong parts |

Material Performance | DMLS | Supports high-performance alloys with excellent mechanical properties |

Speed (Layer Deposition) | MBJ | Faster initial printing; total time depends on sintering |

Post-Processing Flexibility | Both | MBJ requires sintering; DMLS may need minimal finishing |

With these comparisons in mind, you can better assess which metal 3D printing technology aligns with your project needs—whether it’s speed, precision, or material performance.

Ready to get started? Talk to Unionfab experts to determine the best solution for your parts.

How Much Will MBJ and DMLS Cost?

Before finalizing your choice of metal 3D printing technology, it’s important to understand how costs are calculated, since the total expense involves more than just the raw material.

The total expense combines several elements, which can be summarized as follows:

Total Cost = Printing Cost (material price × part weight) + Post-Processing Cost + Packaging Fees + Shipping Fees + Customs Duty

Printing Cost

This forms the base cost of producing the part and depends primarily on two factors:

● Material Price: The cost of the raw metal, usually quoted per gram or kilogram.

● Part Weight: Determined by multiplying the CAD model’s volume by the density of the chosen material.

Example: Calculating the printing cost for a bipolar forceps tip made from 316L Stainless Steel:

● Material: 316L Stainless Steel

● Price: $0.40 per gram

● Weight: 20 grams

Printing Cost: 20 g × $0.40/g = $8

Unionfab’s instant quoting tool automates this calculation, but this example shows how it works manually.

Ready to get your precise cost?

*Note: Prices are for reference only—please contact our sales team for a formal quotation. For high-volume orders, special pricing can be negotiated with our sales team.

Additional Cost Factors

Beyond printing, several other elements influence the final price:

● Post-Processing: All orders include basic support removal and media blasting. Optional services such as polishing, heat treatment, or plating are priced according to your specific requirements.

● Packaging: Standard packaging is included, but custom or protective packaging may be required for delicate or medical components.

● Shipping: Costs vary depending on destination, delivery speed, and order weight.

● Customs Duty: International shipments may incur duties or taxes imposed by the destination country.

For a complete breakdown of pricing variables, see our full guide to 3D printing costs.

Unionfab’s Metal 3D Printing Service

Unionfab offers comprehensive metal 3D printing solutions using both Metal Binder Jetting and DMLS/SLM technologies. Whether your project demands cost-efficient high-volume production or high-precision, structurally critical parts, Unionfab has the expertise and capabilities to meet your needs.

Unionfab’s Metal Binder Jetting and DMLS Services

Below is an overview of the main features and specifications available for each technology that we provide:

Feature | SLM / DMLS | Metal Binder Jetting |

|---|---|---|

Materials | Aluminum (AlSi10Mg, 6061), Titanium (TC4), Stainless Steel 316L, Stainless Steel 17-4PH, Maraging Steel, Inconel 625, CuCrZr | Stainless Steel 316L, Stainless Steel 17-4PH |

Build Size | up to 400 × 300 × 400 mm | up to 400 x 250 x 250 mm |

Layer Thickness | 0.035 mm | 0.05 mm |

Dimensional Tolerance | ±0.2 mm | ±0.3 mm |

Minimum Wall Thickness | 0.5 mm | 2.0 mm |

Pass Rate | 99.5% | 99.5% |

Lead Time | As fast as 4-5 days | As fast as 4-5 days |

On-Time Delivery Rate | 98% | 98% |

Certification | ISO 9001, ISO 13485, AS 9001D | ISO 9001, ISO 13485, AS 9001D |

For a more detailed overview of our metal 3D printing services, check out our Metal Binder Jetting service or our DMLS/SLM 3D printing service.

Why Choose Unionfab?

Unionfab offers reliable metal 3D printing services backed by years of experience and a strong focus on quality, speed, and cost-effectiveness:

● Experience: Operates over 100 3D printers with more than 20 years in additive manufacturing.

● Quality Assurance: Maintains ISO 9001 certification to ensure consistent, high-quality production.

● Fast Shipping: Air delivery in 3–5 days via DHL Express and FedEx.

● Competitive Pricing: Offers up to 70% cost savings compared to European and American suppliers without compromising quality.

● Rapid Production: Capable of producing parts in as little as 1 day for quantities ranging from 1 to 100K.

● Wide Material Selection: Supports 80+ materials, including metals, resins, plastics, and composites.

● Large Build Capacity: Maximum build size up to 2100 × 900 × 700 mm.

● Certified Precision: ISO 9001, ISO 13485, and AS 9001D certifications for consistent, precise parts.

If this is your first time using Unionfab’s 3D printing services, sign up now to enjoy 10% off your first order!

FAQs

What is the difference between SLS and DMLS 3D printing?

SLS (Selective Laser Sintering) uses a laser to sinter plastic or polymer powders, while DMLS (Direct Metal Laser Sintering) uses a laser to sinter or melt metal powders. In short, SLS is for plastics, and DMLS is for metals.

How does DMLS compare to EBM 3D printing?

DMLS uses a laser to melt metal powders layer by layer, producing high-precision parts, while EBM (Electron Beam Melting) uses an electron beam in a vacuum, which is faster for large parts but may result in slightly lower surface finish quality.

What is the difference between DMLS and LPBF?

LPBF (Laser Powder Bed Fusion) is a broader category that includes both DMLS and SLM technologies. DMLS typically focuses on sintering metal powders, whereas SLM fully melts them. LPBF refers to the general laser-based powder fusion process.

Where can I find DMLS 3D printing services in China?

Many companies in China provide DMLS 3D printing services for prototypes, small-batch production, and custom metal parts. You can contact Unionfab for professional DMLS services, instant quotes, and technical support.

What is the tolerance of Metal Binder Jetting?

Metal Binder Jetting typically achieves tolerances around ±0.2 mm, depending on the size and complexity of the part. Tighter tolerances may require additional post-processing. Overall, it is suitable for functional prototypes and parts where extreme precision is not critical.

How accurate is DMLS printing?

DMLS printing provides high dimensional accuracy, typically within ±0.1–0.2 mm, making it ideal for intricate geometries and performance-critical components. The layer-by-layer fusion process ensures consistent results across complex parts. This level of precision is difficult to achieve with other metal 3D printing methods.

What is the difference between CNC and DMLS?

CNC machining is a subtractive process that removes material from a solid block, whereas DMLS is additive, building parts layer by layer from powdered metal. DMLS can create complex internal structures that are impossible with CNC. Additionally, DMLS allows for more efficient material usage in small-batch production.

Which is better, zirconia or DMLS?

Zirconia is primarily used in dental or ceramic applications, offering biocompatibility and aesthetic advantages. DMLS produces strong metal components suitable for industrial, aerospace, or medical implants. The "better" option depends entirely on whether the application requires metal strength or ceramic properties.

What is the most accurate method of metal 3D printing?

Powder Bed Fusion technologies, like DMLS and SLM, are currently the most accurate methods for metal 3D printing. They provide tight tolerances, high part density, and excellent mechanical properties. These processes are ideal for aerospace, automotive, and medical components requiring precision and strength.