3D Printing Layer Lines: What They Are and How to Reduce?

Learn what 3D printing layer lines are, why they appear, and how to remove or prevent them for smoother prints.

Introduction

3D printing layer lines are the visible ridges or grooves that appear on the surface of printed parts.

They are a natural result of the additive manufacturing process, where each layer of material is deposited or cured in sequence.While layer lines are common in FDM, resin, and metal printing, they can affect both aesthetic appearance and functional precision.

This guide explains what layer lines are, what causes them, and how to minimize or eliminate them through better materials, technologies, and printing settings.

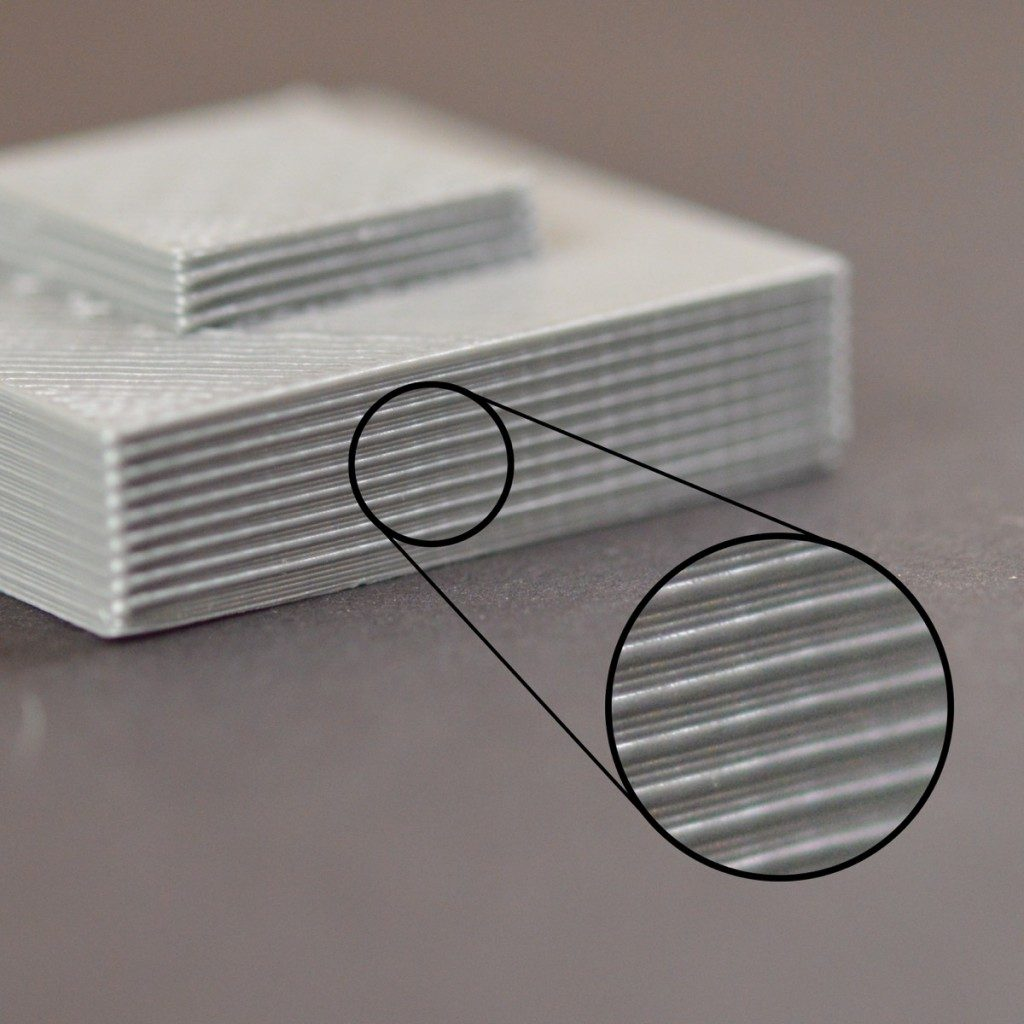

What Are 3D Printing Layer Lines?

Source: Home | Simplify3D Software

Layer lines are the fine horizontal marks visible on 3D printed parts, formed as each layer bonds to the next during the printing process.

They’re most noticeable on curved or sloped surfaces, where small height differences between layers become visible to the eye.Although all additive processes inherently create layers, the visibility of those lines varies greatly depending on:

● The printing technology used

● The material’s flow and curing behavior

● The precision of machine calibration

In general:

● Thicker layers print faster but create more pronounced lines.

● Thinner layers improve smoothness but take longer to print.

● High-precision processes like SLA or MJF yield far smoother finishes than basic FDM systems.

Causes of Layer Lines

3D printing layer lines result from a combination of three main factors: printing settings, printing process, and material properties.

Printing Settings

These are user-controlled parameters that directly affect surface smoothness.

● Layer height: Thicker layers create rougher surfaces; thinner layers reduce visible steps.

● Print speed: Fast printing can cause poor layer bonding.

● Nozzle calibration: Incorrect Z-offset or bed leveling leads to uneven thickness.

● Temperature & flow rate: Inconsistent extrusion creates gaps or ripples.

● Machine vibration: Loose frames or belts cause “ringing” or wavy patterns.

Optimization tip: Use smaller layer heights (≤0.1 mm), slower print speeds, precise bed leveling, and consistent extrusion temperature.

Printing Process / Technology

Different 3D printing technologies form layers in distinct ways, which naturally impacts the surface finish.

Process | Layer Appearance | Description |

|---|---|---|

FDM (Fused Deposition Modeling) | Most visible | Builds parts by extruding melted filament; ridges are typical. |

SLA / DLP (Resin Printing) | Very fine | Uses UV light to cure resin; ultra-thin layers produce glossy finishes. |

SLS / MJF (Powder Printing) | Matte and uniform | Fuses nylon powder; fine texture hides layer lines. |

SLM / DMLS (Metal Printing) | Fine but rough | Melts metal powder; smooths after polishing. |

Optimization tip: For smooth surfaces, choose SLA or MJF; for cost-effective prototypes, FDM remains ideal.

Material Properties

The flow, cooling, and bonding behavior of each material affect how visible the layers become.

Material Type | Surface Character | Notes |

|---|---|---|

PLA / PETG | Smooth | Flows evenly and cools quickly. |

ABS / ASA | Rough but repairable | Can be chemically smoothed using vapor. |

Resin (SLA/DLP) | Very fine | Naturally glossy and detailed. |

Nylon (SLS/MJF) | Matte | Powdery texture hides lines. |

Metal powders (Ti, Al, SS) | Fine ridges | Requires polishing or machining. |

How to Remove Layer Lines From 3D Prints?

Improving surface finish can be achieved at two stages — before printing and after printing.

Choosing the right materials, technologies, and parameters helps prevent layer lines from forming, while proper post-processing removes or disguises them afterward.

Before Printing

Choose the Right Material and Technology

Each printing process produces a different base surface quality.

Here’s how the most common technologies compare:

Technology | Typical Layer Height | Surface Finish | Suitable Materials | Remarks |

|---|---|---|---|---|

FDM | 0.1–0.3 mm | Visible ridges | PLA, ABS, PETG | Strong, affordable, but rough. |

SLA / DLP | 0.025–0.05 mm | Ultra-smooth | Photopolymer resin | Best for detailed or visual models. |

SLS / MJF | 0.07–0.12 mm | Matte, fine-grain | Nylon 12, Nylon 11 | Durable, hides lines naturally. |

SLM / DMLS | 0.03–0.05 mm | Fine but rough | Titanium, Aluminum, Stainless Steel | Industrial-grade, needs polishing. |

Recommendations:

● For display or decorative parts → SLA/DLP

● For functional prototypes → MJF/SLS

● For low-cost engineering parts → FDM (with sanding or coating)

● For precision metal parts → SLM/DMLS with post-machining

Optimize Your Printing Settings

Fine-tuning your setup can significantly reduce visible layering.

Here are ideal parameter ranges and effects:

Parameter | Recommended Range | Purpose / Effect | Notes |

|---|---|---|---|

Layer height | 0.06–0.12 mm (fine) / 0.2–0.3 mm (fast) | Thinner layers = smoother finish | Use ≤0.1 mm for visible or curved parts |

Print speed | 30–50 mm/s (fine) / 60–80 mm/s (fast) | Slower = better bonding | Too fast → under-extrusion |

Bed leveling & Z-offset | ~0.1 mm first-layer gap | Ensures even adhesion | Recalibrate regularly |

Temperature | PLA: 190–210 °C · PETG: 230–250 °C · ABS/ASA: 230–260 °C | Consistent extrusion | Avoid ±5 °C swings |

Nozzle size | 0.2–0.3 mm (detail) / 0.4 mm (standard) / 0.6 mm+ (speed) | Smaller = finer lines | Slower print required |

Flow rate | 95–105 % | Avoids gaps or bulges | Calibrate using test cubes |

Cooling fan | PLA: 60–100 % · ABS/ASA: 30–50 % | Helps layer solidification | Too strong causes warping |

Mechanical stability | Check every 20–30 hrs | Prevents vibration “ringing” | Tighten belts, lower acceleration |

Quick Reference by Goal

Goal | Ideal Settings |

|---|---|

Best surface finish | ≤0.1 mm layer, ≤40 mm/s speed, 0.2–0.3 mm nozzle |

Balanced speed & quality | ~0.15 mm layer, ~60 mm/s speed, 0.4 mm nozzle |

Fast prototype | ≥0.25 mm layer, ≥70 mm/s speed, ≥0.6 mm nozzle |

Pro Tip:

Always test with a small calibration cube. Visible stripes usually point to Z-offset, temperature, or flow issues — the main culprits for FDM layer lines.

After Printing

Even with perfect settings, layer lines can remain visible.

Post-processing allows you to refine, seal, or completely smooth surfaces — depending on your goals and budget.

FDM (PLA, ABS, PETG, ASA)

Method | Description | Cost | Effect |

|---|---|---|---|

Sanding & Polishing | Sand (400→2000 grit) and polish manually. | Low (< $5 / part) | Smooths small parts effectively. |

Chemical Smoothing | Use acetone or solvent vapor to melt ridges. | Medium ($5–15) | Works best for ABS/ASA; not for PLA. |

Filler Primer + Painting | Spray filler primer and paint evenly. | Medium ($10–20) | Great for colored or display parts. |

Epoxy Coating | Apply resin layer for gloss and sealing. | Medium ($15–25) | Durable finish, hides imperfections. |

⭐ Best Value: Sanding + Primer Painting — excellent improvement for minimal cost.

Learn how to sand prints effectively, read our previous guide: How to Sand 3D Prints?

Resin Printing (SLA / DLP)

Method | Description | Cost | Effect |

|---|---|---|---|

Wet Sanding + Clear Coat | Light sanding then UV-resistant coating. | Low–Medium ($5–15) | Restores transparency and shine. |

Extra UV Curing + Polish | Strengthens resin and smooths surface. | Low | Improves clarity and hardness. |

Epoxy Dip / Spray | Adds glossy protective finish. | Medium ($10–20) | Ideal for decorative parts. |

⭐ Best Value: Wet Sanding + Clear Coat — quick, preserves details, affordable.

Nylon Powder Printing (SLS / MJF)

Method | Description | Cost | Effect |

|---|---|---|---|

Bead Blasting / Media Tumbling | Polish using ceramic or glass beads. | Medium ($10–30) | Matte, uniform texture. |

Vapor Smoothing (Chemical Fusion) | Fuses powder layer into satin finish. | High ($20–40) | Professional sealed surface. |

Dyeing / Painting | Adds color, hides texture. | Low ($5–10) | Cosmetic improvement. |

⭐ Best Value: Bead Blasting + Dyeing — industrial-grade look at moderate cost.

Metal Printing (SLM / DMLS)

Method | Description | Cost | Effect |

|---|---|---|---|

CNC Machining / Grinding | Remove ridges with precision tools. | High ($30–100) | Highest accuracy and smoothness. |

Shot Peening / Sandblasting | Abrasive finishing for matte uniformity. | Medium ($10–25) | Removes lines, strengthens surface. |

Electropolishing | Electro-chemical smoothing to mirror finish. | High ($30–60) | Premium finish for implants or luxury parts. |

⭐ Best Value: Shot Peening + Light CNC Finish — balance between quality and cost.

Overall Cost-Performance Summary

Technology | Recommended Post-Process | Cost | Value Summary |

|---|---|---|---|

FDM | Sanding + Primer Painting | Low–Medium | Best DIY, strong visual improvement |

SLA / DLP | Wet Sanding + Clear Coat | Low | Fast, affordable, glossy |

SLS / MJF | Bead Blasting + Dyeing | Medium | Industrial matte texture |

Metal (SLM / DMLS) | Shot Peening + Light CNC | Medium–High | Professional-grade balance |

Best Overall Cost-to-Quality Choice

● For hobbyists and prototyping: FDM + Sanding & Primer — best surface upgrade per dollar.

● For industrial parts: MJF/SLS + Bead Blasting — uniform, durable, professional matte finish.

Comparing Pre- and Post-Printing Optimization

Stage | Key Actions | Primary Benefit | Ideal Use |

|---|---|---|---|

Before Printing | Use smoother processes (SLA, MJF) + fine settings (≤ 0.1 mm) | Prevents visible lines | Precision prototypes |

After Printing | Sanding, coating, bead blasting, vapor smoothing | Removes existing lines | Finished or display parts |

Source: youtube.com/@UnfinishedProjects-yt8km

Summary:

Effective surface optimization requires a two-step mindset:

● Prevention — through proper technology, materials, and printer calibration.

● Correction — via targeted post-processing to achieve a professional appearance.

Balancing both ensures parts that meet functional, aesthetic, and budget goals.

Conclusion

Layer lines are an inherent part of 3D printing, but with the right technology, settings, and post-processing, they can be minimized or completely removed. To identify and resolve more layer problems in 3d printing, read our previous article: 3D Printing First Layer Problems (+Tips & Solutions)

Whether you prioritize speed, strength, or appearance, understanding how to manage layer lines allows you to produce parts that look and perform at a professional level.

By applying both preventive (before printing) and corrective (after printing) methods, you can achieve the perfect balance between cost-efficiency and surface quality — from home prototypes to industrial-grade components.

Unionfab's 3D Printing Services

Achieving a smooth and precise surface finish often requires more than just good printer settings—it depends on advanced equipment, expert process control, and professional finishing capabilities. That’s where Unionfab comes in.

As one of the leading digital manufacturing service providers, Unionfab delivers industrial-grade 3D printing, CNC machining, and surface finishing with consistent quality and precision. From prototypes to end-use parts, our team ensures every print meets exact dimensional and aesthetic requirements.

Whether you are an engineer optimizing a design, a manufacturer seeking low-volume production, or a designer aiming for perfect visual detail, Unionfab provides the tools, materials, and expertise to bring your project to life.

To help you plan efficiently, you can instantly estimate your project cost or consult directly with our technical team for tailored solutions. Use the options below to take the next step with confidence.

Quickly upload your 3D model and receive a real-time production quote.

Enjoy 10% off your first order with Unionfab and experience professional-grade 3D printing at a lower cost.