Titanium Grades Guide: Detailed Comparison Chart

Explore different titanium grades, their composition, properties, and uses across aerospace, medical, and industrial manufacturing.

Introduction

Titanium is a high-performance metal known for its exceptional strength, light weight, and corrosion resistance. With one of the best strength-to-weight ratios among engineering materials, it is widely used in aerospace, medical, and industrial manufacturing. Its biocompatibility also makes it ideal for implants and surgical instruments.

Different titanium grades vary in composition, strength, and corrosion resistance, affecting their machinability, fabrication methods, and cost. Choosing the right grade helps engineers and manufacturers achieve the best balance of performance, durability, and efficiency for each application.

What Are Titanium Grades?

Titanium grades are classifications that define the purity and alloy composition of titanium materials. These grades are established based on international standards such as ASTM B348 and ISO 5832, which specify the chemical composition, mechanical properties, and intended applications of each type.

In general, titanium materials are divided into two main categories:

Commercially Pure Titanium (Grades 1–4):

These grades contain more than 99% pure titanium with only small amounts of oxygen, iron, or other trace elements.

They are known for excellent corrosion resistance, good formability, and biocompatibility, making them suitable for chemical processing, marine environments, and medical use.

Titanium Alloys (Grades 5, 9, 12, 23, etc.):

These grades include alloying elements such as aluminum (Al), vanadium (V), molybdenum (Mo), and nickel (Ni) to enhance specific properties like strength, heat resistance, and fatigue performance.

Titanium alloys are widely used in aerospace, automotive, energy, and high-performance manufacturing where both strength and lightweight characteristics are essential.

Understanding the grades of titanium and their composition differences allows engineers to match material properties to application requirements, ensuring both performance reliability and cost efficiency.

Titanium Grades Comparison

Titanium is available in a wide range of grades, each offering unique combinations of composition, mechanical strength, corrosion resistance, and workability. These differences allow titanium to be used across industries—from aerospace and automotive to medical implants and chemical processing.

The following comprehensive comparison summarizes how the major titanium grades (1–12, 23) differ in terms of composition, properties, machinability, cost, and applications.

Titanium Grades Chart: Composition and Properties

Titanium Grade | Composition | Tensile Strength (MPa) | Density (g/cm³) | Corrosion Resistance | Weldability | Machinability | Cost | Typical Applications |

|---|---|---|---|---|---|---|---|---|

Grade 1 | Pure Titanium (>99.5%) | ~240 | 4.51 | Excellent | Excellent | Excellent | Low | Chemical equipment, marine components |

Grade 2 | Pure Titanium (~99.2%) | ~345 | 4.51 | Excellent | Good | Good | Medium | Medical instruments, industrial piping, aerospace |

Grade 4 | Pure Titanium (~99%) | ~550 | 4.51 | Excellent | Moderate | Fair | Medium | Pressure vessels, structural frames |

Grade 5 (Ti-6Al-4V) | Ti + 6% Al + 4% V | ~895 | 4.43 | Good | Fair | Difficult | High | Aerospace parts, automotive, 3D printing |

Grade 9 (Ti-3Al-2.5V) | Ti + 3% Al + 2.5% V | ~620 | 4.48 | Good | Good | Good | Medium | Aircraft tubing, sports and bicycle frames |

Grade 12 (Ti-0.3Mo-0.8Ni) | Ti + Mo + Ni | ~480 | 4.54 | Excellent (acidic environments) | Good | Good | Medium | Chemical and heat-exchanger systems |

Grade 23 (Ti-6Al-4V ELI) | Low interstitial Ti-6Al-4V | ~860 | 4.43 | Excellent (biocompatible) | Fair | Fair | High | Medical implants, dental and surgical tools |

Composition and Alloying Elements

Titanium’s performance depends greatly on its chemical composition.

● Commercially pure titanium grades (1–4) contain over 99% titanium with small oxygen variations that affect strength and ductility.

● Alloyed grades (5, 9, 12, 23) include aluminum (Al), vanadium (V), molybdenum (Mo), or nickel (Ni) to enhance strength, heat resistance, or chemical stability.

● For example, Grade 5 (Ti-6Al-4V) gains high strength and hardness from Al and V, while Grade 12 (Ti-0.3Mo-0.8Ni) gains acid resistance from Mo and Ni.

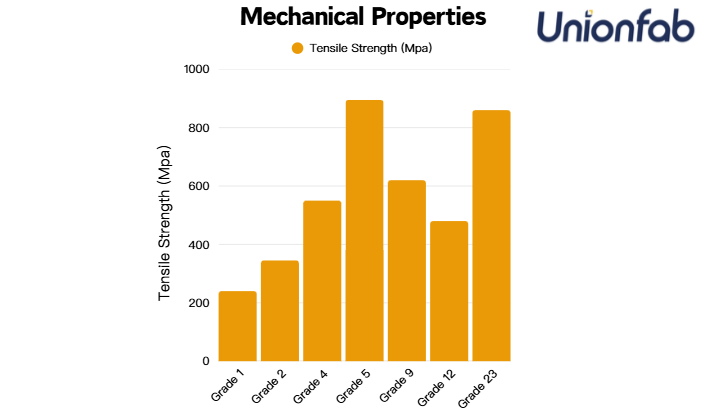

Mechanical Properties

The mechanical performance of titanium varies widely across different grades. The chart below illustrates how tensile strength increases as alloying elements are added, highlighting the balance between strength and lightweight performance.

Source: Unionfab

As shown,Titanium’s strength and ductility vary widely among grades.

● Grades 1–2: Excellent ductility and formability but relatively low tensile strength; ideal for forming, welding, and marine exposure.

● Grade 4: Highest strength among commercially pure titanium grades, suitable for load-bearing applications.

● Grade 5 (Ti-6Al-4V): Exceptional strength-to-weight ratio, making it the most popular structural titanium alloy.

● Grade 23 (Ti-6Al-4V ELI): Slightly lower strength than Grade 5 but better toughness and fracture resistance, ideal for medical implants.

Engineering insight: The tensile strength of titanium can vary from ~240 MPa (Grade 1) to nearly 900 MPa (Grade 5), giving designers wide flexibility depending on the required performance level.

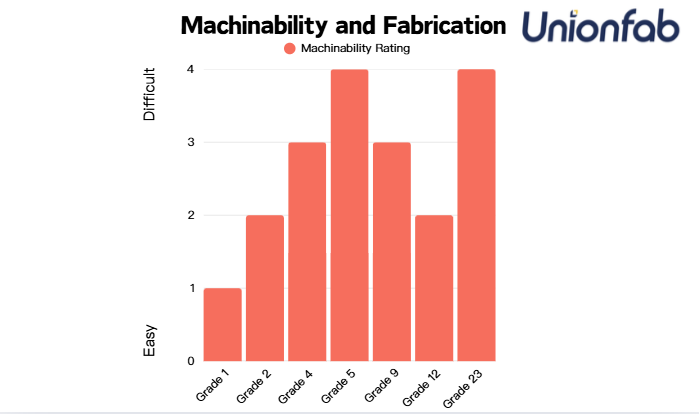

Machinability and Fabrication

While mechanical strength is critical for structural applications, machinability plays an equally important role in determining production efficiency. The following infographic compares how titanium grades perform in both aspects.

Source: Unionfab

Titanium’s machinability depends on alloy type, hardness, and thermal conductivity.

● Grade 1 & 2: Easy to machine and weld; widely used for prototypes and industrial parts.

● Grade 5 & 9: More difficult to machine because of higher hardness and lower thermal conductivity, which can cause tool wear.

● Grade 9 offers an excellent balance—high fatigue strength with relatively easy cold working.

● Proper cooling, cutting speed control, and carbide or ceramic tools are essential for efficient titanium machining.

Tip for manufacturers: When using CNC or 3D printing, Grade 5 is preferred for performance parts, while Grade 2 is better for cost-effective production with easier processing.

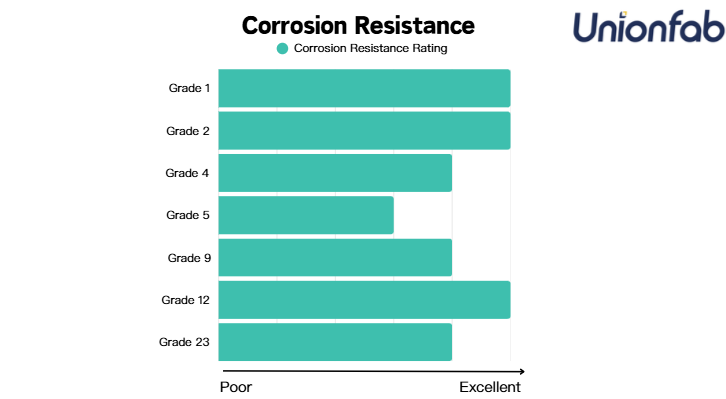

Corrosion Resistance

To better illustrate how different titanium grades perform in various environments, the chart below compares their corrosion resistance levels.

Source: Unionfab

Corrosion resistance is one of titanium’s defining strengths.

● Grades 1–2: Naturally form a stable oxide layer (TiO₂) that protects against seawater, chlorides, and oxidizing acids.

● Grade 12: Enhanced corrosion resistance in acidic or reducing environments due to added molybdenum and nickel—ideal for chemical and petrochemical industries.

● Grade 5: Slightly less corrosion-resistant because alloying elements can reduce the protective oxide layer’s stability.

● Grade 23: Maintains strong corrosion resistance, essential for biomedical implants exposed to body fluids.

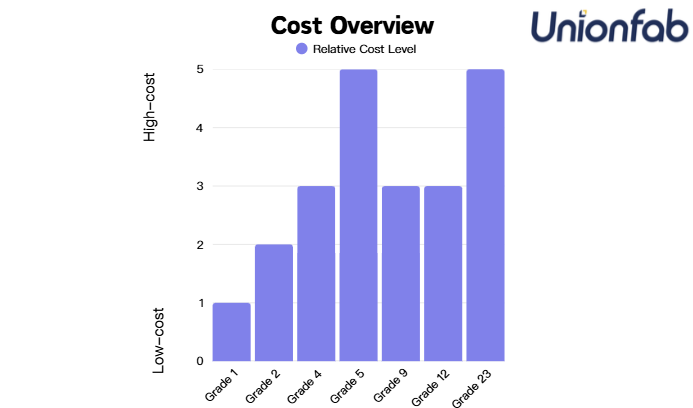

Cost Overview

The cost of titanium increases with alloy complexity, melting control, and processing requirements.

● Low-cost grades: Grade 1 and Grade 2 (commercially pure titanium).

● Mid-range: Grade 4, 9, and 12 (enhanced strength or corrosion resistance).

● High-end: Grade 5 and Grade 23 (aerospace and medical alloys).

Source: Unionfab

Cost efficiency tip:

● For general industrial use → Grade 2 offers the best balance of performance and price.

● For high-stress or precision parts → Grade 5 delivers unmatched performance despite higher cost.

Key Grade Comparison: Grade 2 vs Grade 5

Among all titanium grades, Grade 2 and Grade 5 are the most commonly compared due to their wide industrial use. The table below summarizes their key differences in strength, machinability, corrosion resistance, cost, and applications, helping manufacturers decide which grade offers the best balance between performance and production efficiency.

Property | Grade 2 | Grade 5 |

|---|---|---|

Strength | Moderate (~345 MPa) | Very High (~895 MPa) |

Weight-to-Strength Ratio | Good | Excellent |

Machinability | Easy | Difficult |

Corrosion Resistance | Excellent | Good |

Cost | Lower | Higher |

Common Use | Industrial, medical | Aerospace, automotive, 3D printing |

Recommendation:

● Choose Grade 2 Titanium for applications requiring corrosion resistance and easy fabrication at a lower cost.

● Choose Grade 5 Titanium when maximum strength, lightweight performance, and structural integrity are critical.

Surgical Grade Titanium

Surgical grade titanium generally refers to Grade 23 (Ti-6Al-4V ELI), where ELI stands for Extra Low Interstitials. This designation indicates a low impurity version of the well-known aerospace alloy Grade 5 (Ti-6Al-4V), offering superior toughness and reliability for biomedical applications.

Surgical grade titanium is distinguished by its excellent biocompatibility, high fracture toughness, and exceptional fatigue strength, making it ideal for long-term use inside the human body. It maintains outstanding corrosion resistance when exposed to body fluids and ensures a stable, non-reactive interface with surrounding tissues.

Because of these properties, Grade 23 is widely used in orthopedic implants, dental fixtures, bone screws, and prosthetics. Its combination of strength, purity, and safety makes it the preferred choice for both surgeons and medical device manufacturers seeking durable, reliable materials for life-critical applications.

How to Choose the Best Grade of Titanium

Choosing the right titanium grade depends on your specific application, performance requirements, manufacturing process, and budget. The guide below provides practical recommendations to help engineers and product designers quickly identify the most suitable titanium alloy for their needs.

Titanium Grades and Uses

To simplify material selection, the following table lists the recommended titanium grades for different applications, along with their key performance needs and selection rationale.

Application Field | Recommended Titanium Grade | Main Performance Requirement | Reason for Selection |

|---|---|---|---|

Industrial Equipment / Chemical Containers | Grade 2 | High corrosion resistance, good machinability | Cost-effective and easy to weld; ideal for chemical and industrial environments. |

High-Strength Industrial Structures | Grade 4 | High tensile strength, good corrosion resistance | Strongest commercially pure titanium; suitable for pressure vessels and heavy-duty components. |

Aerospace Structures / Automotive Parts | Grade 5 (Ti-6Al-4V) | High strength, lightweight, heat resistance | Industry standard alloy for aerospace and performance parts. |

Tubing / Sports Equipment | Grade 9 (Ti-3Al-2.5V) | High fatigue strength, formability | Excellent balance between strength and workability; used in tubing and bicycles. |

Chemical / Heat Exchanger Systems | Grade 12 (Ti-0.3Mo-0.8Ni) | Superior acid and chemical resistance | Molybdenum and nickel enhance acid corrosion resistance; ideal for harsh chemical environments. |

Medical Implants / Surgical Instruments | Grade 23 (Ti-6Al-4V ELI) | High toughness, low impurities, biocompatibility | Medical-grade titanium suitable for long-term implantation and surgical tools. |

Jewelry / Watch Cases / Decorative Components | Grade 1 | High ductility, anodizing capability | Lightweight and easy to color; ideal for aesthetic and wearable designs. |

Selection Tips

1. Define the Application Environment

a. For exposure to acids, bases, or seawater → choose Grade 1 or Grade 2.

b. For high-load or high-temperature components → choose Grade 5.

2. Evaluate Fabrication and Forming Requirements

a. For projects requiring cold working or welding → use Grade 2 or Grade 9.

b. For precision 3D-printed parts → use Grade 5 or Grade 23.

3. Balance Cost and Lead Time

a. In cost-sensitive cases → Grade 2 offers the best balance of price and performance.

b. For high-performance, small-batch precision parts → Grade 5 or Grade 23 are ideal.

4. Consider Sustainability and Future Trends

a. For longevity and recyclability → select pure titanium grades (Grade 1–2).

b. For next-generation performance → explore β titanium alloys and powder metallurgy titanium materials.

Tip: When considering overall performance, machinability, and budget, Grade 2 provides the most versatile and cost-effective option. Grade 5 and Grade 23 represent high-end choices for performance-critical applications.Titanium Color and Finish

Titanium Natural Color

Source: hosnti.com

● Natural Appearance: Silvery-gray metallic tone with a smooth matte surface.

● Protective Oxide Layer: Forms naturally in air, giving titanium excellent corrosion resistance.

● Surface Treatment: The natural color can be modified through anodizing, which enhances both appearance and durability.

● Applications: Commonly used in engineering and medical components for its clean, professional look.

Titanium Color Chart

source: besttechnologyinc.com

To illustrate how titanium’s surface color changes during the anodizing process, the following table presents the relationship between anodizing voltage and resulting color.

Anodizing Voltage (Approx.) | Color | Description / Notes | Typical Applications |

|---|---|---|---|

15–18 V | Light Gold | Subtle champagne tone; thin oxide layer | Surgical tools, medical markers, aerospace fasteners |

20–22 V | Bronze | Warm metallic brown, stable visual tone | Industrial components, knife hardware, tactical gear |

25–27 V | Purple / Violet | Decorative, strong contrast | EDC gear, jewelry, bike components |

30–32 V | Blue | Bright electric blue, highly popular | Electronics housings, performance parts, titanium pens |

35–38 V | Light Blue / Teal | Transition between blue & green | Custom bicycle parts, diving gear, consumer accessories |

40–55 V | Green | Mint to olive tone depending on alloy | Military equipment, outdoor gear, tool handles |

60–70 V | Yellow-Gold | Deeper, saturated gold | Luxury accessories, premium fasteners, jewelry |

70–75 V | Pink / Rose | Rare and visually striking | Custom jewelry, artistic components, high-end EDC |

75–80 V | Magenta | Deep reddish purple | Decorative hardware, collectible items |

80–90 V | Red | Harder to achieve consistently | Medical markers, aesthetic parts requiring strong contrast |

90–110 V | Rainbow / Multi-Color | Gradient effect from varied oxide thickness | Showpieces, knives, artistic titanium work |

110+ V | Slate Grey | Thick oxide, darker matte look | Industrial parts, aerospace, high-wear components |

Notes on Titanium Colors:

● Color accuracy depends on alloy type

Ti-6Al-4V (Grade 5) produces the most consistent colors.

● Surface prep affects color clarity

Polished surface → bright, reflective colors

Sandblasted surface → matte, desaturated tones

● Colors are not pigments

They result from light interference within the oxide layer—so no peeling or flaking.

● Precision tolerance

Anodized coatings add negligible thickness (usually < 0.5 µm), making it suitable for tight-tolerance parts.

Titanium in 3D Printing

Different titanium grades show distinct characteristics in machining and additive manufacturing.

● Grade 2: Easy to machine, low-cost, and suitable for industrial parts and prototyping.

● Grade 5 (Ti-6Al-4V): High strength and heat resistance; the most common titanium powder material for 3D printing.

Titanium is widely processed through SLM (Selective Laser Melting), a leading metal 3D printing technology, as well as CNC precision machining. These methods enable the production of lightweight, high-performance components for aerospace, medical, and automotive applications.

To explore more about titanium additive manufacturing and cost estimation, visit Unionfab’s detailed guide: Titanium 3D Printing: A Complete Guide [+ Free Cost Calculator]

Discover how affordable titanium 3D printing can be — Calculate your cost with Unionfab now.

Why Choose Unionfab

As one of China’s leading on-demand manufacturing platforms, Unionfab provides global customers with high-quality metal 3D printing and precision machining services.

● Comprehensive Manufacturing Capabilities: Equipped with over 800 industrial-grade machines, covering SLM, SLS, MJF, FDM, and CNC technologies.

● Advanced Metal Printing Strength: Supports a wide range of metals, including titanium alloys (Ti-6Al-4V / TC4), and offers full post-processing options such as polishing, anodizing, heat treatment, and CNC finishing.

● Fast Delivery: For small-batch titanium parts, turnaround times can be as quick as 2–4 days.

● Competitive Pricing: Metal 3D printing services are typically 30–50% more affordable than comparable Western providers.

● Quality Assurance: In-house production facilities with a four-step quality inspection system ensure consistent precision and reliability.

● One-Stop Service: From file upload, instant quoting, production, and post-processing to global delivery, Unionfab offers a complete end-to-end manufacturing solution.

Emerging Titanium Grades and Market Trends

With the continuous advancement of manufacturing technologies, titanium materials are entering a new stage of innovation. While the traditional Grade 1–5 series remains the industry standard, new titanium alloys are rapidly emerging in 3D printing, medical implants, and high-performance engineering.

These developments include:

● Grade 23 (Ti-6Al-4V ELI): An extra-low impurity alloy offering exceptional toughness and biocompatibility.

● Powder Metallurgy Titanium: Enables precise control of microstructure and composition, improving strength-to-weight efficiency.

● β Titanium Alloys: Contain elements such as molybdenum (Mo) and vanadium (V), offering higher strength and flexibility for advanced structural and biomedical applications.

Driven by additive manufacturing and the medical industry, these emerging materials represent the future of titanium—lighter, stronger, and more adaptable to complex engineering demands.

FAQs About Titanium Grades

1. How many grades of titanium are there?

There are more than 30 recognized titanium grades, but Grades 1–5, 9, 12, and 23 are the most commonly used in industrial and medical applications.

2. Which is better, Grade 2 or Grade 5 titanium?

Grade 2 offers easier processing and lower cost, while Grade 5 provides much higher strength and heat resistance—ideal for aerospace and structural uses.

3. What is Grade 9 titanium used for?

Grade 9 (Ti-3Al-2.5V) is often used for tubing, aircraft hydraulic systems, and sporting goods, thanks to its strength and formability balance.

4. Can titanium rust or tarnish?

No. Titanium forms a natural oxide layer that protects it from rust and tarnish, even in seawater or harsh chemical environments.

5. Can titanium conduct electricity?

Yes, but its conductivity is much lower than copper or aluminum. It’s generally used for structural, not electrical, applications.

6. How much atmospheric pressure can titanium withstand?

Depending on the grade and wall thickness, titanium can withstand extremely high pressures—making it suitable for deep-sea and aerospace use.

7. What is medical grade titanium?

Medical-grade titanium usually refers to Grade 23 (Ti-6Al-4V ELI), known for its purity, toughness, and biocompatibility.

8. What color is titanium?

Naturally silver-gray, titanium can be anodized to display colors like blue, gold, purple, or green depending on voltage and surface treatment.