Custom Silicone Molds: How 3D Printing Enhances it?

Introduction

Silicone molding remains one of the most versatile manufacturing methods for creating detailed prototypes, functional test parts, and small-batch production components. Its ability to replicate complex geometries with excellent surface finish makes it a go-to solution across industries — from consumer products to medical devices and automotive components.

But traditional silicone mold making is often slow, costly, and difficult to iterate — especially during early-stage product development. This is where 3D printing changes everything.

By combining additive manufacturing with silicone molding, modern product teams can cut development cycles from weeks to days, reduce machining costs, and unlock far greater design freedom.

This guide explains how it works — and why leading innovators are combining 3D printing + silicone molding as a strategic manufacturing tool.

What Is a Custom Silicone Mold?

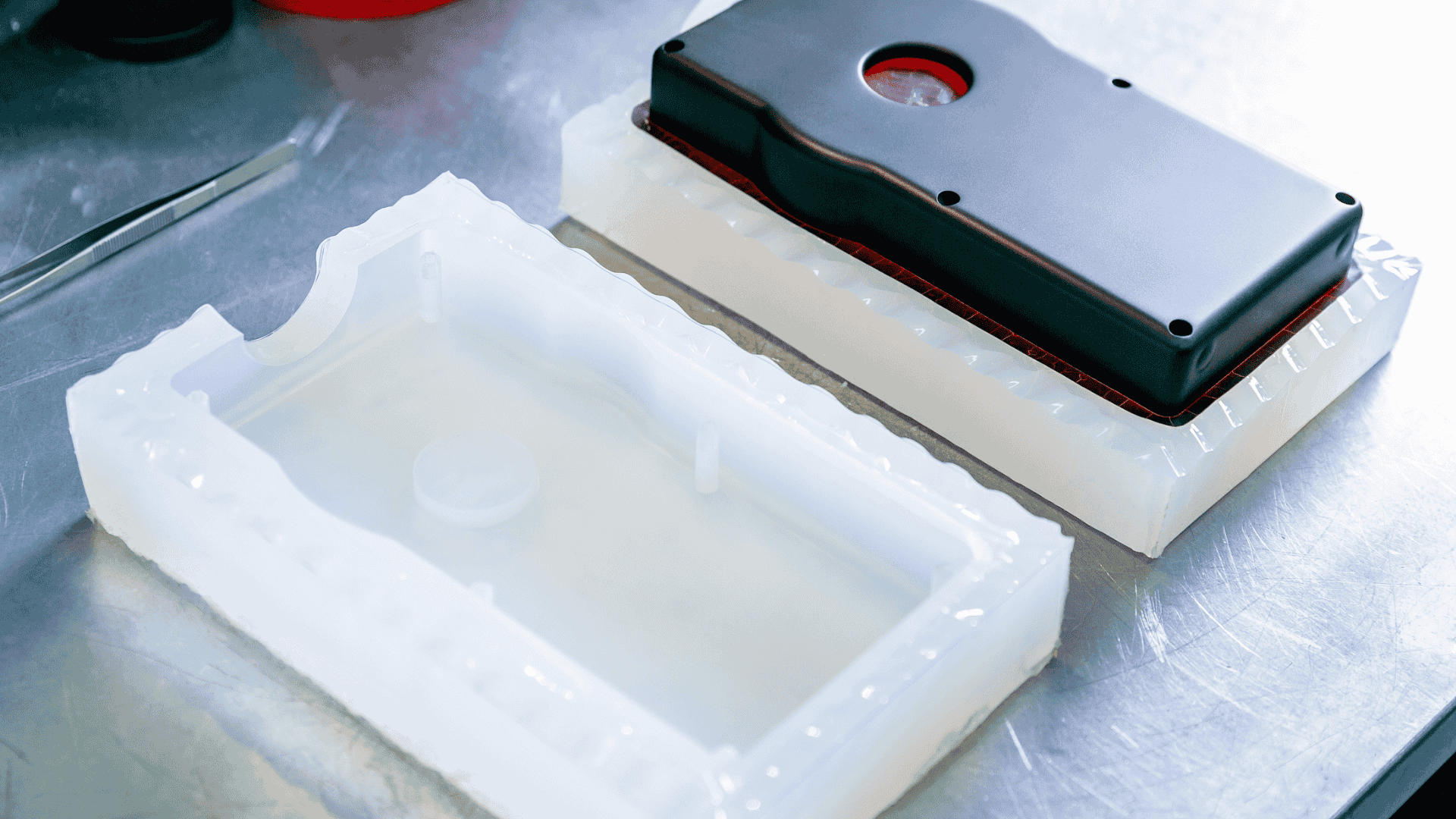

Source: hollywood3dprinting.com

A silicone mold is a flexible rubber-like mold made of RTV (room-temperature vulcanizing) silicone used to reproduce the shape of a master object.Its flexibility allows for high detail, smooth surface replication, and easy part removal without damage.

Key Advantages

High fidelity surface replication — clean, near-polished finish

Flexible — no rigid demolding fixtures needed

Supports undercuts and complex geometries

Cost-effective for low-volume production & iterative testing

Safe to use with resins, PU, wax, low-temp metals, and even food

Common Applications

Industry | Use Case | Why Silicone Molding Works |

|---|---|---|

Automotive | Gaskets, lens housings, quick test parts | Fast validation before tooling |

MedTech | Device shells, prosthetic samples | Biocompatible, skin-safe materials |

Consumer Goods | Wearables, smart device housings | Ergonomic & soft-touch friendly |

Art / Jewelry | Replicas, collectibles | Sculptural detail + smooth finish |

Food / Culinary | Chocolate, ice, baking molds | Certified food-grade silicone |

How 3D Printing Improves the Silicone Molding Process?

Traditionally, the master model for a silicone mold was handcrafted or CNC-machined — often expensive and slow.

Today, 3D printing allows manufacturers to produce high-resolution master patterns within hours, drastically reducing lead time and iteration cost.

Benefits of Using 3D Printed Masters

Aspect | CNC / Handcraft | 3D Printed Master |

|---|---|---|

Production Time | 3–7 days | Same day / next day |

Iteration | Manual rework | Reprint instantly |

Cost | Tooling & setup cost | Zero tooling, low volume-friendly |

Geometry | Limited | Organic / freeform allowed |

Best for | Established parts | Early-stage R&D & complex testing |

3D printing and silicone molding together create a hybrid manufacturing process — ideal for rapid prototyping, functional testing, and short-run production.

How to Make a Silicone Mold (Step-by-Step)

Source: forgelabs.com

Step 1: 3D Print or Prepare Your Master Model

Use SLA or SLS 3D printing to produce a master model with a smooth surface finish.

At Unionfab, we use industrial-grade 3D printers to guarantee mold-ready surface quality.Clean the part → apply mold release agent → prepare for silicone casting

Step 2: Build a Mold Box

Construct a box slightly larger than your master using acrylic sheets or foam board.

Seal edges to prevent leakage and fix the master securely inside.

Step 3: Mix & Degas the Silicone

Measure silicone base and curing agent by weight. Mix slowly to minimize bubbles.

(Optional) Use a vacuum chamber to remove trapped air (bubble-free molds = better surface quality).

Step 4: Pour and Cure

Pour the silicone slowly from one corner, letting it flow naturally around the model.

Allow to cure for several hours at room temperature or under mild heat.

Step 5: Demold

Once fully cured, peel away the mold box and remove the master pattern. You now have a custom silicone mold ready for casting.

Common Failure Scenarios

Pitfall | What Goes Wrong in Real Projects | How a Good Manufacturer Prevents It |

|---|---|---|

No Draft Angle | Master gets locked inside mold → mold tears on first demolding | Add 2–5° draft during CAD phase — not post-fix |

No Venting Channel | Trapped air → bubbles, warped edges, incomplete fill | Engineer hidden vent channels based on casting flow |

Material Shrink Not Pre-Compensated | 0.3–1% shrink = incorrect snap-fit / tolerance fails | Adjust master scale before printing — not after manufacture |

Wrong Silicone Grade Chosen | Food / medtech / wearable → rejected due to safety req | Pre-select silicone grade vs compliance standards (FDA, ISO, etc.) |

Misaligned Parting Line | Visible seam lines or poor demolding → aesthetics fail | Simulation-based parting logic before mold build |

Combining 3D Printing and Silicone Molding

When paired together, 3D printing and silicone molding create a bridge between design validation and early production — solving the gap that neither method can address alone.

Typical workflow:

CAD design → SLA / SLS 3D printed master (polished or textured if needed)

Silicone mold creation (single- or multi-part mold, depending on geometry)

Final parts cast in PU, resin, elastomer, or wax — under vacuum for bubble-free results

This combination offers:

From idea to functional parts in days — not weeks

No upfront tooling commitment while still getting production-like part quality

Freedom to test multiple materials (soft, rigid, transparent, skin-contact safe, etc.)

Visually presentation-ready parts — suitable for investor demos or user testing

At Unionfab, we specialize in this hybrid approach, enabling clients to move seamlessly from 3D printed prototypes to short-run silicone mold production. Our engineers can help you choose the right printing process and material for your next mold or prototype.

Applications of 3D Printing + Silicone Molding

Industry | Use Case | Key Benefit |

|---|---|---|

Automotive | Gaskets, light housings, test parts | Heat-resistant, flexible, fast iteration |

Medical | Device enclosures, prosthetic samples | Biocompatibility, precision, soft-touch |

Consumer Electronics | Wearables, shell housings | Excellent finish, ergonomic surfaces |

Art & Jewelry | Replicas, collectibles | High detail, smooth aesthetic |

Food & Beverage | Baking, chocolate, ice molds | Food-safe, easy to clean |

Quick Comparison — Which Method Should You Use?

Method | Best For | Complexity | Cost | Speed |

|---|---|---|---|---|

CNC | Metal, ultra-precise, hard goods | Low-medium | Higher | Medium |

3D Printing | One-offs, internal testing | High | Medium | Fast |

Silicone Molding | Bridge-to-production, ergonomic prototypes | High | Low | Very fast |

Injection Molding | Mass production (1k–100k+) | Low | High upfront | Slow to start |

Silicone molding dominates the “10–300 parts batch” zone — especially when time-to-market > per-unit cost.

To learn more details, you can refer to our previous article: 3D Printing vs. CNC vs. Vacuum Casting: the Ultimate Comparison

When Silicone Molding Is NOT the Right Method?

Understanding boundaries = engineering maturity.

Not optimal for mass production (beyond ~100–300 parts → injection molding becomes more efficient)

Not suitable for parts exposed to extreme temperatures (>200°C continuous operating)

Ultra-high precision < 0.05mm tolerances? → CNC machining or metal 3D printing is more reliable

Large structural parts needing strength over flexibility → silicone casting is inferior to CNC/machining

If you’re validating early, doing functional tests, soft material exploration, or low-volume production → silicone molding is ideal.

If you’re already committed to scaling → this is a bridge, not the final destination.

How to Choose a Custom Silicone Mold Manufacturer?

If your project goes beyond DIY scale, partnering with a reliable custom silicone mold manufacturer ensures consistent quality and faster delivery.

What to Look For

3D Printing Integration – Can they print your master model accurately?

Material Expertise – Do they use food-safe, medical, or industrial-grade silicone?

Equipment & Process Control – Do they offer vacuum casting, pressure curing, and post-processing?

Quality Assurance – Dimensional inspection, durability testing, surface verification.

Transparent Quotation – Get a full cost breakdown before production.

At Unionfab, we combine industrial 3D printing with custom silicone molding to provide one-stop service—from digital model to finished part.

Curious about how much your next 3D printed master or custom silicone mold will cost? You can get an accurate estimate within minutes through our interactive online quoting system. Simply upload your 3D file, and you’ll see real-time pricing, lead time, and manufacturing options—all before placing an order.

Ready to Check Feasibility or Cost?

We’ll calculate master strategy, mold complexity, material options, and guide you to the most efficient path — not just the most expensive one. Upload your 3d model to get real-time quote before production.

FAQs

Q1: How many parts can I realistically get from one silicone mold?

Typically 20–50 shots depending on part geometry, material, and curing temperature.

For softer resins, the mold may last longer — for high-detail or heat-sensitive parts, fewer.

Q2: Can silicone molding be used for final production — not just prototypes?

Yes — especially for pre-production runs, beta testing units, pilot batches (10–300 pcs) or premium low-volume products. Many medical, wearable, and custom consumer brands ship final products made this way.

Q3: How close is the surface quality compared to injection molding?

Very close — especially with an SLA master + controlled silicone flow + vacuum casting setup. Texture, gloss level, and matte finishing can also be intentionally engineered.

Q4: Can Unionfab help me choose the right material and process — even if I’m not sure yet?

Absolutely. Many of our projects start with just a functional goal or use-case description — not a locked-in material. We’ll advise whether SLA, SLS, CNC, or silicone molding is the optimal path based on strength, texture, compliance, or timeline requirements.

Q5: What’s the minimum quantity required to start?

There is no minimum order — we often start with just 1–5 functional test parts before scaling into 50–200+ pieces using the same mold.