Exhaust Manifold vs Headers: When to Use Which?

Compare exhaust manifolds vs headers, learn their design, performance, cost, and sound differences to choose the best option for your vehicle.

Introduction

The exhaust system plays a vital role in an engine’s performance. It manages how exhaust gases exit the combustion chambers, which directly influences:

● Power output — efficient gas flow helps the engine breathe better.

● Fuel economy — smoother exhaust flow can improve combustion efficiency.

● Engine temperature — proper exhaust routing reduces heat buildup.

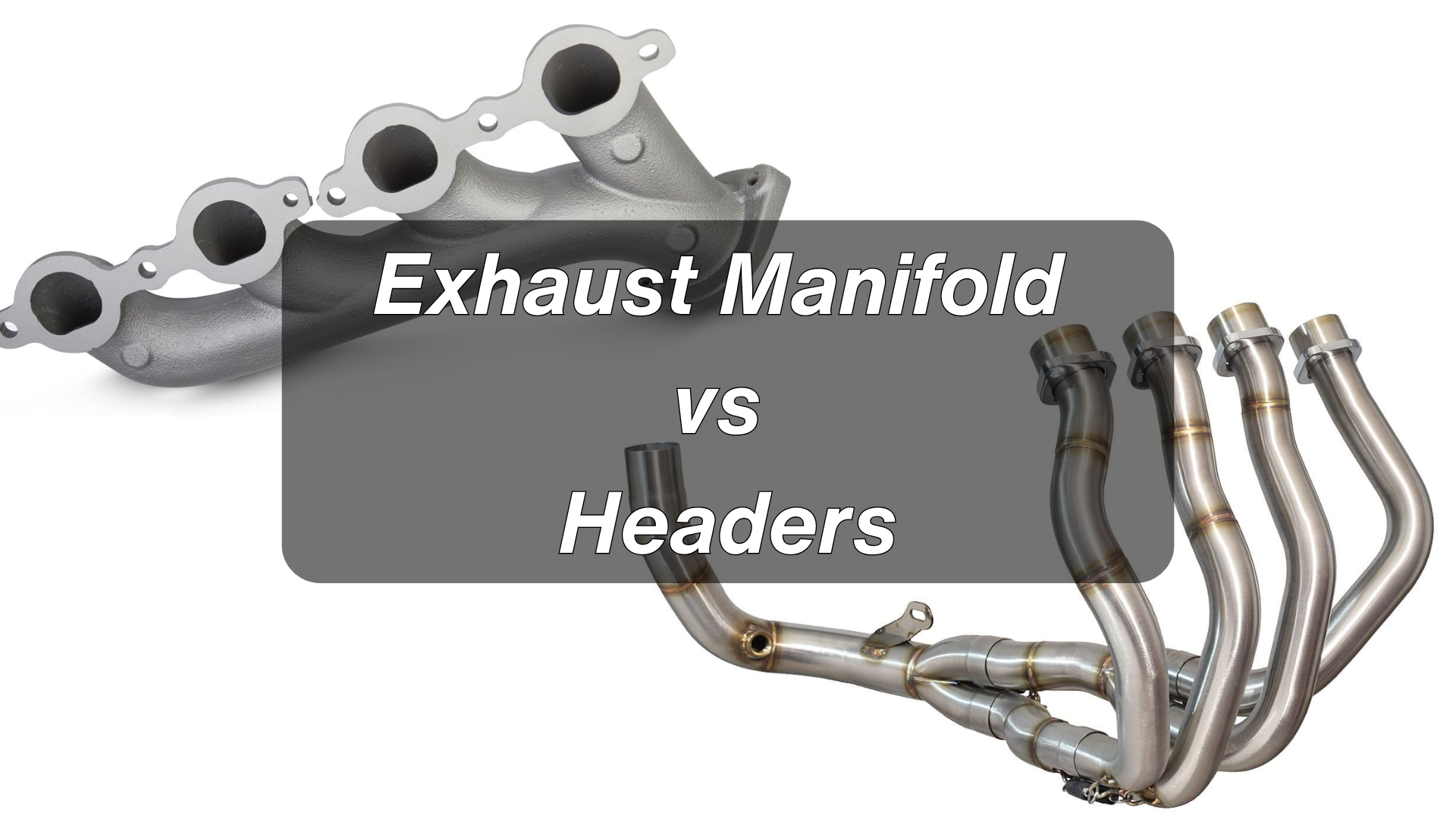

Among its components, the exhaust manifold and headers are often compared in performance discussions. Both serve the same core purpose: channeling exhaust gases from the cylinders to the rest of the exhaust system. However, they differ greatly in design, materials, performance effects, and ideal applications.

This article analyzes exhaust manifolds vs headers from an engineering perspective, explaining how each works, where they excel, and what factors to consider when choosing between them.

Basic Concepts and Working Principles

What Is an Exhaust Manifold?

Source: hjs.com

An exhaust manifold is a key part of the exhaust system that collects exhaust gases from each cylinder and directs them into a single pipe. It is commonly used in factory vehicles for reliability and cost efficiency. Most exhaust manifolds are made from cast iron or thick steel, offering excellent heat resistance and long service life.

● Main characteristics:

Compact and durable structure

Lower production cost

Creates more back pressure, which can limit exhaust flow and slightly reduce power

Because of their simplicity and strength, exhaust manifolds are ideal for daily-use vehicles that prioritize durability over performance.

What Are Exhaust Headers?

Source: holley.com

Headers, sometimes called “performance exhaust manifolds,” are designed to improve exhaust flow and engine performance. Each cylinder has its own separate pipe, which merges further down into a collector. This setup helps reduce exhaust restriction and allows gases to flow more smoothly. Headers are usually made from thin-wall stainless steel, titanium, or other heat-resistant alloys, making them lighter and more efficient for high-performance applications.

● Main characteristics:

Independent exhaust tubes for each cylinder

Reduced back pressure, smoother gas flow

Better engine breathing and higher power output

Commonly used in sports cars, race cars, and custom builds

Learn more about their design, materials, and advantages in our full guide: Exhaust Header Guide: Types, Installation, Leak Repair & Performance Tips.

Back Pressure and Scavenging Explained

In comparing exhaust manifolds vs headers, two engineering concepts—back pressure and scavenging—are key to understanding their performance differences.

Back Pressure

● Exhaust Manifold: Because manifolds use a short, compact design with shared passages, they tend to create higher back pressure. This restricts exhaust gas flow and slightly reduces engine efficiency. However, the added resistance can help maintain exhaust velocity at lower RPMs, which benefits smooth idle and low-end torque.

● Headers: Headers are specifically engineered to minimize back pressure through equal-length and wider individual tubes. This allows gases to exit the cylinders more freely, reducing resistance and improving power output—especially at mid to high RPM.

Scavenging Effect

● Exhaust Manifold: The short, uneven design of a manifold limits scavenging efficiency. Exhaust pulses can interfere with each other, reducing the cylinder’s ability to fully expel burnt gases.

● Headers: The tuned-length tubes in headers create a strong scavenging effect, where one exhaust pulse helps pull the next out of the cylinder. This process improves combustion efficiency, resulting in better throttle response, increased torque, and cleaner exhaust flow.

In summary, manifolds prioritize simplicity and cost, offering stability at lower speeds, while headers optimize airflow and scavenging for maximum performance and engine breathing efficiency.

Unionfab offers advanced CNC machining and metal 3D printing services to produce customized exhaust components with optimized flow paths and lightweight, durable designs.

Structural and Material Differences

Design Structure

The main distinction between an exhaust manifold and headers lies in their design.

● Exhaust manifold: Built as a single cast piece with short internal passages, creating a compact layout. This design saves space and is easier to install, but the short, uneven paths can cause higher exhaust resistance.

● Headers: Made up of multiple independent tubes, each connected to one cylinder. These tubes merge smoothly into a collector. Depending on the engine setup, headers can be short-tube or long-tube designs. Long-tube headers improve exhaust flow and enhance performance at high RPM, while short-tube headers favor lower and mid-range torque.

Common Materials

The materials used directly affect weight, heat resistance, and durability.

● Exhaust manifold: Usually made from cast iron or steel alloy, providing excellent thermal endurance and cost efficiency.

● Headers: Often made from stainless steel, titanium, or Inconel. These lightweight and heat-resistant metals handle extreme temperatures while reducing overall mass, making them ideal for racing and performance tuning.

Manufacturing Process

Different manufacturing techniques give each component its unique characteristics:

● Exhaust manifold: Commonly produced through casting or CNC machining, ensuring strength and consistency for high-volume production.

● Headers: Built using tube bending, TIG welding, CNC forming, or the latest metal 3D printing technologies. These methods allow more precise flow shaping and smoother internal surfaces for optimized gas velocity.

Comparison Overview

Feature | Exhaust Manifold | Headers |

|---|---|---|

Structure | One-piece cast design | Multi-tube, tuned-length design |

Material | Cast iron, steel alloy | Stainless steel, titanium, Inconel |

Manufacturing | Casting, CNC machining | Tube bending, welding, metal 3D printing |

Heat Resistance | Excellent | Very high |

Weight | Heavy | Lightweight |

Cost | Lower | Higher |

Precision | Moderate | High |

Modern manufacturing techniques, especially CNC machining and metal additive manufacturing, allow engineers to combine durability with optimized airflow geometry. These advances enable the production of exhaust components that are both lightweight and thermally efficient, balancing performance and longevity for diverse automotive applications.Performance Comparison: Power, Heat, and Durability

When comparing exhaust manifolds vs headers, the differences in performance mainly come down to how efficiently each design manages airflow, heat, and structural stress.

Comparison Item | Exhaust Manifold | Headers |

|---|---|---|

Power Output | Higher exhaust resistance results in slightly lower power. | Smooth exhaust flow improves horsepower and torque, especially at high RPM. |

Heat Management | Retains heat effectively but concentrates temperature around the engine bay. | Dissipates heat faster, though it may increase engine bay temperature. |

Cost | Simple casting process keeps manufacturing cost low. | More complex fabrication and materials make it more expensive. |

Durability | Cast iron construction ensures long service life and resistance to cracks. | Thin-walled stainless steel or titanium may require heat protection to prevent fatigue. |

Performance Overview

● Power and Torque: Headers deliver more efficient exhaust flow, reducing back pressure and improving engine breathing. This leads to noticeable gains in power and throttle response.

● Thermal Behavior: Manifolds are better at containing heat but may transfer more heat into the cylinder head. Headers, on the other hand, expel gases faster, improving cooling at the expense of higher under-hood temperatures.

● Cost and Maintenance: Manifolds are cheaper and easier to maintain, while headers require more careful installation and heat management.

● Durability: Cast manifolds resist wear and heat cycles for years, but headers, especially lightweight versions, need proper coatings or wraps to prevent oxidation and fatigue.

In real-world applications, neither exhaust manifolds nor headers is a perfect solution — the best design needs the durability of cast manifolds and the flow efficiency of performance headers. This is where metal additive manufacturing stands out.

Unionfab uses topology optimization and metal 3D printing to create exhaust systems that are stronger, lighter, and thermally efficient — engineered for motorsport and high-demand applications.

Interested in exploring how this applies to your project? Talk to our engineering experts.

Installation and Maintenance Guidelines

Proper installation and regular maintenance are crucial to ensure the long-term performance and reliability of both exhaust manifolds and headers. Neglecting these details can lead to leaks, reduced efficiency, or even component failure over time.

Installation Tips

● Check flange flatness and sealing: Ensure all contact surfaces are smooth and properly aligned before installation to prevent exhaust leaks.

● Use quality gaskets and fasteners: High-temperature gaskets and corrosion-resistant bolts improve durability and sealing performance.

● Inspect heat shielding: Install adequate thermal insulation or wraps to protect nearby components from excessive heat.

● Verify sensor placement: Confirm that oxygen sensors and temperature probes are correctly positioned to maintain accurate readings.

Maintenance Tips

● Regularly check bolts and welds: Re-torque bolts after initial heat cycles and inspect welds periodically to prevent fatigue cracks.

● Monitor for leaks: Listen for exhaust noise changes or visible soot marks around joints, which may indicate leakage.

● Surface care: For stainless steel or titanium headers, occasional cleaning helps maintain performance and appearance by preventing oxidation.Applications and Selection Recommendations

When to Choose an Exhaust Manifold

An exhaust manifold is the right choice when reliability and practicality matter most. It is commonly used in:

● Daily commuting vehicles where quiet operation and low cost are priorities.

● Mass-production models that need long-lasting, low-maintenance components.

● Applications where heat retention and durability are more important than high power output.

When to Choose Exhaust Headers

Headers are preferred for drivers and engineers focused on performance and efficiency. They are best suited for:

● Racing and high-performance cars that demand maximum exhaust flow and reduced back pressure.

● Modified or tuned engines seeking better throttle response and improved horsepower.

● Projects where lightweight design and thermal efficiency are key performance factors.

Decision Factors

Choosing between manifolds and headers depends on several practical aspects:

● Engine type – high-revving engines benefit more from headers.

● Purpose of use – daily driving, performance tuning, or competition.

● Budget – headers offer performance gains at a higher cost.

● Regulatory compliance – some aftermarket headers may not meet emissions standards in certain regions.

Unionfab offers end-to-end manufacturing solutions that combine precision, speed, and versatility. With advanced CNC machining, metal 3D printing, and surface finishing capabilities, we help turn complex exhaust designs into high-performance, production-ready components.

Ready to build your part? Upload your CAD file to try Unionfab’s online cost calculator for instant pricing.

Cost and Manufacturing Considerations

Understanding how costs are formed is essential to achieving the best balance between performance and budget when choosing headers or manifolds.

Here we would like to break down the cost of 3d printing exhaust components. The total cost is typically composed of the following major elements:

Total Cost = Printing Cost + Post-Processing + Packaging + Shipping & Customs

Printing Cost

This represents the base cost of producing the part and is determined by two primary factors:

● Material price — the cost of the metal powder, usually measured per gram or kilogram. High-temperature alloys such as Inconel or Ti-6Al-4V significantly affect cost.

● Part weight — derived from the CAD model’s volume multiplied by the density of the chosen material.

Post-Processing Cost

For exhaust components operating under high thermal and mechanical stress, two post-processing steps are commonly required:

● Heat treatment / stress relief — to stabilize material properties and prevent deformation during high-temperature operation.

● Precision machining on interfaces or flanges — to ensure sealing accuracy, dimensional tolerance, and assembly fit.

These post-processing requirements are typically factored into the total project cost by the manufacturer rather than listed as separate line items.

Packaging

Standard industrial packaging is sufficient in most cases, but customized protective solutions may be required for thin-walled or high-value heat-resistant components.

Shipping & Customs

Costs vary based on destination, shipping priority, and the material classification of high-performance alloys, which may involve additional import duties.

For a more detailed breakdown of the 3d printing cost of exhaust components, see our full pricing guide:

How Much Does It Cost to 3D Print Something (2024)?

If you're also comparing CNC machining as an alternative, refer to:

Cost of CNC: A Comprehensive Guide [+Price Comparison]

First-time manufacturing exhaust components with Unionfab? Get 10% discount for your first order.

Modern Manufacturing Trends: From Casting to Metal 3D Printing

With the continuous advancement of manufacturing technology, traditional casting methods are being gradually replaced by high-precision CNC machining and metal additive manufacturing (3D printing). These modern techniques allow for greater design flexibility, accuracy, and material efficiency, transforming how exhaust components are developed and produced.

Advantages of Metal 3D Printing in Exhaust Components

Metal 3D printing enables engineers to create designs that were once impossible with conventional manufacturing. Key benefits include:

● Lightweight flow channels: Internal geometries can be optimized to reduce weight while maintaining strength.

● Integrated structures: Complex assemblies can be produced as a single piece, eliminating welds and weak points.

● High-temperature alloys: Advanced materials such as Inconel and titanium can withstand extreme heat and pressure, ideal for racing and high-performance engines.

This technology has become increasingly popular in motorsport engineering and prototype development, where precision, speed, and performance are top priorities. The ability to rapidly produce complex, high-strength exhaust parts gives teams a competitive edge while reducing lead times and development costs.

Conclusion

Understanding the difference between exhaust manifolds and headers is essential when optimizing your vehicle’s exhaust system. While exhaust manifolds are durable, cost-effective, and ideal for daily driving, headers offer smoother exhaust flow, improved horsepower, and better engine efficiency for high-performance applications. Your choice should depend on your engine type, driving purpose, and budget.

Modern manufacturing technologies—such as CNC machining and metal 3D printing—now allow engineers to create exhaust components with optimized flow paths, lightweight designs, and superior heat resistance. These innovations make it easier to achieve both reliability and performance in one solution.

FAQs

1. What is better, headers or an exhaust manifold?

Neither is universally “better”—it depends on your goals. Exhaust manifolds are ideal for factory or daily-use vehicles due to their durability and low cost. Headers are designed for performance, improving airflow and horsepower, but they are more expensive and require more maintenance.

2. Are headers louder than manifolds?

Yes. Headers typically produce a louder and more aggressive exhaust sound because they allow gases to flow more freely and reduce restriction. Manifolds, being thicker and more enclosed, tend to muffle noise and offer a quieter ride.

3. Are manifolds the same as headers?

No. Although both parts guide exhaust gases from the cylinders to the exhaust pipe, manifolds are compact cast pieces, while headers use individual tuned tubes to optimize gas flow. The design difference results in distinct performance and sound characteristics.

4. Will headers increase horsepower?

Yes, in most cases. By reducing back pressure and improving scavenging, headers can deliver a noticeable increase in horsepower and torque, especially at higher RPMs. The exact gain depends on the engine type, header design, and overall exhaust setup.

5. Exhaust manifold vs headers: pros and cons?

● Exhaust Manifold Pros: durable, affordable, easy to maintain

● Exhaust Manifold Cons: heavier, higher back pressure, less power

● Headers Pros: better flow, higher power output, improved sound

● Headers Cons: higher cost, more heat, more complex installation

6. Exhaust manifold vs headers: sound difference?

Headers generally produce a sharper, sportier, and louder tone, while manifolds deliver a more subdued, factory-level sound. The sound difference is one of the main reasons enthusiasts switch to headers.

7. Are motorcycle headers and car headers the same concept?

Yes, the principle is similar. Motorcycle headers also aim to reduce exhaust restriction and improve performance, though they’re typically more compact and tuned for specific RPM ranges due to the smaller engine size.