Guide to Sculpture 3D Printing [+Cost Calculator]

Learn about 3D printed sculptures with free models, detailed guides on materials, technologies, costs, and expert design tips. Partner with Unionfab to manufacture your 3D sculpture designs with high-fidelity detail and industrial-scale one-piece molding.

Introduction

Sculpture creation is undergoing a quiet but significant shift. As skilled manual sculptors become harder to find and traditional workflows struggle to keep up with modern production demands, more artists and creative teams are moving the early stages of sculpture development into the digital space.

Digital sculpting tools and 3D printing now make it possible to design, refine, and reproduce complex forms with a level of consistency and scalability that traditional methods alone cannot achieve.

This is especially valuable for IP brands developing designer toys, collectibles studios producing high-precision master patterns, and landscape or exhibition design firms working on large-scale installations where accuracy, repeatability, and timelines matter.

What Is 3D Print Sculpture?

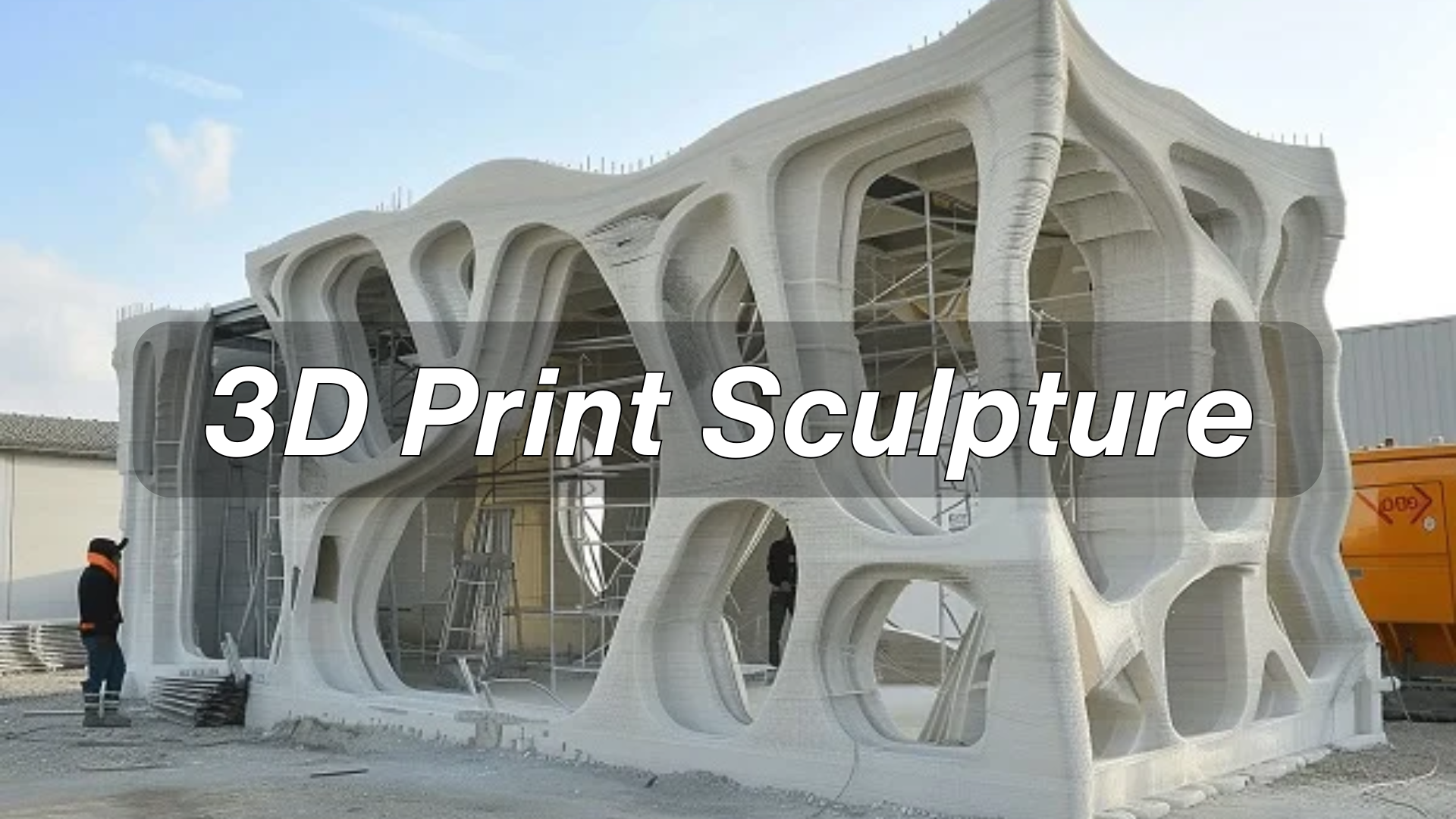

source: 3dacme.com

3D printed sculpture is the process of creating three-dimensional artwork by building forms layer by layer from a digital file. Unlike traditional approaches that rely on shaping oil clay, water-based clay, or carving wood by hand, this method constructs the object from the ground up through additive manufacturing.

It allows artists to translate a design directly from the computer into a physical form with high fidelity, helping the final piece closely reflect the original digital model and creative intent.

3D Printed vs. Traditional Handmade Sculptures

The table below compares traditional handmade sculpture and 3D printed sculpture across key practical dimensions.

Dimension | Traditional Handmade Sculpture | 3D Printed Sculpture | Key Advantage |

|---|---|---|---|

Fidelity | Results vary with hand technique and visual judgment, which can introduce small deviations from the original design. | Follows the digital model closely, reproducing complex geometry with consistent accuracy. | Preserves the original digital intent with minimal translation loss. |

Skill Dependence | Relies on highly skilled artisans; quality and consistency depend on individual experience. | Centers on digital modeling and machine operation with more standardized production steps. | Reduces reliance on scarce manual craftsmanship. |

Digital Archiving | Typically exists as a physical original with limited version tracking or recovery options. | Stored as a digital file that can be revised, scaled, and reproduced as needed. | Enables reuse, version control, and accurate replication. |

Geometric Complexity | Limited by tools and materials, especially for internal or highly intricate structures. | Supports complex internal forms and fine details through layer-by-layer fabrication. | Expands design freedom beyond manual constraints. |

Iteration Speed | Changes often require reworking or remaking the piece, increasing time and effort. | Design updates are made digitally and printed directly. | Allows faster iteration and lower modification cost. |

Material Efficiency | Subtractive processes often generate significant material waste. | Additive processes use material only where needed, with higher overall utilization. | Improves material efficiency and reduces waste. |

Common Applications of 3D Printed Sculptures

In the manufacturing workflow of sculpture, prototyping remains the most widespread entry point. It allows artists, designers, and engineers to rigorously test size, shape, and detail at a low cost before committing to expensive materials.

At the same time, the landscape is shifting. High-quality 3D printing is no longer limited to testing; it is increasingly used to create end-use products (finished sculptures) and manufacturing aids (such as sacrificial patterns for bronze casting).

The table below summarizes the main application areas:

Application Area | Typical Use Cases |

|---|---|

Fine Art | Visual Studies: Printing small "sketches" to test composition and balance before sculpting the final piece in stone or metal. |

Cultural Heritage | Restoration Tests: Prototyping missing fragments to see if they fit the original statue before applying final materials. |

Art Toys | Master Patterns: Printing the initial high-precision prototype to test fitment and aesthetics before creating expensive steel molds for mass production. |

Film Props | Character Concepts: Creating physical creature or character maquettes for directors to approve the design before filming starts. |

Architecture | Scale Models (Maquettes): Rapidly producing detailed 1:100 scale models for client presentations and design verification. |

Education | Teaching Aids: Printing anatomy or geometric models to help students visualize complex 3D concepts in the classroom. |

Popular 3D Sculpture Models for Printing

Digital sculpting tools and open model libraries have made high-quality sculpture files more accessible than ever, allowing artists and makers to create or download detailed sculptures ready for 3D printing.

Digital sculpting software: ZBrush, Blender, SculptGL, and similar software used for creating complex forms and fine surface details.

Model platforms: Printables, Thingiverse, Cults3D, MakerWorld, and other community-driven libraries.

Below are some popular sculpture models for 3D printing:

3D Printable Sculpture Model | Website | Author | File Format | Free or Paid | License |

|---|---|---|---|---|---|

Printables | STL | Free | |||

Cults3D | STL | Paid | |||

Printables | STL | Free | |||

MakerWorld | STL | Free | Standard Digital File License | ||

Thingiverse | STL | Free | |||

Printables | STL | Free | |||

Printables | STL | Free | |||

Printables | STL | Free |

Case Studies: Real-World 3D Printed Sculpture Projects by Unionfab

Below are selected real-world sculpture projects that demonstrate how Unionfab applies industrial 3D printing technologies to artistic, exhibition, and collectible applications.

Case Study 1: Large-Scale Outdoor Artworks

For large-scale outdoor installations, artists often face the challenge of translating fluid, organic designs into durable, physical forms. These sculptures feature complex, wave-like surfaces and thin-walled structures that are difficult and costly to manufacture using traditional casting or manual fabrication.

Unionfab addressed this by employing large-format SLA 3D printing (with a maximum build volume of 2100 x 700 x 800 mm) to produce these pieces in a single print or through a simplified modular process. This industrial capacity allows for the creation of lightweight yet structurally sound foundations, while the precision of SLA ensures the artwork maintains its flowing, "silk-like" aesthetic even at a massive scale.

Technology: SLA

Material: Somos Ledo Resin

Post-Processing: Precision sanding and UV-resistant protective coating

Case Study 2: Transparent Lotus Sculpture

To recreate the translucent quality of a blooming lotus, Unionfab combined SLA 3D printing with transparent clear resin and high-gloss post-processing. This approach preserved delicate, overlapping petal geometries while achieving a crystal-clear, glass-like finish that traditional methods could not deliver.

Technology: SLA

Material: Transparent Clear Resin

Post-Processing: Advanced polishing and clear coating

Case Study 3: High-Detail Character Sculpture — Wukong

This high-end collectible project required exceptional detail and a premium visual finish for a character inspired by Wukong from Black Myth: Wukong. Unionfab utilized high-resolution SLA 3D printing to accurately reproduce intricate armor patterns, facial expressions, and fine textures.

Following printing, professional spray painting and manual finishing techniques were applied to achieve vibrant colors and refined metallic effects, resulting in a museum-quality sculpture suitable for collectibles and brand displays.

Technology: SLA

Material: High Detail Resin

Post-Processing: Professional spray painting & manual finishing

Case Study 4: Human Brain Sculpture

Unionfab utilizes PolyJet 3D Printing to reconstruct brain lesions and associated tumors with exceptional precision. This technology enables a deeper understanding of even the smallest pathological brain features. In addition, PolyJet 3D printed brain models are increasingly used for surgical rehearsal and other medical applications.

Technology: Polyjet

Material: Multi Color Resin

Post-Processing: Cleaning and surface finishing

Ready to bring your design to life?

Upload your digital file to our Instant Cost Calculator and get a real-time quote.

3D Printing Technologies and Materials for Sculptures

The following table compares common 3D printing technologies and materials used in sculptural production, helping you quickly identify the best option based on detail level, material performance, and end-use requirements.

Technology | Description | Materials | Key Features | Best for |

|---|---|---|---|---|

Uses a UV laser to cure liquid resin into solid layers with extreme precision. | Standard, High-Detail, Transparent, Tough Resins, and more | Superior surface finish, supports optical clarity, efficient for large-scale high-precision parts | Large-scale models, high-fidelity visual prototypes, and master patterns for casting | |

Extrudes thermoplastic filament layer by layer; the most versatile method. | PLA, PETG, TPU, ASA, and more | Low cost, broad material selection, diverse aesthetic finishes, durable for functional use | Art toys & collectibles, functional props, custom jigs/fixtures, and low-cost proof-of-concept models | |

Jets liquid photopolymers and cures them instantly with UV light. | Multi-color resin | Full-color printing, multi-material/variable hardness in a single build | Realistic product prototypes, medical models, and multi-material aesthetic tests | |

High-power lasers fully melt metal powders into dense components. | Stainless Steel, Aluminum, Titanium, and more | Exceptional strength, heat resistance, long-term durability | Aerospace parts, high-end sculptures, and luxury jewelry/accessories | |

Uses a laser to fuse nylon powder; no support structures required. | Nylon (PA12), Glass-Filled Nylon, TPU Powder, and more | High structural strength, isotropic properties, matte textured surface | Complex geometries, internal channels, and durable moving assemblies | |

Applies fusing agents and solidifies powder using thermal energy. | Nylon (PA11, PA12), TPU, Polypropylene, and more | Higher part density than SLS, watertight surfaces, fast production cycles | End-use consumer products, small-batch manufacturing, and industrial housings |

Key Cost Drivers for 3D Printed Sculptures

Several factors influence the final price of a 3D printed sculpture. Understanding these cost drivers helps you make more informed decisions during design, material selection, and production planning:

● Size of the Sculpture:

Sculpture size directly affects material consumption and machine time.

Unionfab’s large-format SLA 3D printing supports one-piece fabrication of large sculptures, with a maximum build volume of 2100 × 700 × 800 mm, minimizing segmentation and assembly requirements.

For other technologies or oversized designs beyond a single build volume, models can be split into multiple sections and assembled after printing, helping manage production cost, feasibility, and logistics.

● Level of Detail (Resolution):

Finer layer heights increase printing time, as the laser or print head must process more layers. Higher resolution improves surface quality and visual fidelity but also raises machine and labor costs.

● Material Type:

Entry-level materials such as standard resins or PLA are typically the most cost-effective. Advanced materials, including Transparent Clear Resin, SLS Nylon, and metal powders (such as stainless steel or titanium), come at a higher cost due to raw material pricing and more complex processing requirements.

● Design Complexity:

Intricate geometries, overhangs, or floating features often require additional support structures and more extensive post-processing, increasing both material usage and manual labor.

● Post-processing & Finishing:

Finishing plays a critical role in achieving the desired artistic and functional quality. Processes such as support removal, surface polishing, vapor smoothing, painting, or clear coating can significantly affect the final cost depending on the level of refinement required.

● Quantity:

While 3D printing is well suited for one-off or low-volume production, producing multiple identical parts can benefit from batch efficiency, reducing the cost per unit.

If you’d like a more detailed cost breakdown and a comparison of pricing across different 3D printing technologies, you can explore our guide: How Much Does 3D Printing Cost.

Pro Tips: How to Optimize Your Sculpture Design for 3D Printing

Designing a sculpture for 3D printing is not only an artistic process. It also requires practical considerations to ensure printability, structural integrity, and cost efficiency.

The following tips help optimize sculptural designs before production, reducing rework and unnecessary expenses.

1. Design to Minimize Supports

Supports are often necessary to hold up overhanging parts, but they leave marks on the surface. The best way to limit them is to design your sculpture so it supports itself:

Adjust the Pose: Modify steep overhangs to be self-supporting. For example, angling an arm downwards or connecting a flowing cape to the base can eliminate the need for external scaffolding.

Plan the "Sacrificial" Side: Decide early which side of your model is less critical (e.g., the back or bottom). Design the geometry so that unavoidable supports attach only to these hidden areas, leaving faces and textures pristine.

2. Hollow Large Models (SLA/SLS)

Printing a large sculpture as a solid block is often unnecessary and risky. It increases the chance of warping or cracking due to material shrinkage.

Wall Thickness: We recommend a uniform wall thickness (typically 2–3mm) to maintain strength while saving material.

Add Drainage Holes: For resin (SLA) or powder (SLS) prints, always include "escape holes" in discreet locations. This prevents internal pressure and allows trapped material to exit.

3. Split Complex Designs into Assemblies

Don’t be afraid to break your sculpture into multiple parts. This is a common industry practice for high-end collectibles.

Better Surface Finish: By printing components separately, you can orient each piece perfectly to avoid support scarring.

Mind the Tolerances: When designing "keys" or "pegs" for assembly, remember to include a clearance of 0.1–0.2mm. This ensures parts fit together snugly even after they are painted or coated.

4. Ensure Your Geometry is "Watertight" (Manifold)

A 3D printer needs to understand what is "inside" and what is "outside" of a volume. Unlike digital models for games, 3D print files must be manifold.

Check for Errors: Before exporting, scan your mesh for holes, flipped normals, or zero-thickness surfaces.

The Result: A watertight mesh ensures the slicing software interprets your design correctly, preventing failed prints and wasted material.

5. Optimize Polygon Count (Decimation)

While you want high detail, an excessively high polygon count can make files too heavy to process without adding visible quality.

Smart Decimation: Use a decimation tool to reduce the mesh density in flat or less detailed areas while preserving sharp features.

Balance: The goal is to keep the file size manageable while ensuring the "resolution" of the mesh matches the capability of the printing technology.

Upload your sculpture today and receive a free DFM (Design for Manufacturing) feedback from our engineers to optimize your design before production!

Start Your Sculpture 3D Printing Project with Unionfab

For creative enterprises and art professionals, whether you are an IP brand developing a new series of designer toys, a collectibles studio in need of high-precision master patterns, or a landscape design firm executing large-scale installations, Unionfab provides the industrial scalability and precision your vision demands.

Unlike boutique printing shops, we deliver consistent, gallery-ready quality suitable for high-end retail and public exhibition.

● Risk-Free Batch Production:

We understand that committing to a large production run of art pieces or collectibles is a significant decision. To ensure your peace of mind, we offer one-time free prototyping for batch orders. We will cover the production cost up to $70 USD (excluding shipping fees), allowing you to verify every intricate detail and surface texture before the full run begins. (Unionfab reserves the right of final interpretation.)

● Comprehensive Art Technologies:

We provide a full spectrum of industrial manufacturing methods optimized for aesthetic excellence:

SLA (Stereolithography): The gold standard for sculpture. It offers "pixel-level" detail for hair and skin textures, with a massive 2100mm one-piece build capacity to eliminate visible seams on large-scale installations.

Industrial FDM: Ideal for art toy prototypes, functional props, and large structural armatures. It offers cost-effective production with diverse aesthetic finishes like silk, matte, or wood-filled textures.

PolyJet (Multi-Color): Perfect for digital sculptures requiring full-color gradients or multi-material transparency without the need for manual painting.

Metal 3D Printing (SLM/DMLS): Providing permanent, high-end solutions in Stainless Steel, Titanium, or Bronze for luxury sculptures and jewelry.

SLS & MJF: Ideal for durable, complex sculptures. No support structures are required, enabling intricate floating geometries and interlocking parts, with excellent strength and matte, dye-ready finishes.

● Professional Post-Processing & Finishing:

Our in-house post-processing lab specializes in elevating raw prints to exhibition standards. Our capabilities include precision manual sanding, professional Pantone color matching, and high-vacuum electroplating for a flawless metallic finish.

Ready to bring your masterpiece to life?

Get a 10% discount on your first order.

FAQs

Can I create a 3D printed sculpture from a photo?

Yes. A photo can be used as a reference to create a 3D model, typically through digital sculpting. For best results, multiple angles or reference images are recommended.

Can I print a full-color sculpture?

Yes. Full-color results can be achieved through multi-material printing or professional painting, depending on the level of realism and durability required.

What is 3D print art, and how is it different from traditional sculpture?

3D print art uses digital models and additive manufacturing to create physical artworks. It enables precise replication, easier iteration, and scalable production compared to fully handmade methods.

What is a 3D printed layered sculpture?

Layered sculptures showcase the visible layer-by-layer structure of 3D printing, either as a design feature or a result of the printing process. This aesthetic is often used in contemporary or experimental art.

Can 3D printing be used for fashion or wearable art?

Yes. 3D printing is increasingly used in fashion for sculptural garments, accessories, and experimental designs, especially with lightweight plastics or flexible materials.

What’s the maximum size you can print?

Large sculptures can be produced as one-piece prints using large-format technologies such as SLA (with a maximum build volume of 2100 × 700 × 800 mm), or printed in sections and assembled after printing, depending on the material and process.

Can Unionfab help optimize my sculpture design for printing?

Yes. Our engineers review geometry and provide DFM feedback to help improve printability, surface quality, and cost efficiency before production.

Do you offer post-processing and finishing services?

Yes. We offer various post-processing and finishing services, including support removal, surface smoothing, polishing, painting, and coating, with additional options available upon request.