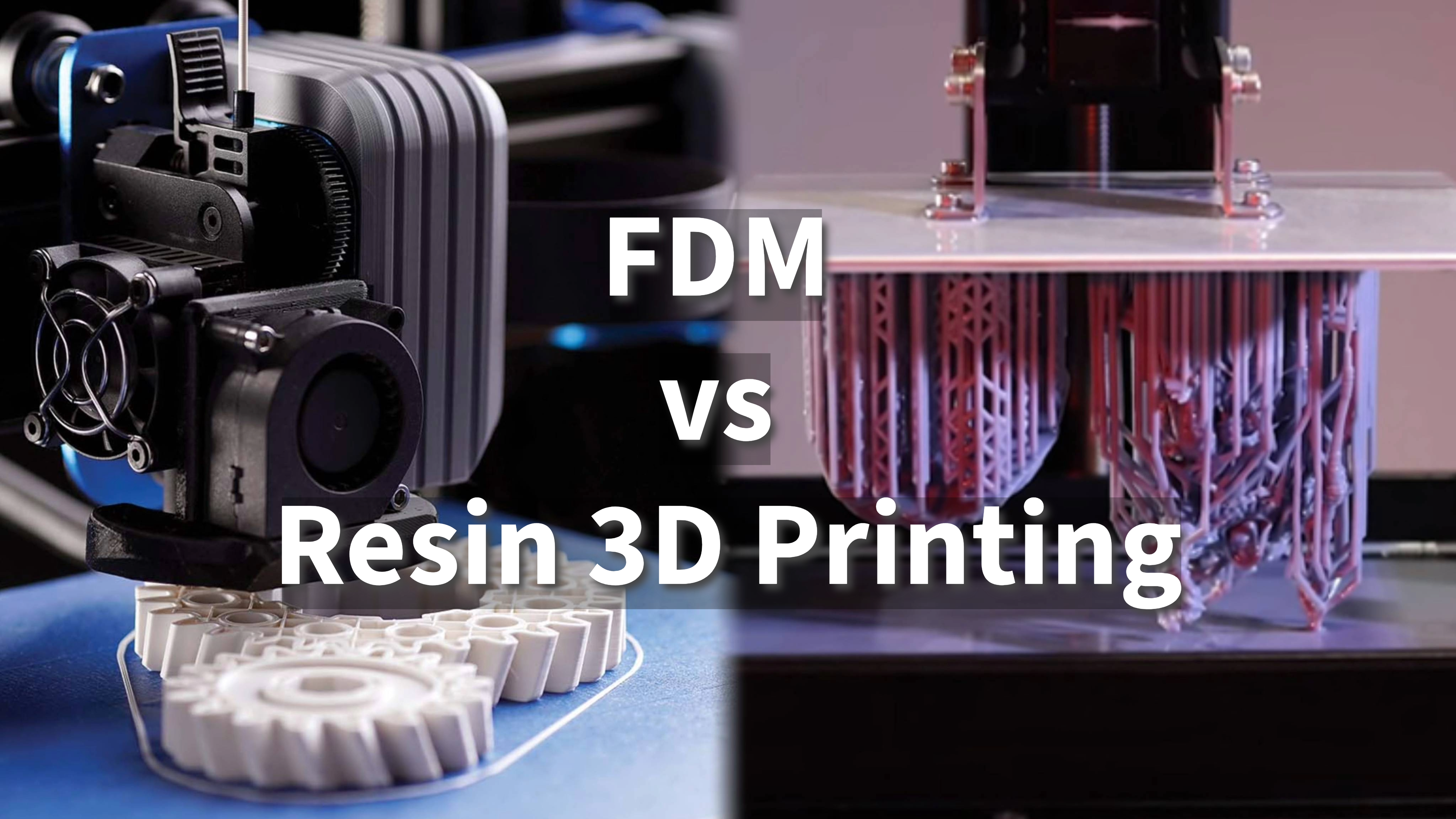

FDM vs Resin 3D Printing: Key Differences

Explore the differences between FDM and resin 3D printing, their strengths, weaknesses, and applications to find the best option for your needs.

Introduction

3D printing is a way to make physical objects by building them up layer by layer from a digital design. There are different types of 3D printing, and choosing the right one can have a big impact on your project. Two popular 3D printing methods are FDM (Fused Deposition Modeling) and resin printing.

In this blog, we'll explain these two types of 3D printing and help you figure out which one is best for your project. Understanding the key differences between FDM and resin printing will help you make better decisions for your 3D printing needs.

What is FDM 3D Printing?

FDM (Fused Deposition Modeling) is one of the most common types of 3D printing. It works by melting a plastic filament and then laying it down layer by layer to create the final object. The printer's nozzle moves based on the digital design, building each layer until the object is complete.

FDM printers use different materials, including:

PLA: A popular, biodegradable plastic that is easy to use and great for beginners.

ABS: A strong, durable plastic used for functional parts, but it needs higher temperatures and gives off fumes during printing.

PETG: A durable, flexible, and easy-to-print thermoplastic material commonly used in 3D printing for functional parts and prototypes.

Key Advantages of FDM

Affordable and Easy to Use: FDM printers are usually cheaper and simple to operate, making them a great choice for beginners and hobbyists.

Wide Range of Materials: FDM has a variety of materials, including flexible and strong plastics, that are good for different projects.

Bigger Print Size: FDM printers often have larger print areas, which means you can print bigger objects.

Limitations of FDM

Lower Detail Quality: Compared to resin printing, FDM usually creates objects with visible lines between the layers, which might not be good for projects needing fine details.

Rough Surface Finish: FDM prints often have a rough surface, which may need extra work to make smooth.

Limited Material Types: FDM mostly uses thermoplastics, which may not be suitable for all types of projects.

What is Resin 3D Printing?

Resin 3D printing uses liquid resin and light to make objects with high detail and smooth surfaces. The most common types of resin printing are SLA (Stereolithography) and DLP (Digital Light Processing). Both methods cure liquid resin layer by layer using a light source. SLA uses a laser to draw each layer, while DLP uses a projector to create each layer all at once.

Resin printers use different types of resin, including:

Standard Resin: Used for general-purpose printing, with good detail and a smooth finish.

Flexible Resin: Creates parts that are bendable, like rubber, which is useful for products that need to be soft or flexible.

Tough Resin: Designed for parts that need to handle stress and impact, making it good for functional prototypes.

Key Advantages of Resin Printing

High Detail and Smooth Finish: Resin printing creates very detailed objects with smooth surfaces, which is great for projects needing precision.

Different Material Properties: Resin can have different properties, like flexibility or toughness, which makes it useful for many applications.

Ideal for Small, Detailed Prints: Resin printers are perfect for making small parts with fine details, like figurines or jewelry.

Limitations of Resin Printing

Higher Cost: Resin printers and materials are more expensive than FDM, which may not be ideal for beginners or those on a budget.

Smaller Print Size: Resin printers often have smaller build areas, which limits the size of objects you can print.

Messy and Needs Safety: Handling liquid resin can be messy, and you need safety gear like gloves and good ventilation, as the resin can be toxic before it hardens.

FDM vs Resin: Key Differences

Feature | FDM 3D Printing | Resin 3D Printing |

|---|---|---|

Print Quality | Visible layer lines, lower resolution. | High resolution, smooth surfaces, perfect for detailed prints. |

Materials | Uses thermoplastics, less post-processing needed. | Uses liquid resins, requires washing and curing. |

Speed | Generally faster for larger prints | Slower due to curing each layer and post-processing. |

Cost | Budget-friendly. | More expensive. |

Durability | Strong prints, but with visible layer lines. | Can be brittle (tough resin offers better durability). |

Applications of FDM and Resin 3D Printing

Use Cases for FDM

Prototyping: FDM is often used to create quick prototypes to test the shape, fit, and function of a design.

Functional Parts: FDM can make strong, functional parts for practical use, especially with materials like ABS or TPU.

Large Prints: FDM printers are good for making bigger objects because they usually have larger print areas.

Source: Unionfab

Use Cases for Resin

Dental Models: Resin printing is commonly used for dental models because of its high detail and accuracy.

Jewelry: The precision and smooth surface finish of resin prints make them ideal for making jewelry prototypes and detailed designs.

Miniatures: Resin printing is popular for making small, detailed miniatures for tabletop games or collections.

Source: Unionfab

How to Choose Between FDM and Resin

Choosing between FDM and resin 3D printing depends on your project needs, budget, and experience. Here's a table to help you decide:

Consideration | FDM 3D Printing | Resin 3D Printing |

|---|---|---|

Budget | Lower cost, cheaper materials. | Higher cost, resin is more expensive. |

Precision | Good for functional parts, but visible layer lines. | Excellent precision and smooth finish, great for detailed models. |

Durability | Strong parts with ABS or TPU, good for functional use. | Tough resin is durable, but standard resin can be brittle. |

Ease of Use | Easier for beginners, less messy. | More complex, needs careful handling and safety. |

Project Type | Larger prints, prototypes, functional parts. | Small, detailed prints, like jewelry or miniatures. |

Tips for Beginners vs. Professionals

Beginners: FDM is a good choice for beginners because it is affordable, easier to set up, and uses less toxic materials. It is a great way to learn the basics of 3D printing without spending too much.

Professionals: Resin printing is better for professionals who need high-precision parts with a smooth finish. It requires more experience and involves handling chemicals safely, but it is perfect for creating detailed models and prototypes.

Conclusion

Choosing between FDM and resin 3D printing depends on your needs. FDM is great for bigger, functional parts and is budget-friendly—perfect for beginners. Resin printing, on the other hand, gives unmatched detail and is best for professionals who need high-quality prints.

Bring Your Ideas to Life with Unionfab

Ready to bring your ideas to life with 3D printing? Check out Unionfab's 3D printing services for both FDM and resin printing. Our expert team can help you turn your ideas into reality. We are here to make your manufacturing process easy from start to finish.

Get started with Unionfab with an instant quote today and bring your vision to life!

Contact us and let us help you make the right choice for your project.