3D Printed Turbos [+Metal Material Comparison]

Discover how to design and manufacture 3D printed turbos using high-temperature metal alloys like Inconel.

Introduction

Turbochargers play a vital role in performance engineering, from motorsports to aerospace. As design cycles shrink and the demand for high-performance components increases, 3D printed turbos are becoming a preferred solution for rapid prototyping and functional testing.

In this article, we explore how additive manufacturing reshapes turbo development, what materials and processes are commonly used, and why it’s becoming a go-to choice for engineers and manufacturers.

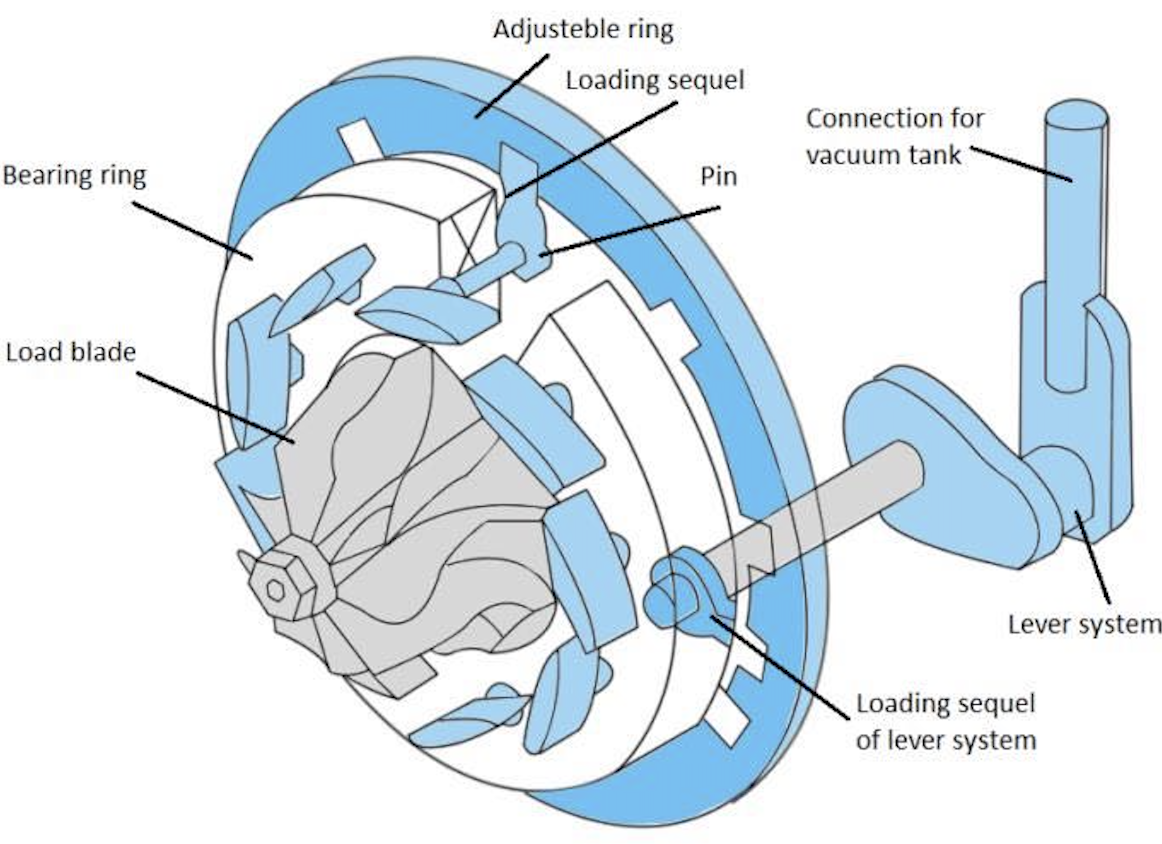

Source: researchgate.net

Challenges of Traditional Turbocharger Manufacturing

Turbocharger parts often feature intricate shapes such as curved turbine blades and internal cooling channels, which are difficult to machine using traditional subtractive methods.

Casting or CNC machining complex parts requires custom tooling and fixtures, resulting in high upfront costs.

Lead times are typically long, especially for small-batch or custom turbo designs.

Design changes are costly and time-consuming to implement, limiting innovation in R&D cycles.

Advantages of 3D Printed Turbos

3D printing, especially metal additive manufacturing, allows engineers to bypass many of the limitations posed by conventional methods.

Rapid prototyping enables the production of fully functional parts within days, allowing quick iteration and testing.

Complex geometries can be produced in a single build without the need for assembly or tooling. The process is also material-efficient, reducing waste and cost for high-value metals.

What Is a 3D Printed Turbo?

A 3D printed turbo refers to a turbocharger or turbine component manufactured using additive manufacturing (AM) technologies, typically metal 3D printing methods like Selective Laser Melting (SLM) or Direct Metal Laser Sintering (DMLS).

These parts can be either fully functional prototypes or end-use components, depending on the material and finishing process.

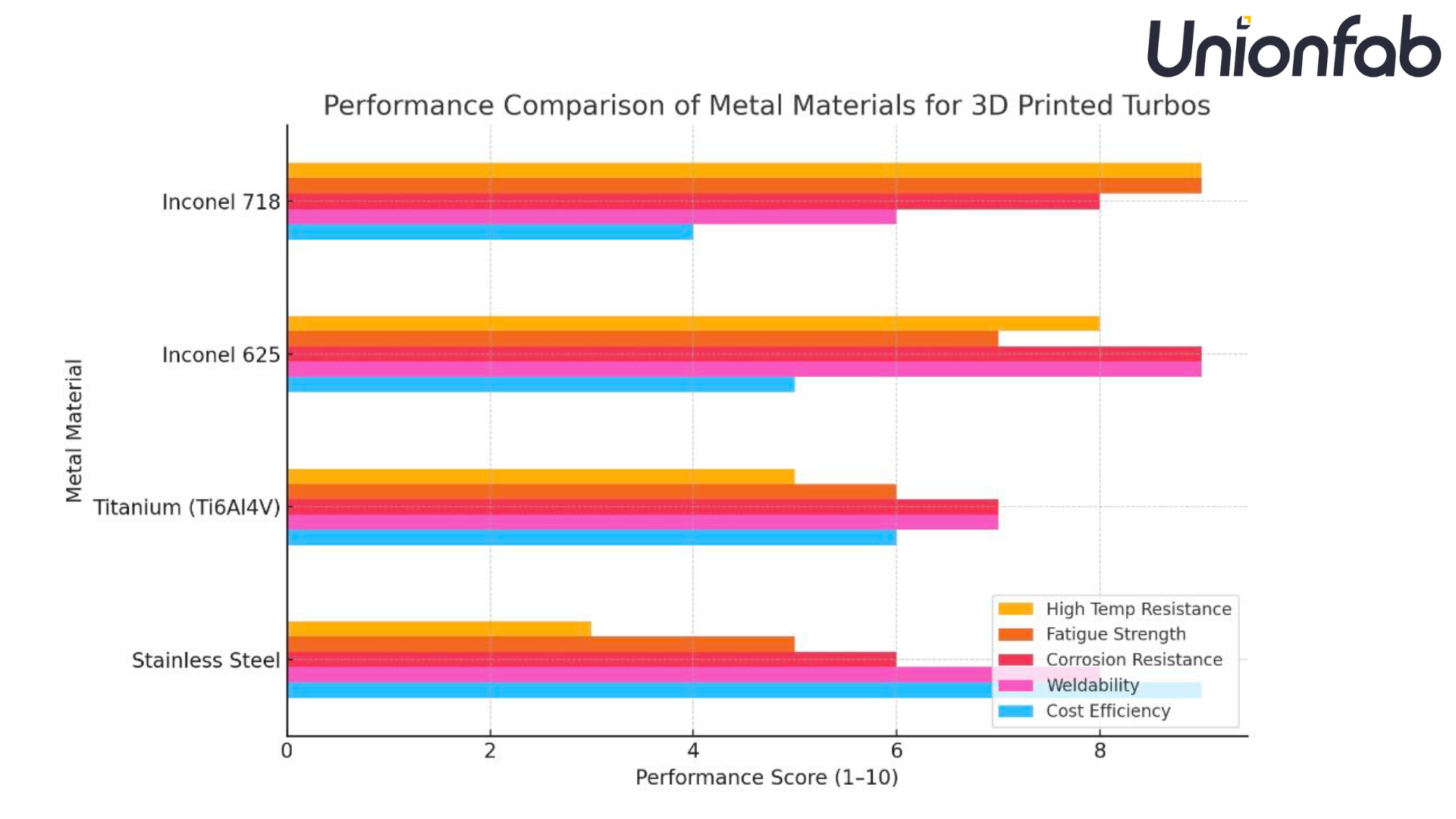

Metal Materials for 3D Printed Turbos

When manufacturing turbo components, engineers prioritize materials that can withstand extreme temperatures, resist fatigue under high rotational stress, and endure corrosive exhaust gases. Based on user demand and industry use, the most important performance metrics include:

High Temperature Resistance

Fatigue Strength

Corrosion Resistance

Weldability

Cost Efficiency

Only metal materials are suitable for turbocharger applications due to these demanding operating conditions. Below is a comparison of four commonly used metals:

Metal Material Comparison Table

Metal Material | High Temp Resistance | Fatigue Strength | Corrosion Resistance | Weldability | Cost Efficiency | Typical Use Cases |

|---|---|---|---|---|---|---|

Inconel 718 | Excellent thermal stability at high temperatures. | High resistance to cyclic stress. | Good protection against corrosion. | Moderate; requires controlled conditions. | Expensive material and processing. | Turbine housings, rotating blades |

Inconel 625 | Good performance under heat. | Moderate resistance to fatigue. | Excellent chemical corrosion resistance. | Good weldability. | Moderately high cost. | Turbo parts exposed to corrosive gases |

Titanium (Ti6Al4V) | Stable at elevated temperatures. | Consistent under repeated loading. | Strong resistance to corrosion. | Fair; needs careful handling. | High material cost. | Aerospace, motorsport turbo components |

Stainless Steel | Limited high-temp capability. | Moderate fatigue strength. | Good environmental corrosion resistance. | Excellent weldability. | Cost-effective and accessible. | Entry-level or non-critical turbo parts |

Key Takeaway:

For high-performance turbo applications,

Inconel 718 provides the strongest combination of high-temperature endurance and fatigue resistance, ideal for core components under extreme stress.

Inconel 625 offers the best corrosion resistance and weldability, making it suitable for harsh gas environments.

Titanium is valued in lightweight, speed-sensitive sectors.

Stainless steel is mainly used for budget-conscious, low-load designs.

To learn more about inconel material, read our previous dedicated guide: Inconel 3D Printing: A Complete Guide.

Manufacturing Process for 3D Printed Turbo Components

Selective Laser Melting (SLM) is the most suitable metal 3D printing process for turbocharger components. It involves the use of a high-powered laser to fully melt fine metal powder, layer by layer, according to a digital model.

This allows the production of dense, high-precision parts with intricate internal structures that traditional methods cannot easily replicate.

This method supports high resolution, complex geometries, and excellent material density, making it ideal for producing functional turbine parts that must withstand extreme mechanical and thermal loads.

For more details about SLM technology and its applications, read our in-depth guide on Guide to SLM 3D Printing/Metal LPBF [+Cost Calculator].

To help you estimate the cost of producing your design with SLM, try our interactive calculator below:

Design and Production Tips for 3D Printed Turbos

Optimize part orientation:

Position turbine blades and housing features to minimize the need for support structures, which can be difficult to remove and affect surface finish.

Use internal lattice structures:

For non-critical areas, introduce lattice or gyroid infill to reduce weight while maintaining structural integrity. This is especially useful in compressor housings.

Integrate multi-functional features:

Combine adjacent components, such as the housing and mounting flanges, into a single print to reduce post-assembly and improve sealing.

Design for heat dissipation:

If the turbo operates under sustained high temperatures, include thermal relief zones or fin structures that assist with heat management.

Apply proper wall thickness:

Ensure that walls are neither too thin (risk of failure under stress) nor unnecessarily thick (adds weight and cost). Use simulation to validate.

Prepare for post-processing:

Add machining allowances on interfaces that require tight tolerances, and consider accessibility for CNC or surface finishing tools.

Run thermal and stress simulations:

Use FEA (Finite Element Analysis) and CFD (Computational Fluid Dynamics) during the design stage to validate thermal load, pressure, and fatigue performance.

Post-processing for 3D Printed Turbos

To achieve full mechanical and thermal performance, post-processing is essential. Common steps include:

Stress relief and heat treatment for Inconel or Ti6Al4V parts

CNC finishing of mating surfaces and shafts

Shot peening to improve fatigue resistance

CT scanning or pressure testing to validate internal channels

Unionfab provides all of these services in-house or via trusted partners, ensuring every turbo part is ready for functional testing or deployment.

Popular Applications of 3D Printed Turbos

● Motorsports:

In F1, endurance racing, and tuning industries, printed turbos allow custom designs that enhance engine responsiveness and airflow, often with optimized blade shapes only possible through AM.

● Aerospace:

Weight reduction is a constant goal in aviation. Turbos printed with titanium or Inconel contribute to fuel efficiency and performance without compromising durability.

● R&D and Academic Engineering:

Universities and research labs use 3D printed turbines for aerodynamic flow testing and material experimentation.

● Electric Turbo Prototypes:

Developers use 3D printing to quickly prototype integrated e-turbo systems, combining motor housings with compressors.

From Concept to Production: How Unionfab Supports Your Turbo Projects

At Unionfab, we provide industrial-grade metal 3D printing services for complex components such as turbochargers.

Our engineers work closely with you to determine the best material, optimize your part’s geometry for additive manufacturing, and execute post-processing steps from heat treatment to final machining.

We also offer DFAM consultation, prototype validation, and short-run production. Contact us to help turn your design into reality today.

Frequently Asked Questions about 3D Printed Turbos

Is 3D printing strong enough for turbochargers?

Yes. With materials like Inconel 718 and titanium, metal 3D printing can meet the thermal and mechanical requirements of high-speed rotating parts when properly heat-treated.

Can I use a 3D printed turbo in real engines?

It depends on the material and design validation. For prototype and race-use parts, metal AM is increasingly used. Unionfab offers post-processing services to meet performance criteria.

What’s the lead time for a 3D printed turbo?

Typically 5–10 working days from approved design to finished part, depending on complexity.

How does cost compare with traditional machining?

For low-volume and complex designs, 3D printing is often more cost-effective due to tooling-free production.