Guide to Custom Car Hoods [+Cost Calculator]

Custom car hoods with vents, scoops, and ornaments. Learn how 3D printing speeds up prototypes and reduces costs with Unionfab.

Introduction

Custom car hoods are a top choice for car owners who want to upgrade both style and performance. A hood is not only a cover for the engine but also one of the most eye-catching parts of a vehicle. With the right design, a custom hood can reduce weight, improve cooling through hood vents or hood scoops, and create a bold, unique look.

This article explains how custom car hoods are made, the most common materials and methods, and why 3D printing is a fast and cost-effective way to build prototypes.

We also look at related components — such as hood props, hinges, louvers, emblems, and hood ornaments — and show how Unionfab helps car owners and builders turn their custom hood ideas into real parts.

Why Do People Customize Car Hoods?

There are mainly three reasons why many car owners decide to change their hoods.

1.Style and Personalization

A custom car hood makes a strong style statement. It’s one of the first parts people notice, and a new design, shape, or material can give the car a fresh and unique look. For enthusiasts, it’s about making the car stand out from all the others on the road.

2.Performance Improvements

Many custom hoods are designed to reduce weight or improve airflow. Lighter materials like carbon fiber reduce weight, while features such as vents or scoops help the engine breathe better and stay cooler. These changes don’t just look good — they can make a car run more efficiently too.

3.Replacement or Restoration

In cases of accidents or aging vehicles, a custom hood is often chosen as a replacement. Upgrading to a custom hood is a chance to restore the car and add an upgrade at the same time.

Common Materials for Custom Car Hoods

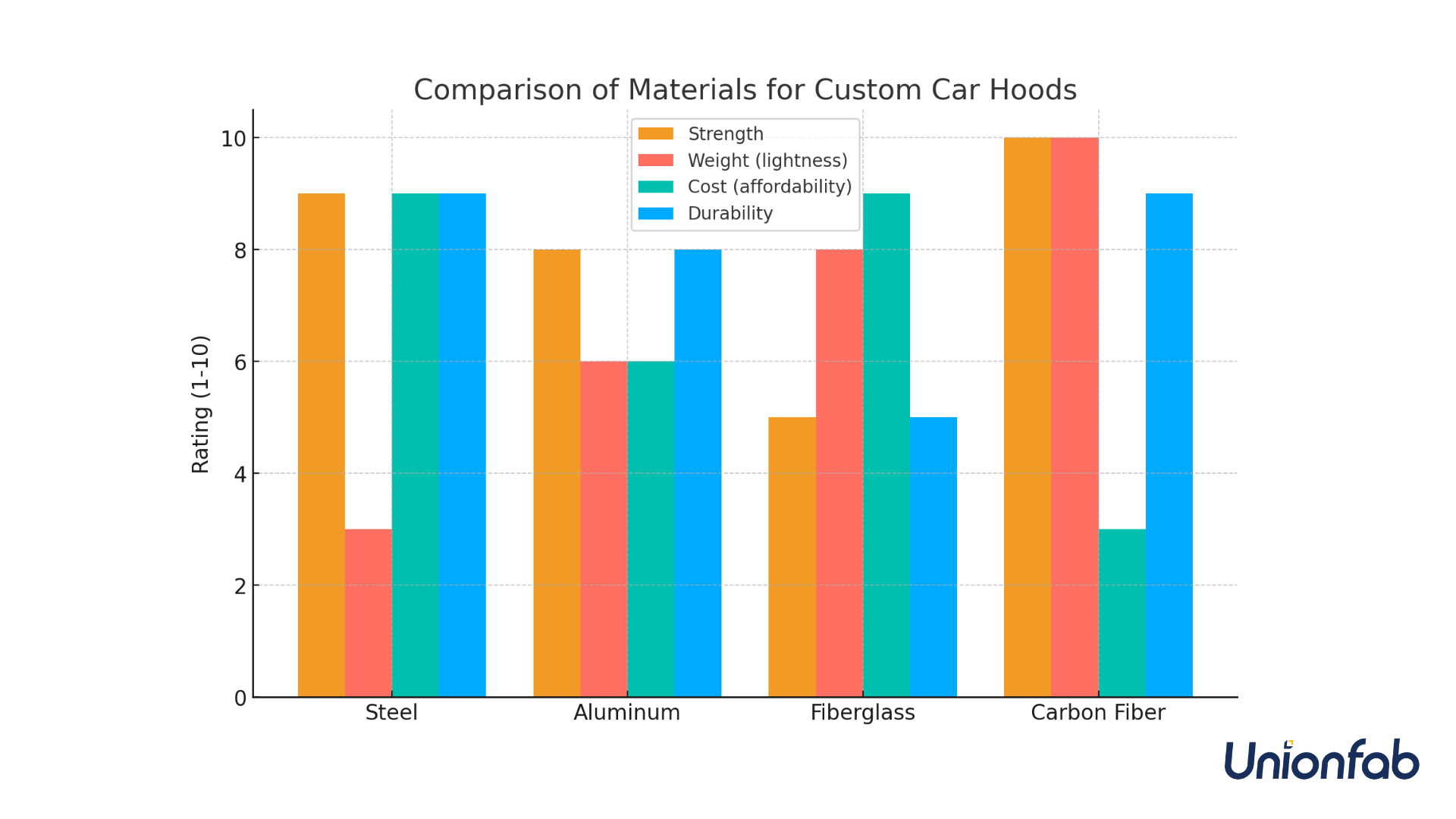

When choosing a material for a custom car hood, car owners usually compare strength, weight, cost, and durability. The table below highlights the key differences between the four main materials.

Material | Strength | Weight | Cost | Durability | Typical Use |

|---|---|---|---|---|---|

Steel | Very high | Heavy | Low | Long-lasting but can rust | OEM hoods, budget builds |

Aluminum | High | Medium-light | Medium | Good corrosion resistance | Modern cars, performance builds |

Fiberglass | Moderate | Light | Low | Can crack under stress | Styling-focused aftermarket hoods |

Carbon Fiber | Very high | Very light | High | Excellent, premium look | Racing, high-performance upgrades |

Choosing the Right Material

Steel is the most affordable and durable, but it adds weight.

Aluminum offers a good balance of lightness and strength, often used in modern and performance vehicles.

Fiberglass is the cheapest way to get bold styling, though it’s less durable under impact.

Carbon fiber is the premium choice — extremely light and strong, but also the most expensive.

For most everyday builds, aluminum or fiberglass is a practical choice. For racing or high-end customization, carbon fiber is worth the investment.

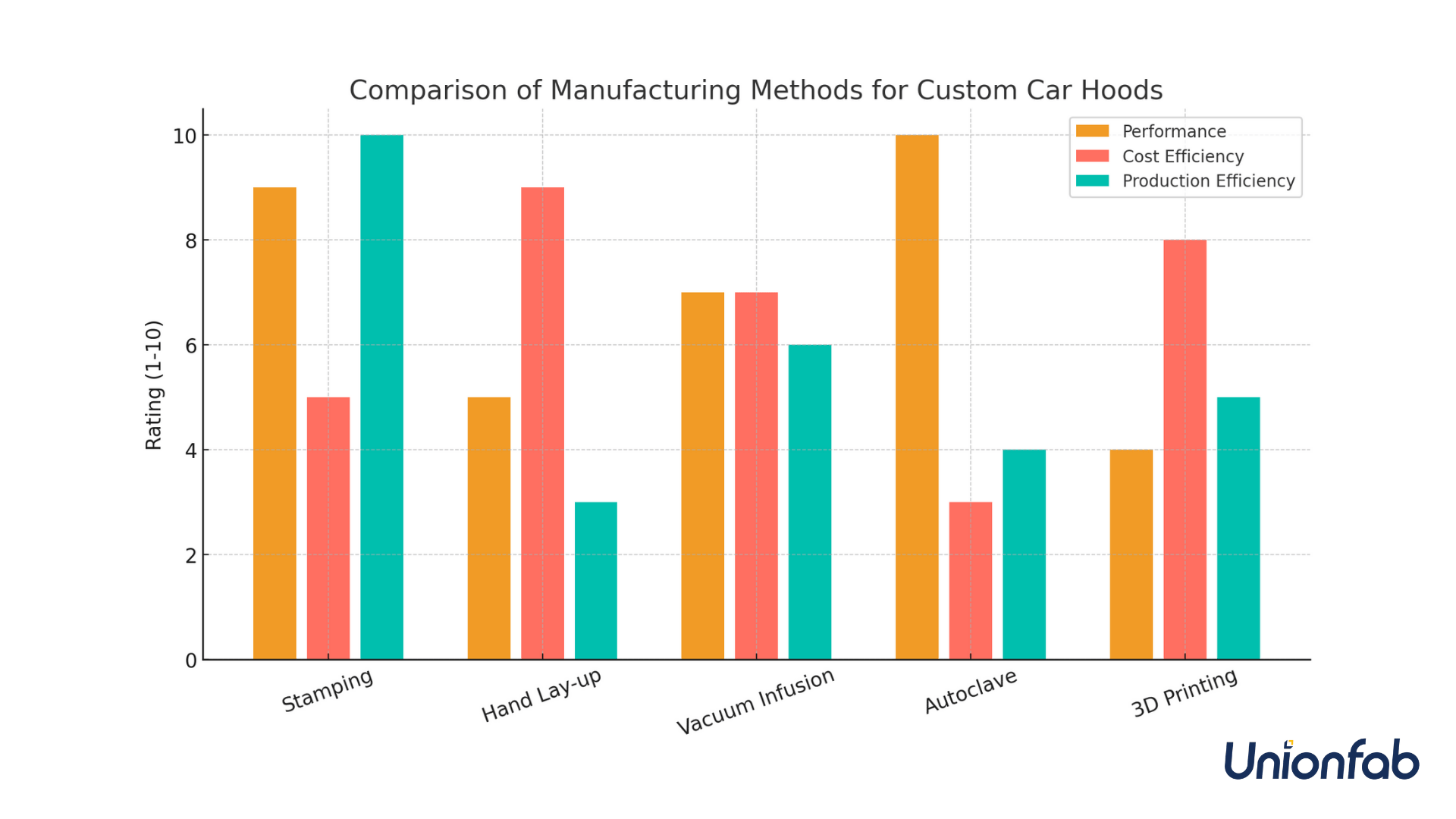

Manufacturing Methods for Custom Car Hoods

The choice of manufacturing method is just as important as the material itself. Different processes can dramatically change the hood’s strength, finish, cost, and production scale. The table below compares the most common methods used to produce custom car hoods.

Method | Suitable Materials | Performance | Cost | Production Efficiency | Best Use Case |

|---|---|---|---|---|---|

Stamping (Pressing) | Steel, Aluminum | Very high strength, consistent results | High mold cost, low per piece | Excellent for mass production | OEM hoods, large-scale builds |

Hand Lay-up | Fiberglass, Carbon Fiber | Moderate strength, quality depends on skill | Low | Slow, labor-intensive | Styling-focused custom hoods, low-budget projects |

Vacuum Bagging / Infusion | Fiberglass, Carbon Fiber | Higher strength and better resin control than hand lay-up | Medium | Suitable for small to mid batches | Aftermarket hoods, mid-range builds |

Autoclave Curing (Prepreg) | Carbon Fiber | Aerospace-grade strength and lightness, excellent finish | Very high | Slow, requires advanced equipment | Racing, high-performance sports cars |

3D Printing (Prototype) | PA12, PA-CF, ABS, sometimes metals | Great for design validation, not for long-term full-size hoods | Low (no mold cost) | Best for one-offs | Prototyping, test fitting, design iteration |

Choosing the Right Method

Stamping is the best choice for large-scale production with steel or aluminum, but mold investment is high.

Hand lay-up is cheap and flexible but best only for small projects where appearance matters more than strength.

Vacuum infusion balances strength and cost, making it popular in the aftermarket for functional fiberglass or carbon fiber hoods.

Autoclave curing delivers the lightest and strongest hoods, but at a premium cost — ideal for racing or luxury builds.

3D printing is not for final production hoods, but it’s perfect for prototypes, saving time and money before committing to expensive molds.

In short, choose stamping or autoclave curing for top-level performance, vacuum infusion for balanced aftermarket builds, hand lay-up for budget styling, and 3D printing for early-stage design validation.

The Role of 3D Printing in Custom Car Hoods

In the development process of custom car hoods, 3D printing is not the final production method, but it plays an important role in the early stages. Its main applications include the following two scenarios:

Prototyping

Quickly turn CAD models into physical parts to verify dimensions, structure, and overall styling.

Helps design teams and car owners confirm whether the appearance and function meet expectations before investing in expensive molds.

Show Cars & Demonstration

Full-size or partial parts produced by 3D printing can be finished (sanding, painting) and used for show cars, photography, or short-term road tests.

Commonly seen at car shows, tuning exhibitions, or as temporary parts while waiting for final carbon fiber/metal hoods.

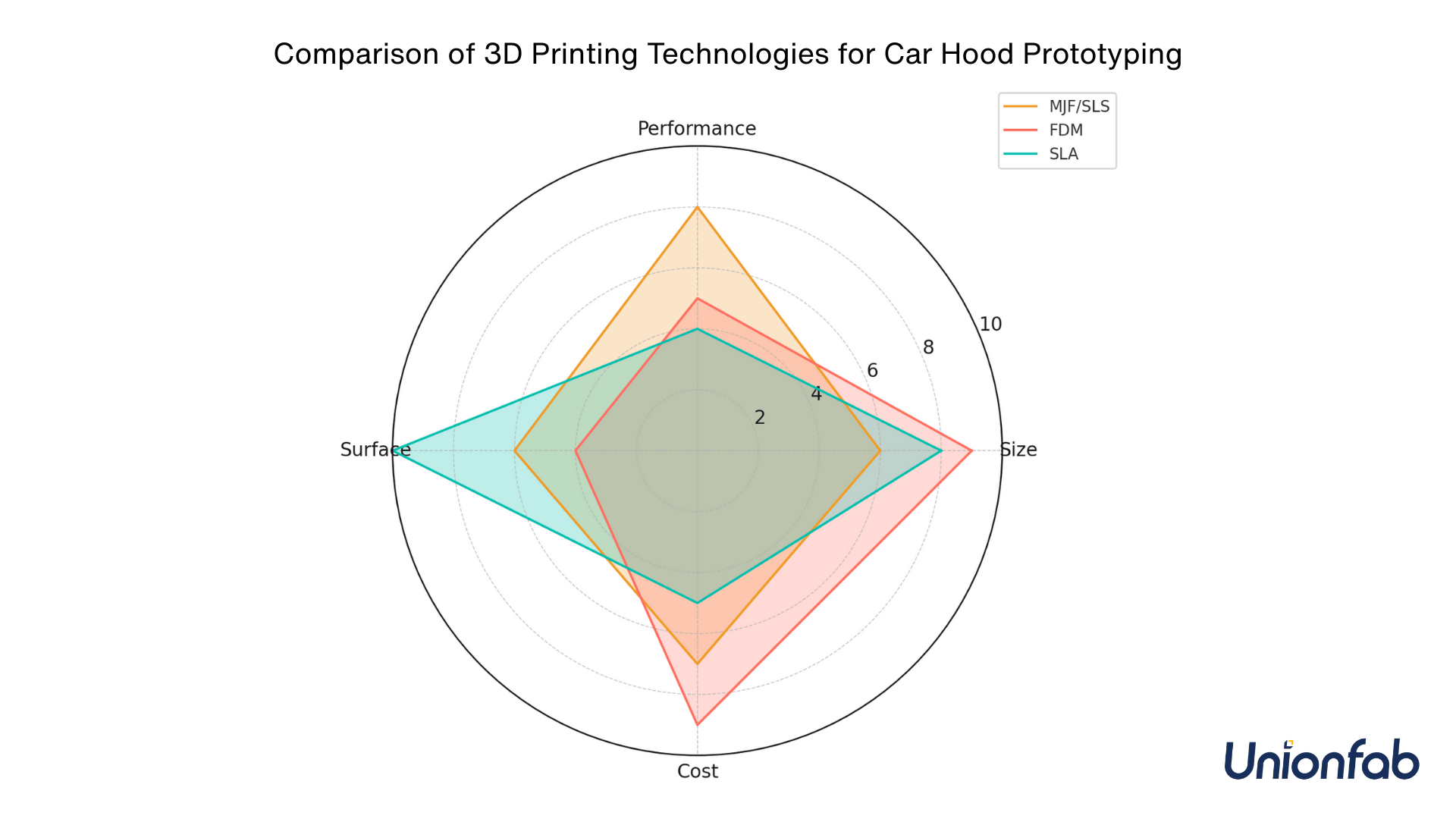

Common 3D Printing Materials and Processes for Custom Car Hoods

Material / Process | Build Size Capability | Strength & Heat Resistance | Surface Quality | Cost & Efficiency | Best Use Case |

|---|---|---|---|---|---|

Medium volume; can print hood sections or split panels | Good strength and heat resistance; PA12-CF offers higher stiffness | Rough surface; moderate finishing needed | Medium cost, high efficiency | Prototyping (functional validation), partial hood testing | |

FDM (ABS, ASA, PA-CF) | Very large parts; suitable for full hood by splitting | Average strength; weak layer adhesion; heat resistance depends on material | Rough surface; requires heavy sanding and coating | Low cost, high efficiency | Prototyping (large parts), show cars, full-size display |

SLA (Resin-based) | Can print large parts, but slower and needs splitting | Limited strength, poor weather/UV resistance; not for long-term use | Very smooth, close to Class-A finish | Higher cost, lower efficiency | Prototyping (aesthetic evaluation), showroom-grade parts |

Key Takeaways

Engineering validation & functional testing → Choose MJF/SLS (especially PA12-CF).

Large structural prototypes & show hoods → Choose FDM, post-processed for exhibitions or short-term road use.

Aesthetic evaluation & showroom display → Choose SLA, best surface quality for proposals or exhibitions.

Still unsure which material to choose? Consult with Unionfab experts to get professional tips.

Advantages

Speed: From design to part in just a few days, with early real-world visualization.

Low-cost iteration: No tooling required, test multiple concepts, reduce rework and sunk costs.

Design freedom: Easily realize complex geometries such as scoops and airflow channels.

Risk control: Start with sections or scaled-down models before committing to full size, lowering risk of failure.

Versatility: Beyond hood prototypes, can also produce jigs, templates, and master patterns.

Limitations

Limited long-term durability: Nylon or reinforced plastics work for short-term road tests but cannot replace composites or metals for long-term use.

Size and assembly: Full-size hoods typically require splitting into parts, bonding, and surface finishing.

Surface finishing: To reach automotive Class-A standards, significant sanding, coating, and painting are required.

Related Components Beyond Custom Car Hoods

When customizing a car hood, the project often extends to other related components. These parts not only support the hood’s function but also enhance the vehicle’s style and individuality.

Importantly, with today’s additive manufacturing technologies, many of these components can be directly produced as final parts using 3D printing.

Component | Pictures | Main Function | Customization Purpose | Recommended 3D Printing Process & Material (Final Part) |

|---|---|---|---|---|

Custom Car Hood Props |  | Hold and support the hood when open | Improve durability and reliability | Metal SLM (Aluminum, Stainless Steel) → strong, long-term use |

Custom Car Hood Vents |

| Improve airflow and heat dissipation | Performance upgrade, sporty styling | SLS/MJF (PA12-CF) → strong, heat-resistant, durable |

Custom Car Hood Louvers |  | Channel hot air out of the engine bay | Racing-inspired look and cooling | SLS/MJF (PA12-CF) → stiff, heat-resistant, long-term use |

Custom Hood Scoops |  | Direct outside air into the engine | Boost cooling and performance | SLS/MJF (PA12-CF) → functional and durable; long-term users may combine with composite finishes |

Custom Car Hood Emblems |

| Decorative, brand or personal identity | Personalization, unique styling | SLA Resin Printing → high-resolution, smooth surface, finish-ready (plating/painting) |

Custom Hood Ornaments |  | Decorative, classic or luxury look | Enhance recognition and character | SLA Resin Printing → strong, fine detail, ideal for chrome-plating or coating |

Custom Car Hood Hinges |

| Control how the hood opens and closes | Improve stability, enable special opening angles | Metal SLM (Aluminum, Stainless Steel) → high strength and durability |

Key Takeaways

Functional parts (props, hinges) → best made with metal SLM for long-term reliability.

Airflow-related parts (vents, louvers, scoops) → SLS/MJF with PA12-CF is the best balance of strength, heat resistance, and lightweight performance.

Decorative parts (emblems, ornaments) → SLA resin provides fine detail and smooth finishes suitable for plating or painting. In short: SLM for strength, SLS/MJF for performance, SLA for aesthetics.

Cost Breakdown of 3D Printing Custom Car Hoods and Related Parts

General Formula

The total expense for producing a custom hood or its related components with 3D printing can be summarized as: Overall Price = Printing Expense (material rate × part mass) + Finishing Expense + Packaging + Logistics + Import Duties

Printing Expense

Material Rate: Refers to the unit price of raw printing material, generally calculated per gram.

Part Mass: Determined by part volume × density of the chosen material. CAD software provides the volume directly.

Sample Calculation

Material: PA12-CF (carbon fiber reinforced nylon)

Unit Rate: $0.30 / g

Weight Estimate: 3,00 g (based on CAD model data)

Printing Expense = $0.30 × 3,00 g = $90

Once you upload a CAD file, our automated system performs this calculation instantly and provides a quote with manufacturability feedback.

Instant Quote: Upload your CAD model to get real-time pricing and design suggestions.

Additional Expenses

Finishing: Basic processes like support removal or surface blasting are included. Premium options (e.g., painting, polishing, or protective coatings) are available at extra cost.

Packaging: Covers protective wrapping and handling to ensure the part reaches you safely.

Logistics: Charges vary by shipping method, region, and urgency.

Import Duties: Applicable for international deliveries, depending on local customs regulations.

For a broader overview of additive manufacturing costs, see our detailed guide: How Much Does It Cost to 3D Print Something?

Case Study: Unionfab’s 3D Printed Car Hood Prototypes and Other Components

At Unionfab, we have helped multiple automotive clients develop and test custom exterior parts using SLA (stereolithography) 3D printing. SLA is ideal for producing large, detailed prototypes with smooth surfaces, making it especially useful in fit checks, modification trials, and show models.

Here are three real-world examples from recent projects:

1. BMW Front Hood Prototype

Process: SLA 3D printing

Purpose: Modification testing for a custom hood design

Outcome: The large hood was produced in sections, bonded, and finished to allow fitment checks and design validation before committing to high-cost composite tooling.

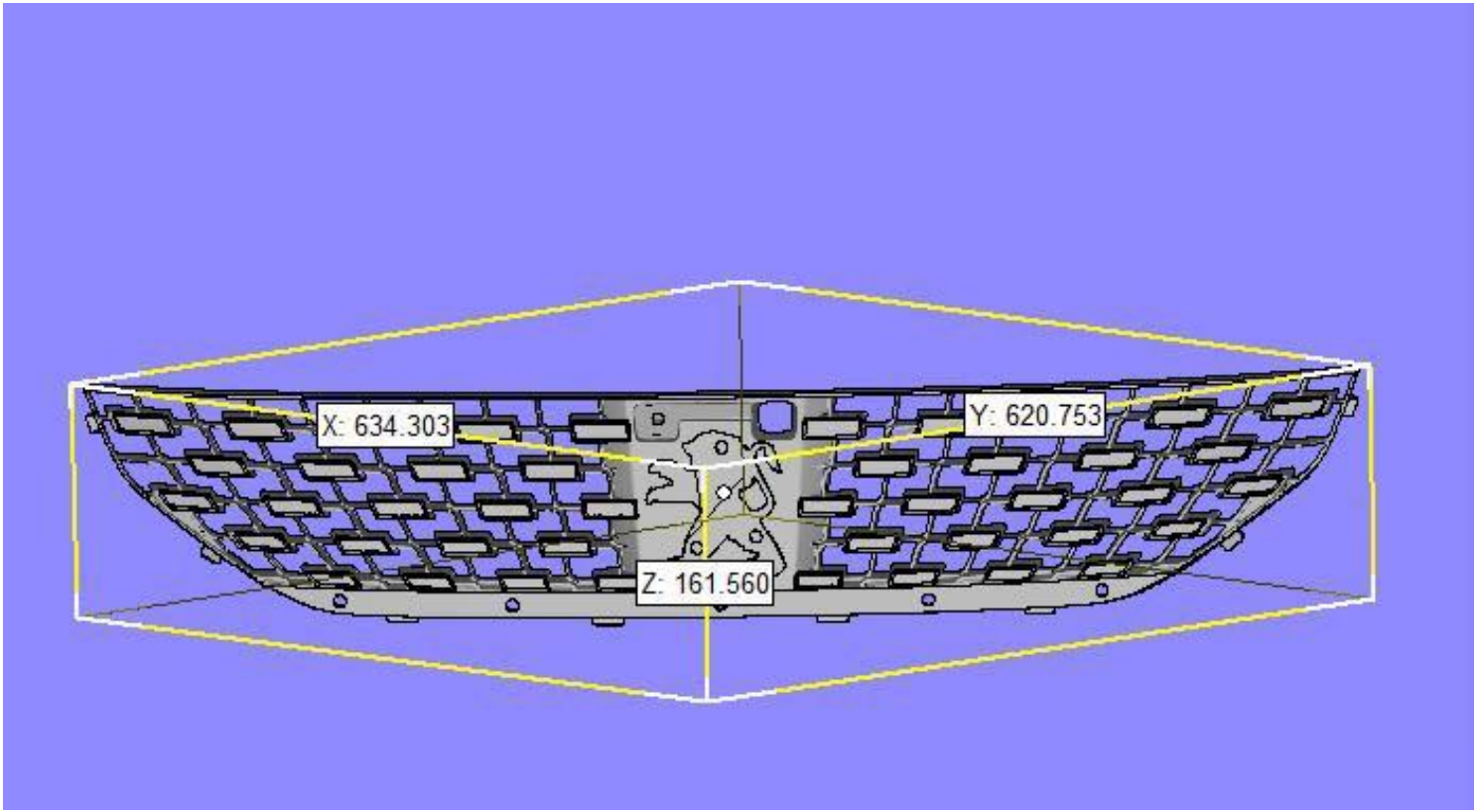

2. Peugeot Front Grille Prototype

Process: SLA 3D printing

Purpose: On-car testing and appearance validation

Outcome: The complex grille geometry with multiple openings was printed with high accuracy. This enabled direct installation on the vehicle to evaluate styling and ensure structural compatibility.

3. Daytime Running Light (DRL) Housing

Process: SLA 3D printing

Purpose: Prototype development and on-vehicle testing

Outcome: The full DRL assembly, including the outer lens and internal structure, was built with SLA. The prototype supported both aesthetic evaluation and mounting verification.

Why Work with Unionfab for Custom Hood Prototypes and More

Unionfab, the overseas branch of Uniontech, which holds 60% of China's 3d printing market share, is the largest 3D printing manufacturer in China, specializing in rapid prototyping and on-demand production.

With 20+ years of expertise, 1,000+ industrial 3D printers, and 6 cutting-edge factories, Unionfab, certified with ISO 9001, ISO 13485, and AS 9001D, is committed to delivering high-quality, cost-effective 3D printing services.

We offer 80+ 3d printing materials and advanced technologies such as SLA, SLM, SLS, MJF, FDM, DLP, and PolyJet, all at prices up to 70% lower than competitors. The followings are the details of the 3d printing services we provide.

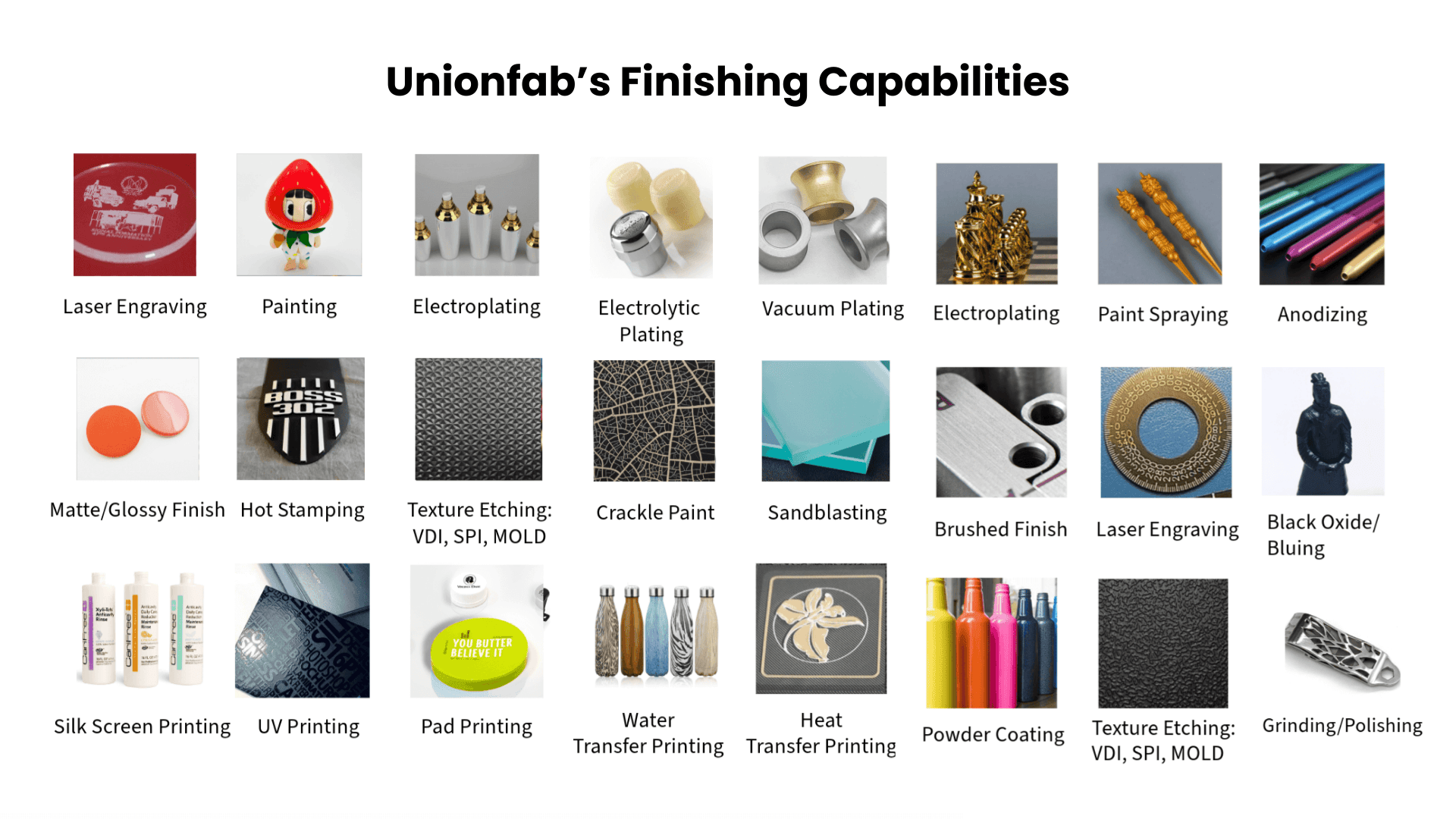

Post Processings

We not only provide high-precision printing but also a range of post-processing options below, including sandblasting, electroplating, and polishing etc., to improve surface quality, durability, and aesthetics of the prints, ensuring the perfect fit for various applications.

QA Report

In addition to delivering cost-effective prints, we also offer quality assurance services and can send the QA report with the shipment.

Btw, if you haven’t used Unionfab’s 3d printing service yet, sign up now to get a 10% discount on your first order!

FAQs

Can I get a custom car hood with a logo?

Yes. A hood can feature embossed or engraved logos, or even custom emblems. 3D printing is a fast way to prototype the logo before final production.

Who are reliable custom car hood manufacturers?

From composite specialists to 3D printing service providers like Unionfab, there are many options. The best choice depends on whether you need prototypes, styling upgrades, or full production.

How do I find custom car hood fabrication near me?

Local fabrication shops may offer CNC, composites, or 3D printing. Unionfab provides online ordering with international shipping, so you don’t need to limit yourself to local providers.

Where can I buy a custom car hood for sale?

Custom hoods are available from aftermarket shops and tuning specialists. For unique designs, many start with 3D printing prototypes before moving to carbon fiber or metal production.

What are custom car hood vents and why use them?

They are openings that let hot air escape from the engine bay. They improve cooling efficiency and also give the car a sportier look.

Are there custom hoods for trucks?

Yes. Truck owners often choose raised hoods, scoops, or vented designs for improved airflow and tougher styling.

What is a hood scoop?

It’s an intake opening on the hood that channels fresh air into the engine. Popular on muscle and performance cars, it improves cooling and adds aggressive styling.