Guide to Silicone Molding [+ Cost Analysis]

![Guide to Silicone Molding [+ Cost Analysis]](https://ufc-dtc-cms.oss-accelerate.aliyuncs.com/blog/20250926/235503_76gfm3inu.png)

Discover everything about silicone molding – from vacuum casting techniques and material options to cost calculation and applications.

Introduction

Silicone molding is a versatile manufacturing process widely used for small-batch production, prototyping, and aesthetic model making. By creating a flexible silicone mold around a master model, manufacturers can replicate parts with fine details, smooth surfaces, and consistent quality.

Compared with traditional tooling, silicone mold making is faster and more cost-effective, making it ideal for rapid product validation and low-volume manufacturing.

Today, industries ranging from consumer electronics to automotive and healthcare rely on custom silicone mold solutions to shorten development cycles and reduce costs. With the right silicone mold supplies and professional service support, businesses can achieve production-grade results without investing in expensive metal tooling.

Techniques of Silicone Molding

Vacuum Casting – The Core of Silicone Molding

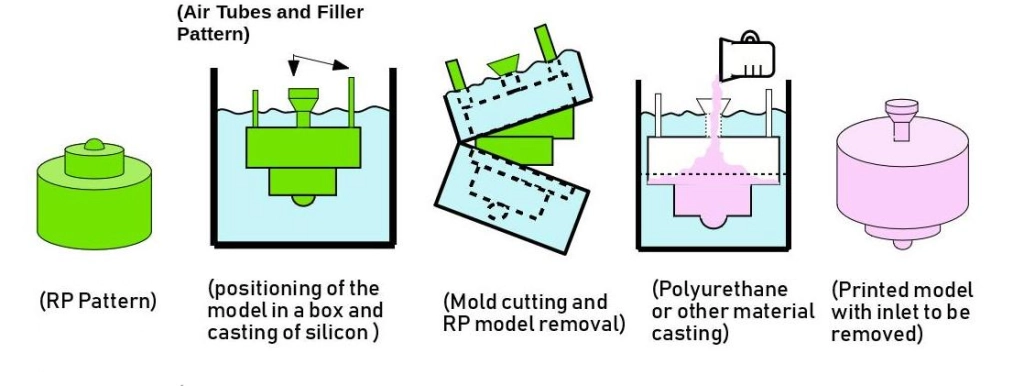

Source: Marmax Design

Among all silicone molding methods, vacuum casting is the most widely adopted due to its ability to produce parts with excellent surface finish and minimal defects. The process begins with a master model, which defines the accuracy and quality of the final mold.

Today, most master models are made using 3D printing, which offers precision and flexibility for complex designs.

Learn more in 3D Printed Molds: A Game Changer for Manufacturing and Prototyping

Process Overview of Vacuum Casting:

1. Master Model Creation – Usually made by 3D printing or CNC machining.

2. Silicone Mold Preparation – The master is encapsulated in liquid silicone to form the mold.

3. Vacuum Casting – Under vacuum, polyurethane or transparent resin is poured into the mold, eliminating bubbles and ensuring smooth surfaces.

4. Curing – The mold and resin are cured under controlled conditions.

5. Demolding & Finishing – The part is removed and undergoes surface finishing if necessary.

Compared with other silicone molding methods, vacuum casting delivers superior dimensional accuracy and surface quality, making it the preferred choice for custom silicone mold making supplies and professional prototyping.

Other Techniques of Silicone Molding

While vacuum casting is the most reliable method, other silicone molding techniques are also used depending on material type, part geometry, and production needs:

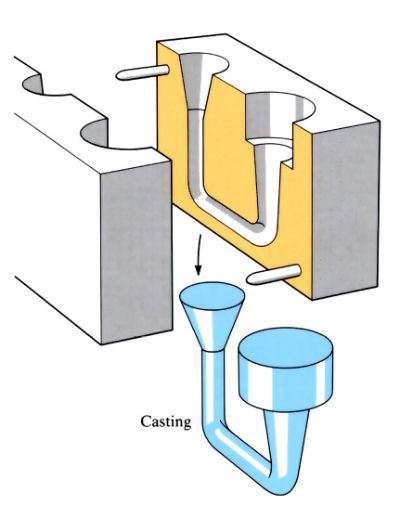

● Gravity Casting – The simplest form of silicone mold making. Resin or wax is poured directly into the mold without vacuum or pressure. It is inexpensive but prone to bubbles and limited in quality.

Source: The Open University

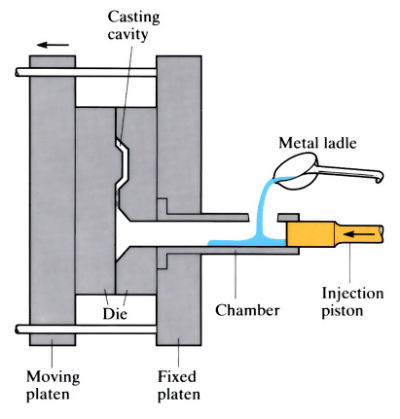

● Pressure Casting – After pouring resin into the silicone mold, the mold is placed in a pressure chamber. The pressure minimizes voids, improves density, and enhances part strength.

Source: The Open University

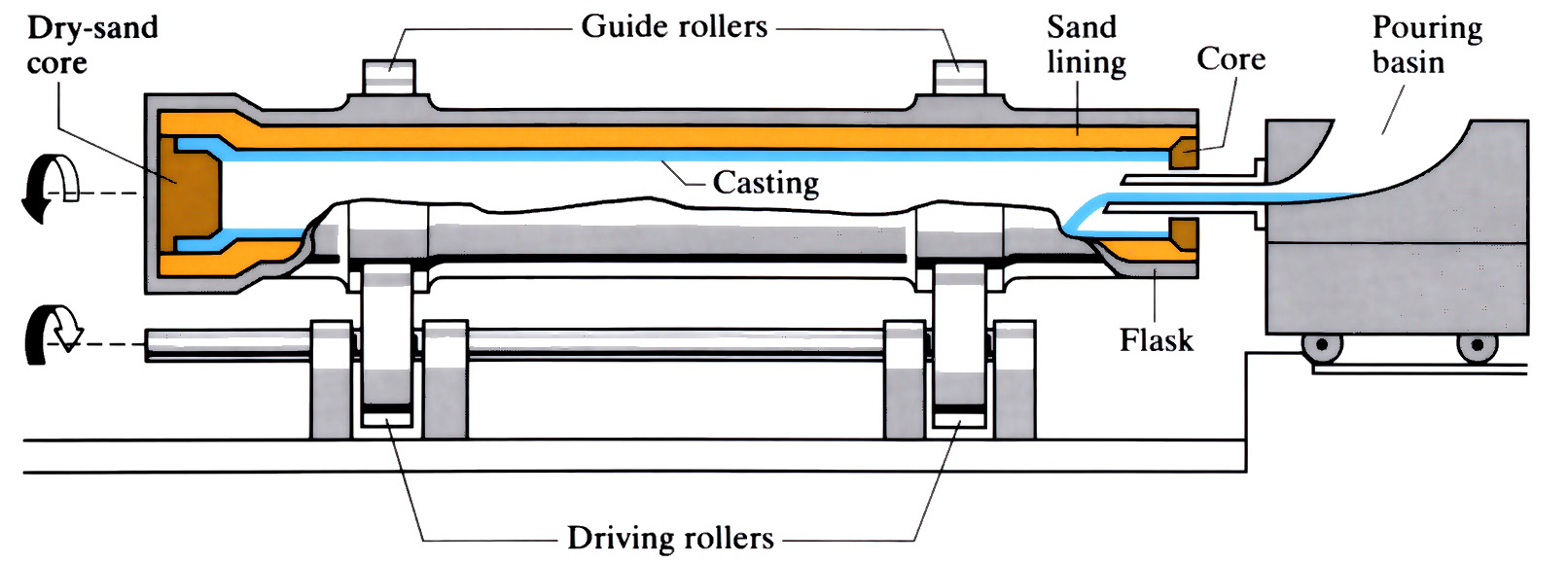

● Rotational / Centrifugal Casting – The mold rotates at high speed, ensuring even resin distribution. This method is well-suited for hollow or thin-walled parts such as toys and decorative models.

Source: The Open University

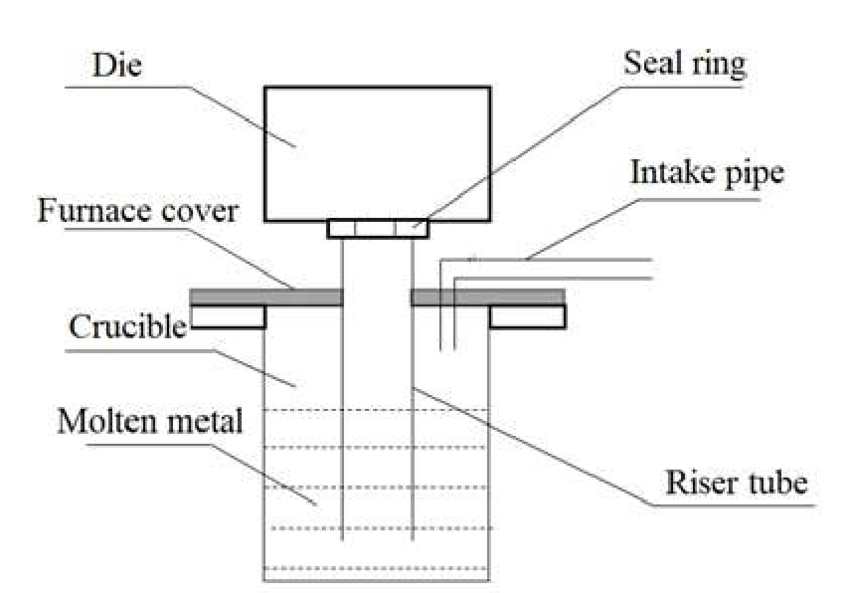

● Low-Melting Alloy Casting – Silicone molds can withstand certain low temperatures, making them suitable for casting tin-bismuth alloys to produce small metal parts or decorative items.

Source: ResearchGate

These alternative processes are often chosen when specific material properties or cost considerations outweigh the need for high surface quality.

Comparison of Silicone Molding Techniques

Each silicone molding technique offers unique advantages in terms of material compatibility, production cost, and part quality. While vacuum casting is often the default choice for industrial-grade prototypes, other methods such as gravity casting or rotational casting can be more practical for specific applications like crafts or hollow parts.

The following table highlights the key differences to help you evaluate which process best fits your project needs.

Technique | Vacuum Environment | Compatible Materials | Surface Quality | Typical Applications |

|---|---|---|---|---|

Gravity Casting | No | Resins, plaster, wax | Fair, bubbles likely | Small replicas, crafts |

Vacuum Casting | YES | Urethane resins, transparent PU | Excellent, near injection molding | Functional prototypes, appearance models |

Pressure Casting | Optional | Resins, polyurethane | High, improved strength | Structural parts, low-volume production |

Rotational Casting | No (centrifugal force) | Resins, silicone, wax | Even distribution, hollow parts | Toys, thin-walled models |

Low-Melting Metal Casting | No | Tin-bismuth alloys | Good | Small metal parts, jewelry |

Choosing the right silicone mold making technique depends on part requirements, material performance, and cost constraints. For most industrial applications, vacuum casting remains the first choice.

Looking to identify the right silicone molding method for your project? Talk to our experts and get tailored guidance.

Materials for Silicone Molding

The choice of material plays a decisive role in the performance, durability, and appearance of molded parts. In silicone mold making, different resins and composites are used to simulate engineering plastics, rubber-like materials, or even metals.

Below are the most common materials used in custom silicone mold production:

● Urethane Resins – The most widely used material. They can replicate the properties of ABS, PP, PC, and silicone. Urethane resins are versatile for both appearance and functional prototypes.

● Epoxy Resins – Known for their heat resistance, but they are relatively brittle. Suitable for applications where thermal stability is critical.

● Transparent PU – Simulates PC or PMMA, often used for lenses, lampshades, or transparent housings.

● Rubber-like Materials – Flexible materials that mimic silicone or TPU, ideal for seals, grips, and cushioning components.

● Composite-Filled Resins – Resin mixed with fillers such as metal powders (for metallic appearance) or glass/ceramic fibers (for strength reinforcement).

● Low-Melting Alloys – Tin-bismuth alloys occasionally used within the thermal limits of silicone molds to create decorative or functional metal parts.

Material Comparison Table

When selecting materials for silicone mold making, engineers need to balance mechanical properties, transparency, elasticity, and cost-effectiveness. The table below provides a side-by-side comparison of commonly used materials to guide the decision-making process.

Material Type | Key Properties | Limitations | Typical Applications |

|---|---|---|---|

Urethane Resins | Versatile, simulates ABS/PP/PC | Higher cost | Functional prototypes, low-volume parts |

Epoxy Resins | Excellent heat resistance | Brittle | Heat-resistant prototypes, tooling models |

Transparent PU | High clarity, simulates PC/PMMA | Susceptible to yellowing | Lampshades, transparent casings |

Rubber-like Materials | Flexible, good elasticity | Limited durability | Seals, grips, soft-touch parts |

Composite-Filled Resins | Enhanced strength/appearance | Complex processing | Decorative items, reinforced prototypes |

Tin-Bismuth Alloys | Metallic finish, strong feel | Limited applications | Small metal parts, jewelry |

When selecting silicone mold supplies, designers should consider the balance between mechanical properties, transparency, flexibility, and production cost. Among these, urethane resins remain the most common choice for industrial-grade vacuum casting.

Not sure which material is best for your project? Talk to our experts and get tailored recommendations.

Applications of Silicone Molding

Silicone molding is highly valued in product development because it enables the production of accurate, small-batch parts without the high cost of traditional tooling. With the right custom silicone mold, companies can replicate prototypes or functional components that closely match the properties of end-use products.

Below are the most common and impactful applications:

Appearance Models

Silicone molds are often used to reproduce high-quality appearance models for product presentations, design validation, or exhibition displays. Since vacuum casting delivers smooth surfaces and detailed replication, the resulting models can be painted, polished, or textured to match final products.

This makes them ideal for consumer electronics housings, automotive interior parts, or marketing prototypes that must look production-ready.

Functional Prototypes

Beyond aesthetics, silicone molding is widely applied for functional testing. By selecting the appropriate silicone mold supplies such as urethane resins or composite-filled materials, manufacturers can produce prototypes that simulate the mechanical strength, flexibility, or heat resistance of real engineering plastics.

This approach helps engineers verify structural performance and make design adjustments before investing in expensive injection molds.

Transparent Components

Transparent polyurethane and epoxy resins can be cast into silicone molds to create clear parts such as light covers, optical windows, or display housings.

These applications are especially common in automotive lighting, medical equipment, and consumer devices, where transparency and smooth finishes are critical. Silicone molding ensures that even complex geometries are faithfully replicated without compromising clarity.

Silicone Molding vs. CNC vs. 3D Printing

In modern prototyping and low-volume manufacturing, the three most common methods are silicone molding (vacuum casting), CNC machining, and 3D printing. Each has unique strengths, and the right choice depends on part requirements, budget, and lead time.

Silicone Molding (Vacuum Casting)

As the most widely used silicone molding technique, vacuum casting provides exceptional surface quality, dimensional accuracy, and material flexibility. It is especially valuable when multiple identical parts are needed, or when the prototype must closely simulate injection-molded performance. Vacuum casting bridges the gap between custom silicone mold prototyping and mass production.

CNC Machining

CNC machining is best suited for functional parts that require high precision, strength, and durability. Since parts are directly milled from engineering plastics or metals, CNC ensures excellent structural properties. However, it is less efficient for complex geometries and can be costly for small-batch production due to material waste.

3D Printing

3D printing offers unmatched design freedom and rapid turnaround, making it ideal for early-stage design validation. It is highly effective for complex geometries, internal structures, or when design iterations are frequent.

However, surface finish and mechanical properties often require post-processing or reinforcement, making it less suitable for production-grade prototypes compared with vacuum casting.

Comparison Table

To better understand the strengths and limitations of each method, the following table provides a side-by-side comparison of silicone molding (vacuum casting), CNC machining, and 3D printing. It highlights how each process performs in terms of quality, efficiency, and application suitability.

Method | Strengths | Limitations | Best Use Cases |

|---|---|---|---|

Silicone Molding (Vacuum Casting) | High-quality surface finish, replicates injection molding, suitable for small batches | Requires a master model, limited mold life | Prototypes, appearance models, functional testing |

CNC Machining | High precision, strong mechanical properties, wide material options | High cost for complex shapes, material waste | Structural prototypes, end-use parts |

3D Printing | Fast turnaround, complex geometries, cost-effective for low volume | Lower surface quality, weaker mechanical strength | Design validation, early-stage prototypes |

Compared with CNC and 3D printing, silicone molding through vacuum casting is often the most balanced solution for projects requiring both functional performance and near-production appearance.

For a deeper comparison, see our detailed guide: 3D Printing vs. CNC vs. Vacuum Casting: the Ultimate Comparison.

How to Calculate the Cost of Silicone Molding?

The cost of silicone molding varies depending on several technical and production factors. Unlike injection molding, which requires expensive steel tooling, silicone molding offers a more affordable solution for prototypes and low-volume production. Still, several key elements influence the final price:

1. Master Model Fabrication

The master model is the foundation of the silicone mold. Its cost depends on the manufacturing method:

● 3D Printing – Faster and cost-effective for complex geometries.

● CNC Machining – Higher precision, but more expensive for intricate shapes.

The complexity, surface finish, and size of the master model directly impact overall expenses.

2. Mold Complexity

More intricate part geometries require additional mold preparation, such as multiple parting lines or complex cavity structures. This increases labor time and material usage for silicone mold making.

3. Material Selection

Different resins or alloys vary significantly in price. For example:

● Urethane resins are versatile but more costly.

● Transparent PU requires additional processing to maintain clarity.

● Filled composites or low-melting alloys also add cost due to specialized handling.

4. Production Volume

Silicone molds have a limited lifespan, typically producing 15–30 parts before degradation. The higher the quantity required, the more molds must be produced, raising the total cost. For small-batch runs, silicone molding remains cost-efficient compared to injection molding.

5. Post-Processing and Finishing

Surface treatments such as painting, polishing, or coating can add to costs, especially for appearance models intended for marketing or customer presentation.

In summary, the cost of silicone molding is a balance between design complexity, material performance, and production scale. For businesses, obtaining an accurate quotation requires sharing 3D design files and discussing project requirements with a professional silicone mold manufacturer.

Looking to evaluate your project cost more precisely? Use our cost calculator or connect with our engineers for a tailored estimate.

How to Choose a Silicone Molding Service Provider?

Selecting the right partner is critical to ensure consistent quality, reliable delivery, and competitive pricing. When evaluating a silicone mold company or silicone mold manufacturer, consider the following factors:

1. Technical Expertise

Look for providers with proven experience in vacuum casting and other silicone molding techniques. A knowledgeable team can recommend the most suitable process and material for your application.

2. Range of Materials

The ability to offer multiple silicone mold supplies—from urethane and epoxy resins to transparent or rubber-like materials—ensures flexibility in meeting both functional and aesthetic requirements.

3. Quality Assurance

Check whether the company follows strict inspection standards, including dimensional checks, surface finish evaluation, and functional testing. Reliable suppliers often provide test reports and part validation results.

4. Lead Time and Scalability

Fast turnaround is essential for prototyping and low-volume runs. Ensure the provider can meet your deadlines and scale production if higher volumes are required later.

5. Customer Support

Effective communication and technical support are key. A good supplier should provide clear quotations, material guidance, and after-sales assistance to help streamline your development process.

Choosing the right silicone molding service provider can make the difference between a successful prototype and a costly delay.

Looking for a trusted partner in custom silicone mold production? Talk to Unionfab’s experts and get end-to-end support, from material selection to final delivery.

Unionfab’s Vacuum Casting Services

Unionfab provides professional vacuum casting services to help businesses bridge the gap between prototyping and mass production. With years of experience in silicone mold making and a wide selection of silicone mold supplies, we deliver high-quality custom parts that replicate the look and performance of injection molding—without the high upfront cost.

Why Choose Unionfab?

● High-Precision Master Models

We use advanced 3D printing and CNC machining to produce accurate master models, ensuring that every custom silicone mold delivers consistent dimensional accuracy and fine surface details.

● Diverse Material Options

Our service supports a wide range of polyurethane, epoxy, transparent, and rubber-like resins. Whether you need appearance prototypes, transparent housings, or functional rubber-like parts, Unionfab provides the right material solution.

● Cost-Effective Small-Batch Production

Vacuum casting is ideal for quantities of 10–30 parts per mold. This makes it a perfect choice for product validation, market testing, or pilot runs before scaling to mass production.\

● Excellent Surface Finish

Parts made with Unionfab’s vacuum casting process achieve surface quality close to injection molding, reducing the need for secondary finishing and enabling production-ready prototypes.

● Fast Turnaround

With streamlined workflows and expert technicians, Unionfab delivers parts quickly—helping your team accelerate product development cycles.

Get Started with Unionfab

Whether you need custom silicone molds for functional prototypes, transparent components, or small-batch production runs, Unionfab has the expertise to support your project.

Request a Quote Today and enjoy 10% off your first order with Unionfab’s professional vacuum casting services.

FAQs

What is silicone mold?

A silicone mold is a flexible mold made from liquid silicone poured around a master model. Once cured, it can be used to reproduce parts in resin, rubber-like materials, or even low-melting alloys with high accuracy and fine surface details.

What are the disadvantages of silicone molds?

Silicone molds have a limited lifespan, typically allowing 15–30 castings before wear affects quality. They are also unsuitable for very high-temperature materials and may deform when handling very large or complex shapes.

Can you make your own silicone molds?

Yes. With a Silicone Molding Kit, you can make simple molds for DIY resin or craft projects. However, for industrial applications requiring precision and material consistency, it is recommended to work with a professional silicone mold manufacturer.

How to make a silicone mold?

To make a silicone mold:

1. Prepare a clean master model.

2. Place it in a mold box.

3. Mix and pour liquid silicone around the model.

4. Allow the silicone to cure fully before removing the part.

For higher accuracy and bubble-free results, professional silicone molding supplies and vacuum casting equipment are used.

How to get bubbles out of resin in silicone mold?

The most effective method is vacuum casting, which removes air during pouring. For small-scale work, gently warming the resin or tapping the mold surface can help bubbles rise before curing.

How long does a silicone mold take to cure?

Curing time depends on the silicone type and environmental conditions, but most molds take between 4–24 hours. Fast-curing formulations can reduce this to just a few hours.

How much does it cost to make a silicone mold?

The cost depends on master model complexity, mold size, material selection, and production volume. Simple DIY molds may cost a few dozen dollars, while professional vacuum casting molds can range from hundreds to thousands for industrial applications.

How many times can you use a silicone mold?

On average, a silicone mold can be reused 15–30 times. Proper handling, careful demolding, and selecting suitable casting materials can extend mold life.