3D Print not Sticking to Bed

Struggling with 3D prints not sticking to the bed? Discover causes, expert fixes, and top adhesion tips to boost first-layer success—fast and frustration-free.

Introduction

Strong bed adhesion is critical to the success of any 3D print. The first layer serves as the foundation of the entire model—if it doesn’t properly stick to the bed, it can lead to problems such as warping, layer shifting, or complete print failure. Different materials and bed surfaces interact in unique ways, and optimizing this interaction is key to print reliability.

By understanding how various filaments adhere and choosing the right bed surface or adhesive method, you can dramatically improve first-layer success and overall print quality.

Adhesion Performance of Different Materials

Each filament type has distinct bed adhesion requirements and behaviors:

Material | Nozzle Temp (°C) | Bed Temp (°C) | Adhesion Characteristics | Warping Tendency | Recommendations |

|---|---|---|---|---|---|

PLA | 190–220 | 50–60 | Good adhesion on glass, painter' s tape, or glue stick; PEI bed works best | Low | Use a thicker first layer; apply glue stick or blue tape for extra grip |

PETG | 220–240 | 70–80 | Naturally sticky; adheres well to PEI or glass (with glue) | Medium | Use glue stick on glass; control cooling fan; avoid over-extrusion |

ABS | 220–250 | 85–110 | Poor adhesion; needs high bed temp, Kapton tape, or ABS glue | High | Use ABS/acetone slurry or glue stick on Kapton/glass; print in enclosed area with fan off |

TPU | 200–230 | 30–60 | Very strong adhesion, especially on PEI; harder to remove when cooled | Low | Use PEI bed or glue on glass; print slowly; ensure firm first-layer contact |

Summary:

Different filaments have unique adhesion needs and respond differently to bed surfaces and temperatures. Understanding these material-specific behaviors is key to choosing the right bed surface and settings for successful prints.

Print Bed Surface Analysis

Different bed surfaces offer varying levels of adhesion and compatibility:

Bed Type | Characteristics | Suitable Materials | Notes |

|---|---|---|---|

Glass | Flat, smooth, heat-resistant | PLA, ABS, PETG | Provides smooth bottoms; requires adhesives for ABS; fragile; easy to clean |

Aluminum | Durable, heats fast, good thermal conductivity | PLA, ABS, PETG | Needs Kapton tape or adhesives; prone to scratches; good for high-temp prints |

PEI Sheet | Very strong adhesion, reusable | PLA, PETG, ABS, TPU | Little to no glue needed; model releases easily after cooling; needs cleaning/maintenance |

Magnetic Spring Steel Plate | Flexible, easy removal | All (depends on surface coating) | Coated with PEI or BuildTak; flexible for part removal; may degrade over time |

Other options like BuildTak, 3Dlac spray, and Kapton tape are enhancement solutions rather than bed types. Choose based on the material—for example:

PLA: Glass or aluminum with tape

ABS: Heated glass or taped aluminum

PETG: PEI-coated surface

TPU: PEI or glue-coated glass

Summary:

Bed surfaces play a key role in print adhesion and vary in performance based on material compatibility and thermal properties:

Glass offers a smooth finish but often requires adhesives for materials like ABS.

Aluminum heats quickly and is durable but needs surface treatments like tape.

PEI sheets provide excellent all-around adhesion with minimal prep, especially for PLA and PETG.

Magnetic spring steel plates offer easy print removal and flexibility, depending on their surface coating.

Choosing the right bed surface based on the filament type ensures stronger first-layer adhesion and more reliable prints.

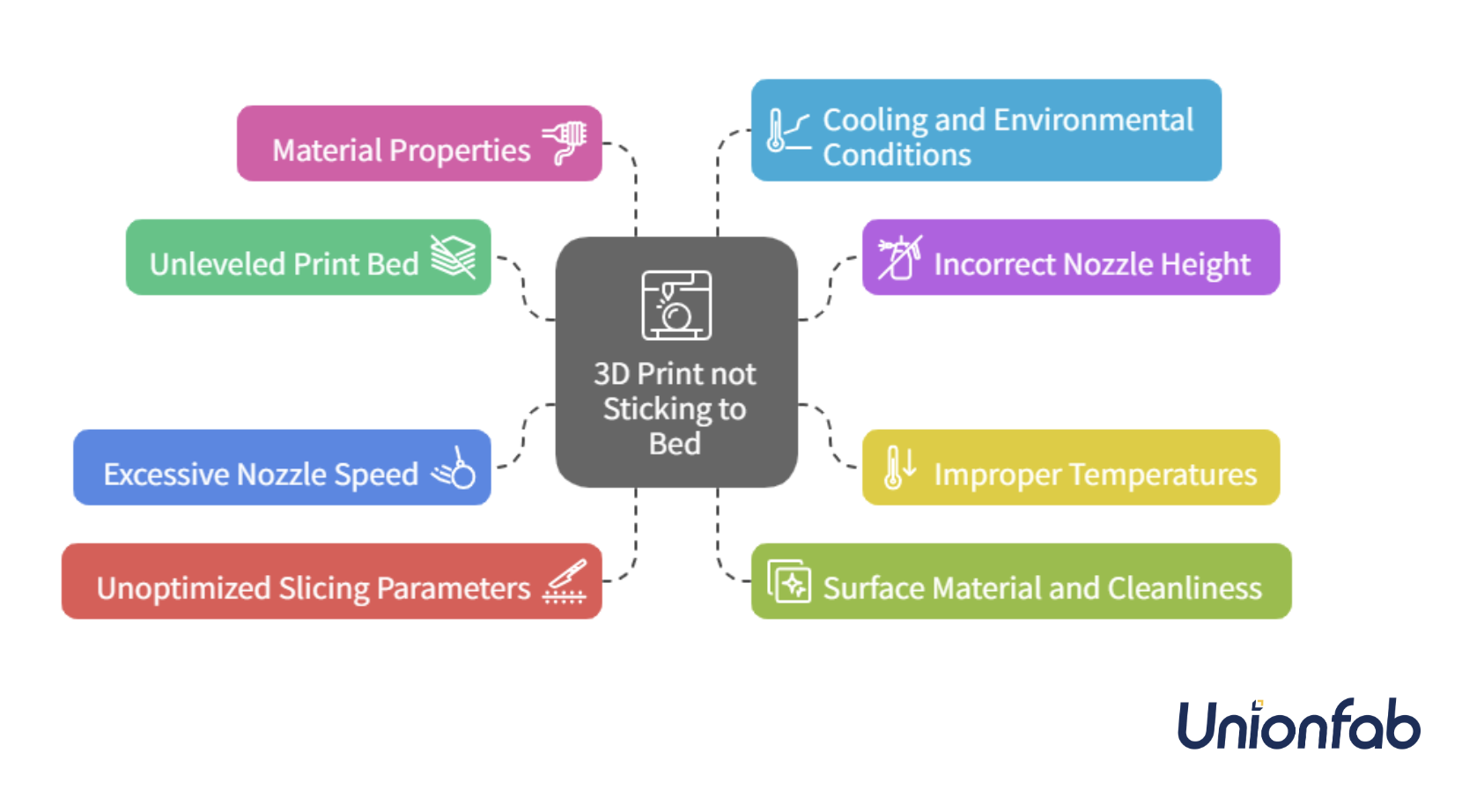

Possible Causes & Solutions

Achieving srong bed adhesion is essential for a successful 3D print. Various issues—such as warping, first-layer detachment, or incomplete prints—can arise due to poor adhesion. These problems often originate from mechanical inaccuracies, incorrect temperature settings, unsuitable surface conditions, or environmental factors.

Below is a breakdown of common causes and practical solutions.

1. Unleveled or Loose Print Bed

Cause: An uneven bed results in inconsistent nozzle-to-bed gaps, leading to poor or uneven first-layer adhesion.

Solution:

Re-level the bed using manual or automatic leveling tools.

Check for warped surfaces (e.g., bent glass or bowed aluminum) and replace if necessary.

Tighten any loose screws or springs supporting the bed.

Use a feeler gauge or leveling paper to verify uniform nozzle distance across the surface.

2. Incorrect Nozzle Height (Z-offset)

Cause: A nozzle that is too far or too close to the bed causes weak adhesion or filament blockage.

Solution:

Adjust the Z-offset so the first layer is slightly squished, creating a smooth and consistent extrusion.

Perform test prints to fine-tune the height.

Use live Z-adjustment or firmware settings if supported.

3. Improper Bed and Nozzle Temperatures

Cause: Suboptimal temperatures prevent proper bonding or lead to warping.

Solution:

Refer to filament guidelines for optimal temperature ranges.

Increase the bed temperature by 5–10°C if adhesion is weak.

Preheat the bed adequately before printing.

For materials like ABS, use an enclosure to retain heat.

4. Excessive Nozzle Speed

Cause: A fast-moving nozzle during the first layer doesn't allow the filament enough time to stick.

Solution:

Lower the first-layer print speed to 20–30% of the normal print speed.

Allow the first few layers to print slowly to establish a solid base.

Increase speed gradually after the first few layers are completed.

5. Unoptimized Slicing Parameters

Cause: Poor slicing settings such as thin first layers, low flow, or incorrect line widths weaken adhesion.

Solution:

Increase the first-layer height (e.g., 0.3–0.4 mm) and line width (120–150%).

Raise the flow rate (extrusion multiplier) to 110–120% for the first layer.

Disable or reduce fan speed for the first layer.

Use brims, skirts, or rafts to increase bed contact and thermal stability.

6. Print Bed Surface Material and Cleanliness

Cause: Dirty or incompatible surfaces prevent proper filament bonding.

Solution:

Clean the bed regularly with isopropyl alcohol or mild detergent.

Sand or replace worn-out surfaces (like PEI or BuildTak).

Apply adhesives such as glue stick, painter’s tape, or hairspray when needed.

7. Material Properties

Cause: Filament characteristics such as moisture content or low viscosity affect adhesion performance.

Solution:

Dry hygroscopic materials (e.g., Nylon, PETG) before use.

Use recommended bed surfaces for specific filaments (e.g., PEI for TPU).

Adjust temperature and cooling settings according to material requirements.

8. Cooling and Environmental Conditions

Cause: Excessive cooling or ambient drafts lead to rapid shrinkage and warping.

Solution:

Disable or reduce part cooling fans for the first few layers.

Print in an enclosed environment or use a draft shield.

For high-temp materials like ABS, maintain a stable, warm ambient temperature.

Summary:

Bed adhesion issues often stem from a combination of mechanical, thermal, and environmental factors. Proper calibration, optimal temperature control, clean and suitable surfaces, and material-specific settings are essential to ensure prints adhere correctly. Implementing these targeted solutions can greatly reduce first-layer failures and improve overall print reliability.

A solid first layer is crucial for good bed adhesion and print success. Most issues—like warping or lifting—stem from misalignment, wrong temperatures, or surface problems.

For detailed tips on avoiding these, check out our guide on 3D Printing First Layer Problems.

Adhesion Enhancement Methods Comparison Table

Adhesion enhancement methods play a crucial role in ensuring the first layer of a 3D print bonds securely to the build surface. Different materials and bed types respond better to specific adhesives or surface treatments.

This comparison table outlines the most common adhesion aids—ranging from glue sticks and tapes to advanced polymer solutions—highlighting their compatibility, advantages, drawbacks, and overall usability.

Method | Compatible Materials | Bed Surface | Advantages | Disadvantages | Ease of Use | Cost | Reusable |

|---|---|---|---|---|---|---|---|

PVA Glue Stick / White Glue | PLA, PETG, ABS, TPU | Glass, PEI, Metal | Widely available, water-soluble, easy to clean, prevents PETG over-adhesion | Requires frequent cleaning and reapplication | ★★★★☆ | Low | No (must reapply each time) |

Painter’s Tape / Blue Tape | PLA, TPU | Glass, Metal | Good adhesion, inexpensive, reduces warping | Wears out easily, requires careful application | ★★★☆☆ | Low | No (replace after few prints) |

Kapton Tape | ABS, PC | Glass, Metal | High-temperature resistance, good for thermoplastics | Poor adhesion alone, prone to bubbling | ★★☆☆☆ | Medium | Limited (easily damaged) |

Hairspray (e.g., AquaNet) | PLA, PETG | Glass, Metal | Quick application, improves grip | Leaves residue, odor, requires ventilation | ★★★★☆ | Low | No (must reapply each time) |

ABS Slurry (ABS + Acetone) | ABS | Glass, Kapton | Excellent bonding strength, ideal for large prints | Flammable, toxic fumes, hazardous handling | ★★☆☆☆ | Low | Yes (must be stored airtight) |

PEI Sheet (Smooth/Textured) | PLA, PETG, ABS, TPU | Built-in | Durable, wide material compatibility, low maintenance | PETG sticks too well, may need glue stick barrier | ★★★★★ | Medium-High | Yes (lasts for years) |

BuildTak / FlexPlate-type Surfaces | PLA, PETG, ABS | Built-in / Glass | Strong adhesion, reusable | Expensive, full sheet replacement if damaged | ★★★★☆ | High | Yes (limited lifespan) |

Magigoo / Nano Polymer Adhesives | Most materials (model-specific) | Glass, PEI | Professionally designed, material-specific formulations | High cost, some require heated bed to activate | ★★★☆☆ | High | Yes (dozens of uses) |

Textured Glass / Textured PEI / Carborundum Plate | PLA, PETG, TPU | Built-in | Rough surface improves grip, durable | Needs cleaning or replacement if dirty or worn | ★★★★☆ | Medium | Yes (light maintenance) |

Enclosed Printer Chamber (not an adhesive) | ABS, ASA, PC, Nylon | All | Maintains temperature, prevents warping, stabilizes environment | High cost, space-consuming | ★★★☆☆ | High | Yes |

Summary:

No single adhesion method fits all materials or print environments.

Low-cost solutions like glue sticks, painter’s tape, and hairspray are effective for PLA and PETG but require frequent reapplication.

Specialized options like PEI sheets, BuildTak, and Magigoo offer strong, reusable adhesion with varying costs and maintenance needs.

High-performance materials such as ABS or PC may benefit from advanced methods like ABS slurry or enclosed chambers to combat warping.

Choosing the right combination of adhesive and surface—based on your material, printer setup, and budget—can greatly enhance print reliability and first-layer quality.

Have more questions about 3D printing?

Our experts are here to help! Whether you're troubleshooting adhesion issues or optimizing your print quality, feel free to reach out to our team for personalized support and solutions.

FAQs

Does higher bed temperature help adhesion?

Yes, increasing the bed temperature can improve adhesion by helping the filament stick better to the surface and reducing warping, especially for materials like ABS and PETG. However, too high a temperature can cause other issues, so it’s important to follow recommended temperature ranges for each filament.

Is a 70 degree bed too hot for PLA?

A 70°C bed is generally safe for PLA but on the higher end. Most PLA prints well between 50°C and 60°C. Higher bed temperatures may improve adhesion slightly but could also lead to softer prints or slight deformation, depending on the PLA brand.

Why do my prints keep lifting off the bed?

Prints lifting off the bed is usually caused by poor bed adhesion due to factors like an unleveled bed, incorrect nozzle height, low bed temperature, dirty or unsuitable bed surface, or rapid cooling. Adjusting these settings and using adhesion aids can help prevent lifting.