Titanium Exhaust Explained: Why It’s Worth It?

Why Titanium Exhausts Are Becoming Popular

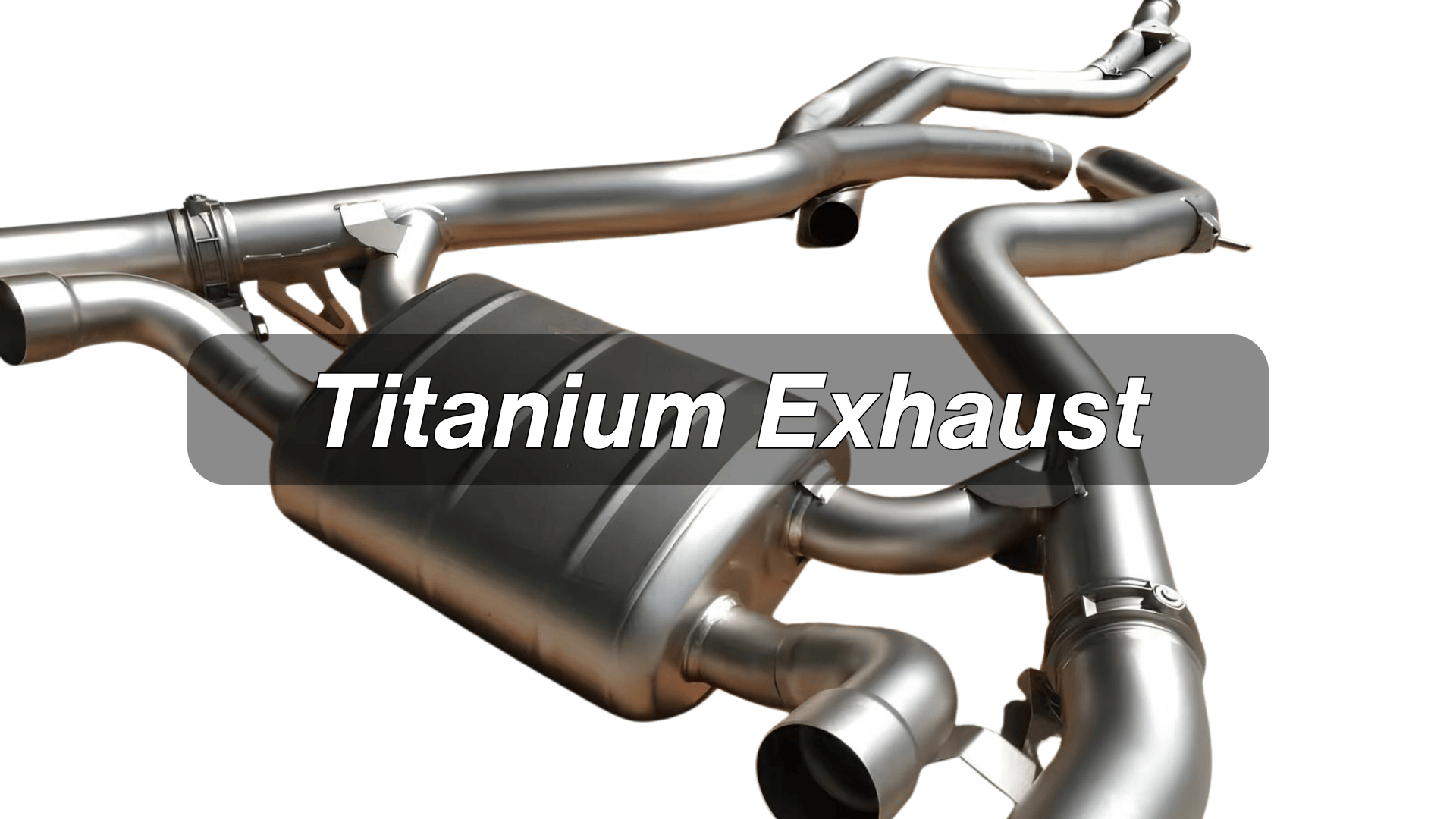

In the world of performance tuning, one upgrade keeps showing up across track cars, supercars, and high-end motorcycles — the titanium exhaust system.

Lightweight, heat-resistant, and visually striking with its signature blue-purple gradient, a titanium exhaust isn’t just about aesthetics. It reflects a pursuit of efficiency, sound quality, and precision engineering.

As materials technology becomes more accessible, even daily drivers and enthusiasts are beginning to consider titanium upgrades that were once reserved only for racing teams.

What Is a Titanium Exhaust?

Before diving into titanium systems, let’s first understand what an exhaust system actually includes.

Common Components of an Exhaust System

Source: researchgate.com

A modern exhaust system isn’t just a “pipe that lets gases out” — it’s a precisely engineered flow circuit designed to optimize performance, emissions, sound, and safety.

Below are the key components and their functions:

Component | Primary Function | Notes |

|---|---|---|

Exhaust Manifold / Header | Collects exhaust gases from each cylinder and channels them into a single flow path | Performance headers are tuned for exhaust pulse timing to improve scavenging and throttle response |

Catalytic Converter | Converts toxic gases (CO, NOx, hydrocarbons) into less harmful emissions | Required by law on road cars — removing or modifying it may affect emissions compliance |

Resonator / Mid-Pipe / Link Pipe | Fine-tunes the exhaust sound frequency and smooths gas flow | Often included in cat-back or full exhaust upgrades to adjust tone without affecting emissions |

Muffler / Silencer | Reduces noise volume while maintaining flow efficiency | Design varies by brand — chambered, straight-through, valvetronic, etc. |

Tailpipe / Exhaust Tip | The exposed end of the system — shapes final sound output & visual signature | Aesthetic focus, but can slightly influence tone & exhaust flow behavior |

What Exactly Is a Titanium Exhaust?

Source: forcebeyond.com

When people say “titanium exhaust”, they usually refer to a titanium exhaust system — meaning a system made wholly or partially from titanium alloy (commonly Ti-6Al-4V or Grade 2 titanium).

However, “titanium exhaust” is an umbrella term that can describe different levels of titanium usage:

Term | Actual Meaning | Titanium Content | Common Use |

|---|---|---|---|

Titanium Exhaust | Some parts made from titanium (often just the tail section) | 10–40% | Street modifications |

Titanium Cat-back Exhaust | Titanium used from the catalytic converter back | 60–80% | Performance street cars |

Full Titanium Exhaust System | Almost all structural components made of titanium, except minor fittings | 90–95% | Track cars / Supercars |

100% Titanium Exhaust System | Every component, including flanges and brackets, made from titanium | 100% (rare) | Custom racing systems |

In short — titanium exhaust doesn’t always mean “all titanium,” but rather that titanium plays a major role in the system’s construction.

Key Benefits of Titanium Exhaust Systems

1. Ultra-Lightweight for Performance Gain

With a density of just 4.5 g/cm³, titanium is around 40% lighter than stainless steel — meaning significant weight reduction, especially when replacing a full system.

Less weight equals sharper throttle response, better handling, and improved overall vehicle dynamics — crucial for both racing and spirited driving.

2. Extreme Heat Tolerance

Titanium can sustain continuous operating temperatures above 800 °C without warping or structural fatigue.

This makes it ideal for turbocharged engines, endurance racing, and aggressive track sessions, where stainless steel often begins to degrade.

3. Exceptional Corrosion Resistance

Unlike steel, titanium naturally forms a self-protective oxide layer, preventing oxidation and salt-induced corrosion.

This not only ensures long-term durability, but also means the exhaust can maintain peak performance for years — even in harsh climates.

4. Distinctive Sound & Visual Identity

Titanium produces a crisp, race-inspired exhaust tone — sharper and more responsive than the deeper rumble of stainless steel.

When exposed to heat, it develops a signature blue-purple gradient — an unmistakable visual trait appreciated by enthusiasts and professional builders alike.

While stainless steel remains a practical choice for everyday use, titanium is engineered for drivers who demand race-grade performance, long-term durability, and a distinctive visual and acoustic signature in one package.

Stainless Steel vs Titanium Exhaust

While both materials are widely used in performance exhausts, their characteristics differ significantly. Here’s a concise comparison of the two:

Feature | Titanium | Stainless Steel |

|---|---|---|

Weight | Extremely light | Much heavier |

Heat Resistance | Excellent (up to 800 °C) | Moderate (500–600 °C) |

Corrosion Resistance | Very high | Good but degrades over time |

Sound | Crisp, race-like tone | Deeper, bass-heavy tone |

Weldability | Difficult; requires inert gas shielding | Easy and cost-effective |

Cost | High | Affordable |

Best For | Racing and high-performance builds | Street and daily drivers |

This topic deserves a deeper comparison — you can read our upcoming article “Stainless Steel vs Titanium Exhaust” for an in-depth breakdown of materials, sound, and durability.

Top Brands for Titanium Exhausts

Below are some of the most recognized brands offering titanium exhaust systems on the market today:

Brand | Example Product | Vehicle Type | Approx. Price (USD) |

|---|---|---|---|

Akrapovic | Evolution Line Full Titanium | BMW M3 / Ducati Panigale | $3,000 – $6,000 |

Tomei | Expreme Ti Titanium Cat-Back | Nissan 350Z / Subaru WRX | $1,200 – $2,000 |

HKS | Full Ti Hi-Power | Toyota Supra / Nissan GTR | $2,500 – $4,500 |

Arrow | Titanium Race Exhaust | Yamaha R7 / CBR600RR | $900 – $1,800 |

Cobb | Titanium Cat-Back | Subaru STI / GR86 | $1,500 – $2,500 |

RK Titanium | Custom Full Titanium | Supra / R35 GTR | $5,000 – $8,000 |

Prices vary depending on configuration, vehicle compatibility, and whether it’s a full system or a partial cat-back.

Who Should (and Should NOT) Choose a Titanium Exhaust?

Who It’s Perfect For

Track use / time attack / professional racing teams — every kilogram matters; titanium delivers real lap-time advantages

Drivers who prioritize weight reduction & high thermal stability — especially boosted engines and high-rev NA builds

Enthusiasts who pursue both performance AND aesthetics — titanium’s heat bluing & sharp race-tone sound are unmatched

Show / SEMA / premium custom builds — where material craftsmanship and visual impact matter as much as function

Who May Not Need Titanium

Daily commuters who rarely push the engine hard — stainless steel provides 90% of the benefit at a much lower cost

Budget-focused performance builds — ECU tuning + better tires may deliver a bigger performance-per-dollar gain

Sound-only modders — axle-back stainless or valvetronic system may be more cost-effective

Owners sensitive to heat discoloration — titanium’s natural blue-purple hue is beautiful to most, but not all

Custom Titanium Exhaust System

Titanium exhausts can also be fully customized — perfect for unique builds or motorsport projects. Here’s how custom titanium systems are made and what materials may be involved.

Manufacturing Process | Typical Materials | Advantages | Notes |

|---|---|---|---|

CNC Bending & Welding | Titanium tubing | Precise geometry, high durability | Requires TIG welding in inert gas |

Hydroforming | Titanium or stainless steel | Smooth flow, fewer welds | Ideal for complex bends; higher cost |

Ti-6Al-4V alloy powder | Ultimate design freedom | Best for prototype or race-grade systems |

At Unionfab, we specialize in metal 3D printing for titanium and other alloys, enabling true design flexibility — from one-off race systems to small-batch production. Our instant online quotation platform allows engineers to upload CAD files, choose materials, and receive real-time pricing and lead times.

How to Clean and Maintain a Titanium Exhaust

Proper maintenance keeps your titanium exhaust system performing and looking its best for years.

Here are a few practical steps and tips to follow:

Avoid abrasive cleaners — use mild, pH-neutral products only.

Abrasive or acidic cleaners can damage the titanium surface and its oxide layer.

Mild, pH-balanced products remove dirt effectively while preserving the exhaust’s finish and corrosion resistance.Let the exhaust cool completely before wiping.

Titanium holds heat longer than steel, so cleaning it while hot can cause streaks or marks.

Waiting until it cools prevents surface damage and ensures a cleaner result.Do not polish off the blue coloration — it’s a natural oxide layer, not a stain.

The blue and purple hues are formed by heat oxidation, which protects against corrosion.

Polishing them away removes this protective layer and dulls the metal’s appearance.Inspect welds and hangers regularly for cracks or fatigue if used in track conditions.

Track heat and vibration can stress welds and brackets.

Regular checks help spot small cracks early and keep the system secure and leak-free.Rinse after winter driving to remove any salt residue.

Road salt can leave residue that dulls the metal over time.

A quick rinse keeps the surface clean and maintains the titanium’s natural sheen.

FAQs

Q: Is a titanium exhaust worth the upgrade?

A: Yes — if you value performance, weight savings, and long-term durability.

Q: What do exhaust tips do?

A: They affect sound tone and appearance but not performance.

Q: What is a cat-back exhaust?

A: Replaces everything from the catalytic converter to the tailpipe.

Q: What does white smoke from exhaust mean?

A: Usually condensation — or coolant leak in worse cases.

Q: What is an axle-back exhaust?

A: Replaces only the rear section for sound/aesthetic upgrades.

Q: What do exhaust mufflers do?

A: They reduce noise using chambers or perforated tubes.

Q: What causes an exhaust leak?

A: Cracked pipes, failed gaskets, or rusted joints.